Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Manufacturing Technology II Syllabus

Caricato da

smg26thmayDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Manufacturing Technology II Syllabus

Caricato da

smg26thmayCopyright:

Formati disponibili

SEMESTER SUBJECT L T P C

IV MANUFACTURING TECHNOLOGY II 3 0 0 3

Aim The aim of the subject is to provide knowledge in cutting process of manufacturing

sector.

Scope 1. To understand the metal cutting processes.

2. To understand the types, construction and operations of lathes.

3. To gain the knowledge of different operations on special machines

4. To understand the types and operations of sawing, broaching and gear cutting

machines.

5. To learn the various machining processes that uses abrasives.

Outcome The students would be able to operate lathe machines and special machines perform

operations.

UNIT – I THEORY OF METAL CUTTING 9

Introduction: metal cutting methods - mechanics of metal machining –chip formation – types of

chips-chip breaker- Merchant Circle Diagram-cutting force calculation- Single point cutting tool

nomenclature-Cutting tool materials –Tool wear - Tool life - cutting fluids.

UNIT – II CENTRE LATHE AND SPECIAL PURPOSE LATHES 9

Centre lathe- constructional features and various operations- taper turning methods- thread cutting

methods- special attachments- machining time and power estimation.

Capstan and turret lathes - automats – Swiss type–automatic screw type.

UNIT – III SHAPER, PLANNER, MILLING AND DRILLING MACHINES 9

Shaper– planer– slotting Machines – quick return mechanism – Milling Machines–milling cutters–

operations; Drilling- reaming– boring– tapping.

UNIT – IV SAWING - BROACHING AND GEAR CUTTING 9

Sawing machine: hack saw- band saw- circular saw; broaching machines –types-working

principle-nomenclature. Gear Generation: forming- shaping- hobbing

UNIT – V ABRASIVE PROCESSES 9

Abrasive processes: grinding wheel – specifications and selection- types of grinding machines.

Honing- lapping- super finishing- polishing and buffing.

TOTAL HOURS :45

TEXT BOOKS

1. Serope Kalpajian- Steven R.Schmid- Manufacturing Engineering and Technology- Pearson

Education- Inc. 2002 (Second Indian Reprint).

2. Rao- P.N. “Manufacturing Technology”- Metal Cutting and Machine Tools- TMH- 2003.

3. Hajra Choudhury- Elements of Workshop Technology- Vol. I and II- Media Promoters Pvt

Ltd.- Mumbai- 2001

REFERENCES

1. Richerd R. Kibbe- John E. Neely- Roland O. Merges and Warren J. White- “Machine Tool

Practices”- Prentice Hall of India- 2003.

2. P.C. Sharma- “A Text Book of Production Engineering”- S. Chand and Co. Ltd- IV edition,

2002.

3. Hajra Choudry, “Elements of Work Shop Technology – Vol. II”- Media Promoters. 2002.

4. B.L.Juneja G.S.Sekhon nithsethan ‘’Fundamentals of metal cutting and machine tools’’

Potrebbero piacerti anche

- Tos Varnsdorf WHN 13.8 CNC BJ 1995 en v1Documento14 pagineTos Varnsdorf WHN 13.8 CNC BJ 1995 en v1MareNessuna valutazione finora

- Mechatronics Unit III and IV Question and AnswersDocumento6 pagineMechatronics Unit III and IV Question and AnswersSaravanan MathiNessuna valutazione finora

- Mtech Thermal Engineering 2021 1-1 Sem Question Papers (Thermal Engineering)Documento8 pagineMtech Thermal Engineering 2021 1-1 Sem Question Papers (Thermal Engineering)ganesh ghuttsNessuna valutazione finora

- Manufacturing ProcessDocumento1 paginaManufacturing ProcessRonald Reagon20% (5)

- Machine Tools LabDocumento37 pagineMachine Tools LabAbdelhay Mohamed HassanNessuna valutazione finora

- Refrigeration Air Conditioning Lab ManualDocumento13 pagineRefrigeration Air Conditioning Lab Manualjayshah1991100% (1)

- Rac Assignment 1Documento4 pagineRac Assignment 1Guru Ravindra ReddyNessuna valutazione finora

- Lec 3. Centfg - Compressor ExDocumento30 pagineLec 3. Centfg - Compressor ExmichaelNessuna valutazione finora

- High Velocity FormingDocumento54 pagineHigh Velocity FormingKirandeep Singh Srao100% (8)

- Manufacturing Processes - Iiprof. A.b.chattopadhyay, Prof. A.K. ChattopadhyayDocumento618 pagineManufacturing Processes - Iiprof. A.b.chattopadhyay, Prof. A.K. ChattopadhyayVivek Jaiswal88% (8)

- Basic Mechanical EngineeringDocumento1 paginaBasic Mechanical EngineeringKailas Sree ChandranNessuna valutazione finora

- Question Bank 3D PrintingDocumento2 pagineQuestion Bank 3D PrintingSujit Mule100% (1)

- Machine Design Lab ManualDocumento28 pagineMachine Design Lab ManualEr Raghvendra Singh100% (1)

- Manufacturing Process 1 Question BankDocumento11 pagineManufacturing Process 1 Question BankAshok PradhanNessuna valutazione finora

- Me8792 - Power Plant EngineeringDocumento48 pagineMe8792 - Power Plant EngineeringPalanivel Rajan A RNessuna valutazione finora

- Metal Joining PrcocessDocumento42 pagineMetal Joining PrcocessDheerajSharmaNessuna valutazione finora

- SheetDocumento3 pagineSheetBarun BeheraNessuna valutazione finora

- Mechanics of Chip FormationDocumento10 pagineMechanics of Chip FormationRavigggNessuna valutazione finora

- Mechanical Engineering PPT of AltafDocumento10 pagineMechanical Engineering PPT of AltafAltaf HussainNessuna valutazione finora

- Advance MFG Processes Lecture1newDocumento30 pagineAdvance MFG Processes Lecture1newirum,Nessuna valutazione finora

- Theory of Metal CuttingDocumento3 pagineTheory of Metal CuttingGeorge Oliver100% (1)

- Introduction To UCMPDocumento27 pagineIntroduction To UCMPGowtham sivateja100% (2)

- RAC Assignments 24062016 091508AMDocumento37 pagineRAC Assignments 24062016 091508AMsakalidhasavasanNessuna valutazione finora

- Heat and Mass Transfer NotesDocumento40 pagineHeat and Mass Transfer NotesSanwar TagraNessuna valutazione finora

- Wollega University: Title: - Design of Motor Operated Circular Pipe Bending MachineDocumento2 pagineWollega University: Title: - Design of Motor Operated Circular Pipe Bending MachineFuad MuktarNessuna valutazione finora

- Viva Voce Questions: CNC MachinesDocumento4 pagineViva Voce Questions: CNC MachinesguruNessuna valutazione finora

- Metal Forming ProcessDocumento39 pagineMetal Forming ProcessRa Balamurugan100% (1)

- 1.5.1 Intro To MicromachiningDocumento24 pagine1.5.1 Intro To MicromachiningAshish MishraNessuna valutazione finora

- Non Conventional Machining PDFDocumento55 pagineNon Conventional Machining PDFMarthande100% (1)

- Chapter 1-Introduction To Machining: Learning ObjectivesDocumento6 pagineChapter 1-Introduction To Machining: Learning ObjectivesjagbirNessuna valutazione finora

- Ucmp 2 Mark With AnswerDocumento17 pagineUcmp 2 Mark With AnsweranithayesurajNessuna valutazione finora

- ME405 RAC Question BankDocumento8 pagineME405 RAC Question BankDeepakNessuna valutazione finora

- Solidification ShrinkageDocumento16 pagineSolidification ShrinkageSherif El-soudyNessuna valutazione finora

- Nov Dec 2016 PPC Question PaperDocumento21 pagineNov Dec 2016 PPC Question PapersathyadallyNessuna valutazione finora

- Lecture-17: Multi-Stage Vapour Compression Refrigeration SystemsDocumento13 pagineLecture-17: Multi-Stage Vapour Compression Refrigeration SystemsMuhaamad TiloNessuna valutazione finora

- Ch-12 Unconventional MachiningDocumento188 pagineCh-12 Unconventional MachiningAbhishek AroraNessuna valutazione finora

- Tool Wear and Tool LifeDocumento5 pagineTool Wear and Tool LifenkchandruNessuna valutazione finora

- Introduction To Casting ProcessDocumento11 pagineIntroduction To Casting ProcessMuraliMohan0% (1)

- RAC Complete Notes PDFDocumento76 pagineRAC Complete Notes PDFdipsankar chatterjeeNessuna valutazione finora

- ME8491 Engineering Metallurgy COURSE PLANDocumento4 pagineME8491 Engineering Metallurgy COURSE PLANKarthick NNessuna valutazione finora

- Cad Notes PDFDocumento11 pagineCad Notes PDFRammohan ReddyNessuna valutazione finora

- Manufacturing Process 1 Question BankDocumento8 pagineManufacturing Process 1 Question Bankashok PradhanNessuna valutazione finora

- Question Paper Code:: (10×2 20 Marks)Documento2 pagineQuestion Paper Code:: (10×2 20 Marks)jastraNessuna valutazione finora

- Project Title ListDocumento12 pagineProject Title ListShrishant PatilNessuna valutazione finora

- Lecture 5 Heat Generation in Metal Cutting OperationsDocumento36 pagineLecture 5 Heat Generation in Metal Cutting Operationsnickokinyunyu11Nessuna valutazione finora

- Subject Metal Cutting and Tool Design de PDFDocumento2 pagineSubject Metal Cutting and Tool Design de PDFBabuli KumarNessuna valutazione finora

- KOM Important QuestionsDocumento12 pagineKOM Important QuestionsJithin KNessuna valutazione finora

- Course Code Course Title: ME212 Machine Drawing 1 6 5Documento4 pagineCourse Code Course Title: ME212 Machine Drawing 1 6 5Kantha RaoNessuna valutazione finora

- Cryogenics NotesDocumento37 pagineCryogenics NotesGodwin BenedictNessuna valutazione finora

- Welding ProcessesDocumento46 pagineWelding Processesbabitasharma100% (1)

- Nontraditional Machining and Thermal Cutting Processes - Chapter 26Documento67 pagineNontraditional Machining and Thermal Cutting Processes - Chapter 26xharpreetxNessuna valutazione finora

- Theory of MachineDocumento21 pagineTheory of MachineVaibhav Vithoba NaikNessuna valutazione finora

- DMM-2 Second Mid Bit PaperDocumento2 pagineDMM-2 Second Mid Bit PaperYeswanth Kumar ReddyNessuna valutazione finora

- Mt-I 2 Marks With Answer PDFDocumento15 pagineMt-I 2 Marks With Answer PDFSiva RamanNessuna valutazione finora

- Cad Lab Manual 2019-20Documento71 pagineCad Lab Manual 2019-20Rambabu mokatiNessuna valutazione finora

- CuttingDocumento28 pagineCuttingburakNessuna valutazione finora

- Two Marks Questions With AnswersDocumento18 pagineTwo Marks Questions With AnswersSaravanan Mani100% (2)

- Machine Design Report 1Documento15 pagineMachine Design Report 1WaqasNessuna valutazione finora

- Dsa 5500Documento12 pagineDsa 5500Nguyen Van ToanNessuna valutazione finora

- 1492Documento15 pagine1492_Anggyaa_Nessuna valutazione finora

- Objective Assignment 1: (Https://swayam - Gov.in)Documento7 pagineObjective Assignment 1: (Https://swayam - Gov.in)smg26thmayNessuna valutazione finora

- Objective Assignment 4: (Https://swayam - Gov.in)Documento5 pagineObjective Assignment 4: (Https://swayam - Gov.in)smg26thmayNessuna valutazione finora

- Objective Assignment 2: (Https://swayam - Gov.in)Documento4 pagineObjective Assignment 2: (Https://swayam - Gov.in)smg26thmayNessuna valutazione finora

- Objective Assignment 5: (Https://swayam - Gov.in)Documento4 pagineObjective Assignment 5: (Https://swayam - Gov.in)smg26thmayNessuna valutazione finora

- Objective Assignment 3: (Https://swayam - Gov.in)Documento8 pagineObjective Assignment 3: (Https://swayam - Gov.in)smg26thmayNessuna valutazione finora

- Objective Assignment 6: (Https://swayam - Gov.in)Documento5 pagineObjective Assignment 6: (Https://swayam - Gov.in)smg26thmayNessuna valutazione finora

- Objective Assignment 8: (Https://swayam - Gov.in)Documento4 pagineObjective Assignment 8: (Https://swayam - Gov.in)smg26thmayNessuna valutazione finora

- The Nord Lock WasherDocumento3 pagineThe Nord Lock Washersmg26thmayNessuna valutazione finora

- WT Signature AnalysisDocumento16 pagineWT Signature Analysissmg26thmayNessuna valutazione finora

- Nadappu in June 2020Documento53 pagineNadappu in June 2020smg26thmayNessuna valutazione finora

- What Is Shot Peening?: ShareDocumento2 pagineWhat Is Shot Peening?: Sharesmg26thmayNessuna valutazione finora

- Objective Assignment 7: (Https://swayam - Gov.in)Documento4 pagineObjective Assignment 7: (Https://swayam - Gov.in)smg26thmayNessuna valutazione finora

- Sep in EnglishDocumento105 pagineSep in Englishsmg26thmayNessuna valutazione finora

- Infosys Mysore Campus: Infosys Mysore Training Question Pattern For FA1 and FA2Documento4 pagineInfosys Mysore Campus: Infosys Mysore Training Question Pattern For FA1 and FA2smg26thmayNessuna valutazione finora

- Concise Process Improvement Definition With Case StudiesDocumento22 pagineConcise Process Improvement Definition With Case Studiessmg26thmayNessuna valutazione finora

- Statistics: Descriptive and Inferential: Statistics Is Concerned With Developing and Studying DifferentDocumento4 pagineStatistics: Descriptive and Inferential: Statistics Is Concerned With Developing and Studying Differentsmg26thmayNessuna valutazione finora

- Process-Mapping Six Sigma Project Work: Tool Usage and Expected ResultsDocumento1 paginaProcess-Mapping Six Sigma Project Work: Tool Usage and Expected Resultssmg26thmayNessuna valutazione finora

- Bolt and ThreadsDocumento5 pagineBolt and Threadssmg26thmayNessuna valutazione finora

- Title Needed Person: SL - NoDocumento3 pagineTitle Needed Person: SL - Nosmg26thmayNessuna valutazione finora

- What Are Different Types of TurbineDocumento18 pagineWhat Are Different Types of Turbinesmg26thmayNessuna valutazione finora

- Economics DefinitionsDocumento21 pagineEconomics Definitionssmg26thmayNessuna valutazione finora

- Saturation Curve Analysis and Quality ControlDocumento4 pagineSaturation Curve Analysis and Quality Controlsmg26thmayNessuna valutazione finora

- Sri Vidya College of Engineering and Technology, Virudhunagar Course Material (Lecture Notes)Documento45 pagineSri Vidya College of Engineering and Technology, Virudhunagar Course Material (Lecture Notes)smg26thmayNessuna valutazione finora

- Compounding of Steam TurbinesDocumento4 pagineCompounding of Steam Turbinessmg26thmay100% (1)

- Unit IIDocumento29 pagineUnit IIsmg26thmayNessuna valutazione finora

- TGN-RT-03 - Bolting Procedure For Steel Structures Rev 1Documento3 pagineTGN-RT-03 - Bolting Procedure For Steel Structures Rev 1mostafamaroc0% (1)

- LatheDocumento8 pagineLathevinothkumarNessuna valutazione finora

- Ameridrives - ProductosDocumento2 pagineAmeridrives - Productosmarcelo castilloNessuna valutazione finora

- Stub - Acme - Thread - Data - Sheets Rev ADocumento4 pagineStub - Acme - Thread - Data - Sheets Rev Aakaalj qhseNessuna valutazione finora

- MP-II MCQ Unit IIIDocumento6 pagineMP-II MCQ Unit IIIMagnus CarlsenNessuna valutazione finora

- Permanent Adjustment of Theodolite: Figure 21.2aDocumento4 paginePermanent Adjustment of Theodolite: Figure 21.2aKosygin Leishangthem83% (6)

- Check List (Pre Entry) For Portable Grinding MachineDocumento4 pagineCheck List (Pre Entry) For Portable Grinding Machinealvhyan anandolaki100% (1)

- Breaker Piping InstallationDocumento11 pagineBreaker Piping InstallationZawminhtunNessuna valutazione finora

- Differential Pressure Control Valve (DPCV) : DP971F DN65 - DN150Documento2 pagineDifferential Pressure Control Valve (DPCV) : DP971F DN65 - DN150dhawk94Nessuna valutazione finora

- Machines and Water Wheels-Cl V - Answer Key PDFDocumento3 pagineMachines and Water Wheels-Cl V - Answer Key PDFSuvam DasguptaNessuna valutazione finora

- RS 42, RS 51, RS 65, SR 150, SR 200, and SR 200 Big Bore: Parts ListDocumento280 pagineRS 42, RS 51, RS 65, SR 150, SR 200, and SR 200 Big Bore: Parts ListGareth RichardsNessuna valutazione finora

- Catalogue Porta 2012Documento41 pagineCatalogue Porta 2012Porta_ChucksNessuna valutazione finora

- CoroBore 92008Documento85 pagineCoroBore 92008NILOHAYASHINessuna valutazione finora

- IT 03 130522 Arcate HF ENDocumento16 pagineIT 03 130522 Arcate HF ENJosé SalazarNessuna valutazione finora

- Cat ZFDocumento239 pagineCat ZFMarkus Glarner100% (1)

- Banding PliersDocumento16 pagineBanding PliersViera Valachová100% (1)

- Catalogo Westlock Posicionador VCTDS-02772Documento4 pagineCatalogo Westlock Posicionador VCTDS-02772liusdhgNessuna valutazione finora

- Basic Considerations in Machining Processes - MAA - Faculty of Engineering - MTI UniversityDocumento30 pagineBasic Considerations in Machining Processes - MAA - Faculty of Engineering - MTI UniversityMohamed A. AbbasNessuna valutazione finora

- National Stock Numbers For Federal Supply Class 1005Documento7 pagineNational Stock Numbers For Federal Supply Class 1005sgtmonroeNessuna valutazione finora

- Bobcat S300 Bobtach Lift ArmDocumento3 pagineBobcat S300 Bobtach Lift ArmБогдан КолодяжнийNessuna valutazione finora

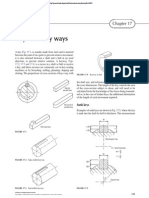

- Pages From Chapter 17 Keys and Key Ways Chapter 18 Worked Examples in Machine DrawingDocumento4 paginePages From Chapter 17 Keys and Key Ways Chapter 18 Worked Examples in Machine DrawingNagaraju GummadiNessuna valutazione finora

- CNC Quiz 1 (Compile)Documento13 pagineCNC Quiz 1 (Compile)Shafi AbdullahNessuna valutazione finora

- Recirculation Energy Recovery Unit - TraneDocumento12 pagineRecirculation Energy Recovery Unit - TraneShaik Bepari JakeerNessuna valutazione finora

- Unit 2 - Hydraulic Actuators and MotorsDocumento38 pagineUnit 2 - Hydraulic Actuators and MotorsAnirudh SrinivasNessuna valutazione finora

- CTN10 Compressor AssemblyDocumento17 pagineCTN10 Compressor AssemblyKakashi KamotoNessuna valutazione finora

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 123Documento1 paginaManual de Taller Excavadora Hitachi Zx200 225 230 270 - 123Andi KaNessuna valutazione finora

- Jig and FixtureDocumento14 pagineJig and Fixturepramodkb_cusat100% (1)

- Quotation RenovationDocumento2 pagineQuotation RenovationTajul Rijal Annuar100% (1)

- KCC Buildcon Private Limited: DepartmentDocumento13 pagineKCC Buildcon Private Limited: DepartmentQuality JamNessuna valutazione finora