Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

WP Flwins 1

Caricato da

Jamesh BabuTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

WP Flwins 1

Caricato da

Jamesh BabuCopyright:

Formati disponibili

The Essential Guide to Vertical Piping

Preferred Flow up

Horizontal Piping -

(And sloping)

Side View

AdviseIT

AnalyzeIT

FieldIT

Flowmeter Installation

MeasureIT

1 Differential Pressure

Orifice Venturi/Flow Nozzle Flow Tube Elbow Pitot/Averaging Pitot VA Meter

OperateIT Minimum pipe length Concentric, eccentric, conical, quadrant Before meter, 6; After meter, 2. Note 15. Before meter, 4; After meter, none. Usually the same as a concentric Before meter, 7; After meter, 3; Note 15. None.

(diameters): and segmental types: orifice. PIPING NOTES

Before plate 10; after plate 4. See Note 15. Flow conditioner: includes conventional flow straighteners such as tube-bundles, plate or honeycomb types for swirl.

OptimizeIT For severely distorted flow profiles, jets, or persistent swirl patterns, proprietary flow conditioner designs are

Power requirements: DC or pneumatic. DC or pneumatic. DC or pneumatic. DC or pneumatic. DC or pneumatic. None. recommended for example Sprenke, Zanker, Mitsubishi, Vortab.

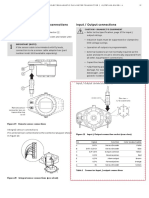

Piping connections: Flanged, threaded, welded. Flanged, threaded, welded, insert, Flanged, insert. Flanged, welded. Insertion, hot tap. Flanged, threaded. Flow Disturbance:

(A) Includes pipe fittings for example elbows or tees, fabricated pipe bends and other fabricated pipe configurations,

Type of measurement: Whole body. Concentric can be in a Whole body. Whole body. Whole body. Sampling. Whole body, by-pass. equipment such as pumps, strainers and air eliminators, shut-off valves must be either fully opened or fully closed.

bypass configuration. Throttling valves must be located downstream of the meter (see Flow Disturbance B)

Installation requirements: Upstream pipe ID, circularity and The average diameter of the pipe at Types with manifolds which average local Bidirectional when pressure taps are at 45º, Some designs bi-directional. Locate to Meter must be vertical. (B) Includes elbows, tees, and other pipe fittings as well as fabricated pipe bends or other fabricated pipe configurations,

roughness are important factors. the meter inlet should be within ± 1% pressure are recommended if less than Flow must enter end nearest pressure taps assure developed turbulent flow. Avoid piping 2 or more sizes throttling or shut-off valves.

Upstream pipe joints must be smooth of the meter diameter and the pipe desirable flow profiles are anticipated. when using 22.5º taps. Inside diameter of smaller than end connections. Flowmeter: Includes volumetric, velocity, and mass type flowmeters. Differential pressure types include all orifice

and gaskets must not project into the flow. roundness should not exceed 2% elbow at taps and the radius of the bend must variations; Venturis, flow nozzles, flow tubes, pitots, averaging pitots, and elbows, all of which require associated sensing

of nominal. Gaskets must not project be measured for the best results: Pipe ID and piping (impulse lines), a 3-valve manifold and a dp transmitter. The transmitter location relative to the dp producer, is

into the flow. elbow ID must agree within 1%. Gaskets must determined by the type of fluid being measured (liquid, gas, or steam). Orientation is important for some types of meters.

not project into flow. Some types of turbine meters, for example, are intended only for installation in horizontal piping; installation in sloping or

vertical piping must be reviewed with the manufacturer.

Orientation requirements: Orifice plate inlet must face upstream. Pressure tap orientation depends upon None. None. Dependent on pipe orientation and type Must be vertical. Pipe:

The centerline of concentric orifice plates the pipe orientation and the fluid of fluid. Tube must be within ± 3% of (A) Included in the upstream piping requirements when a flow straightener or flow conditioner is used. Pipe size should

must be the same centerline as that of the measured. flow direction (yaw), ± 5% of transverse be the same as the meter size. Length is determined by Standards, Recommended Practices, or the Manufacturer’s

pipe. Plane of orifice must be perpendicular plane (pitch). And ± 3% of pipe centreline Specifications.

to the centreline. Pressure tap orientation perpendicular to flow (roll). (B) Pipe size should be the same as the meter size. Pipe length is established by Standards, Recommended Practices, or

depends upon pipe orientation and the Manufacturer’s Specifications. The inside diameter of the pipe, and its condition may be important, concentricity of

type of fluid being metered; see piping diagram. the pipe with the meter’s inside diameter may also be important. Gaskets must not protrude into the flow stream.

Ancillary equipment Flow conditioners may be required when Flow conditioners may be required when Flow conditioners may be required when Flow conditioners may be required when Flow conditioners may be required when None. (C) Pipe size should be the same as the meter size. Pipe length is defined by Standards, Recommended Practices, or

requirements upstream straight pipe is limited. upstream straight pipe is limited. upstream straight pipe is limited. upstream straight pipe is limited, low range for some applications , low range Manufacturer’s Specifications.

Drain, vent and blowoff valves may be Shut-off valves are usually used at every differential pressure transmitter required. differential pressure transmitter required. Pipe Support: Type hanger (from above), or support (from below) is influenced by the type of flow meter being used.

needed. Shut off valves are usually. pressure tap location. Some flowmeter types can accept piping induced line stresses, and are handled as just another concentrated mass. Some

used at each pressure tap location. types of flow meters must be isolated from external stresses including piping induced stresses. These meters require

special care in the type and location of hangers/supports which are used. Although large and heavy meters include integral

Standards or AGA 3, ANSI/API 2530, ANSI/ASME MFC 3M, ANSI/API 2530, ANSI/ASME MFC 3M, None. None. ISO 7174 (pitot). None. base supports, associated hanger/support requirements must be considered to minimise (eliminate) transfer of stresses to

recommended practices ASME Fluid meters, ISO 5167, ASME fluid Meters, ISO 5167. the flow meter housing.

Shell Flowmeter engineering handbook.

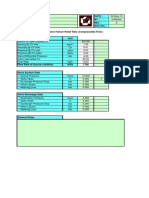

2 Mass

Piping Requirements (note 1)

Meter Orientation Support

Ancillary Equipment Requirements (see piping diagram)

Flow Conditioners

7 Target

Meter Principle Minimum pipe length (diameters): Before meter, 6; After meter, 3.5. Note 15.

Upstream Downstream Pipe Pipe Wall Condition Concentricity Horizontal Vertical Sloping By-Pass As a As a Plate, Tube Other Strainer Air Block Transmitter Sensing Isolation

Thermal Coriolis Power requirements: AC/DC or pneumatic.

Pipe Length Pipe Length Material Thickness of Pipe ID of meter ID Piping Valve Pump or Honey- or Filter Eliminator Valves Location Piping Manifold

Minimum pipe length Body type: Before meter, 10; Some designs require with pipe ID comb Piping connections: Flanged, threaded, flangeless (wafer style), Note 4, and insertion.

(diameters): After meter, 0. Insertion type: upstream straight pipe,

No. Category Type Note 2 Note 3 Note 4 Note 5 Note 6 Note 7 Note 8 Note 9 Note 10 Note 11 Note 12 Note 13 Note 14 Type of measurement: Whole body: insertion type is sampling.

Before meter, 15; After meter, 5. refer to manufacturer.

Orifice Installation requirements: Some designs require specific pipe IDs at meter entrance.

Power requirements: AC/DC. AC/DC.

Ventura Gaskets should not protrude into flow stream.

Piping connections: Flanged, threaded, sanitary. Flanged, threaded, sanitary.

Flow Nozzle Ancillary equipment requirements: Flow conditioners recommended for some flow

Type of measurement: Whole body, by-pass, sampling. Whole body. profiles to reduce upstream piping requirements. Strainers usually recommended.

1 Differential Flow Tube

Installation In some insertion types, the Pipe supports must be Pressure Elbow

requirements: sensor head must not touch located on adjoining pipe

the opposite pipe wall. and go to a common Pitot

reference to minimize transfer Averaging Pitot

of pipe stress to the meter.

Meters in series must be VA 8 Positive Displacement

separated by 15 pipe Coriolis Minimum pipe length (diameters): Before or after meter, none.

diameters. Some designs are 2 Mass Thermal Insert

bidirectional. Isolate meters Power requirements: Basic versions do not require power, AD/DC or battery used for

from flow and pump Thermal Meter Body accessories.

pulsations and minimize Fluidic Piping connections: Flanged, threaded, sanitary.

external vibrations. 3 Oscillatory Vortex Presession Type of measurement: Whole body (true volumetric).

Orientation Some types require installation Must be oriented so that any Vortex Shedding

requirements: with the same orientation used gas bubbles or sediment do Installation requirements: Larger and heavier designs require base mounting. Housing

during calibration. Insertion not collect in the measuring AC Excited should not be subjected to undue pipe stress. By-pass piping may be required, especially

types will have orientation region of the meter.

4 Magnetic where blocked flow due to meter failure is not acceptable. Drip traps for wet gas

Pulse DC Excited

requirements that vary with Specific orientations allow applications are recommended. Meters should be installed to allow draining to minimize

their design. Some designs self-draining and vary with

5 Turbine deposits forming on meter internals. Piping interior should be flushed before meter is

require insertion plane to be the meter design. Dop. Clamp-on installed.

parallel with flow plane to Dop. Meter Body Orientation requirements: Meters should not be at low point in the piping where

within ±2º. 6 Ultrasonic particulate matter would accumulate. Meter should be level.

ToF Clamp-on

Ancillary equipment None. Block valves are Ancillary equipment requirements: Strainers and air eliminators are generally

requirements recommended to perform

ToF Meter Body

recommended. Flow restricting orifices or flow limiting valves used where transient high

zero adjustment with no flow. 7 Target low rates are experienced. Air chambers or shock arrestor may also be recommended.

Standards or ISO 14511. California Weights & 8 Positive Displacement Standards or recommended practices: API-Chapter 5, Section 2, PD Meters: RP2535,

recommended practices Standards Bureau PTB Recommended Practice for Viscous Hydrocarbons: ASME Fluid Meters; ANSI: B109.1 and

ISO 10790. Installation requirements essential to Installation requirements recommended B109.2 for diaphragm type meters AGA 6; API 1101.

Consult manufacturer Not a factor

good measurement for good measurement

3 Oscillatory 4 Magnetic 5 Turbine 6 Ultrasonic

Fluidic Vortex Shedding Vortex Precession Minimum pipe length (diameters): Before meter, 5; After meter, 2. Minimum pipe length (diameters): Before meter, 10; After meter, 5; Note 15.

Doppler (Dop.) Time of Flight (ToF)

Minimum pipe length Follow recommendations for 0.7 Beta Before meter, 10; After meter, 5. Before meter 3; Power requirements: AC/DC battery. Power requirements: None for most versions. AC/DC or battery used for RF signal

(diameters): orifice meter. Varies with manufacturer. Note 15. After meter, 1. systems and accessories. Minimum pipe length Follow recommendations for a 0.7 Beta ratio Before meter, 10; After meter, 2.

Piping connections: Flanged, Victaulic, Dresser, Sanitary, Flangeless (wafer style) Note 4. (diameters): orifice meter installation. Swirling and jet

Power requirements: AC/DC, 2-wire DC available. AC/DC, 2-wire DC , Battery power. AC/DC, 2 wire DC. Piping connections: Flanged, Threaded Sanitary, Flangeless (wafer style)

Type of measurement: Whole body. Insertion type is sampling. flows must be avoided.

Piping connections: Flanged, flangeless (wafer style) Flanged, threaded, sanitary, weld ends, Note 4 and insertion.

Installation requirements: Some designs are bi-directional. Grounding is a function of Power requirements: AC/DC battery. AC/DC

Note 4. flangeless (wafer style) Note 4. Flanged. Type of measurement: Whole body, insertion type is sampling.

the adjoining pipe material for most designs. Gaskets must not project into the flow. There Piping connections: Usually non-invasive (clamp-on); meter body Flanged; non-invasive

Type of measurement: Whole body by-pass larger than 4 inches. Whole body. Insertion type is sampling. Whole body. are specific pipe support requirements for some designs. Note 10. Do not inject additives Installation requirements: Locate meter as far as practical from flow disturbance. types are also available. (clamp-on) also available.

Installation requirements: Pipe wall thickness should be specified. Gaskets should not protrude into flow immediately upstream of the meter. Strainers and flow conditioners must be specifically located; Varies with standards,

recommended practices, and manufacturers. By-pass piping frequently recommended; it is Type of measurement: Sampling. Sampling.

Gaskets must not project into stream; some designs require specific Orientation requirements: Larger sizes have an integral base support for installation on

the flow stream.. pipe inside diameter at meter entrance. None. essential for cryogenic applications. Clean piping before installing meter. Avoid abnormal Installation Allow adequate upstream pipe length following a Allow adequate upstream pipe length to

a slab at ground level.

pipe stresses at meter. requirements: disturbance to assure a fully developed turbulent assure a fully developed turbulent

Orientation requirements: Horizontal plane is preferred. Some designs require specific orientation None. Ancillary equipment requirements: None.

Orientation requirements: Some designs must be oriented as calibrated. profile. Avoid severely vibrating pipe sections. Deposits profile. Clamp-on types are dependent

based on the type of application or

Standards or recommended practices ISO 6817. on pipe ID may affect the meters ability to make on pipe material, pipe wall thickness

operating temperature, Check manufacturer. Ancillary equipment requirements: Flow conditioners and strainers or filters are measurements. Clamp-on: Pipe material and or type and condition of pipe interior.

Ancillary equipment Flow conditioners are recommended for Flow conditioners are recommended for None. usually required. A separator for condensate removal is recommended for gas flows. of pipe lining may affect the measurement. Particle

requirements persistent swirl profiles or jet flow profiles. persistent swirl profiles or jet flow profiles. Standards or recommended practices: AGA7, API 2534, API Manual for Petroleum (bubble) velocity being sensed, so particles must be

Management Standards, Chapter 5, Section 3, ISO 2715, ASME Fluid Meters. of uniform size, uniformly distributed, be of uniform

materials, and have a velocity the same as the liquid.

Standards or None. ASME.ANSI MFC 6M None.

Meter location must be selected so there is adequate

recommended practices ISO 12764.

velocity to prevent particles from rising or settling

which introduces measurement errors.

NOTES

Orientation Locate transducers so they look away None.

1. When measuring liquids and slurries, pipe must be full. Flow through meters must be in the direction 6. Preferred flow direction is up to assure a full pipe; this is mandatory in gravity feed systems 13. Entrained gas will affect the accuracy of volumetric liquid measurement and calibration; signal output is requirements: from flow disturbances.

marked on the meter body. 7. Sloping lines are generally handled as horizontal lines. related to total volume, not just liquid phase. Air eliminators are an important consideration in custody

2. Includes straight length of pipe before a flow conditioner as well as that at the meter entrance: 8. The criteria are whether flow will be able to pass through the meter if there is a meter failure, whether the transfer and billing applications. Some liquid mass meters have specific limits on percent gas they can Ancillary equipment None. None.

see piping diagram. measurement is critical to the process or access to the meter, at any time, is important. tolerate (void fraction). requirements

3. Most meters prefer that the inside diameter of the upstream pipe be slightly greater than the meter inside 9. Many smaller meters are essentially another piece of pipe and can accept piping stresses. They are 14. Block valves must be leak-tight so that a true no-flow condition is established. Similar requirements exist

Standards or None. ANSI/ASME MFC-YY.

diameter. For some meters, such as orifice, the inside diameter should be precisely known. considered in the piping system as concentrated mass. for by-pass piping arrangements. recommended practices

4. Concentricity is important to many meters including orifice types. It is essential to all wafer-style meters 10. Some meters require that there are low (no) piping stresses transferred to the meter body (housing). 15. The required length of straight upstream pipe increases with the need for accuracy. It also increases with

regardless of the operating principle. Wafer-style meters are either furnished with or recommend centering Performance may be impaired if this criterion is not followed. an increasing Beta-ratio, where that is a factor. It also varies with the type of upstream disturbance and

devices which must be used. Gaskets must not protrude into the flow stream. 11. Plate, tube, honeycomb, and similar conditioners (flow straighteners) are beneficial for swirling flows. whether or not the correct flow conditioner is used. For technical advice and further

5. Horizontal is the most common orientation, but special care must be taken when measuring liquids which

have entrained gas or particles, and gases in which liquids are present. Some meters calibrated in the

They may be detrimental if used when distorted profiles are present.

12. If profiles are severely distorted, or swirl flow is persistent, flow conditioners such as Mitsubishi,

information on the ABB range

horizontal will require installation in that orientation. Sprenkle, Vortab, Zanker, and so on should be used. Pressure drops should be checked. of flow products call:

0870 600 6122

visit us at www.abbiap.co.uk www.abb.co.uk/instrumentation ABB Limited, Howard Road, St Neots, Cambridgeshire, PE19 8EU, UK. Tel: 0870 600 6122

WP/FLWINS Issue 1 (03.04)

Potrebbero piacerti anche

- 10-3 Primary Elements PDFDocumento10 pagine10-3 Primary Elements PDFAbderrahmaneTemhachetNessuna valutazione finora

- Ci Fex300 Fex500-En HDocumento76 pagineCi Fex300 Fex500-En HJamesh BabuNessuna valutazione finora

- Description: Dura Mag Flow Meter With Procomm ConverterDocumento6 pagineDescription: Dura Mag Flow Meter With Procomm ConverterJamesh BabuNessuna valutazione finora

- Description: M0300 Strap-On Saddle Flow MeterDocumento5 pagineDescription: M0300 Strap-On Saddle Flow MeterJamesh BabuNessuna valutazione finora

- ABB Aquamaster3&4 Terminal ConnectionDocumento2 pagineABB Aquamaster3&4 Terminal ConnectionJamesh BabuNessuna valutazione finora

- 43 PDFDocumento10 pagine43 PDFJamesh BabuNessuna valutazione finora

- MA WATERFLUX3070 V3 en 200520 4004999702 R02Documento96 pagineMA WATERFLUX3070 V3 en 200520 4004999702 R02Jamesh BabuNessuna valutazione finora

- ABB Ability Verification For Measurement Devices: SRV500 EnhancedDocumento42 pagineABB Ability Verification For Measurement Devices: SRV500 EnhancedJamesh BabuNessuna valutazione finora

- MC Propeller Flow Meters: Municipal Water, Agriculture, IrrigationDocumento4 pagineMC Propeller Flow Meters: Municipal Water, Agriculture, IrrigationJamesh BabuNessuna valutazione finora

- Fpi Mag Flow Meter With Procomm ConverterDocumento10 pagineFpi Mag Flow Meter With Procomm ConverterJamesh Babu0% (1)

- Ultrasonic, level, flow meters, switches proposalDocumento5 pagineUltrasonic, level, flow meters, switches proposalJamesh BabuNessuna valutazione finora

- Flow Tool Siemens MAG 8000Documento18 pagineFlow Tool Siemens MAG 8000Jamesh BabuNessuna valutazione finora

- Waagner Biro Model Code Clarification 2Documento1 paginaWaagner Biro Model Code Clarification 2Jamesh BabuNessuna valutazione finora

- Mag 8000 Oi en En-UsDocumento165 pagineMag 8000 Oi en En-UsJamesh BabuNessuna valutazione finora

- My InvitationDocumento1 paginaMy InvitationJamesh BabuNessuna valutazione finora

- Gas Density MeasurementDocumento31 pagineGas Density MeasurementJamesh BabuNessuna valutazione finora

- Getting Started with HTML - An IntroductionDocumento14 pagineGetting Started with HTML - An IntroductionJamesh BabuNessuna valutazione finora

- Transmitter SpecsDocumento40 pagineTransmitter SpecsJamesh BabuNessuna valutazione finora

- Getting Started with HTML - An IntroductionDocumento14 pagineGetting Started with HTML - An IntroductionJamesh BabuNessuna valutazione finora

- FET 200 Aquamaster TransmiterDocumento48 pagineFET 200 Aquamaster TransmiterJamesh BabuNessuna valutazione finora

- DS Wm-En XDocumento20 pagineDS Wm-En XJamesh BabuNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Chilled, Chilled-Hot and Condenser Water Piping SystemsDocumento51 pagineChilled, Chilled-Hot and Condenser Water Piping SystemsgabrielNessuna valutazione finora

- Common Valve ProblemsDocumento76 pagineCommon Valve ProblemsAhmed Sabry El-sotohyNessuna valutazione finora

- Perform Pipe Threading of Joints and Connection - PLUMBINGDocumento3 paginePerform Pipe Threading of Joints and Connection - PLUMBINGRuel DelgadoNessuna valutazione finora

- Is 2065 1983Documento47 pagineIs 2065 1983suresh kumarNessuna valutazione finora

- Writeup On Safety Valve & ErvDocumento28 pagineWriteup On Safety Valve & Ervtek_surinder100% (3)

- Control Valve Failure Relief Rate - Gas ServiceDocumento3 pagineControl Valve Failure Relief Rate - Gas ServiceSaeid Rahimi Mofrad100% (1)

- Useful Piping AbbreviationsDocumento3 pagineUseful Piping AbbreviationsahmedNessuna valutazione finora

- Nu Division 22 Combined 20170330Documento235 pagineNu Division 22 Combined 20170330Jothimanikkam SomasundaramNessuna valutazione finora

- Rheem Hot Water ManiualsDocumento16 pagineRheem Hot Water ManiualsTran Hung100% (1)

- PlumbingDocumento14 paginePlumbingRaizen TanNessuna valutazione finora

- Bwms3 Type-F HW Io List Template Rev1.0 Gd1221!1!20211119Documento229 pagineBwms3 Type-F HW Io List Template Rev1.0 Gd1221!1!20211119Trong HuynhNessuna valutazione finora

- Produksi OktDocumento31 pagineProduksi OktnoviNessuna valutazione finora

- Cliente: Tally Casing, Liner & TubingDocumento2 pagineCliente: Tally Casing, Liner & TubingJose CervantesNessuna valutazione finora

- Hydraulic EngineeringDocumento8 pagineHydraulic Engineeringcharan__Nessuna valutazione finora

- 1011a AgfDocumento2 pagine1011a Agfrvalentino2012Nessuna valutazione finora

- Uponor Hydronic Piping Design Assistance Manual (HPDAM)Documento177 pagineUponor Hydronic Piping Design Assistance Manual (HPDAM)mohammadKhw100% (1)

- 2010 AWWA Life Cycle HDPE in PW Apps Camille RubeizDocumento37 pagine2010 AWWA Life Cycle HDPE in PW Apps Camille RubeizmbobterateraNessuna valutazione finora

- Drawings 1 PDFDocumento20 pagineDrawings 1 PDFjoegieNessuna valutazione finora

- Unit - 2 Plumbing PDFDocumento25 pagineUnit - 2 Plumbing PDF20BCS4054 MADHAVAN VNessuna valutazione finora

- MS1919 Span EdipDocumento1 paginaMS1919 Span EdipNaqiudin ZainudinNessuna valutazione finora

- Refresher Exam 3Documento15 pagineRefresher Exam 3Christopher Joshua MartinezNessuna valutazione finora

- Pump Calc ExampleDocumento21 paginePump Calc ExampleMohammad Usman HabibNessuna valutazione finora

- G4K 4-Way High Pressure Ball ValvesDocumento5 pagineG4K 4-Way High Pressure Ball ValvesLuis Marco Mora PobleteNessuna valutazione finora

- Piping Questions and Answers PDF Free Download AWS-CWI Certification - Certified Welding Inspector Exam Training CourseDocumento12 paginePiping Questions and Answers PDF Free Download AWS-CWI Certification - Certified Welding Inspector Exam Training CourseKalaiYarasan100% (2)

- MEP Work Schedule: XXX XXXDocumento79 pagineMEP Work Schedule: XXX XXXamitadhikari333100% (3)

- SDM 143 eDocumento20 pagineSDM 143 eseaqu3st100% (1)

- Group 5 combined operation outlineDocumento9 pagineGroup 5 combined operation outlineالمهندسوليدالطويلNessuna valutazione finora

- StubFlangeAndBackingRingTablesV1 PDFDocumento4 pagineStubFlangeAndBackingRingTablesV1 PDFhendrynNessuna valutazione finora

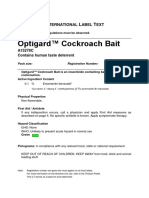

- ILT - Optigard RBDocumento5 pagineILT - Optigard RBrei estacioNessuna valutazione finora

- Parker Fluid Connectors - General Technical InfoDocumento32 pagineParker Fluid Connectors - General Technical InfoJenner Volnney Quispe ChataNessuna valutazione finora