Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Fs-Gap CHK Harvest v6!0!092112 Web

Caricato da

ArtPachecoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Fs-Gap CHK Harvest v6!0!092112 Web

Caricato da

ArtPachecoCopyright:

Formati disponibili

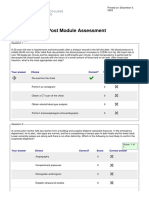

Harvesting Operation Practices

Auditors' Checklist

Audited Field: 0 Field 0 Date: 1/1/04

Location:

Section # CATEGORY/REQUIREMENTS Poss.

Pnts. N/A S NI US Auto Auditor's Note

1.0 MANAGEMENT RESPONSIBILITY

Sub Category 1.1 Management Commitment and Review

Mgmt Commitment 1.1.1 Is management following GAP principles? [Refer to Guide to Minimize Microbial Food Safety 10

Hazards for Fresh Fruits and Vegetables, and/or the Good Manufacturing Practices (21 CFR Part

110.10).] (10 points)

Mgmt Commitment 1.1.2 Are customer specific requirements (foreign country guidelines) being followed? (10 points) 10

Mgmt Commitment 1.1.3 Are the potential contamination risks associated with harvesting operation(s) identified in a 10

written document (Hazard Analysis)? (Consider use of agricultural water, worker health and

hygiene.) (10 points)

Mgmt Commitment 1.1.3.a Are corrective actions or preventative measures identified in a written document and available for 10

review? (10 points)

Mgmt Commitment 1.1.4 1. Are pre-harvest inspections performed on the fields being harvested and harvest crews? 10

2. Are observations documented and available for review? (10 points)

Total Points 50 0 0 0 0 0

Section 2.0 HARVESTING OPERATIONS

Sub Category 2.1 Employee Practices (Assessed by Observation and/or Documentation)

Employee Practices General Expectation: Compliance with the Guide to Minimize Microbial Food Safety Hazards for Fresh Fruits and Vegetables, Section IV.A.B.

Employee Practices 2.1.1 Are employees with: a. open and/or infected wounds or cuts on their hands or face, or with 10

symptoms of infections or illness (e.g., diarrhea, vomiting), prohibited from having direct contact

with the product or any equipment used in harvesting, packing, sorting and shipping containers?

(10 points)

Version 6-0 (September 2012) | © SCS Global Services 1

Harvesting Operation Practices

Auditors' Checklist

Section # CATEGORY/REQUIREMENTS Poss.

Pnts. N/A S NI US Auto Auditor's Note

Employee Practices 2.1.1.a. Do employees with injuries such as open wounds, lesions, cuts, or sores, that could come in 10

contact with equipment or produce, keep them completely covered with appropriate first aid

materials and covered with gloves, if on hands/wrists?(10 points)

Employee Practices 2.1.1.b. Have corrective actions been taken if a worker is found to be infected?(10 points) 10

Employee Practices 2.1.2 Are employees maintaining: a. clean clothing, including outer garments (e.g., aprons)? b. 10

adequate personal cleanliness? (10 points)

Employee Practices 2.1.3 Are employees removing aprons, gloves, and other protective clothing (when in use) before 10

entering the toilets and storing the items in a designated area, separate from the field and toilet

areas? (10 points)

Employee Practices 2.1.4 Are employees washing and/or sanitizing hands and/or gloves prior to beginning or returning to 10

work or whenever the hands and/or gloves may have become soiled or contaminated? (10 points)

Employee Practices 2.1.5 Where applicable, are employees maintaining gloves, if they are used in product handling, in an 10

intact, clean, and sanitary condition? (10 points)

Employee Practices 2.1.6 Are employees prohibited from eating food, drinking beverages, spitting, chewing gum, and using 10

tobacco and/or toothpicks in harvesting areas? (10 points)

Employee Practices 2.1.7 When employees take their breaks, are they storing personal clothing and/or belongings in a 10

designated area, separate from the field and toilet areas? (10 points)

Employee Practices 2.1.8 Are all products, materials and packaging that come in contact with blood destroyed, and any 10

equipment, tool and/or product contact surface that comes in contact with blood cleaned and

sanitized before use? (10 points)

Employee Practices 2.1.9. Does the operation have a written policy, which addresses applicable worker health and hygiene 10

issues? (must cover all policies indicated from question 2.1.1.to 2.1.8) (10 points)

Total Points 110 0 0 0 0 0

Sub Category 2.2 Training and Education (Assessed by Observation, Interview, and Documentation)

Version 6-0 (September 2012) | © SCS Global Services 2

Harvesting Operation Practices

Auditors' Checklist

Section # CATEGORY/REQUIREMENTS Poss.

Pnts. N/A S NI US Auto Auditor's Note

Training & Education General Expectation: Compliance with the Guide to Minimize Microbial Food Safety Hazards for Fresh Fruits and Vegetables, Section IV.2.0

Training & Education 2.2.1 Is there a documented employee training program, which includes initial and ongoing and/or 10

refresher food safety training (e.g., cGMPs, personnel practices) for all employees, and training on

cleaning and sanitation procedures for sanitation employees? (10 points)

Training & Education 2.2.2 Is there an assigned person or an outside agency responsible for conducting training on topics such 4

as food safety, cGMPs, and sanitation and cleaning procedures? (4 points)

Training & Education 2.2.3 1. Is there an initial and ongoing and/or refresher employee training program, that addresses food 10

safety related issues (e.g., GAPs, personnel practices, sanitation procedures, worker health and

hygiene issues), for all employees, including new employees, and that addresses cleaning and

sanitation procedures for sanitation employees, including new sanitation employees?

2. Is the general content of the training sessions included? (e.g., topics covered, who was trained,

who provided the training, date of training)

3. Is the training program reviewed on an annual basis? (10 points)

Training & Education 2.2.4 1. Is worker participation in respective training programs (initial and ongoing and/or refresher, 10

addressed in 2.2.3) documented, including the employee’s signature, and available for review?

2. Are records legible? (10 points)

Training & Education 2.2.5 Do employees appear to have received and understood training and are they practicing proper 10

food handling procedures? (10 points)

Training & Education 2.2.6 Is there a supervisor with appropriate training and/or experience, who oversees the food safety 4

practices? (4 points)

Total Points 48 0 0 0 0 0

Sub Category 2.3 Sanitary Facilities (Assessed by Observation and Documentation)

Toilet Facilities General Expectation: Compliance with the Guide to Minimize Microbial Food Safety Hazards for Fresh Fruits and Vegetables, Section V.

Toilet Facilities (a) Toilet Facilities

Version 6-0 (September 2012) | © SCS Global Services 3

Harvesting Operation Practices

Auditors' Checklist

Section # CATEGORY/REQUIREMENTS Poss.

Pnts. N/A S NI US Auto Auditor's Note

Toilet Facilities General Expectation: Operators should operate their facilities or farms in accordance with the laws and regulations that describe field and facility sanitation practices.

Toilet Facilities 2.3.1 Are toilet facilities provided? (10 points) 10

Toilet Facilities 2.3.1.a 1. Is a minimum of one toilet provided for every 20 people? 10

2. Are toilets within a 1/4 mile or 5-minute walk for all workers?

3. Are separate toilets or mobile toilets provided if there are 5 or more employees of each gender?

(10 points)

Toilet Facilities 2.3.1.b Do toilets have: 10

a. self-closing doors?

b. ventilation systems to eliminate odors?

c. floors, walls, ceilings and toilets built in such a way that they can be cleaned and sanitized

properly? (10 points)

Toilet Facilities 2.3.1.c Are toilets located and designed so as to reduce the possibility of contamination to water sources 10

or product in the event of a malfunction? (10 points)

Toilet Facilities 2.3.1.d Are catch basins of toilets designed to prevent contamination to the field or surrounding area? (10 10

points)

Toilet Facilities 2.3.1.e Are toilets maintained in clean condition? (10 points) 10

Toilet Facilities 2.3.1.f Are toilet supplies monitored/stocked throughout the day? (10 points) 10

Toilet Facilities 2.3.1.g Are toilets cleaned and emptied outside the growing and/or product handling area? (10 points) 10

Toilet Facilities 2.3.1.h Are toilet facilities serviced on a scheduled basis or as needed? (by outside company or by the 10

owner) (10 points)

Toilet Facilities 2.3.1.i Is cleaning service documented and are sanitation records available for review? (4 points) 4

Hand Washing (b) Hand washing facilities

Hand Washing General Expectation: Hand washing facilities shall be adequate and convenient and be furnished with running water at a suitable temperature.

Hand Washing 2.3.3 Are hand washing stations provided? (10 points) 10

Hand Washing 2.3.3.a Is a minimum of one hand washing station provided for every 20 people? (10 points) 10

Hand Washing 2.3.3.b Are hand washing stations provided in close proximity to the toilet facilities and are they easily 4

accessible to workers? (4 points)

Version 6-0 (September 2012) | © SCS Global Services 4

Harvesting Operation Practices

Auditors' Checklist

Section # CATEGORY/REQUIREMENTS Poss.

Pnts. N/A S NI US Auto Auditor's Note

Hand Washing 2.3.3.c 1. Are single-use towels available at hand washing stations? 10

2. Are hand washing stations functional, equipped with suitable water, bacteriostatic soap and/or

hand sanitizer?

3. Written signs and/or pictures in appropriate language(s) located next to the hand washing

stations reminding employees to wash and sanitize their hands, when necessary? (10 points)

Hand Washing 2.3.3.d Are hand washing stations located and/or designed in such a way to: 4

a. prevent contamination of product, equipment, and packaging materials (e.g., to capture rinse

water, etc)?

b. facilitate hands-free operations (e.g., knee or foot levers)? (4 points)

Hand Washing 2.3.3.e Are hand washing stations and/or hand sanitizing stations maintained in clean condition? (4 4

points)

Hand Washing 2.3.3.f 1. Are hand washing and/or sanitizing stations cleaned on a scheduled basis or as needed? 4

2. Are the cleaning procedures described in a document that details how and when to clean (at

least daily)?

3. Is cleaning documented and are records available for review? (4 points)

Hand Washing 2.3.3.g Are hand washing stations and/or hand sanitizing stations monitored and stocked throughout the 10

day? (10 points)

Total Points 150 0 0 0 0 0

Sub Category 2.4 Water (Assessed by Observation)

Water General Expectation: Compliance with the Guide to Minimize Microbial Food Safety Hazards for Fresh Fruits and Vegetables, Section VII.B.1.0

Water (a) Drinking Water

Water 2.4.1 Is fresh potable drinking water provided? (4 points) 4

Water 2.4.2 Are drinking water containers cleaned periodically AND do they appear to be in sanitary condition? 4

(4 points)

Water 2.4.3 Are single use paper cups available to prevent the spread of germs? (4 points) 4

Total Points 12 0 0 0 0 0

Sub Category 2.5 Grounds (Assessed by Observation)

Grounds 2.5.1 1. Is general clean-up of litter and waste conducted on a continual basis during harvesting? 10

2. Are garbage containers provided? (10 points)

Total Points 10 0 0 0 0 0

Version 6-0 (September 2012) | © SCS Global Services 5

Harvesting Operation Practices

Auditors' Checklist

Section # CATEGORY/REQUIREMENTS Poss.

Pnts. N/A S NI US Auto Auditor's Note

Sub Category 2.6 General Practices and Procedures (Assessed by Observation and Documentation)

Packaging Materials (a) Packaging Materials

Packaging Materials 2.6.1 Are packaging materials used? If yes, go to 2.6.1.a. If no, skip to 2.6.3 Unscored Question

Packaging Materials 2.6.1.a Are packaging materials only used to pack produce and not used to store other things? (10 points) 10

Packaging Materials 2.6.1.b Are packaging materials kept clean, dry, and free from contamination (evidence of pest activity, 10

foreign materials, and chemicals) during transportation and use? (10 points)

Packaging Materials 2.6.1.c. During harvesting process, are packaging materials handled in a manner to eliminate 10

contamination from the ground or from inappropriate employee handling? (10 points).

Packaging Materials 2.6.1.d Are corrective actions taken if the packaging material is discovered to be contaminated? (10 10

points)

Packaging Materials 2.6.1.e Carton/Packaging Material Storage Area: 10

1. Are packaging materials stored in areas that have a written and fully implemented pest control

program?

2. Are the areas monitored for pest activities on a continuous basis? (10 points)

Packaging Materials 2.6.1.f. Is a sanitation program in place for the packaging materials storage area, and is the area cleaned 4

on a regular basis and inspected from a sanitation standpoint? (4 points)

Packaging Materials 2.6.1.g. Are packaging materials inspected prior to use to ensure they are free of contamination (e.g., 10

rodent or bird droppings, glass fragments, metal fillings, chemicals)? (10 points)

Packaging Materials 2.6.1.h. Is FIFO (First In First Out) practiced, i.e., stock rotated on packaging materials? (4 points) 4

Packaging Materials 2.6.2 Field storage: Does management have a policy prohibiting storing containers and packaging 10

materials overnight in the field, unless protected from possible contamination (e.g. materials must

be covered and must not be stored directly on the ground, and must be stored away from

chemicals used on the farm)? (10 points)

Recall/ Traceability (b) Recall/Traceability Program

Recall/Traceability 2.6.3 Is there a documented recall procedure? (4 points) 4

Version 6-0 (September 2012) | © SCS Global Services 6

Harvesting Operation Practices

Auditors' Checklist

Section # CATEGORY/REQUIREMENTS Poss.

Pnts. N/A S NI US Auto Auditor's Note

Recall/Traceability 2.6.4 In the event of an actual recall, is the associated documentation available for review? (4 points) 4

Recall/Traceability 2.6.5 Is there a product coding system that can identify products, if a recall is required, and can the 10

system track products back to the farm? (10 points)

Recall/Traceability 2.6.6. Is each individual unit package properly identified with date of harvest, field #, lot #, and other 10

information required to track back to its source? (10 points)

Recall/Traceability 2.6.7 Is a mock recall performed at least annually, and are results documented and maintained on file? 4

(4 points)

Recall/Traceability 2.6.8 Are records of food safety related customer complaints and company responses kept on file and 4

available for review? (4 points)

General (c) General

General 2.6.9 Is there a policy prohibiting any objects such as farming equipment, mechanical tools, or loose 4

objects from being placed in or on top of product containers? (4 points)

General 2.6.10 Is there a policy prohibiting glass objects in the field, harvesting and packing areas? (4 points) 4

General 2.6.11 Are first aid kits available and appropriately stocked? (4 points) 4

Total Points 126 0 0 0 0 0

Sub Category 2.7 Cleaning Equipment and Chemicals (Assessed by Observation and Documentation)

General Expectation: Compliance with the Guide to Minimize Microbial Food Safety Hazards for Fresh Fruits and Vegetables, Section VI.B.2.0

Cleaning Equip. & 2.7.1 Are cleaning compounds and sanitizing agents appropriate (anti-microbial, food grade approved) 10

Chemicals for product and non-product contact surfaces? (10 points)

Cleaning Equip. & 2.7.2 1. Are chemical preparations tested by trained personnel for concentration via test kits or sanitizer 10

Chemicals strength strips prior to use or on a periodic basis?

2. Is concentration documented and available for review? (10 points)

Cleaning Equip. & 2.7.3 Are cleaning and sanitizing chemicals clearly identified? (4 points) 4

Chemicals

Version 6-0 (September 2012) | © SCS Global Services 7

Harvesting Operation Practices

Auditors' Checklist

Section # CATEGORY/REQUIREMENTS Poss.

Pnts. N/A S NI US Auto Auditor's Note

Cleaning Equip. & 2.7.4 Are MSDSs and copies of labels maintained for cleaning and sanitizing chemicals? (4 points) 4

Chemicals

Cleaning Equip. & Are cleaning and sanitizing chemicals stored in secure areas away from the harvesting areas? (4 4

Chemicals points)

2.7.5

Total Points 32 0 0 0 0 0

Sub Category 2.8 Cleaning and Sanitation Procedures (Assessed by Observation and Documentation)

Sanitation General Expectation: Compliance with the Guide to Minimize Microbial Food Safety Hazards for Fresh Fruits and Vegetables, Section VI.B.1.0

Sanitation 2.8.1 Are harvesting containers and/or product contact surfaces on harvesting machinery cleaned on a 10

scheduled basis or as needed? (10 points)

Sanitation 2.8.1.a Are all harvesting tools collected, cleaned and sanitized on a daily basis? (10 points) 10

Sanitation 2.8.2 Are the cleaning procedures described in a written document that details how and when to clean? 4

(4 points)

Sanitation 2.8.3 Is cleaning documented and available for review? (4 points) 4

Total Points 28 0 0 0 0 0

Sub Category 2.9 Containers/Tools/Equipment Construction, Design, and Maintenance (Assessed by Observation and Documentation)

General Expectation: Compliance with the Guide to Minimize Microbial Food Safety Hazards for Fresh Fruits and Vegetables, Section VI.B.2.0

Harvesting Containers (a) Harvesting Containers

Harvesting Containers 2.9.1 Are harvesting containers (e.g. bins, field totes, re-usable containers), that come in direct contact Yes/No

with the product, used during harvesting? If yes, go to 2.9.1.a. If no, go to 2.9.2

Unscored Question

Harvesting Containers 2.9.1.a Are the product contact surfaces that are designed for food use (e.g. non-corrosive), able to be 10

cleaned and/or sanitized to withstand repeat cleaning, to be maintained in good condition, and to

be used for the tasks for which they were intended? (10 points)

Harvesting Tools (b) Harvesting Tools

Version 6-0 (September 2012) | © SCS Global Services 8

Harvesting Operation Practices

Auditors' Checklist

Section # CATEGORY/REQUIREMENTS Poss.

Pnts. N/A S NI US Auto Auditor's Note

Harvesting Tools 2.9.2 Are harvest tools (e.g., knives, coring rings) used during harvesting? If yes, go to 2.9.2.a. If no, go Yes/No

to 2.9.3. Unscored Question

Harvesting Tools 2.9.2.a Are harvest tools designed for food use (e.g., non-corrosive, no wood), able to be cleaned and/or 10

sanitized, to withstand repeat cleaning, to be maintained in good condition, and to be used for the

tasks for which they were intended? (10 points)

Harvesting Tools 2.9.2.b Are harvest tools only used for harvesting and not taken into break and/or toilet areas? (10 10

points).

Harvest Machinery (c) Harvest Machinery

Harvest Machinery 2.9.3 Is harvest machinery used? If yes, go to 2.9.3.a. If no, go to 2.10 Unscored Question Yes/No

Harvest Machinery 2.9.3.a Are all product contact surfaces designed for food use, able to be cleaned and/or sanitized, to 10

withstand repeat cleaning, to be maintained in good condition, and to be used for the tasks for

which they were intended? (10 points)

Harvest Machinery 2.9.3.b For the harvest machinery: 10

a. Are catch pans used under all motors, where there is potential for leakage of gearbox oil or

other lubricants?

b. If platforms are above product or packaging, are they equipped with kick plates to prevent

product contamination? (10 points)

Harvest Machinery 2.9.3.c Are only approved food grade lubricants (if in use) used near food contact areas? (10 points) 10

Harvest Machinery 2.9.3.d Is the harvesting equipment free of maintenance tools, gloves, rags, and other miscellaneous 4

materials that might contaminate the product? (4 points)

PM Program (d) Preventive Maintenance

Harvest Machinery 2.9.4 1. Does the operation have an effective preventative maintenance program for its harvesting 4

machinery, containers and/or tools?

2. Is the preventative maintenance program audited? (4points)

Total Points 68 0 0 0 0 0

Sub Category 2.10 Transportation and Distribution (Assessed by Observation and Documentation)

Transp & Dist. General Expectation: Compliance with the Guide to Minimize Microbial Food Safety Hazards for Fresh Fruits and Vegetables, Section VIII.

Transp & Dist. 2.10.1 Does the facility uses an outside carrier company for transportation? If yes, go to 2.10.1.a. If no, go

to 2.10.2 Unscored Question

Version 6-0 (September 2012) | © SCS Global Services 9

Harvesting Operation Practices

Auditors' Checklist

Section # CATEGORY/REQUIREMENTS Poss.

Pnts. N/A S NI US Auto Auditor's Note

Transp & Dist. 2.10.1.a. Is protocol on safe transportation and proper product handling procedures provided to the carrier 4

companies? (4 points)

Transp & Dist. 2.10.1.b. Is the protocol issued to the drivers when they enter the site as a reminder? (4 points) 4

Transp & Dist. 2.10.2 Is there a cleaning procedure for trucks that requires adequate cleaning and inspection (incoming 4

and outgoing)? (4 points)

Transp & Dist. 2.10.2.a. 1. Do trucks, trailers, or transport containers that are used for transporting product appear to be 4

clean and in good condition? (e.g. no glass, dirt, other foreign bodies/structures, odor, etc).

2. Are the inspections documented and signed off ? (4 points)

Transp & Dist. 2.10.3 Is the harvested product covered when transported from the field or packing shed or cooler 4

directly to another location? (4 points).

Total Points 20 0 0 0 0 0

Sub Category 3.0 Document Control (Assessed by Documentation)

Document Control 3.1.1. Are all GAP records legible and accurate? (4 points) 4

Document Control 3.1.2 Does the farm employ a formal system to manage and control all food safety related 4

documentation, data and records? (4 points)

Document Control 3.1.3 Are procedures in place to control document transmission, changes and removal of obsolete 4

documents? (4 points)

Document Control 3.1.4 Is there an authorized person to issue food safety documents? (4 points) 4

Document Control 3.1.5 Do document control procedures ensure customer confidentiality? (4 points) 4

Document Control 3.1.6 Does a document control system protect physical and electronic documents against loss and 4

unauthorized access? (4 points)

Document Control 3.1.7 Is there a records retention policy for food safety related documentation, data and records? (4 4

points)

Other Section Total Points 28 0 0 0 0 0

Version 6-0 (September 2012) | © SCS Global Services 10

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Defining Child Abuse TypesDocumento14 pagineDefining Child Abuse TypesAndreas Springfield GleasonNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Lower Gastrointestinal Bleeding: Practice EssentialsDocumento28 pagineLower Gastrointestinal Bleeding: Practice EssentialsJohnPaulOliverosNessuna valutazione finora

- Maximizing NICU Care Through Cost-Effective TechnologiesDocumento29 pagineMaximizing NICU Care Through Cost-Effective TechnologiesVonrey Tiana73% (11)

- Atls Pre Test SolvedDocumento18 pagineAtls Pre Test SolvedDr.Mukesh KumarNessuna valutazione finora

- Geriatrics Prescribing GuidelinessDocumento27 pagineGeriatrics Prescribing GuidelinessSayli Gore100% (1)

- Republic Act No. 7305, Magna Carta of Public Health Workers PDFDocumento15 pagineRepublic Act No. 7305, Magna Carta of Public Health Workers PDFSorayah M. Sharief-TabaoNessuna valutazione finora

- PT Behavioral ProblemsDocumento11 paginePT Behavioral ProblemsAmy LalringhluaniNessuna valutazione finora

- Bioaccumulation-Biomagnification WorksheetDocumento2 pagineBioaccumulation-Biomagnification Worksheetapi-277387172100% (2)

- Factors Affecting Adherence to Intranasal CorticosteroidsDocumento20 pagineFactors Affecting Adherence to Intranasal CorticosteroidsKathrinna Feliz AlertaNessuna valutazione finora

- Ecoglobal Foundation - Jean-Philippe HenryDocumento22 pagineEcoglobal Foundation - Jean-Philippe HenryEnergy for AllNessuna valutazione finora

- TechnologiesDocumento11 pagineTechnologiesabdelrahmanelsayed368Nessuna valutazione finora

- 5150 Holds in San Diego CountyDocumento28 pagine5150 Holds in San Diego CountynoxinqwertyNessuna valutazione finora

- Case Study Peran Teori Keperawatan PDFDocumento5 pagineCase Study Peran Teori Keperawatan PDFLayung SariNessuna valutazione finora

- 03-Ischemic Heart Disease - 2020 OngoingDocumento151 pagine03-Ischemic Heart Disease - 2020 OngoingDana MohammadNessuna valutazione finora

- CUA Guide: Cost-Utility Analysis ExplainedDocumento13 pagineCUA Guide: Cost-Utility Analysis Explainedhabiba nafea100% (1)

- Templates For Planning and M&E (AIP, WFP, SMEA Templates)Documento6 pagineTemplates For Planning and M&E (AIP, WFP, SMEA Templates)Genzo TaniaNessuna valutazione finora

- M102 Notes 3. Presumptive Sign: Extreme Form of Morning Sickness ThatDocumento3 pagineM102 Notes 3. Presumptive Sign: Extreme Form of Morning Sickness ThatNano KaNessuna valutazione finora

- Philippines Volume 10 FernDocumento2 paginePhilippines Volume 10 FernJen Aquino ZetaNessuna valutazione finora

- 10 1016@j Mcna 2019 10 003Documento10 pagine10 1016@j Mcna 2019 10 003Arnold BarraNessuna valutazione finora

- Dr. Sanjida Sultana's CVDocumento4 pagineDr. Sanjida Sultana's CVHasibul Hassan ShantoNessuna valutazione finora

- Leprosy Patient Record CardDocumento2 pagineLeprosy Patient Record CardAdane Belay100% (2)

- Mega BlueDocumento9 pagineMega Bluepollito AmarilloNessuna valutazione finora

- Major Case Presentation On Acute Pulmonary Embolism WithDocumento13 pagineMajor Case Presentation On Acute Pulmonary Embolism WithPratibha NatarajNessuna valutazione finora

- Strategi Koping Ibu Dengan Anak Penderita Kanker (Studi Deskriptif Di Komunitas Peduli Anak Kanker Dan Penyakit Kronis Lainnya)Documento15 pagineStrategi Koping Ibu Dengan Anak Penderita Kanker (Studi Deskriptif Di Komunitas Peduli Anak Kanker Dan Penyakit Kronis Lainnya)Yan ParirakNessuna valutazione finora

- Neurological Assessment 1 - Assessing Level of ConsciousnessDocumento1 paginaNeurological Assessment 1 - Assessing Level of ConsciousnesskyawswakyawswaNessuna valutazione finora

- Vitamin D and CalciumDocumento33 pagineVitamin D and CalciumAkhmadRoziNessuna valutazione finora

- BipMED Price List May 2022Documento9 pagineBipMED Price List May 2022erlinNessuna valutazione finora

- CV FormatDocumento1 paginaCV FormatpanchodomNessuna valutazione finora

- 1st Lecture ImprovedDocumento26 pagine1st Lecture ImprovedSahan SahANessuna valutazione finora

- The ICF-CY model as a framework for pediatric rehabilitationDocumento2 pagineThe ICF-CY model as a framework for pediatric rehabilitationAtet KurniadiNessuna valutazione finora