Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

8M26 2-GB PDF

Caricato da

Irda OnesDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

8M26 2-GB PDF

Caricato da

Irda OnesCopyright:

Formati disponibili

Réf.

IC 03/A

LD SC - 04-2016

4 stroke diesel engine, direct injection

8 M26.2

Bore and stroke 150 x 150 mm

Number of cylinders 8 in V

Total displacement 21.2 litres

Compression ratio 14/1

Engine rotation (ISO 1204 standard) CCW *

Idle speed 700 rpm

Weight (without water & oil) 2475 kg

Flywheel housing SAE 0

Flywheel SAE 14"

Not contractual picture * counter-clockwise

RATED POWER: E3 cycle (FPP propeller) Please contact us for information regarding the E2 cycle (CPP propeller).

Duty rpm kW hp Peak torque / speed Full load fuel IMO CE 97 / 68 CCNR

(N.m / rpm) consumption (g / kW.h)

P1 1800 442 600 2696 / 1400 203 II IIIA II

P1 1800 491 668 2948 / 1400 209 II IIIA II

P2 1900 539 733 3110 / 1400 220 II IIIA II

P2 1950 588 800 3393 / 1400 233 II - -

Power definition (Standard ISO 3046/1 - 1995 (F) Our ratings also comply with classification societies maximum temperature definition without

power derating.

Reference conditions

Ambiant temperature 25 °C / 77 °F Ambient temperature 45 °C / 113 °F

Barometric pressure 100 kPa Raw water temperature 32 °C / 90 °F

Relative humidity 30 %

Raw water temperature 25 °C / 77 °F P1 duty P2 duty

Fuel oil Application unrestricted continuous continuous

Relative density 0,840 ± 0,005 Engine load variations very little or none numerous

Lower calorific power 42 700 kJ/kg Mean engine load factor 80 to 100 % 30 to 80 %

Consumption tolerances 0±5% Annual working time more than 5000 h 3000 to 5000 h

Inlet limit temperature 35 °C / 95 °F Time at full load unlimited 8 h each 12 h

STANDARD EQUIPMENTS

Engine and block Lubrification system

Cast iron cylinder block Full flow screwable oil filters

One inspection door per cylinder for access to conrod cap Lube oil purifier with replaceable cartridge

Cast iron cylinder liners, wet type Fresh water cooled lube oil cooler

Separate cast iron cylinder heads equipped with 4 valves

Replaceable valves guides and seats Fuel system

8 cylinders head tightening bolts In line injection pump with flanged mechanical governor

Hardened steel forged crankshaft with induction hardened journals, Double wall injection bundle with leakage collector

crankpins and radius Duplex fuel filters replaceable engine running

Camshaft with polynomial cams profile

Distribution with tempered, hardened and grinded helicoïdal gears

Intake air and exhaust system

Chromium-Molibdenum steel conrods

Lube oil cooled light alloy pistons with high performance piston rings Fresh water cooled turbo blower

Double flow raw water cooled intake air cooler

Cooling system

Fresh / raw water heat exchanger with integrated thermostatic valves Electrical system

and expansion tank Voltage: 24Vcc

Cast iron centrifugal fresh water pump, mechanically driven Electrical starter on flywheel crown

Bronze self-priming raw water pump, mechanically driven 175A battery charger

OPTIONAL EQUIPMENTS (extract) *

Cooling system adapted for box / keel cooling Free end PTO

Connection for emergency raw water and lube oil circuits Resilient mounts under engine

Bilge pump Equipment and factory trial according to Major Classification Societies rules

Air starter with storage bottles and compressor * contact us for further information regarding our options.

8 M26.2

DIMENSIONS

931

533

PERFORMANCES 1468 1884

P1 rating - 442 kW / 600 hp @ 1800 rpm P1 rating - 491 kW / 668 hp @ 1800 rpm

P2 rating - 539 kW / 733 hp @ 1900 rpm P2 rating - 588 kW / 800 hp @ 1950 rpm

Moteurs Baudouin reserve the right to modify these specifications, without notice. Document not contractual.

Speed: rpm

Société Internationale des Moteurs Baudouin

Technoparc du Brégadan - CS 50001 - 13711 Cassis Cedex - France - tél. +33 488 688 500 - fax +33 488 588 501 - www.baudouin.com

Potrebbero piacerti anche

- Scania d12Documento2 pagineScania d12Shreyas Mg67% (3)

- Mtu MT 881Documento2 pagineMtu MT 881AndrewScotson100% (1)

- KM385BT ㌫ࡇḤ⋩ᵪ䈤᰾Җ: Diesel Engine Model Km385Bt Series Operation ManualDocumento24 pagineKM385BT ㌫ࡇḤ⋩ᵪ䈤᰾Җ: Diesel Engine Model Km385Bt Series Operation ManualFlavio Edison QNessuna valutazione finora

- 12M26 2-GBDocumento2 pagine12M26 2-GBirdawan0% (1)

- The New Marine Power Reference: Customer Benefi TsDocumento2 pagineThe New Marine Power Reference: Customer Benefi TsCarlos PariNessuna valutazione finora

- 4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"Documento2 pagine4 Stroke Diesel Engine, Direct Injection: 126 X 155 MM 6 in Line 11.6 Litres 17/1 CCW 600 RPM 1200 KG Sae 1 SAE 14"NarcisaNessuna valutazione finora

- 12 M26.3 With SCR: IMO III / EPA IV - CompliantDocumento2 pagine12 M26.3 With SCR: IMO III / EPA IV - CompliantAlbertoNessuna valutazione finora

- Powerkit Engine 12M26 Series: General SpecificationsDocumento3 paginePowerkit Engine 12M26 Series: General SpecificationsstorkbNessuna valutazione finora

- N67 TM3A: Engine For Power Generation ApplicationsDocumento4 pagineN67 TM3A: Engine For Power Generation ApplicationsВладислав ЛеоновNessuna valutazione finora

- 4 Stroke Diesel Engine, Direct Injection, Common-RailDocumento2 pagine4 Stroke Diesel Engine, Direct Injection, Common-RailSANTOSA MARINENessuna valutazione finora

- C87te1d P4a04c011eDocumento4 pagineC87te1d P4a04c011eSharen Robert GardnerNessuna valutazione finora

- 6M16 BaudouinDocumento3 pagine6M16 BaudouinsustrasNessuna valutazione finora

- APD2750MDocumento4 pagineAPD2750MParinyaNessuna valutazione finora

- 9976 Weichai WP7 Spec Sheet RevmDocumento3 pagine9976 Weichai WP7 Spec Sheet Revmmurjani macindoNessuna valutazione finora

- Diesel Engines Series 4000 R04: For Push-Pull Trains and Locomotives Eu Stage IiibDocumento2 pagineDiesel Engines Series 4000 R04: For Push-Pull Trains and Locomotives Eu Stage IiibJavier Quintero100% (1)

- V10 1100 CRMDocumento4 pagineV10 1100 CRMditer najarNessuna valutazione finora

- WD10Documento3 pagineWD10service alatberatNessuna valutazione finora

- Marine Engine-8170 Series: General SpecificationsDocumento2 pagineMarine Engine-8170 Series: General SpecificationsMd. Arefin ShawonNessuna valutazione finora

- 6170 SpesDocumento3 pagine6170 SpesAmin GuiNessuna valutazione finora

- WP6Documento3 pagineWP6arf89Nessuna valutazione finora

- Generating Rates: Model:HMW-1020 T6Documento10 pagineGenerating Rates: Model:HMW-1020 T6pedrodany9098Nessuna valutazione finora

- Datasheet HGM1875: Googol Diesel Power Generator 1350kW-1688kVA 1500kW-1875kVA 50HzDocumento4 pagineDatasheet HGM1875: Googol Diesel Power Generator 1350kW-1688kVA 1500kW-1875kVA 50HzAmpolNessuna valutazione finora

- Datasheet HGM1875: Googol Diesel Power Generator 1350kW-1688kVA 1500kW-1875kVA 50HzDocumento4 pagineDatasheet HGM1875: Googol Diesel Power Generator 1350kW-1688kVA 1500kW-1875kVA 50HzAmpolNessuna valutazione finora

- Atp 650 Kva PDFDocumento3 pagineAtp 650 Kva PDFsaif loayNessuna valutazione finora

- Weichai Marine Engine - WD12 SeriesDocumento3 pagineWeichai Marine Engine - WD12 SeriesAT Solution TechnologyNessuna valutazione finora

- Motordatenblatt MTU 12V4000G63 PDFDocumento2 pagineMotordatenblatt MTU 12V4000G63 PDFTaz UddinNessuna valutazione finora

- C87 Te1dDocumento2 pagineC87 Te1dEvandro LinoNessuna valutazione finora

- Honny Power Generator Datasheet HGM880Documento4 pagineHonny Power Generator Datasheet HGM880Bayu Suryo WirantoNessuna valutazione finora

- cw6250 0Documento2 paginecw6250 0tayfun atabeyNessuna valutazione finora

- DataSheet LOMBARDINI (CHD SERIES)Documento4 pagineDataSheet LOMBARDINI (CHD SERIES)CristianTeodorescuNessuna valutazione finora

- WP4CD 1Documento2 pagineWP4CD 1Manuel Del aguilaNessuna valutazione finora

- KORD3!20!074 Technical Information For V1505Documento27 pagineKORD3!20!074 Technical Information For V1505carlos miras mondejarNessuna valutazione finora

- P4a06n003e1010 N45 Sm1aDocumento2 pagineP4a06n003e1010 N45 Sm1aВладислав ЛеоновNessuna valutazione finora

- P4a06n003e1010 N45 Sm1aDocumento2 pagineP4a06n003e1010 N45 Sm1aВладислав ЛеоновNessuna valutazione finora

- P4a06n003e1010 N45 Sm1aDocumento2 pagineP4a06n003e1010 N45 Sm1aВладислав ЛеоновNessuna valutazione finora

- G.E. 250 KW - WPG275-86Documento3 pagineG.E. 250 KW - WPG275-86Ali Yamilé Camizan CuniasNessuna valutazione finora

- TM1540TDocumento4 pagineTM1540Tdargom salamanNessuna valutazione finora

- Apd1255m 6Documento4 pagineApd1255m 6Magaly PeraltaNessuna valutazione finora

- Heavy FV 51 MWB - 13sp Manual 12sp AMT Steel SuspensionDocumento4 pagineHeavy FV 51 MWB - 13sp Manual 12sp AMT Steel Suspensionajay dattNessuna valutazione finora

- Volvo Single Drum Compactors 11.1 T 74 KW: Volvo Construction Equipment. Building TomorrowDocumento2 pagineVolvo Single Drum Compactors 11.1 T 74 KW: Volvo Construction Equipment. Building TomorrowMannanNessuna valutazione finora

- Powerkit Engine 6M11 Series: General SpecificationsDocumento3 paginePowerkit Engine 6M11 Series: General SpecificationsstorkbNessuna valutazione finora

- 2206C-E13TAG3 EngineDocumento5 pagine2206C-E13TAG3 EngineAnamta KhanNessuna valutazione finora

- Apd2500m 6Documento30 pagineApd2500m 6Magaly PeraltaNessuna valutazione finora

- Marine Propulsion Engine (Imo Ii)Documento2 pagineMarine Propulsion Engine (Imo Ii)avinash_1229Nessuna valutazione finora

- Motordatenblatt MTU 20V4000G63L 1Documento2 pagineMotordatenblatt MTU 20V4000G63L 1JeevaganNessuna valutazione finora

- Generators: Model: PDG20SS 20 KVA / Single PhaseDocumento2 pagineGenerators: Model: PDG20SS 20 KVA / Single PhaseFritz NatividadNessuna valutazione finora

- Engine Type DI12 56 A (381) : Standard EquipmentDocumento2 pagineEngine Type DI12 56 A (381) : Standard EquipmentignacioNessuna valutazione finora

- Technical Information: For V1505Documento27 pagineTechnical Information: For V1505hendra100% (1)

- The Engine For Construction Equipment.: 92 - 235 KW at 2000 - 2300 RPMDocumento6 pagineThe Engine For Construction Equipment.: 92 - 235 KW at 2000 - 2300 RPMFranz JW Monteza100% (1)

- NEF67 TE5 - 202kW - 217kWDocumento3 pagineNEF67 TE5 - 202kW - 217kWMatheus TonetaNessuna valutazione finora

- Spe 15 LD 350Documento4 pagineSpe 15 LD 350António AbrunhosaNessuna valutazione finora

- Marine Engine-WP12 Series: General SpecificationsDocumento2 pagineMarine Engine-WP12 Series: General SpecificationsDolfin YohanesNessuna valutazione finora

- WP4Documento2 pagineWP4arf89Nessuna valutazione finora

- DIESEL ENGINES 12V/16V 2000 M72: MarineDocumento2 pagineDIESEL ENGINES 12V/16V 2000 M72: Marinenaufragato100% (1)

- Cummins 50kVADocumento2 pagineCummins 50kVAabdiNessuna valutazione finora

- MES LTD Iveco FPT n67 450Documento4 pagineMES LTD Iveco FPT n67 450tariqNessuna valutazione finora

- Surat Izin Product Presentasi Rs Rs Wonosobo 1 PDFDocumento3 pagineSurat Izin Product Presentasi Rs Rs Wonosobo 1 PDFIrda OnesNessuna valutazione finora

- Continuous Duty: WAF 464L - 572LDocumento1 paginaContinuous Duty: WAF 464L - 572LIrda OnesNessuna valutazione finora

- Spek Tek Dan Scope of SupplyDocumento7 pagineSpek Tek Dan Scope of SupplyIrda OnesNessuna valutazione finora

- Telescopic/knuckleboom Cranes: Shipboard Handling ExcellenceDocumento4 pagineTelescopic/knuckleboom Cranes: Shipboard Handling ExcellenceIrda OnesNessuna valutazione finora

- Gantt Project Planner1Documento1 paginaGantt Project Planner1Irda OnesNessuna valutazione finora

- Never Underestimate Your Fresh Water Needs: Coral Sea Key FeaturesDocumento7 pagineNever Underestimate Your Fresh Water Needs: Coral Sea Key FeaturesIrda OnesNessuna valutazione finora

- Certificate of Achievement: John DoeDocumento2 pagineCertificate of Achievement: John DoeIrda OnesNessuna valutazione finora

- SICE-ICASE International Joint Conference 2006Documento6 pagineSICE-ICASE International Joint Conference 2006ShamsMohdNessuna valutazione finora

- Ict502 - Final Report Group7Documento26 pagineIct502 - Final Report Group7Ahmad SyamiNessuna valutazione finora

- OS Lec 11 Peterson SoutionDocumento16 pagineOS Lec 11 Peterson Soutionvibivo3532Nessuna valutazione finora

- Computer Systems Servicing: Grade 11 Second Semester (Third Quarter) Week 3Documento13 pagineComputer Systems Servicing: Grade 11 Second Semester (Third Quarter) Week 3MichelleNessuna valutazione finora

- Tier Architecture 2 and 3 TiersDocumento10 pagineTier Architecture 2 and 3 TierssrinivasareddyNessuna valutazione finora

- Analisis Pengendalian Persediaan Bahan Baku Pada PT NT Piston Ring Indonesia PDFDocumento16 pagineAnalisis Pengendalian Persediaan Bahan Baku Pada PT NT Piston Ring Indonesia PDFRizkyHaryogiNessuna valutazione finora

- Jeppesen Cycle 1822 VALID TILL 23 Nov 2018-1Documento969 pagineJeppesen Cycle 1822 VALID TILL 23 Nov 2018-1Farid SuhaimiNessuna valutazione finora

- PSR-1613 - Claro Brazil - ClickStream Analysis - V1Documento95 paginePSR-1613 - Claro Brazil - ClickStream Analysis - V1glm.mendesrNessuna valutazione finora

- Chapter 7 Software EngineeringDocumento38 pagineChapter 7 Software EngineeringMaya DanaNessuna valutazione finora

- Toyota OBD Trouble CodesDocumento6 pagineToyota OBD Trouble Codespalandia50% (4)

- Sistem Informasi Manajemen Berbasis Key Performance: Indicator (KPI) Dalam Mengukur Kinerja GuruDocumento11 pagineSistem Informasi Manajemen Berbasis Key Performance: Indicator (KPI) Dalam Mengukur Kinerja GuruTimothy Merfry TiwowNessuna valutazione finora

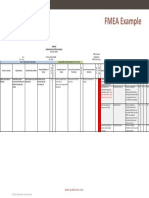

- FMEA ExampleDocumento1 paginaFMEA Exampleanass sbniNessuna valutazione finora

- Failure Mode Effect AnalysisDocumento25 pagineFailure Mode Effect AnalysisStuart HawkshawNessuna valutazione finora

- Sowtware TestingDocumento9 pagineSowtware TestingGagan SapraNessuna valutazione finora

- SodaPDF Merged Merging ResultDocumento197 pagineSodaPDF Merged Merging ResultStephen OHaraNessuna valutazione finora

- C15 Fuel System OperationDocumento7 pagineC15 Fuel System OperationTaka100% (1)

- MIS Reference ReportDocumento35 pagineMIS Reference ReportJuda Rose SanchezNessuna valutazione finora

- PrinceKumarNirala (2 1) .DocxjavaDocumento3 paginePrinceKumarNirala (2 1) .DocxjavaUsha MNessuna valutazione finora

- Project SOW - Bank Website DevelopmentDocumento2 pagineProject SOW - Bank Website DevelopmentAhmad ShubitaNessuna valutazione finora

- Analyse Check Policy SelinuxDocumento14 pagineAnalyse Check Policy Selinuxal teNessuna valutazione finora

- NETACTDocumento12 pagineNETACTCHIRAG NAGPAL100% (1)

- Sequential Reliability TestsDocumento2 pagineSequential Reliability Teststanpreet_makkadNessuna valutazione finora

- S4H - 552 How To Approach Fit-to-Standard Analysis and Design - CloudDocumento46 pagineS4H - 552 How To Approach Fit-to-Standard Analysis and Design - CloudYasai MoyashiNessuna valutazione finora

- 12-How To Write A Methodology SectionDocumento20 pagine12-How To Write A Methodology SectionShelaniejean LimNessuna valutazione finora

- 1a Mecatronique Slides 1Documento107 pagine1a Mecatronique Slides 1pehe SmartTechNessuna valutazione finora

- Mbed Course Notes - Modular Design PDFDocumento32 pagineMbed Course Notes - Modular Design PDFPancho BerríosNessuna valutazione finora

- Comparison of Voting Arrangements in SISDocumento5 pagineComparison of Voting Arrangements in SISChelo FishaoNessuna valutazione finora

- 1Nz-Fe Engine Mechanical: Service DataDocumento3 pagine1Nz-Fe Engine Mechanical: Service Dataalbert phiriNessuna valutazione finora

- SailPoint IdentityNow Architecture Multi Tenancy Microservices MatterDocumento4 pagineSailPoint IdentityNow Architecture Multi Tenancy Microservices MatterDavid YoungNessuna valutazione finora

- The Ultimate C - C - MDG - 1909 - SAP Certified Application Associate - Master Data GovernanceDocumento2 pagineThe Ultimate C - C - MDG - 1909 - SAP Certified Application Associate - Master Data GovernanceTeresaNessuna valutazione finora