Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

NRMC CIP 28p

Caricato da

Pedja0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni2 pagineTesting Series - 10 Topics TC

Jobsite Addition of Water CIP 26

Discrepancies in Yield CIP 8

Loss of Air Content In Pumped Concrete CIP 21

Acceptance Testing of Concrete CIP 41

Making Concrete Cylinders in the Field CIP 34

Testing Compressive Strength of Concrete CIP 35

Low Concrete Cylinder Strength CIP 9

Strength of In-Place Concrete CIP 10

Flexural Strength of Concrete CIP 16

Concrete Maturity CIP 39

Troubleshooting Series - 16 Topics TS

Cracking Concrete Surfaces CIP 4

Plastic Shrinkage Cracking CIP 5

Crazing Concrete Surfaces CIP 3

Cracks in Concrete Basement Walls CIP 7

Dusting Concrete Surfaces CIP 1

Scaling Concrete Surfaces CIP 2

Concrete Blisters CIP 13

Aggregate Popouts CIP 40

Delamination of Troweled Surfaces CIP 20

Curling of Concrete Slabs CIP 19

Discoloration CIP 23

Corrosion of Steel in Concrete CIP 25

Discrepancies in Yield CIP 8

Low Concrete Cylinder Strength CIP 9

Thermal Cracking of Concrete CIP 42

Alkali Aggregate Reactions (AAR) CIP 43

Best Practices Series - 11 Topics BP

Ordering Ready Mixed Concrete CIP 31

Concrete Pre-Construction Conference CIP 32

Joints in Concrete Slabs on Grade CIP 6

Finishing Concrete Flatwork CIP 14

Curing In-Place Concrete CIP 11

Vapor Barriers Under Slabs On Grade CIP 29

Concrete Slab Moisture CIP 28

Cold Weather Concreting CIP 27

Hot Weather Concreting CIP 12

Alkali Aggregate Reactions CIP 43

Durability Requirements for Concrete CIP 44

RMC Value Series - 10 topics RMCV

Ordering Ready Mixed Concrete CIP 31

Supplementary Cementitious Materials CIP 30

Chemical Admixtures for Concrete CIP 15

Synthetic Fibers for Concrete CIP 24

High Strength Concrete CIP 33

Self Consolidating Concrete CIP 37

Structural Lightweight Concrete CIP 36

Pervious Concrete CIP 38

Flowable Fill Materials CIP 17

Grout CIP 22

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoTesting Series - 10 Topics TC

Jobsite Addition of Water CIP 26

Discrepancies in Yield CIP 8

Loss of Air Content In Pumped Concrete CIP 21

Acceptance Testing of Concrete CIP 41

Making Concrete Cylinders in the Field CIP 34

Testing Compressive Strength of Concrete CIP 35

Low Concrete Cylinder Strength CIP 9

Strength of In-Place Concrete CIP 10

Flexural Strength of Concrete CIP 16

Concrete Maturity CIP 39

Troubleshooting Series - 16 Topics TS

Cracking Concrete Surfaces CIP 4

Plastic Shrinkage Cracking CIP 5

Crazing Concrete Surfaces CIP 3

Cracks in Concrete Basement Walls CIP 7

Dusting Concrete Surfaces CIP 1

Scaling Concrete Surfaces CIP 2

Concrete Blisters CIP 13

Aggregate Popouts CIP 40

Delamination of Troweled Surfaces CIP 20

Curling of Concrete Slabs CIP 19

Discoloration CIP 23

Corrosion of Steel in Concrete CIP 25

Discrepancies in Yield CIP 8

Low Concrete Cylinder Strength CIP 9

Thermal Cracking of Concrete CIP 42

Alkali Aggregate Reactions (AAR) CIP 43

Best Practices Series - 11 Topics BP

Ordering Ready Mixed Concrete CIP 31

Concrete Pre-Construction Conference CIP 32

Joints in Concrete Slabs on Grade CIP 6

Finishing Concrete Flatwork CIP 14

Curing In-Place Concrete CIP 11

Vapor Barriers Under Slabs On Grade CIP 29

Concrete Slab Moisture CIP 28

Cold Weather Concreting CIP 27

Hot Weather Concreting CIP 12

Alkali Aggregate Reactions CIP 43

Durability Requirements for Concrete CIP 44

RMC Value Series - 10 topics RMCV

Ordering Ready Mixed Concrete CIP 31

Supplementary Cementitious Materials CIP 30

Chemical Admixtures for Concrete CIP 15

Synthetic Fibers for Concrete CIP 24

High Strength Concrete CIP 33

Self Consolidating Concrete CIP 37

Structural Lightweight Concrete CIP 36

Pervious Concrete CIP 38

Flowable Fill Materials CIP 17

Grout CIP 22

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni2 pagineNRMC CIP 28p

Caricato da

PedjaTesting Series - 10 Topics TC

Jobsite Addition of Water CIP 26

Discrepancies in Yield CIP 8

Loss of Air Content In Pumped Concrete CIP 21

Acceptance Testing of Concrete CIP 41

Making Concrete Cylinders in the Field CIP 34

Testing Compressive Strength of Concrete CIP 35

Low Concrete Cylinder Strength CIP 9

Strength of In-Place Concrete CIP 10

Flexural Strength of Concrete CIP 16

Concrete Maturity CIP 39

Troubleshooting Series - 16 Topics TS

Cracking Concrete Surfaces CIP 4

Plastic Shrinkage Cracking CIP 5

Crazing Concrete Surfaces CIP 3

Cracks in Concrete Basement Walls CIP 7

Dusting Concrete Surfaces CIP 1

Scaling Concrete Surfaces CIP 2

Concrete Blisters CIP 13

Aggregate Popouts CIP 40

Delamination of Troweled Surfaces CIP 20

Curling of Concrete Slabs CIP 19

Discoloration CIP 23

Corrosion of Steel in Concrete CIP 25

Discrepancies in Yield CIP 8

Low Concrete Cylinder Strength CIP 9

Thermal Cracking of Concrete CIP 42

Alkali Aggregate Reactions (AAR) CIP 43

Best Practices Series - 11 Topics BP

Ordering Ready Mixed Concrete CIP 31

Concrete Pre-Construction Conference CIP 32

Joints in Concrete Slabs on Grade CIP 6

Finishing Concrete Flatwork CIP 14

Curing In-Place Concrete CIP 11

Vapor Barriers Under Slabs On Grade CIP 29

Concrete Slab Moisture CIP 28

Cold Weather Concreting CIP 27

Hot Weather Concreting CIP 12

Alkali Aggregate Reactions CIP 43

Durability Requirements for Concrete CIP 44

RMC Value Series - 10 topics RMCV

Ordering Ready Mixed Concrete CIP 31

Supplementary Cementitious Materials CIP 30

Chemical Admixtures for Concrete CIP 15

Synthetic Fibers for Concrete CIP 24

High Strength Concrete CIP 33

Self Consolidating Concrete CIP 37

Structural Lightweight Concrete CIP 36

Pervious Concrete CIP 38

Flowable Fill Materials CIP 17

Grout CIP 22

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

CIP 28 - Concrete Slab Moisture

WHAT is the Problem?

70

w/c = 0.40

Moisture Emission Rate, lb/1,000 sq ft/24 hr

60

Concrete slab moisture can cause problems with the w/c = 0.60

adhesion of floor-covering material, such as tile, sheet 50

w/c = 0.80

flooring, or carpet and bond-related failures of non-

40

breathable floor coatings. Many adhesives used for

installation of floor coverings are more water-sensitive 30

than in the past, due to restrictions on the use of volatile

organic compounds (VOCs). To warranty their products, 20

manufacturers require that the moisture emission from

10

the hardened concrete slab be less than some threshold

value prior to installing floor coverings or coatings. Fast- 0

track construction schedules exacerbate the problem 3 7 14 28 60 90 180 365

Time, days

when floor-surfacing material is installed before the

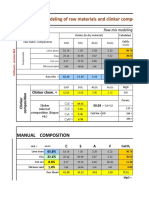

concrete slab has dried to an acceptable level. Figure 1 Drying rate of concretes sealed at the bottom (ref 3)

WHAT are the Sources of Concrete Slab Moisture?

a. Ground water sources and when the floor slab is in HOW do You Avoid Problems?

contact with saturated ground, or if drainage is poor.

Moisture moves to the slab surface by capillary action Avoiding problems associated with high moisture content

or wicking. Factors affecting this include depth of the in concrete can be accomplished by the following means:

water table and fineness of soil below the slab. Fine • Protect against ingress of water under hydrostatic pres-

grained soil promotes moisture movements from con- sure by ensuring that proper drainage away from the

siderable depths compared to coarser subgrade mate- slab is part of the design.

rial. • Use a 6 to 8 inch [150 to 200 mm] layer of coarse

gravel or crushed stone as a capillary break in loca-

b.Water vapor from damp soil will diffuse and condense

tions with fine-grained soil subgrades.

on a concrete slab surface that is cooler and at a lower

• Use a vapor retarder membrane under the slab to pre-

relative humidity due to a vapor pressure gradient.

vent water from entering the slab. Ensure that the va-

c.Wetting of the fill course/blotter layer, if any, between por retarder is installed correctly and not damaged dur-

the vapor retarder and the slab prior to placing the slab ing construction. Current recommendation of ACI

will trap moisture with the only possible escape route Committee 302 is to place the concrete directly on a

being through the slab. A blotter layer is not recom- vapor retarder for interior slabs on grade (CIP 29).

mended for interior slabs on grade (CIP 29). • Use a concrete mixture with a moderately low water-

d.Residual moisture in the slab from the original con- cementitious material (w/cm) ratio (about 0.50). This

crete mixing water will move towards the surface. It reduces the amount of residual moisture in the slab,

may take anywhere from six weeks to one year or will require a shorter drying period, and result in a

longer for a concrete slab to dry to an acceptable level lower permeability to vapor transmission. Water re-

under normal conditions, as illustrated in Figure 1. Fac- ducing admixtures can be used to obtain adequate

tors that affect the drying rate include the original wa- workability and maintain a low water content. The wa-

ter content of the concrete, type of curing, and the ter tightness of concrete can be improved by using fly

relative humidity and temperature of the ambient air ash or slag in the concrete mixture.

during the drying period. This is the only source of • Curing is an important step in achieving excellent hard-

moisture in elevated slabs. Any wetting of the slab af- ened concrete properties. However, moist curing will

ter final curing will elevate moisture levels within the increase drying time. As a compromise, curing the con-

slab and lengthen the drying period. crete under plastic sheeting for 3 days is recommended

and moist curing times greater than 7 days must be

avoided. Avoid using curing compounds on floors of the dry sample weight. This is rarely recommended

where coverings or coatings will be installed. by floor covering manufacturers.

• Allow sufficient time for the moisture in the slab to Nuclear Density and Radio Frequency - This nonde-

dry naturally while the floor is under a roof and pro- structive test instrument is relatively expensive and can

tected from the elements. Avoid maintenance and clean- take a long time to properly correlate correction factors

ing operations that will wet the concrete floor. Use for each individual project. The instrument has a radio-

heat and dehumidifiers to accelerate drying. Since mois- active source and therefore requires licensed operators.

ture transmission is affected by temperature and hu-

midity, maintain the actual service conditions for a long Anhydrous Calcium Chloride Test (ASTM F 1869) -

enough period prior to installing the floor covering. is specified by most floor covering manufacturers for

• Test the slab moisture condition prior to installing the pre installation testing. A measured amount of anhydrous

floor covering. calcium chloride is placed in a cup sealed under a plastic

dome on the slab surface and the amount of moisture

When concrete slab moisture cannot be controlled, con-

absorbed by the salt in 60 to 72 hours is measured to

sider using decorative concrete, less moisture-sensitive

floor coverings, breathable floor coatings, or install mois- calculate the moisture vapor emission rate (MVER).

Maximum limits of vapor transmission generally speci-

ture vapor suppression systems (topical coatings).

fied are 3 to 5 pounds of moisture per 1000 square feet

HOW is Concrete Slab Moisture Measured? per 24 hours. This test is relatively inexpensive, and yields

a quantitative result. However, it has some major short-

Various qualitative and quantitative methods of measur- comings: it determines only a portion of the free mois-

ing concrete slab moisture are described in ASTM E 1907. ture at a shallow depth of concrete near the surface of

Test the moisture condition of the slab in the same tem- the slab. The test is sensitive to the temperature and hu-

perature and humidity conditions as it will be in service. midity in the building. It provides only a “snapshot in

In general, test at three random sample locations for ar- time” of current moisture conditions and does not pre-

eas up to 1000 sq. ft. [100 m2] and perform one addi- dict if the sub-slab conditions will cause a moisture prob-

tional test for each additional 1,000 sq ft. Ensure that the lem later in the life of the floor.

surface is dry and clean. Record the relative humidity Relative Humidity Probe (ASTM F 2170) – This pro-

and temperature at the time of testing. Some of the com- cedure involves measuring the relative humidity of con-

mon tests are: crete at a specific depth from the slab surface inside a

Polyethylene Sheet Test (ASTM D 4263) - is a simple drilled or cast hole in a concrete slab. The relative hu-

qualitative test, where an 18 by 18 inch [450 by 450 midity is measured after allowing 72 hours to achieve

mm] square plastic sheet is taped tightly to the concrete moisture equilibrium within the hole. Typically a relative

and left in place for a at least 16 hours. The presence of humidity of 75% to 80% is targeted for installation of

moisture under the plastic sheet is a positive indication floor coverings. Relative humidity probes can determine

that excess moisture is likely present in the slab. How- the moisture profile from top to bottom in a slab, condi-

ever, a negative indication is not an assurance that the tions below the slab, and can monitor the drying of a

slab is acceptably dry below the surface. slab over time, leading to predictions of future moisture

conditions. These instruments have been used for many

Mat Test - where the adhesive intended for use is ap- years in Europe and are becoming more popular in the

plied to a 24 by 24 inch [600 by 600 mm] area and a United States.

sheet vinyl flooring product is placed face down on the

adhesive and sealed at the edges. A visual inspection of References

the condition of the adhesive is made after a 72-hour 1. Guide to Concrete Floor and Slab Construction, ACI 302.1R,

period. This test is no longer favored since it can pro- American Concrete Institute, Farmington Hills, MI.

duce false negative results. 2. ASTM Standards E 1907, F 1869, D 4263, F 2170, ASTM

International, West Conshohocken, PA, www.astm.org.

Test Strip – in which a test strip of the proposed primer

3. Bruce Suprenant, Moisture Movement Through Concrete Slabs,

or adhesive is evaluated for 24 hours to predict its be-

Concrete Construction, November 1997.

havior on the floor. This procedure is not very reliable.

4. Bruce Suprenant, Design of Slabs that Receive Moisture-Sen-

Moisture meters – Measure electrical resistance or im- sitive Floor Coverings, Concrete International, Vol. 25, No. 3,

pedance to indicate slab moisture. Electronic meters can April 2003, www.concrete.org.

be useful survey tools that provide comparative read- 5. Thomas K. Butt, Avoiding and Repairing Moisture Problems

ings across a floor but should not be used to accept or in Slabs on Grade, The Construction Specifier, December,

reject a floor because they do not provide an absolute 1992.

measure of moisture conditions within the slab. 6. Malcolm Rode and Doug Wendler, Methods for Measuring

Gravimetric - This is a direct and accurate method of Moisture Content in Concrete, Concrete Repair Bulletin,

determining moisture content by weight in the concrete March-April, 1996.

slab. Pieces of concrete are removed by chiseling or 7. Steven H. Kosmatka, Floor-Covering Materials and Moisture

stitch-drilling and dried in an oven to constant weight. in Concrete, Portland Cement Association, Skokie, IL,

The moisture content is then calculated as a percentage www.cement.org.

2004

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- PrEN 13043 - Aggregates For Bituminous Mixtures and SurfaceDocumento45 paginePrEN 13043 - Aggregates For Bituminous Mixtures and SurfacePedja100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Petar Subotic - Prirucnik Za Asfalt I DeoDocumento308 paginePetar Subotic - Prirucnik Za Asfalt I DeoPedjaNessuna valutazione finora

- PrEN 12273 - Slurry Surfacing - Product StandardDocumento25 paginePrEN 12273 - Slurry Surfacing - Product StandardPedjaNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Cement Calculus 28Documento2 pagineCement Calculus 28PedjaNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- PrEN 13020 - Road Surface Treatment MachinesDocumento20 paginePrEN 13020 - Road Surface Treatment MachinesPedjaNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Klinker Composition CalculationProt 231bDocumento28 pagineKlinker Composition CalculationProt 231bPedjaNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Aggregate Pop OutDocumento0 pagineAggregate Pop Outتوان امتياس سامسدينNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Matematika Jedan Nikic Comic RP22Documento152 pagineMatematika Jedan Nikic Comic RP22PedjaNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- PrEN 12271-10 - Factory Production ControlDocumento17 paginePrEN 12271-10 - Factory Production ControlPedjaNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- NRMC CIP 44prDocumento2 pagineNRMC CIP 44prPedjaNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Maturity Method To Estimate Concrete StrengthDocumento2 pagineMaturity Method To Estimate Concrete StrengthRV Vimal100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- NRMC CIP 13pDocumento2 pagineNRMC CIP 13pPedjaNessuna valutazione finora

- PrEN 12271 - Surface DressingDocumento54 paginePrEN 12271 - Surface DressingPedjaNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- NRMC CIP 32pDocumento2 pagineNRMC CIP 32pPedjaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- NRMC CIP 23pDocumento2 pagineNRMC CIP 23pPedjaNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- NRMC CIP 29pDocumento2 pagineNRMC CIP 29pPedjaNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- CIP35 - Testing Compressive Strength of ConcreteDocumento2 pagineCIP35 - Testing Compressive Strength of ConcreteGerardo BeckerNessuna valutazione finora

- High Strength ConcreteDocumento0 pagineHigh Strength ConcreteAris Co AbergosNessuna valutazione finora

- GuidelinesDocumento2 pagineGuidelinesMike2322Nessuna valutazione finora

- Cold Weather ConcretingDocumento2 pagineCold Weather ConcretingBoris DikovNessuna valutazione finora

- NRMC CIP 20pDocumento2 pagineNRMC CIP 20pPedjaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- NRMC CIP 17pDocumento2 pagineNRMC CIP 17pPedjaNessuna valutazione finora

- NRMC CIP 26pDocumento2 pagineNRMC CIP 26pPedjaNessuna valutazione finora

- NRMC CIP 43pDocumento2 pagineNRMC CIP 43pPedjaNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- NRMC CIP 18pDocumento2 pagineNRMC CIP 18pPedjaNessuna valutazione finora

- STANDARD SPECIFICATIONS For HIGHWAY BRIDGESDocumento0 pagineSTANDARD SPECIFICATIONS For HIGHWAY BRIDGESتوان امتياس سامسدينNessuna valutazione finora

- CIP 12 Hot Weather ConcretingDocumento2 pagineCIP 12 Hot Weather ConcretingTim_CNessuna valutazione finora

- CIP 19 - Curling of Concrete SlabsDocumento2 pagineCIP 19 - Curling of Concrete SlabsMaestroColicus100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Finishing Concrete FlatworkDocumento0 pagineFinishing Concrete Flatworkتوان امتياس سامسدينNessuna valutazione finora

- D 6054 - 97 - Rdywntq - PDFDocumento3 pagineD 6054 - 97 - Rdywntq - PDFwilliamNessuna valutazione finora

- 1 s2.0 S0023643818308491 MainDocumento8 pagine1 s2.0 S0023643818308491 Mainzeyin mohammed aumerNessuna valutazione finora

- Autodesk Sustainability Workshop-Building Design ConceptsDocumento14 pagineAutodesk Sustainability Workshop-Building Design ConceptsNaveen KishoreNessuna valutazione finora

- Atlas Copco-Basic Product TrainingDocumento42 pagineAtlas Copco-Basic Product TrainingArstNessuna valutazione finora

- Jeffrey C. May - My House Is Killing Me! - The Home Guide For Families With Allergies and Asthma-The Johns Hopkins University Press (2001)Documento353 pagineJeffrey C. May - My House Is Killing Me! - The Home Guide For Families With Allergies and Asthma-The Johns Hopkins University Press (2001)Jose Malaga100% (1)

- Q2 ch125P RetakeDocumento5 pagineQ2 ch125P RetakeFlorenceNessuna valutazione finora

- Si70 H T S D ' G: XX Umidity AND Emperature Ensor Esigner S UideDocumento41 pagineSi70 H T S D ' G: XX Umidity AND Emperature Ensor Esigner S UidejunkcanNessuna valutazione finora

- Module 1 - AirconDocumento8 pagineModule 1 - AirconSamuel ArzadonNessuna valutazione finora

- CH1104 Chapter 8Documento90 pagineCH1104 Chapter 8Chuah Chong YangNessuna valutazione finora

- Journal of Thermal Biology: A C A A B C B BDocumento9 pagineJournal of Thermal Biology: A C A A B C B BTrần TùngNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Water Vapor Transmission of Organic Coating Films: Standard Test Methods ForDocumento5 pagineWater Vapor Transmission of Organic Coating Films: Standard Test Methods ForROHITNessuna valutazione finora

- SYS-APG001-EN - Application Guide - Designing Dedicated Outdoor-Air Systems - 2003Documento24 pagineSYS-APG001-EN - Application Guide - Designing Dedicated Outdoor-Air Systems - 2003samir rabia100% (1)

- Direct Digital Control of Air Humidity For Plant ResearchDocumento10 pagineDirect Digital Control of Air Humidity For Plant ResearchMohsin ShaikhNessuna valutazione finora

- 922 Water ActivityDocumento8 pagine922 Water ActivityRajib Kumar BaishnabNessuna valutazione finora

- Q2 Retake CHe 111P 4Th Q 2016-17Documento6 pagineQ2 Retake CHe 111P 4Th Q 2016-17Mateo PremarionNessuna valutazione finora

- D 100818 EnfwfwwwfDocumento108 pagineD 100818 Enfwfwwwfkhalisa khal100% (1)

- Unit Operations in Food Processing: 5. Drying of SolidsDocumento32 pagineUnit Operations in Food Processing: 5. Drying of SolidsDavid KocarevNessuna valutazione finora

- DocumentDocumento5 pagineDocumentadithimatekk 99Nessuna valutazione finora

- Building Innovations: A Magazine For ArchitectsDocumento43 pagineBuilding Innovations: A Magazine For ArchitectsZachary EllisNessuna valutazione finora

- Heat Load Class 100KDocumento20 pagineHeat Load Class 100KIsrael MuhiNessuna valutazione finora

- RAC Qualifying ExamDocumento9 pagineRAC Qualifying ExamVirg Sci-hiNessuna valutazione finora

- Drying: - Removal of Relatively Small Amount of Water or Organic Liquids - Final Processing Step Before PackagingDocumento124 pagineDrying: - Removal of Relatively Small Amount of Water or Organic Liquids - Final Processing Step Before PackagingMiscrit Man100% (1)

- Principles of The Refrigeration CycleDocumento22 paginePrinciples of The Refrigeration CycleKarl AttardNessuna valutazione finora

- LM230WF5 TLD1 PDFDocumento31 pagineLM230WF5 TLD1 PDF'RomNessuna valutazione finora

- Technical Standards and Protocol For The Cold Chain in IndiaDocumento95 pagineTechnical Standards and Protocol For The Cold Chain in IndiaMandeep1190100% (2)

- Ethylene Oxide Gas Sterilization ProcessDocumento20 pagineEthylene Oxide Gas Sterilization ProcessBERNADETH YOSTEFANYNessuna valutazione finora

- Psychrometric ChartDocumento39 paginePsychrometric ChartSalley BukhariNessuna valutazione finora

- Otodectes Cynotis (Acari PsoroptidaeDocumento9 pagineOtodectes Cynotis (Acari PsoroptidaeMaJose Madrid CNessuna valutazione finora

- MPCBDocumento21 pagineMPCBDheeraj YadavNessuna valutazione finora

- The Straw Bale House: Not For The Eastern United StatesDocumento11 pagineThe Straw Bale House: Not For The Eastern United StatesJelena SimanjicNessuna valutazione finora

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Da EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Valutazione: 4 su 5 stelle4/5 (17)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingDa EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingValutazione: 4.5 su 5 stelle4.5/5 (845)

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyDa EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyValutazione: 4 su 5 stelle4/5 (277)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterDa EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterValutazione: 4 su 5 stelle4/5 (467)

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeDa EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeValutazione: 5 su 5 stelle5/5 (2)

- Survival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosDa EverandSurvival Mom: How to Prepare Your Family for Everyday Disasters and Worst-Case ScenariosValutazione: 3.5 su 5 stelle3.5/5 (8)

- Simplified Organization: Learn to Love What Must Be DoneDa EverandSimplified Organization: Learn to Love What Must Be DoneNessuna valutazione finora