Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

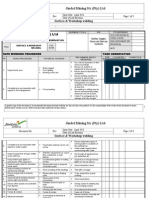

SMP For Calibration of Gauges & Transmitters

Caricato da

pradeep1987coolTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SMP For Calibration of Gauges & Transmitters

Caricato da

pradeep1987coolCopyright:

Formati disponibili

, Vijayanagar Works

D.C.N –CO3/MM/ ISO 9001 : 2008 (7.5.1) / ISO 14001 : 2004 Issue / Rev. No. Effective Date–

WI 9 (4.3.1,4.3.1,4.4.6) / BS OHSAS 18001 : 2007 1/1 26-Mar-12

(4.3.1,4.3.1,4.4.6)

TITLE :- WORK INSTRUCTION FOR REPLACEMENT CALIBRATION OF

PRESSURE GAUGE/TRANSMITTER / DP TRANSMITTER/SWITCH/DP SWITCH

WORK INSTRUCTION FOR REPLACEMENT AND CALIBRATION OF

THE PRESSURE GAUGE/ TRANSMITTER/SWITCH

1. OBJECTIVE:

Replacement and Calibration of pressure gauge/transmitter/switch

2. SCOPE:

This work instruction covers the steps to replacement and calibration of all

pressure measuring/ monitoring instruments, hazard Involvement and safety

control measures required.

3. RESPONSIBILITY:

Section In-charge,Engineers – C & I Department

5. ABBREVATIONS & DEFINITIONS:

All Abbreviations & Definitions are mentioned in main ISO draft document (6.1

& 6.2)

6 PROCEDURE

Preparatory jobs:

1. Local Inspection of the instrument for any leakages or for physical damages.

2. Shifting of necessary tools.

Shut down jobs:

1. Take work permit from the user department

Ensure that the instrument is isolated from the process.

2. Open the drain / vent valves, and ensure instrument is reading zero pressure.

3. Disconnecting all Electrical connections to the instruments if any.

4. Remove the instrument from the line using proper tools.

Reviewed & Page 1 of 3

Prepared by Approved by

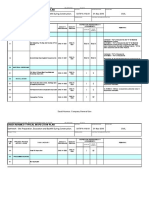

, Vijayanagar Works

D.C.N –CO3/MM/ ISO 9001 : 2008 (7.5.1) / ISO 14001 : 2004 Issue / Rev. No. Effective Date–

WI 9 (4.3.1,4.3.1,4.4.6) / BS OHSAS 18001 : 2007 1/1 26-Mar-12

(4.3.1,4.3.1,4.4.6)

TITLE :- WORK INSTRUCTION FOR REPLACEMENT CALIBRATION OF

PRESSURE GAUGE/TRANSMITTER / DP TRANSMITTER/SWITCH/DP SWITCH

5. Take the Instrument to lab for calibration.

6. connect the instrument on the calibrating instrument and apply the pressure

from the calibrator, check for the display of the instrument against the

standard calibrating value each time.

7. If the standard value is matching with the measured value then no need for

any adjustment. If the deviation is more than the acceptable limit then

adjust the instrument and bring the error within the limit.

8. After calibration depressurize the calibrating instrument and ensure that the

gauge or transmitter is reading zero, then remove the gauge from the

calibrator.

9. Take the gauge/transmitter after calibration to site and install the same in its

location and give the electrical connections if any.

10.Take the instrument in service by slowly opening the process isolation

valve, remove all the air bubbles in the line and then close all drain/ vents.

11.Remove all scraps, tools etc from the location

12.Return permit after successful trial.

Spares requirement:

Nil

Tools & tackles:

1. Spanners

2. Screw-drivers.

3. Calibrator.

7. SAFETY ASPECTS:

Work permit to be obtained from concerned department before starting

the work.

Conduct Tool box talk

Barricading the area

PPE s should be used by all working at site.

Operator should be informed before taking up the work.

In addition to the above any other safety measures with respect to the

department / area will be followed as displayed in that site.

Reviewed & Page 2 of 3

Prepared by Approved by

, Vijayanagar Works

D.C.N –CO3/MM/ ISO 9001 : 2008 (7.5.1) / ISO 14001 : 2004 Issue / Rev. No. Effective Date–

WI 9 (4.3.1,4.3.1,4.4.6) / BS OHSAS 18001 : 2007 1/1 26-Mar-12

(4.3.1,4.3.1,4.4.6)

TITLE :- WORK INSTRUCTION FOR REPLACEMENT CALIBRATION OF

PRESSURE GAUGE/TRANSMITTER / DP TRANSMITTER/SWITCH/DP SWITCH

Ambulance: 43111/44000/43333.

Fire & Safety control room: 9449598000.

7.1 LOTO Aspects:

LOTO is not applicable

7.2 WAH Aspects

WAH is not applicable

7.3 PTW Aspects:

PTW is applicable related documentation number is

PTW/SAFETY/STANDARD/010

8. ENVIRONMENTAL ASPECTS:

Oil/grease , cotton waste is collected and dispatched to incinerator.

Reviewed & Page 3 of 3

Prepared by Approved by

Potrebbero piacerti anche

- Process Flow PDFDocumento4 pagineProcess Flow PDFRiza VirsadaNessuna valutazione finora

- Failure Mode and Effect AnalysisDocumento25 pagineFailure Mode and Effect AnalysislokelooksNessuna valutazione finora

- Control Valve IPF Function Test1Documento5 pagineControl Valve IPF Function Test1btjajadiNessuna valutazione finora

- Plant MIS Month of March '17Documento7 paginePlant MIS Month of March '17MEHAKNessuna valutazione finora

- Supplier Quality System Audit Report: Quanta Computer IncDocumento78 pagineSupplier Quality System Audit Report: Quanta Computer IncVanessa MansurNessuna valutazione finora

- Process Calibration of Measurement InstrumentsDocumento6 pagineProcess Calibration of Measurement InstrumentsDebabrataSenSarmaNessuna valutazione finora

- Cause & Effect TypesDocumento5 pagineCause & Effect TypesArun BiswalNessuna valutazione finora

- 08 FmeaDocumento27 pagine08 FmeanormalNessuna valutazione finora

- Instr 12314 Install InsulationDocumento14 pagineInstr 12314 Install InsulationMeliana Butar-ButarNessuna valutazione finora

- Work Instruction - Welding MCDocumento3 pagineWork Instruction - Welding MCManoj Kt100% (1)

- Fmea PDFDocumento36 pagineFmea PDFalsoraya00100% (1)

- WI QA 14 PIug GaugesDocumento1 paginaWI QA 14 PIug GaugesAnkur Gupta100% (1)

- BakerHughes BN ReciprocatingCompressorsMonitoring Brochure-Web-NA-1112...Documento9 pagineBakerHughes BN ReciprocatingCompressorsMonitoring Brochure-Web-NA-1112...Abbas AlnajjarNessuna valutazione finora

- Control Plan: Pre-Launch Production PrototypeDocumento1 paginaControl Plan: Pre-Launch Production PrototypeAnkur DhirNessuna valutazione finora

- Installation and Calibration of Instruments GuidanceDocumento17 pagineInstallation and Calibration of Instruments GuidanceCarlos SalazarNessuna valutazione finora

- AIAG CQI-15 Special Process: Welding System Assessment Mabuchi Motor Mexico, S.A.De C.VDocumento30 pagineAIAG CQI-15 Special Process: Welding System Assessment Mabuchi Motor Mexico, S.A.De C.VLuis AldanaNessuna valutazione finora

- 120 LOAD CELL CalibrationDocumento4 pagine120 LOAD CELL CalibrationonrabiNessuna valutazione finora

- Aiag Vda FmeaDocumento244 pagineAiag Vda Fmeav56btmnrc4Nessuna valutazione finora

- 8DDocumento8 pagine8DRomie CubalNessuna valutazione finora

- 6000 Series PFMEA (English For Reference)Documento8 pagine6000 Series PFMEA (English For Reference)RonNessuna valutazione finora

- Process Flow Diagram (PFD)Documento1 paginaProcess Flow Diagram (PFD)psathishthevanNessuna valutazione finora

- Process P ID Training 1705304683Documento130 pagineProcess P ID Training 1705304683rajesh_sgNessuna valutazione finora

- Customer-Specific Requirements: For Use With ISO/TS 16949 Second Edition March 2012Documento4 pagineCustomer-Specific Requirements: For Use With ISO/TS 16949 Second Edition March 2012befoaNessuna valutazione finora

- IQ Check List (Inkjet Printer)Documento2 pagineIQ Check List (Inkjet Printer)JR CrusisNessuna valutazione finora

- CAPA Thread OutDocumento80 pagineCAPA Thread OutRohtash fastnerNessuna valutazione finora

- Measurement System AnalysisDocumento2 pagineMeasurement System AnalysispsathishthevanNessuna valutazione finora

- Quality Plan Dyeing FinishingDocumento3 pagineQuality Plan Dyeing FinishingITOPS TeamNessuna valutazione finora

- 3BCN8 15026 A01 G01 DCS Operation and Maintenance ManualDocumento58 pagine3BCN8 15026 A01 G01 DCS Operation and Maintenance Manualramses mantillaNessuna valutazione finora

- Jakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeDocumento24 pagineJakarta Plant Engineering Standard: B. General Rules of PFMEA B.1. ScopeLeonardoViannaNessuna valutazione finora

- MTC Air PurgingDocumento1 paginaMTC Air Purginghari kaiprathNessuna valutazione finora

- 3 3bb0aDocumento7 pagine3 3bb0aEleandro JoaquimNessuna valutazione finora

- Failure Modes Effect AnalysisDocumento33 pagineFailure Modes Effect AnalysisAkhmas MerajNessuna valutazione finora

- Risk Assesment - FormatDocumento3 pagineRisk Assesment - FormatSIBINNessuna valutazione finora

- TestPlan ASTM 123Documento9 pagineTestPlan ASTM 123Fernando Patiño Guevara100% (1)

- Course Title: Basic Instrumentation (Code: 3311701)Documento5 pagineCourse Title: Basic Instrumentation (Code: 3311701)Raja Prathap SinghNessuna valutazione finora

- EG 15-14-1.2 Instrument Calibration: ScopeDocumento21 pagineEG 15-14-1.2 Instrument Calibration: ScopeaminNessuna valutazione finora

- Instrumentation ManualDocumento114 pagineInstrumentation Manualqasim awaisNessuna valutazione finora

- Module I-3 Pressure InstrumentsDocumento41 pagineModule I-3 Pressure Instrumentssuresh6265100% (1)

- Reading Process DrawingDocumento25 pagineReading Process DrawingArif VeyNessuna valutazione finora

- B515 TempDocumento4 pagineB515 TempubraghuNessuna valutazione finora

- FMEA ExampleDocumento4 pagineFMEA ExampleBALAJINessuna valutazione finora

- E - Qamar Hassan Iqbal: ObjectiveDocumento3 pagineE - Qamar Hassan Iqbal: ObjectiveQamar Hassan Iqbal0% (1)

- HSE Activities - FinalDocumento59 pagineHSE Activities - FinalRajanish BiswasNessuna valutazione finora

- SP-2154 - 2015valves Technical SpecificationDocumento23 pagineSP-2154 - 2015valves Technical Specificationarjunprasannan7Nessuna valutazione finora

- Title: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBDocumento1 paginaTitle: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBBharat PatilNessuna valutazione finora

- CHECK-LIST PR-03 P&ID - Fr.enDocumento6 pagineCHECK-LIST PR-03 P&ID - Fr.enYousef SalahNessuna valutazione finora

- Instrument Stand Install Guide PDFDocumento4 pagineInstrument Stand Install Guide PDFChristianNessuna valutazione finora

- F-MP-04-52 (C) Equipment Installation Qualification ReportDocumento6 pagineF-MP-04-52 (C) Equipment Installation Qualification Reportarum100% (1)

- Group 10 Design Parameters, HazopDocumento69 pagineGroup 10 Design Parameters, HazopM. AkmalNessuna valutazione finora

- FMEA Worksheet MiningDocumento1 paginaFMEA Worksheet Miningresure100% (1)

- Job Safety Analysis Record Sheet: Cause & Effect Metrix TestDocumento2 pagineJob Safety Analysis Record Sheet: Cause & Effect Metrix TestFernandoMarquezNessuna valutazione finora

- FMEADocumento6 pagineFMEANavnath TamhaneNessuna valutazione finora

- Self-Assessment Guide: ELCICS306-0510 1 Instrumentation and Control Servicing NC IIIDocumento2 pagineSelf-Assessment Guide: ELCICS306-0510 1 Instrumentation and Control Servicing NC IIIrenjithv_4Nessuna valutazione finora

- SATR-A-2002 Calibration Test Report-Pressure GaugeDocumento1 paginaSATR-A-2002 Calibration Test Report-Pressure GaugeAnonymous S9qBDVkyNessuna valutazione finora

- Xfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsDocumento6 pagineXfmea Report Sample - Machinery FMEA: in Addition To This Summary, This Report Includes The Following FormsRoland JoldisNessuna valutazione finora

- Cause and Effect Analysis (Fishbone Diagram) : CA/PA-RCA: Basic ToolDocumento23 pagineCause and Effect Analysis (Fishbone Diagram) : CA/PA-RCA: Basic ToolDipraj KayasthaNessuna valutazione finora

- Risk Assessment CalculatorDocumento244 pagineRisk Assessment CalculatorJoséAntonioBarbosaNessuna valutazione finora

- Monitoring, Measurement, Analysis and Evaluation: 1.0 PurposeDocumento4 pagineMonitoring, Measurement, Analysis and Evaluation: 1.0 Purposemahsen2000Nessuna valutazione finora

- Capacitance Type Level Switch Calibration Rev.00Documento4 pagineCapacitance Type Level Switch Calibration Rev.00ArdvarkNessuna valutazione finora

- Manipulator SpecsDocumento34 pagineManipulator Specsandi vlog'sNessuna valutazione finora

- Reliability Instrumented System: Arrelic InsightsDocumento8 pagineReliability Instrumented System: Arrelic Insightspradeep1987coolNessuna valutazione finora

- P&IDDocumento18 pagineP&IDhectornicolauNessuna valutazione finora

- Effective FMEADocumento51 pagineEffective FMEAAshok DevarajNessuna valutazione finora

- Compressor Selection GuidelineDocumento1 paginaCompressor Selection Guidelinepradeep1987coolNessuna valutazione finora

- Flare System: Design & Calculation Module 01 - Nov-2020Documento71 pagineFlare System: Design & Calculation Module 01 - Nov-2020pradeep1987cool100% (2)

- Intermediate PythonDocumento75 pagineIntermediate PythonLuis MinayaNessuna valutazione finora

- Safety Instrumented Systems SIS SILDocumento19 pagineSafety Instrumented Systems SIS SILfloredaNessuna valutazione finora

- Single Point Lesson - The Role of A Maintenance Planner PDFDocumento3 pagineSingle Point Lesson - The Role of A Maintenance Planner PDFpradeep1987coolNessuna valutazione finora

- Mistakes I Made in My First Job A Thread..Documento24 pagineMistakes I Made in My First Job A Thread..Akshat AgrawalNessuna valutazione finora

- Pollution Control and Waste ManagementDocumento13 paginePollution Control and Waste ManagementArdh0072Nessuna valutazione finora

- Osho Source BookDocumento641 pagineOsho Source Bookwhitepaladin100% (5)

- 01 - ABB SIL Methodology Brochure PDFDocumento24 pagine01 - ABB SIL Methodology Brochure PDFramkrishnaNessuna valutazione finora

- Flash and Fire Point, Autoignition Temperature, LEL / UELDocumento2 pagineFlash and Fire Point, Autoignition Temperature, LEL / UELpradeep1987coolNessuna valutazione finora

- Quant SilDocumento40 pagineQuant SilMubarik AliNessuna valutazione finora

- TQM - TRG - F-09 - Discriminant Analysis - Rev01 - 20180602 PDFDocumento22 pagineTQM - TRG - F-09 - Discriminant Analysis - Rev01 - 20180602 PDFpradeep1987coolNessuna valutazione finora

- Quality ToolsDocumento2 pagineQuality Toolspradeep1987coolNessuna valutazione finora

- Cert Factsheet CREDocumento2 pagineCert Factsheet CREDhrubajyoti BoraNessuna valutazione finora

- CMRP Candidate Guide For Certification and Recertification 10-25-16Documento42 pagineCMRP Candidate Guide For Certification and Recertification 10-25-16Mohammed MushtahaNessuna valutazione finora

- Safety: Layer of Protection: Process Operability Class MaterialsDocumento48 pagineSafety: Layer of Protection: Process Operability Class MaterialsAquiles_voy100% (1)

- Value Paper FSH InDesign v2Documento32 pagineValue Paper FSH InDesign v2hvananthNessuna valutazione finora

- TQM - TRG - C-22 - Autonomous Maint - Rev00 - 20180630 PDFDocumento71 pagineTQM - TRG - C-22 - Autonomous Maint - Rev00 - 20180630 PDFpradeep1987coolNessuna valutazione finora

- TQM - TRG - C-21 - Kaizen OPL and Poka Yoke - Rev02 - 20180601 PDFDocumento29 pagineTQM - TRG - C-21 - Kaizen OPL and Poka Yoke - Rev02 - 20180601 PDFpradeep1987coolNessuna valutazione finora

- TQM - TRG - C-18 - 5S - Rev01 - 20180528 PDFDocumento56 pagineTQM - TRG - C-18 - 5S - Rev01 - 20180528 PDFpradeep1987cool100% (1)

- Instrument Air Compressor PDFDocumento54 pagineInstrument Air Compressor PDFpradeep1987cool100% (1)

- TQM - TRG - F-10 - Factor Analysis - Rev05 - 20180421 PDFDocumento18 pagineTQM - TRG - F-10 - Factor Analysis - Rev05 - 20180421 PDFpradeep1987coolNessuna valutazione finora

- Wrench Time Analysis: SeriesDocumento27 pagineWrench Time Analysis: Seriespradeep1987coolNessuna valutazione finora

- Practical Guidelines For Identifying and Tuning PID Control Loops With Long Deadtime And/or Time ConstantsDocumento32 paginePractical Guidelines For Identifying and Tuning PID Control Loops With Long Deadtime And/or Time ConstantsManish RaiNessuna valutazione finora

- TQM - TRG - B-08 - Relations Diagram - Rev01 - 20180603Documento28 pagineTQM - TRG - B-08 - Relations Diagram - Rev01 - 20180603pradeep1987coolNessuna valutazione finora

- TQM - TRG - C-10 - DM in Maintenance - Rev04 - 20180602 PDFDocumento109 pagineTQM - TRG - C-10 - DM in Maintenance - Rev04 - 20180602 PDFpradeep1987coolNessuna valutazione finora

- TQM - TRG - C-16 - Improvement Fundamentals - Rev03 - 20180601Documento52 pagineTQM - TRG - C-16 - Improvement Fundamentals - Rev03 - 20180601pradeep1987cool100% (2)

- Reverse Engineering Serial ProtocolDocumento19 pagineReverse Engineering Serial ProtocolRichardmsiska100% (1)

- PCB Design RuleDocumento43 paginePCB Design RuletrinhdieuhvktqsNessuna valutazione finora

- ILI9488 Data Sheet - 100Documento343 pagineILI9488 Data Sheet - 100Zoltán HorvátNessuna valutazione finora

- Cmts l2vpnDocumento14 pagineCmts l2vpnperun_rojsNessuna valutazione finora

- Chrome ListDocumento23 pagineChrome ListXatuna GoqadzeNessuna valutazione finora

- Tg0003en Ed01 ErmaDocumento16 pagineTg0003en Ed01 ErmaEduardo Pereira da SilvaNessuna valutazione finora

- Owner'S Manual: Netcontroller Console KVM and Rackmount KVM SwitchesDocumento36 pagineOwner'S Manual: Netcontroller Console KVM and Rackmount KVM SwitchesGabriel GamezNessuna valutazione finora

- Official Websites: How To Determine Applicable Product Safety Standards: 5 MethodsDocumento9 pagineOfficial Websites: How To Determine Applicable Product Safety Standards: 5 MethodsChandru HanchinalNessuna valutazione finora

- TR - Plumbing NC IIDocumento94 pagineTR - Plumbing NC IImarbd100% (1)

- Xirrus XD SeriesDocumento662 pagineXirrus XD Serieser0zNessuna valutazione finora

- Pr1605020007en 9500 MPR Mss Family r6-1 Ansi DatasheetDocumento2 paginePr1605020007en 9500 MPR Mss Family r6-1 Ansi DatasheetToh Pyie SheinNessuna valutazione finora

- NSA NR 5g Architecture - CiscoDocumento6 pagineNSA NR 5g Architecture - CiscoSandeep KadamNessuna valutazione finora

- BS en 22768-2 1993Documento16 pagineBS en 22768-2 1993Hüseyin BuğdaycıNessuna valutazione finora

- Linked List: Singly, Doubly and CircularDocumento53 pagineLinked List: Singly, Doubly and CircularMia SamNessuna valutazione finora

- Tuv Rheinland Testing and Certification Regulations Pressure Equipment Jan 2018Documento58 pagineTuv Rheinland Testing and Certification Regulations Pressure Equipment Jan 2018hemz.ebayNessuna valutazione finora

- BIC CodeDocumento23 pagineBIC CodevenkatanagasatyaNessuna valutazione finora

- Connection Conditions For Generators of Electricity From Solar EnergyDocumento12 pagineConnection Conditions For Generators of Electricity From Solar EnergyjayapalNessuna valutazione finora

- 5 - Information Technology - DevOps - Building Reliable and Secure Systems Including Application Build, Package and DeploymentDocumento94 pagine5 - Information Technology - DevOps - Building Reliable and Secure Systems Including Application Build, Package and DeploymentAngel Adrian Camal GarciaNessuna valutazione finora

- ALN FP ESA MEC SPC 2201 - 2B6B.1 Piping Materials SupplementDocumento327 pagineALN FP ESA MEC SPC 2201 - 2B6B.1 Piping Materials Supplementahmed.njahNessuna valutazione finora

- Fasteners DIN en ISO Standards PDFDocumento32 pagineFasteners DIN en ISO Standards PDFsardarNessuna valutazione finora

- Va259 14 R 0224 002Documento53 pagineVa259 14 R 0224 002raulneti1984Nessuna valutazione finora

- Manuel - Manual RPL23 Rev1.6 EngDocumento10 pagineManuel - Manual RPL23 Rev1.6 EngMayur GuptaNessuna valutazione finora

- Final (CT) Pr1 11 12 Unit 1 Research PaperDocumento7 pagineFinal (CT) Pr1 11 12 Unit 1 Research PaperRandz TakiawanNessuna valutazione finora

- Manual EasyTech Full Idro UKDocumento12 pagineManual EasyTech Full Idro UKshufuckNessuna valutazione finora

- Oracle ch6Documento56 pagineOracle ch6Jenner Patrick Lopes BrasilNessuna valutazione finora

- Satip A 114 01 Earth WorkDocumento11 pagineSatip A 114 01 Earth WorkZia ur RehmanNessuna valutazione finora

- BP Cat Feb09 ContactorsContactsDocumento25 pagineBP Cat Feb09 ContactorsContactssaqibmaxNessuna valutazione finora

- Functional Safety Assessment of Valve Assemblies Part 1Documento6 pagineFunctional Safety Assessment of Valve Assemblies Part 1Serge RINAUDONessuna valutazione finora

- Installation Manual VRV III BSVQ - PVJU - DaikinDocumento17 pagineInstallation Manual VRV III BSVQ - PVJU - Daikinvineeth8624Nessuna valutazione finora

- 5G Network Architecture and Design PDFDocumento20 pagine5G Network Architecture and Design PDFsmartemNessuna valutazione finora

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Da EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Nessuna valutazione finora

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDa EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNessuna valutazione finora

- Introduction to Power System ProtectionDa EverandIntroduction to Power System ProtectionValutazione: 5 su 5 stelle5/5 (1)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDa EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesValutazione: 4.5 su 5 stelle4.5/5 (21)

- Carbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersDa EverandCarbon Capture, Utilization, and Storage Game Changers in Asia: 2020 Compendium of Technologies and EnablersValutazione: 4.5 su 5 stelle4.5/5 (2)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceDa EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceNessuna valutazione finora

- Shorting the Grid: The Hidden Fragility of Our Electric GridDa EverandShorting the Grid: The Hidden Fragility of Our Electric GridValutazione: 4.5 su 5 stelle4.5/5 (2)

- A Pathway to Decarbonise the Shipping Sector by 2050Da EverandA Pathway to Decarbonise the Shipping Sector by 2050Nessuna valutazione finora

- Grid-Scale Energy Storage Systems and ApplicationsDa EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuNessuna valutazione finora

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDa EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsValutazione: 4.5 su 5 stelle4.5/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Practical Reservoir Engineering and CharacterizationDa EverandPractical Reservoir Engineering and CharacterizationValutazione: 4.5 su 5 stelle4.5/5 (3)

- Nuclear Energy in the 21st Century: World Nuclear University PressDa EverandNuclear Energy in the 21st Century: World Nuclear University PressValutazione: 4.5 su 5 stelle4.5/5 (3)

- Global Landscape of Renewable Energy FinanceDa EverandGlobal Landscape of Renewable Energy FinanceNessuna valutazione finora

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDa EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsNessuna valutazione finora

- Renewable Energy: A Very Short IntroductionDa EverandRenewable Energy: A Very Short IntroductionValutazione: 4.5 su 5 stelle4.5/5 (12)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successDa EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successValutazione: 4.5 su 5 stelle4.5/5 (3)

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Da EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Nessuna valutazione finora

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsDa EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNessuna valutazione finora

- Gas-Liquid And Liquid-Liquid SeparatorsDa EverandGas-Liquid And Liquid-Liquid SeparatorsValutazione: 3.5 su 5 stelle3.5/5 (3)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerDa EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerNessuna valutazione finora

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsDa EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsNessuna valutazione finora

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingDa EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNessuna valutazione finora

- ISO 50001: A strategic guide to establishing an energy management systemDa EverandISO 50001: A strategic guide to establishing an energy management systemNessuna valutazione finora

- The Way Home: Tales from a life without technologyDa EverandThe Way Home: Tales from a life without technologyValutazione: 4 su 5 stelle4/5 (45)