Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Brochure Reachstacker HY33-5051 US

Caricato da

giri_placidCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Brochure Reachstacker HY33-5051 US

Caricato da

giri_placidCopyright:

Formati disponibili

Reachstackers

Electronic Controls Division

Electronic controls and solutions

for reachstackers

Parker – an experienced partner at your service

Market Knowledge and Solutions Value in Use Certified Electronics

Parker’s commitment to the reachstacker Parker has dedicated teams of specialists Parker offers comprehensive control

industry is clearly demonstrated by the working globally to design systems, systems specifically designed for the mobile

products, the solutions, and the customer sub-systems and solutions to meet the industry, fulfilling the latest standards

service provided. Parker has successfully most demanding requirements. Among for safety and environmental protection.

integrated products that address the needs the many immediate value adding benefits User-friendly application software tools

of reachstackers for over 30 years. Innovative realized are; increased productivity, reduced are used to build up the complete system.

products like control systems monitoring production time, reduced fuel consumption The modules communicate via CAN bus,

COG and LMI (Load Moment Indicators) and emissions, and reduced down time. allowing different gateways to other systems.

are just a few examples adding value to the All of Parker’s extensive knowledge and

customers. experience in motion control on mobile units

is built in, providing optimum control and

flexibility as well as on-board and remote

diagnostics capabilities.

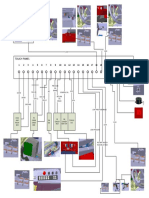

VMM3120 control module with CAN FP2000 and FP3000 ferrous proximity

provides high switches detect spreader bar position

I/O count for to assist in rapid change over from

spreaderbar 20 to 40 foot containers.

functionality.

The integrated

CAN ports allow for reduced wiring down RS70 dual output rotary

the boom, for lower installation costs, and position sensor, with redundant

reduced wire harness costs. signals for added safety,

measures boom angle for load

moment indication (LMI)

XA2 expansion module

DPE70 7" full color display with CAN offers

with CAN provides a clear current regulated

interface for the operator to outputs for precise

see the status of the boom, electro-hydraulic

LMI system, engine and control and CAN

hydraulics interface for reduced

operation, as wiring costs.

well as error

messages.

RM50 tamper

resistant tilt switch

indicates hood

or access panel

position to lock

out functions for

The MC3 controller with safer machine

CAN is designed for mobile maintenance.

hydraulic machinery with

analog and digital inputs

and outputs in accordance

with IEC 61508,

and can be used to LC5 CAN based

implement safety Compact linear lever LST offers smooth joysticks for smooth

functions auxiliary control function with a small and efficient

of up to SIL2. footprint on the operator console. operator control.

1

Overload Loadlimit

3

When rotating the container or lifting the boom with the container in a rotated position;

there is some risk of damage to the boom or container. Adding a rotary sensor in the

spreader slew ring will avoid any interference.

Control System, Summary Horsepower Control Load Moment Indication/Weighing

• Remote diagnostics • Engine RPM Sensors

• Simple fault finding • Hydraulic pressure

1 Length sensor

• Logging functions

• Variable geometry configurations 2 Angle sensor

• Smart lifting 3 Pressure sensor

• Quieter operation Travel

• Cylinder end damping Power

Flow

• Reduced power consumption Economy

• Limp home functions

• Load dependent ramps

• Simplified controls

• Modular system architecture Pressure

Engineering Your Success

With intelligent and innovative solutions.

Whether for off-highway equipment or over the road truck and bus applications, Parker’s

Electronic Controls Division offers full system solutions and products to fit your needs.

With worldwide engineering and manufacturing capabilities, the Electronic Controls

Division has the experience, skills, and capabilities to provide solutions for virtually any

mobile electronic application.

If you would like to discuss your mobile electronics applications,

and how Parker’s Electronic Controls Division can offer you a

competitive advantage, please feel free to contact us.

© 2014 Parker Hannifin Corporation. All rights reserved. HY33-5051/US 05/2014

Parker Hannifin Corporation

Electronic Controls Division

850 Arthur Avenue

Elk Grove Village, IL 60007 USA

phone 800 221 9257

www.parker.com/ecd Your Local Authorized Parker Distributor

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- IQAN MD4 Instructionbook HY33 8408 IB UKDocumento41 pagineIQAN MD4 Instructionbook HY33 8408 IB UKgiri_placidNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- PDF The Ultimate Training Split Guide by Brian Decosta Compress 4Documento23 paginePDF The Ultimate Training Split Guide by Brian Decosta Compress 4Burcu Senol100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Electrical Interface Specification EMS2.3 - 47706487 - ENDocumento62 pagineElectrical Interface Specification EMS2.3 - 47706487 - ENvijaykumarnNessuna valutazione finora

- Electrical Interface Specification EMS2.3 - 47706487 - ENDocumento62 pagineElectrical Interface Specification EMS2.3 - 47706487 - ENvijaykumarnNessuna valutazione finora

- DsaDocumento112 pagineDsadgbooklover0766571100% (3)

- Documents Property VerificationDocumento2 pagineDocuments Property Verificationgiri_placidNessuna valutazione finora

- Inst Manual Engine General 47706356Documento164 pagineInst Manual Engine General 47706356giri_placid100% (1)

- Inst Manual Engine General 47706356Documento164 pagineInst Manual Engine General 47706356giri_placid100% (1)

- She DiedDocumento23 pagineShe DiedCandice ShieldsNessuna valutazione finora

- Wedding DVD ScriptsDocumento23 pagineWedding DVD ScriptsМарина Пилюта50% (2)

- Fundamentals of SONET/SDH: Historical BackgroundDocumento58 pagineFundamentals of SONET/SDH: Historical Backgroundgiri_placidNessuna valutazione finora

- Oil Brake System DiagramDocumento1 paginaOil Brake System Diagramgiri_placidNessuna valutazione finora

- Fault Codes Daewoo CieloDocumento2 pagineFault Codes Daewoo Cielogiri_placidNessuna valutazione finora

- Can 20Documento72 pagineCan 20hemanthbbcNessuna valutazione finora

- Daewoo Cielo Section 1 PDFDocumento603 pagineDaewoo Cielo Section 1 PDFgiri_placid100% (4)

- LoadStar Annexure1 Sl17 Schedule3Documento1 paginaLoadStar Annexure1 Sl17 Schedule3giri_placidNessuna valutazione finora

- Tender Document CONCORDocumento109 pagineTender Document CONCORgiri_placid100% (1)

- Sloa 101 BDocumento17 pagineSloa 101 Brute silvaNessuna valutazione finora

- Loadstar Equipment PVT LTD Logo Hi ResDocumento3 pagineLoadstar Equipment PVT LTD Logo Hi Resgiri_placidNessuna valutazione finora

- Mobile Electronic Solutions: Controllers, Displays, Instrument Clusters, Operator Input Devices & Sensor ProductsDocumento4 pagineMobile Electronic Solutions: Controllers, Displays, Instrument Clusters, Operator Input Devices & Sensor Productsgiri_placidNessuna valutazione finora

- Information Retrieval Data Structures & Algorithms - William B. FrakesDocumento630 pagineInformation Retrieval Data Structures & Algorithms - William B. FrakesHugoEnriqueNessuna valutazione finora

- In Voice ConverterDocumento1 paginaIn Voice Convertergiri_placidNessuna valutazione finora

- Cortex™ M3Documento384 pagineCortex™ M313579krmyNessuna valutazione finora

- Tax Invoice SummaryDocumento1 paginaTax Invoice Summarygiri_placidNessuna valutazione finora

- In Voice MouseDocumento1 paginaIn Voice Mousegiri_placidNessuna valutazione finora

- Forests Near Bangalore - Bangalore ForestsDocumento5 pagineForests Near Bangalore - Bangalore Forestsgiri_placidNessuna valutazione finora

- VHDL QUICK REFERENCE CARDDocumento2 pagineVHDL QUICK REFERENCE CARDgiri_placidNessuna valutazione finora

- CINT252ProjectsDocumento48 pagineCINT252ProjectsWilliam Taylor100% (1)

- 7 ElevenDocumento9 pagine7 ElevenJoshua TingabngabNessuna valutazione finora

- Lenovo Laptop Technical SpecificationDocumento2 pagineLenovo Laptop Technical SpecificationJay SathvaraNessuna valutazione finora

- Alice in W ScriptDocumento4 pagineAlice in W ScriptMedalle RoyNessuna valutazione finora

- Computer Networking Fundamentals Chapter 3 (C)Documento30 pagineComputer Networking Fundamentals Chapter 3 (C)wfidayuNessuna valutazione finora

- claude monet The Lunch - Google претрагаDocumento1 paginaclaude monet The Lunch - Google претрагаClaviusNessuna valutazione finora

- Installation Instructions: Parts ListDocumento4 pagineInstallation Instructions: Parts ListMichael SmithNessuna valutazione finora

- Montreal BagelsDocumento10 pagineMontreal Bagelshana cadNessuna valutazione finora

- R HDB 40 2002 Oas PDF eDocumento65 pagineR HDB 40 2002 Oas PDF eBao Quoc MaiNessuna valutazione finora

- Learnovate Task No. - 05 - Nikita DakiDocumento14 pagineLearnovate Task No. - 05 - Nikita DakiNikita Daki100% (1)

- A Delightful Trip To Cheese WorldDocumento21 pagineA Delightful Trip To Cheese WorldAnkur Sharma100% (1)

- English Year 1 WORD FOCUSDocumento2 pagineEnglish Year 1 WORD FOCUSsharonNessuna valutazione finora

- Important message about deactivated Amazon seller accountDocumento1 paginaImportant message about deactivated Amazon seller accountMuhmmad UmairNessuna valutazione finora

- Application For SLMC Id CardDocumento5 pagineApplication For SLMC Id Cardanapayan.manoranjanNessuna valutazione finora

- Rapunzel ScriptDocumento4 pagineRapunzel ScriptDyosa siobhieNessuna valutazione finora

- Ejercicios Pasado SimpleDocumento2 pagineEjercicios Pasado Simplenuevavida35Nessuna valutazione finora

- Operating Limits and Controls for Hydroplus BoostersDocumento28 pagineOperating Limits and Controls for Hydroplus BoostersPepe PintoNessuna valutazione finora

- Parallel Structure StrategiesDocumento11 pagineParallel Structure StrategieshashemdoaaNessuna valutazione finora

- Datasheet of THC-D320-VF V1.0.1 20181008 PDFDocumento3 pagineDatasheet of THC-D320-VF V1.0.1 20181008 PDFIT.COMPany Intelligent SolutionsNessuna valutazione finora

- Tiếng Anh NgheDocumento12 pagineTiếng Anh NgheNhật DuyNessuna valutazione finora

- 1-Gma Annual Report - 2020 1621409182Documento86 pagine1-Gma Annual Report - 2020 1621409182RonEljun Medalla-EnopiaNessuna valutazione finora

- 0472 História Da ModaDocumento26 pagine0472 História Da ModaMaria VieiraNessuna valutazione finora

- (827956) Bjmp5023 A202 Chapter 3 Value of Loyal Customer ExerciseDocumento6 pagine(827956) Bjmp5023 A202 Chapter 3 Value of Loyal Customer ExerciseFatin AtanNessuna valutazione finora

- Production Weekly - Issue 1126 - Thursday, January 10, 2019 / 91 Listings - 19 PagesDocumento1 paginaProduction Weekly - Issue 1126 - Thursday, January 10, 2019 / 91 Listings - 19 PagesProduction Weekly0% (3)

- Setup Guide for Playpen and Crib "AriaDocumento8 pagineSetup Guide for Playpen and Crib "Ariamanin1215Nessuna valutazione finora

- Breakfast (Morning) Lunch or Dinner (Noon To Evening) Drinks DessertsDocumento4 pagineBreakfast (Morning) Lunch or Dinner (Noon To Evening) Drinks DessertsJa CkiNessuna valutazione finora

- Wandering Monster ActivitiesDocumento1 paginaWandering Monster ActivitiesWilliam Henry CaddellNessuna valutazione finora

- The Day The Bulldozers CameDocumento3 pagineThe Day The Bulldozers CamewiesukhihotuNessuna valutazione finora