Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Hydraulics

Caricato da

Nejbel M Ab0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

51 visualizzazioni15 pagineIT IS VERY NICE REFERENCE CONCERNING HYDAULICS.

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoIT IS VERY NICE REFERENCE CONCERNING HYDAULICS.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

51 visualizzazioni15 pagineHydraulics

Caricato da

Nejbel M AbIT IS VERY NICE REFERENCE CONCERNING HYDAULICS.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 15

PRESSURE MEASUREMENT

Pressure and Pressure head of a liquid –

Pascal’s Law – Absolute and Gauge Pressure

– Measurement of Pressure, Manometers,

Simple Manometers, Differential

Manometers – Advantages and Limitation

of Manometers – Mechanical gauges –

Bourdan tube gauge

Prepared by: Mr. R. Sathyanathan, Asst. Prof., Dept. of Civil Engg.

PASCAL’S LAW

Intensity of pressure at any point in a liquid at rest, is the same in all directions

Pascal, states that the pressure on a fluid is equal in all directions and

in all parts of the container. As liquid flows into the large container at

the bottom of this illustration, pressure pushes the liquid equally up

into the tubes above the container. The liquid rises to the same level

in all of the tubes, regardless of the shape or angle of the tube.

APPLICATIONS OF PASCAL’S LAW

Pascal’s Law may be applied when the velocity of flow is constant

When the man jumps on the small piston, he induces a pressure in the system. This

pressure also works on the large piston: because of the large area of this piston, the

force induced by the pressure is capable to lift the car.

By stepping the brake pedal down 3-cm applying 10-kg force, a

whopping 1,000-kg force or more acting on the brake disc at the

wheels!

F1/A1 =F2/A2

The pressure input at one end is

the same as the pressure output at

the other.

You apply a small force over a small

area, and the output force at the end

with the larger area will be greater.

The work done on one end is the

same as the work output at the other.

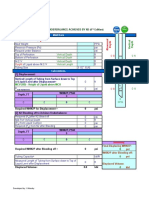

REAL TIME PROBLEM

Ram

Plunger

Problem: The diameter of ram and plunger of an hydraulic press are 200 mm

and 30mm respectively. Find the weight lifted by the hydraulic press when

the force applied at the plunger is 400 N.

Answers: (a) Intensity of pressure due to plunger = 5.66 E+5 N/m2

(b) Weight lifted by the hydraulic press = 17.77 kN.

MEASUREMENT OF PRESSURE

Manometers Mechanical Gauges

Simple Differential

Manometers Manometers

Piezometer U-tube differential manometer

U-tube Manometer Inverted U-tube differential

manometer

Single Column Manometer

Manometers are the devices used for

measuring the pressure at a point in a

fluid by balancing the column of fluid

by the same or another column of

liquid. Suitable for measuring low

pressure and low differential pressure

Mechanical gauges are the devices in

which the pressure is measured by

balancing the fluid column by spring

(elastic element) or dead weight.

Used for measuring high pressures

PIEZOMETER

Simplest form of manometer

Used for measuring moderate

pressures of liquids

Consists of a glass tube inserted in the

wall of a vessel or a pipe

The pressure is indicated by the

height of the liquid in the tube above a

given point

Pressure intensity at A : pa = w h

Not suitable for measuring negative

pressure

Cannot be employed to measure high

pressures

Cannot be used for measuring gas

pressures

U – tube manometer

Consists of a glass tube bent in U-

shape, one end is connected to a

point at which pressure is to be

measured and other end remains

open to the atmosphere

The tube contains a liquid of

specific gravity greater than that of a

the fluid of which pressure is to be

measured

Manometric liquids: Mercury,

Carbon di sulphide, carbon tetra

chloride, alcohol, water etc.

Differential Manometer

Used to measure the difference in pressures between two points in a pipe, or in

two different pipes

Upright U - tube Inverted U - tube

Used for measuring high pressure

Used for measuring low

differences

pressure differences

Density of manometric fluid is more

Density of manometric fluid is

than the metered fluid

less than the metered fluid

BOURDAN TUBE PRESSURE GAUGE

Consists of an elastic element which

deflects under the action of applied

pressure

When the gauge is connected to the

gauge point, fluid under pressure enters

the tube

Elliptical c/s of the tube tends to

become circular and this movement is

mechanically magnified

Operates a pointer moving against a

graduated circumferential scale

Used for measuring high pressures,

where high precision is not required

ADVANTAGES OF MANOMETERS

Easy to fabricate and relatively

inexpensive

Good accuracy

Require little maintenance

Not affected by vibrations

Suitable for measuring low pressure and

low differential pressures

LIMITATIONS OF MANOMETERS

Large in size

Being fragile, get broken easily

Readings are affected by changes in

temperatures, altitude and gravity

Not suitable for measuring high pressures

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Cold Form Inspector ChecklistDocumento16 pagineCold Form Inspector ChecklistbooboosdadNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Doha Port Re-Development Project Combined Mina District and Sea Water Diving Pool WorksDocumento30 pagineDoha Port Re-Development Project Combined Mina District and Sea Water Diving Pool WorksFranklyn GenoveNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Productivity RateDocumento3 pagineProductivity RateJalaludeen Mohammed Ayub100% (4)

- Review of Fluid MechanicsDocumento51 pagineReview of Fluid MechanicsMikko Arvin ChuaNessuna valutazione finora

- Hubei Chengli Special Automobile Co., LTDDocumento5 pagineHubei Chengli Special Automobile Co., LTDNejbel M AbNessuna valutazione finora

- 1 Strongs 23Documento141 pagine1 Strongs 23Nejbel M AbNessuna valutazione finora

- CRSI Tech - Note - ETN B 1 15 PDFDocumento6 pagineCRSI Tech - Note - ETN B 1 15 PDFrickhuezoNessuna valutazione finora

- Ground Improvement Using Stone Column: Rohit Kumar PGRPE 2014Documento20 pagineGround Improvement Using Stone Column: Rohit Kumar PGRPE 2014pranja9999Nessuna valutazione finora

- Hilti CatalogueDocumento40 pagineHilti CatalogueMatt Tremoglie100% (1)

- Slab For Lift ProjectDocumento2 pagineSlab For Lift ProjectAnonymous ptLRLiNNNessuna valutazione finora

- Ethiopian Roads Authoritycalculations, Drawings and Specifications PDFDocumento4 pagineEthiopian Roads Authoritycalculations, Drawings and Specifications PDFNejbel M Ab100% (1)

- تقرير تدريب صيفي لواء الدين مظفرDocumento23 pagineتقرير تدريب صيفي لواء الدين مظفرlalaNessuna valutazione finora

- Foundation Design Philosophy For Rotating EquipmentDocumento8 pagineFoundation Design Philosophy For Rotating EquipmentDan McCarthyNessuna valutazione finora

- Concrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)Documento6 pagineConcrete Mix Design - M60 Grade of Concrete (OPC 53 Grade)jishad_nalakath50% (2)

- ECCECCS PublicationsDocumento2 pagineECCECCS PublicationsDaniel JamesNessuna valutazione finora

- Aci 307 - 98Documento17 pagineAci 307 - 98andri.kusbiantoro9761Nessuna valutazione finora

- Methods of DCP PDFDocumento10 pagineMethods of DCP PDFNejbel M AbNessuna valutazione finora

- Biosystems Research Review 16 2011Documento205 pagineBiosystems Research Review 16 2011Nejbel M AbNessuna valutazione finora

- 3 - OECD Ethiopian CRGES PPT FinalDocumento16 pagine3 - OECD Ethiopian CRGES PPT FinalNejbel M Ab100% (1)

- Michael A. Hamilton, Paul W. Rode, Mark E. Merchant, Joseph SneddonDocumento4 pagineMichael A. Hamilton, Paul W. Rode, Mark E. Merchant, Joseph SneddonNejbel M AbNessuna valutazione finora

- 2014year Truck Model Proforma InvoiceDocumento2 pagine2014year Truck Model Proforma InvoiceNejbel M AbNessuna valutazione finora

- GTP English Version Shortned2Documento84 pagineGTP English Version Shortned2Peter BofinNessuna valutazione finora

- L Esson XivDocumento7 pagineL Esson XivNejbel M AbNessuna valutazione finora

- PE Civil Structural Apr 2008Documento6 paginePE Civil Structural Apr 2008Nejbel M AbNessuna valutazione finora

- Coconut Shell As Partial Replacement ofDocumento5 pagineCoconut Shell As Partial Replacement ofSHAIK SADHIKA APSANANessuna valutazione finora

- Profil Turap LengkapDocumento11 pagineProfil Turap LengkapAlwanNessuna valutazione finora

- Architectural Color Line Weight (MM) DescriptionDocumento10 pagineArchitectural Color Line Weight (MM) DescriptionBagusBudiNessuna valutazione finora

- Heat Load Calculation (Rev-A)Documento86 pagineHeat Load Calculation (Rev-A)Project enghvacNessuna valutazione finora

- Ce2255 Highway Engineering Anna University Question BankDocumento8 pagineCe2255 Highway Engineering Anna University Question Bankviki1981Nessuna valutazione finora

- 1.2 PD - Clivet - AHU - Air Handling Unit - 20201015 - V2Documento27 pagine1.2 PD - Clivet - AHU - Air Handling Unit - 20201015 - V2Arzan AttarNessuna valutazione finora

- American Wide Flange Steel Beams W Beam LetterDocumento7 pagineAmerican Wide Flange Steel Beams W Beam Letterkhajarasool786Nessuna valutazione finora

- Riau GFPP (275Mw) Ipp Project: Pt. Medco Ratch Power Riau Lotte Engineering & ConstructionDocumento1 paginaRiau GFPP (275Mw) Ipp Project: Pt. Medco Ratch Power Riau Lotte Engineering & ConstructionFebri NuansaNessuna valutazione finora

- Need To Know: Building With SipsDocumento20 pagineNeed To Know: Building With SipsFrancisco Barahona UrzúaNessuna valutazione finora

- Lec 1-Week 1 - (Wastewater Collection System)Documento32 pagineLec 1-Week 1 - (Wastewater Collection System)jahanzaibchNessuna valutazione finora

- Peikko GroundDocumento16 paginePeikko GroundQWE2342ER3F5C54V5V45Nessuna valutazione finora

- Soil ReportDocumento59 pagineSoil ReportHarshitha N SNessuna valutazione finora

- Tutorial 1 - Properties and Section ClassificationDocumento20 pagineTutorial 1 - Properties and Section ClassificationCyrus Hong100% (1)

- NSCP Timber Beam DesignDocumento27 pagineNSCP Timber Beam DesignDiztrict GarageNessuna valutazione finora

- Anchoring PDFDocumento2 pagineAnchoring PDFengineer63Nessuna valutazione finora

- N2 Underbalance Calculations 4TH EditionDocumento8 pagineN2 Underbalance Calculations 4TH Editionislam atifNessuna valutazione finora

- 31 10 ESD@ Dispatch Plan PRDDocumento248 pagine31 10 ESD@ Dispatch Plan PRDSubhash ReddyNessuna valutazione finora