Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ingres Eng

Caricato da

Kakiko0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

14 visualizzazioni2 pagineingres pencils

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoingres pencils

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

14 visualizzazioni2 pagineIngres Eng

Caricato da

Kakikoingres pencils

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

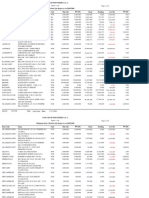

Ingres

description Uncoated laid papers, made with e.c.f. pulp. Pulp-dyed with

light-fast colours. Available in five shades.

range size grain substance

70x100 LG 90 160

technical features substance VSA opacity* roughness

ref. standard/instrument ISO 536 ISO 534 ISO 2471 ISO 8791-2

unit of measure g/m2 cm3/g % ml/min

90 ± 3% 1,4 94 ± 2 1100 ± 300

160 ± 4% 1,4 98 ± 2 1500 ± 300

Brightness (col. Ghiaccio) ISO 2470 (R457) - 94% ± 2

Brightness ( col. Bianco) ISO 2470 (R457) - 70 % ± 2

Relative Humidity 50% ± 5 ref. TAPPI 502-98

* for Bianco shade

ecological features

notes The products could show light differences in papershade

and look due to natural raw materials used. The product is

completely biodegradable and recyclable. Special runs available

upon request.

Fabriano is a trademark of Fedrigoni SpA

The Company reserves the right to modify the technological features of the product in relation to market requirements.

UNI EN ISO 9001:2008 - CQ 539 Product Data Sheet VER/620

UNI EN ISO 14001:2004 - CQ 7847 Update 07/2012

BSI - OHSAS 18001:2007 - CQ 15229 Rev. n° 01

Ingres is ideal for writing papers, corporate image and social applications

communication, elegant monographs, de luxe publications, art

reproductions, list, agendas and image coordinated.

We remember that the paper, as the other laid papers, presents

a characteristical two sidedness marking which increases

proportionally with the substance. The “Laid lines”, the most

accented lines, 26 millimitres far from each other, are parallel

to the grain direction (side 100).

Grain direction

Can be used without problems with the main printing systems: printing

suggestions

letterpress, offset, blind embossing, hot foil stamping,

thermography and screen printing. The macro-porous surface

suggests the use of oxidative drying inks.

Varnishing and plastic laminating must be assessed in advance. converting

suggestions

The varnish coated with an offset machine is almost fully

absorbed and therefore it does not improve gloss or protection.

Screen-printing varnishing achieves better results, although it

is often necessary to perform two shots to achieve a distinctly

evident result. The lamination is not recommended. Good

results with major processing operations such as: cutting, die-

cutting, scoring, folding and glueing.

Potrebbero piacerti anche

- 75-75 MARATHON-75 SEA PRO-90 - 100-115-125-65-80 JET With Serial Numbers United States - 0D283222 and Above Belgium - 09793577 and Above PDFDocumento585 pagine75-75 MARATHON-75 SEA PRO-90 - 100-115-125-65-80 JET With Serial Numbers United States - 0D283222 and Above Belgium - 09793577 and Above PDFjay hixNessuna valutazione finora

- Material Schedule TypicalDocumento3 pagineMaterial Schedule TypicalMwesigwa DaniNessuna valutazione finora

- Hempadur 45070 Product Data SheetDocumento3 pagineHempadur 45070 Product Data Sheetarjunmohanan50% (2)

- Jotun Jota Ep Mastic 66Documento4 pagineJotun Jota Ep Mastic 66Abi PutraNessuna valutazione finora

- ARC 213 History of Architecture Lecture NotesDocumento137 pagineARC 213 History of Architecture Lecture NotesMar Cariaga Opeña57% (7)

- Jotaguard 100: Technical Data SheetDocumento6 pagineJotaguard 100: Technical Data SheetHector MacavilcaNessuna valutazione finora

- As 1125Documento25 pagineAs 1125Quantudogon DangNessuna valutazione finora

- Build Custom PickupsDocumento6 pagineBuild Custom PickupsKakikoNessuna valutazione finora

- Company AddDocumento37 pagineCompany Addapi-3745493100% (3)

- 1Documento96 pagine1Habina ZoranNessuna valutazione finora

- Cocktail enDocumento2 pagineCocktail enNikolche MitrikjevskiNessuna valutazione finora

- Symbol Card Eco 100Documento2 pagineSymbol Card Eco 100nita.kurniaNessuna valutazione finora

- Gloss80 HM300 YG62Documento2 pagineGloss80 HM300 YG62Vkaka AtanasoftNessuna valutazione finora

- Symbol CardDocumento2 pagineSymbol Cardnita.kurniaNessuna valutazione finora

- Matt80 HM100 WG62Documento2 pagineMatt80 HM100 WG62Mahmud RezaNessuna valutazione finora

- Invercote GDocumento2 pagineInvercote Gmohamed fayedNessuna valutazione finora

- MetsBoard Pro FBB Bright_ISO_en-GBDocumento1 paginaMetsBoard Pro FBB Bright_ISO_en-GBRAFAEL FLORESNessuna valutazione finora

- METSABOARDDocumento1 paginaMETSABOARDAlex GonzalezNessuna valutazione finora

- Internal Product Information and Specifications for Premium PrintDocumento1 paginaInternal Product Information and Specifications for Premium PrintKurnia IndahNessuna valutazione finora

- VintackWhite90WSDocumento1 paginaVintackWhite90WSRoger Martí GonzalvoNessuna valutazione finora

- Paperone Script SpecDocumento1 paginaPaperone Script SpecChe MysterNessuna valutazione finora

- Hempadur 47140Documento4 pagineHempadur 47140Hung NGUYEN SYNessuna valutazione finora

- JlikhjhhbDocumento1 paginaJlikhjhhbcaaelestisNessuna valutazione finora

- Rodenburg Biopolymers-Solanyl® C8001Documento4 pagineRodenburg Biopolymers-Solanyl® C8001Xuân Giang NguyễnNessuna valutazione finora

- Multi FineDocumento2 pagineMulti FinehheeggNessuna valutazione finora

- Jotamastic 80.TDS - EngDocumento5 pagineJotamastic 80.TDS - EngchepurthiNessuna valutazione finora

- Penguard HSP MIO E: Technical Data SheetDocumento5 paginePenguard HSP MIO E: Technical Data Sheethardik033Nessuna valutazione finora

- Jotamastic 80: Technical Data SheetDocumento14 pagineJotamastic 80: Technical Data SheetCv RONATAMA GUSLHANNessuna valutazione finora

- Jotatop BC800 加强型聚氨酯叶片涂料 (0K9) United Kingdom - EnglishDocumento5 pagineJotatop BC800 加强型聚氨酯叶片涂料 (0K9) United Kingdom - Englishlong chanNessuna valutazione finora

- TDS Phi 003Documento2 pagineTDS Phi 003dalgido rojano quirozNessuna valutazione finora

- Treofan TDSDocumento1 paginaTreofan TDSAvichai MarcoviciNessuna valutazione finora

- 21020 - TDS E 006Documento2 pagine21020 - TDS E 006Paolo VelasquezNessuna valutazione finora

- TDS SolvalittDocumento5 pagineTDS Solvalittheru firmansyahNessuna valutazione finora

- Jotamastic 87 GFDocumento5 pagineJotamastic 87 GFBiju_PottayilNessuna valutazione finora

- TDS - Paper WS - Niklakett - Medium - PlusDocumento1 paginaTDS - Paper WS - Niklakett - Medium - PlusSundar MoorthiNessuna valutazione finora

- Neopress ArapotiDocumento1 paginaNeopress ArapotihheeggNessuna valutazione finora

- Jotamastic 80: Technical Data SheetDocumento5 pagineJotamastic 80: Technical Data SheetSafinahNessuna valutazione finora

- Jotamastic 87 MIO50Documento5 pagineJotamastic 87 MIO50Biju_PottayilNessuna valutazione finora

- Material PVC WhiteDocumento3 pagineMaterial PVC WhiteSharan KumarNessuna valutazione finora

- Epoxy HR: Technical Data SheetDocumento5 pagineEpoxy HR: Technical Data SheetOrgünOzarNessuna valutazione finora

- Technical Data Sheet (ABS)Documento7 pagineTechnical Data Sheet (ABS)Kelvin Tai Wei LimNessuna valutazione finora

- Hanno Art SilkDocumento1 paginaHanno Art SilkhheeggNessuna valutazione finora

- Tankguard SF: Technical Data SheetDocumento5 pagineTankguard SF: Technical Data SheetRifki ArifinNessuna valutazione finora

- Hempadur Primer 1530yDocumento4 pagineHempadur Primer 1530yRodrigo CondorettyNessuna valutazione finora

- Marathon 1000XHB Technical Data SheetDocumento5 pagineMarathon 1000XHB Technical Data SheetGurdeep Sungh AroraNessuna valutazione finora

- Upgrade Your Recycled Plastic JoncrylDocumento8 pagineUpgrade Your Recycled Plastic JoncrylPopolupus100% (1)

- Technical Data Sheet: DescriptionDocumento5 pagineTechnical Data Sheet: DescriptiongldiasNessuna valutazione finora

- Jota EP15 快干环氧底漆 (6VM) (United Kingdom - English)Documento5 pagineJota EP15 快干环氧底漆 (6VM) (United Kingdom - English)long chanNessuna valutazione finora

- Sociedad ImportadoraDocumento2 pagineSociedad Importadoraelia la torreNessuna valutazione finora

- Jotamastic 80: Technical Data SheetDocumento5 pagineJotamastic 80: Technical Data SheetArif dwi prasetyoNessuna valutazione finora

- MetsBoard Natural FBB_ISO_en-GBDocumento1 paginaMetsBoard Natural FBB_ISO_en-GBRAFAEL FLORESNessuna valutazione finora

- TDS - Tankguard Storage - Issued 04.08.2014Documento5 pagineTDS - Tankguard Storage - Issued 04.08.2014Arya Kemal Pratama PutraNessuna valutazione finora

- Ultimaker ABS (TDS)Documento3 pagineUltimaker ABS (TDS)reinaldolubeNessuna valutazione finora

- FP111 Super Perga WS Opaque ParchmentDocumento2 pagineFP111 Super Perga WS Opaque ParchmentNuri YucelNessuna valutazione finora

- TZ 18 NewDocumento58 pagineTZ 18 NewHans LoonenNessuna valutazione finora

- Terrapress ArapotiDocumento1 paginaTerrapress ArapotihheeggNessuna valutazione finora

- Jota EP15P 快干环氧底漆EP15P(0XT) (United Kingdom - English)Documento5 pagineJota EP15P 快干环氧底漆EP15P(0XT) (United Kingdom - English)long chanNessuna valutazione finora

- Intershield803 MDSDocumento4 pagineIntershield803 MDSSahanNessuna valutazione finora

- Carta Integra 0105Documento1 paginaCarta Integra 0105mohamed fayedNessuna valutazione finora

- Semi Gloss C80 RAA-41 GL62YDocumento1 paginaSemi Gloss C80 RAA-41 GL62YIván CsörgőNessuna valutazione finora

- Epoxy HRDocumento5 pagineEpoxy HRMuthuKumarNessuna valutazione finora

- TDS 15360 Jotacote+Universal+N10 Euk GBDocumento5 pagineTDS 15360 Jotacote+Universal+N10 Euk GBIsyfi QulubanaNessuna valutazione finora

- Industrial Inorganic PigmentsDa EverandIndustrial Inorganic PigmentsGunter BuxbaumValutazione: 5 su 5 stelle5/5 (1)

- Analisys and application of dry cleaning materials on unvarnished pain surfacesDa EverandAnalisys and application of dry cleaning materials on unvarnished pain surfacesNessuna valutazione finora

- Functional Fillers for PlasticsDa EverandFunctional Fillers for PlasticsMarino XanthosNessuna valutazione finora

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsDa EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNessuna valutazione finora

- XLR Mic CablesDocumento6 pagineXLR Mic CablesKakikoNessuna valutazione finora

- The 10 Best Studio Monitors for Home Recording Under 40 CharactersDocumento7 pagineThe 10 Best Studio Monitors for Home Recording Under 40 CharactersKakikoNessuna valutazione finora

- DeadlyDocumento1 paginaDeadlyKakikoNessuna valutazione finora

- What A Nice SiteDocumento1 paginaWhat A Nice SiteKakikoNessuna valutazione finora

- A Meta Study On Pillow SupportDocumento1 paginaA Meta Study On Pillow SupportKakikoNessuna valutazione finora

- DeadlyDocumento1 paginaDeadlyKakikoNessuna valutazione finora

- This Is MyDocumento1 paginaThis Is MyKakikoNessuna valutazione finora

- For EverythinDocumento1 paginaFor EverythinKakikoNessuna valutazione finora

- For EverythinxDocumento1 paginaFor EverythinxKakikoNessuna valutazione finora

- For EverDocumento1 paginaFor EverKakikoNessuna valutazione finora

- Thank You For All Your PatienceDocumento1 paginaThank You For All Your PatienceKakikoNessuna valutazione finora

- For EverythiDocumento1 paginaFor EverythiKakikoNessuna valutazione finora

- For EverythingDocumento1 paginaFor EverythingKakikoNessuna valutazione finora

- ThnksDocumento1 paginaThnkssantosh1318Nessuna valutazione finora

- ThnksDocumento1 paginaThnkssantosh1318Nessuna valutazione finora

- S-P-01440 EPD Polyester FabricsDocumento12 pagineS-P-01440 EPD Polyester FabricssimaproindiaNessuna valutazione finora

- ICE PPT v1Documento16 pagineICE PPT v1Alessio ScarabelliNessuna valutazione finora

- Utter Chaos InstructionsDocumento9 pagineUtter Chaos InstructionsDavid JannkeNessuna valutazione finora

- HL300 Rock Drill - Sandvik Mining & Rock TechnologyDocumento2 pagineHL300 Rock Drill - Sandvik Mining & Rock TechnologymegamNessuna valutazione finora

- Retrofit Additional BatteryDocumento3 pagineRetrofit Additional BatteryAnonymous F4tPbieYEGNessuna valutazione finora

- Sheet Forming Processes ExplainedDocumento4 pagineSheet Forming Processes ExplainedRikhil YalamanchiNessuna valutazione finora

- BNO055 9DOF DatasheetDocumento119 pagineBNO055 9DOF DatasheetPaola HasmannNessuna valutazione finora

- E210 OldDocumento2 pagineE210 OldCoreconNessuna valutazione finora

- Automatic Door Closer Project SynopsisDocumento5 pagineAutomatic Door Closer Project SynopsisAnonymous yhZOSs983Nessuna valutazione finora

- Magma's FineSim Deployed by Toshiba Corporation For AdvancedDocumento5 pagineMagma's FineSim Deployed by Toshiba Corporation For Advancedshruthi1845Nessuna valutazione finora

- L1 Estimating Process MethodsDocumento23 pagineL1 Estimating Process MethodsMirzanusNessuna valutazione finora

- Study of Implementing 5S Techniques inDocumento4 pagineStudy of Implementing 5S Techniques inعزالدين الحسينيNessuna valutazione finora

- Iec 61850Documento18 pagineIec 61850Ricardo DoldanNessuna valutazione finora

- Gate 1533Documento7 pagineGate 1533Darshit D RajNessuna valutazione finora

- Reverse EngineeringDocumento3 pagineReverse EngineeringRahul SureshNessuna valutazione finora

- MSDS Copper Sulfate PentahydrateDocumento2 pagineMSDS Copper Sulfate PentahydrateciscaNessuna valutazione finora

- Moq20 05 09Documento6 pagineMoq20 05 09vassim123Nessuna valutazione finora

- Thermodynamic Architecture for Sustainable Port StructuresDocumento2 pagineThermodynamic Architecture for Sustainable Port StructuresNiña Jayne GurangoNessuna valutazione finora

- General Information: Shutdown SIS Previous ScreenDocumento9 pagineGeneral Information: Shutdown SIS Previous ScreencacafaruqNessuna valutazione finora

- Ghomes - Techincal Design - 25 Dec PDFDocumento350 pagineGhomes - Techincal Design - 25 Dec PDFTanluan NguyenNessuna valutazione finora

- Biofuels From AlgaeDocumento2 pagineBiofuels From AlgaeAdolphout HNessuna valutazione finora

- Cad Cam - 22.12.15-1 PDFDocumento87 pagineCad Cam - 22.12.15-1 PDFGuru MaheshNessuna valutazione finora

- Project Specifications SummaryDocumento3 pagineProject Specifications SummaryAe PocotNessuna valutazione finora