Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CBLM Final1

Caricato da

Victor RosalesCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CBLM Final1

Caricato da

Victor RosalesCopyright:

Formati disponibili

Competency Based Learning Materials

Sector: ELECTRICAL & ELECTRONICS SECTOR

Qualification Title:

ELECTRICAL AND INSTALLATION MAINTENANCE NC II

Unit of Competency:

Install Wiring Devices of Floor and Wall Mounted Outlets, Lighting

Fixtures/Switches, and Auxiliary Outlets

Module Title:

Installing Wiring Devices of Floor and Wall Mounted Outlets,

Lighting Fixtures/Switches, and Auxiliary Outlets

UNIVERSITY OF SCIENCE AND TECHNOLOGY

COLLEGE OF SCIENCE AND TECHNOLOGY EDUCATION

Cagayan de Oro Campus, Lapasan, CDO City

ELECTRICAL AND INSTALLATION

MAINTENANCE NC II

HOW TO USE THIS COMPETENCY BASED LEARNING

MATERIALS

Welcome to the module in “Installing Wiring Devices of Floor and

Wall Mounted Outlets, Lighting Fixtures/Switches, and Auxiliary

Outlets”. This module contains training materials and activities for you to

complete.

The unit of competency “Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting Fixtures/Switches, and Auxiliary Outlets”

contains knowledge, skills and attitudes required for Electrical and

Installation MaintenanceNC II.

You are required to go through a series of learning activities in order to

complete each learning outcome of the module. In each learning outcome

there are Information Sheets, Self-Checks, Task Sheet and Job Sheets.

Follow these activities on your own. If you have questions, don’t hesitate to

ask your facilitator for assistance.

Recognition of Prior Learning (RPL)

You may already have some or most of the knowledge and skills covered

in this learner’s guide because you have:

□ been working for some time

□ already completed training in this area.

If you can demonstrate to your trainer that you are competent in a

particular skill or skills, talk him/her about having them formally recognized

so you don’t have to do the same training again. If you have a qualification

certificate or Certificate of Competency from previous trainings, show it to

your trainer. If the skills you are acquired are still current and relevant to the

unit/s of competency they may become part of the evidence you can present

for RPL. If you are not sure about the currency of your skills discuss this with

your trainer.

This module was prepared to help you achieve the required competency,

in Electrical Installation and Maintenance NC II. This will be the source

of information for to acquire knowledge and skills in this particular trade

independently and at your own pace, with minimum supervision or help from

your instructor.

Remember to:

□ Talk to your trainer and agree on how you will both organize the Training of

this unit. Read through the modules carefully. It is divided into sections,

which cover all kind the skills and knowledge you need to successfully

complete this module

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 2 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

□ Work through all information and complete the activities in each section.

Read information sheets and complete the self-check. Suggested references

are included to supplement the materials provided in this module.

□ Most probably your trainer will also be your supervisor or manager. He/she

is there to support you and show you the correct way to do things.

□ Your trainer will tell you about the important things you need to consider

when you are completing activities and it is important that you will listen and

take notes.

□ You will be given plenty of opportunities to ask questions and practice on

the job. Make sure you practice your new skills during regular work shifts.

This way you will improved both your speed and memory and also your

confidence.

□ Talk to more experience workmates and ask for their guidance.

□ Used the self-check questions at the end of each section to test your own

progress.

□ When you are ready, ask your trainer to watch you perform the activities

outlined in this module.

□ As you work through the activities, ask for written feedback on your

progress. Your trainer keeps feedback/ pre-assessment reports for this

reason. When you have successfully completed each element, ask your trainer

to mark on the reports that you are ready for assessment.

□ When you have completed this module (or several modules), and feel

confident that you have had sufficient practice, your trainer will arrange an

appointment with registered assessor to assess you. The results of your

assessment will be recorded in your Competency Achievement Record.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 3 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

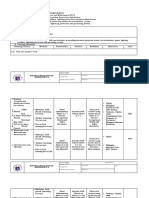

Electrical and Installation MaintenanceNC II

List of Competencies

No. Unit of Competency Module Title Code

Perform roughing-in Performing roughing-in

activities, wiring and activities, wiring and

cabling works for single- cabling works for single-

1. ELC741301

phase distribution, phase distribution, power,

power, lighting and lighting and auxiliary

auxiliary systems systems

Install electrical Installing electrical

protective devices for protective devices for

distribution, power, distribution, power, ELC741302

2. lighting, auxiliary, lighting, auxiliary,

lightning protection and lightning protection and

grounding systems grounding systems

Install wiring devices Installing wiring devices

of floor and wall of floor and wall ELC741303

mounted outlets, mounted outlets,

3.

lighting fixtures/ lighting fixtures/

switches, and switches, and auxiliary

auxiliary outlets outlets

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 4 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

MODULE CONTENT

UNIT OF COMPETENCY: Install Wiring Devices of Floor and Wall Mounted

Outlets, Lighting Fixtures/Switches, and

Auxiliary Outlets

MODULE TITLE : Installing Wiring Devices of Floor and Wall

Mounted Outlets, Lighting Fixtures/Switches,

and Auxiliary Outlets

MODULE DESCRIPTOR:

This module covers the knowledge, skills and attitudes on

selecting and installing wiring devices, installing lighting fixtures/switches

and notifying completion of work of floor and wall mounted outlets and

auxiliary outlets.

NOMINAL DURATION: 60 hours

LEARNING OUTCOMES:

At the end of this module you MUST be able to:

1. Select wiring devices

2. Install wiring devices

3. Install lighting fixture/switches

4. Notify completion of work

ASSESSMENT CRITERIA:

1. Drawings are read and interpreted to determine job requirements

2. Correct type and quantity of wiring devices and consumable items are

identified in line with job requirements

3. Tools and equipment are selected in line with job requirements

4. Correct PPE are identified and selected in line with safety requirements

5. Safety procedures are followed based on safety regulations

6. Correct procedures for installation of wiring devices are performed in

line with job requirements

7. Schedule of work is followed based on agreed time, quality standard

and minimum wastage

8. Further instructions are sought if unplanned events or conditions

occur

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 5 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

9. On-going checking of quality of work is done in accordance with

instructions and requirements.

10. Safety procedures are followed

11. Correct procedures for installation of lighting fixtures/switches

are performed in line with job requirements

12. Schedule of work is followed to ensure work is completed in an

agreed time, to a quality standard and with a minimum waste

13. Further instructions are sought from a supervisor if unplanned

events or conditions occur

14. On-going checks of quality of work are undertaken in accordance

with instructions and requirements

15. Final checks are made to ensure that work conforms with

instructions and to requirements.

16. Supervisor is notified upon completion of work

17. Tools, equipment and any surplus resources and materials are,

where appropriate, cleaned, checked and returned to storage in

accordance with established procedures

18. Work area is cleaned and made safe

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 6 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

LEARNING OUTCOME SUMMARY

Learning Outcome # 1: Select wiring devices

CONTENTS:

1. Types and uses of electrical wiring devices

2. Classification of Wiring devices

3. Proper PPEs

ASSESSMENT CRITERIA:

1. Drawings are read and interpreted to determine job requirements

2. Correct type and quantity of wiring devices and consumable items are

identified in line with job requirements

3. Tools and equipment are selected in line with job requirements

4. Correct PPE are identified and selected in line with safety

requirements

CONDITIONS:

Students/trainees must be provided with the following:

• Equipment • Supplies and Materials

o Simulated work place or o Wiring devices

actual work place

o ladder

• Learning Materials

o Learning elements

• Tools o Drawing plan

o Linesman’s pliers o Books, manuals, and

o Long nose pliers catalogs

o Diagonal cutting pliers o Philippine Electrical Code

o Bar level

o Screw drivers,

o Set of screw drivers

o Chisel

METHODOLOGIES:

1. Demonstration

2. Discussion

3. Practical exercises

4. Laboratory exercises

5. Audio/Visual film showing

ASSESSMENT METHODS:

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 7 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

1. Direct observation of application of tasks

2. Questions related to underpinning knowledge

3. Demonstration/Practical activity

4. Written test

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 8 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Learning Experiences

Learning Outcome # 1 : Select wiring devices

Learning Activities Special Instructions

Read Information Sheet 3.2-1 on Read and understand the

Wiring Devices: Floor and GFCI information sheet and check yourself

Outlets by answering the Self-check. You

must answer all the questions

correctly before proceeding to the

next activity.

Answer Self Check 3.2-1 If you score 100% upon comparing

your answer to answer key of Self

Check 3.2-1, you may proceed to

Information Sheet 3.2-2, if not return

to Info Sheet 3.2-1.

Read Information Sheet 3.2-2 on PEC Read and understand the

Provisions on Wiring Devices information sheet and check yourself

by answering the Self-check. You

must answer all the questions

correctly before proceeding to the

next activity.

Answer Self Check 3.2-2 If you score 100% upon comparing

your answer to answer key of Self

Check 3.2-2, you may proceed to

Information Sheet 3.2-3, if not return

to Info Sheet 3.2-2

Read Information Sheet 3.2-3on Read and understand the

Procedures in Installing Wiring information sheet and check yourself

Devices by answering the Self-check. You

must answer all the questions

correctly before proceeding to the

next activity.

Answer Self Check 3.2-3 If you score 100% upon comparing

your answer to answer key of Self

Check 3.2-3, you may proceed to

Information Sheet 3.2-4, if not return

to Info Sheet 3.2-3.

Perform Task Sheet 3.2-3(a) Task Sheet will help you practice

your skill.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 9 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

The Performance Criteria Checklist

will guide and help you evaluate your

work as you are practicing your skill.

Evaluate your work using the

Performance Criteria. When you are

ready, present your work to your

trainer for final evaluation and

recording.

If you have questions about the use

of the matrix, please ask your trainer.

Perform Task Sheet 3.2-3(b) Task Sheet will help you practice

your skill.

The Performance Criteria Checklist

will guide and help you evaluate your

work as you are practicing your skill.

Evaluate your work using the

Performance Criteria. When you are

ready, present your work to your

trainer for final evaluation and

recording.

If you have questions about the use

of the matrix, please ask your trainer.

Read Information Sheet 3.2-4 Safety Read and understand the

Procedures in Wiring Devices information sheet and check yourself

by answering the Self-check. You

must answer all the questions

correctly before proceeding to the

next activity.

Answer Self Check 3.2-4 If you score 100% upon comparing

your answer to answer key of Self

Check 3.2-4, you may proceed to

Information Sheet 3.2-5, if not return

to Info Sheet 3.2-4.

Read Information Sheet 3.2-5 on GFCI Read and understand the

Outlets information sheet and check yourself

by answering the Self-check. You

must answer all the questions

correctly before proceeding to the

next activity.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 10 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Answer Self Check 3.2-4 If you score 100% upon comparing

your answer to answer key of Self

Check 3.2-5, if not return to Info

Sheet 3.2-5.

After doing all activities of this LO,

you are ready to proceed to the next

LO of this Competency.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 11 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Information Sheet 3.1-1

Types of Wiring Devices

Learning Objectives:

After reading this Information Sheet, you must be able to:

1. Define wiring device according to electrical code

2. Identify the types of wiring devices and its classification

3. Guidelines in selecting wiring devices

Introduction

Wiring devices are defined as single discrete units of electrical

distribution systems which are intended to carry but not utilize electric

energy.

Wiring devices are electrical devices used to control and to provide

connection points for low voltage outlets, lighting systems and appliances

(e.g., wall switches and receptacles).

The Philippine Electrical Code (PEC) and National Electrical Code (NEC)

defines device as a unit of an electrical system that is intended to carry or

control but not utilize electric energy.

Types and Classification of Wiring Devices

This covers a wide assortment of system components that include,

however not limited to the following:

1. Switches and Plates

2. Relays and Contactors

3. Receptacles and Plates

4. Conductors

5. Fuses and Circuit Breakers

6. Outlets (Floor Outlet, Grounding Type Convenience Outlet or

otherwise known as Special Purpose Outlet or SPO)

Further, the devises are classified in terms with their functions as path

devices, control devices, fault devices and protective devices.

Path Devices are devices which serves as path of electric current of the

wiring system like wire (conductor) and all parts of the circuit that has a low

resistance.

Control Devices are devices which can regulate the flow of current. They can

make or break the circuit. Lighting Switches are common examples of

control devices

Fault Devices are devices which can immediately detect any fault in the

wiring system. GFCI and AFCI are common examples of fault devices.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 12 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Protective Devices are devices which is the weakest link of the circuit and

will protect the circuit from overcurrent. Note: An information sheet about

protective devices are explain in the previous competency.

Guidelines for wiring device application designs.

Selecting and applying wiring devices. Receptacles, switches, plates,

and others are available in a wide range of sizes, ratings, and styles with

specific features and characteristics to meet most design/application

requirements. Grades of wiring devices, manufacturer's catalogs use a variety

of terms to indicate the quality or grade of wiring devices offered.

For example, the term "economy," "competitive," "intermediate," or

"residential" are sometimes used to indicate that the device is economically

priced or designed for light-duty applications. Terms such as "specification"

or "super-specification" would indicate devices that are of better quality,

designed for greater reliability and usually higher priced.

However, none of these terms has an official status with standardizing

agencies such as Underwriters Laboratories (UL), Factory-Mutual (FM),

Electrical Testing Laboratories (ETL), or the National Electrical Manufacturers

Association (NEMA).

Presently, UL lists wiring devices for only two grades, standard and

hospital grade. All devices, whether termed intermediate, economy, or

specification must meet identical UL requirements (although as mentioned

above, specification grade devices are of better quality construction).

Above all, the Philippine Electrical Code must be the basis for the

guidelines for wiring devices and application designs.

How to select wiring devices?

Here the steps in selecting wiring devices:

1. Select a known industry manufacturer.

2. Look for a multi- year product warranty.

3. Make sure that there is an easy and clear way to contact the

manufacturers support.

4. Check for a connected equipment damage warranty.

5. Always ask for manufacturer’s manual.

6. Select wiring devices which are well-made and durable.

7. Select materials that easy to use and install.

8. Select wiring devices according to the job requirements

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 13 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Self-Check 3.1-1

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 14 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Answer Key 3.1-1

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 15 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Information Sheet 3.1-2

Ground Fault Circuit Interrupter

Learning Objectives:

After reading this Information Sheet, you must be able to:

1. Explain the theory of operation, connection and purpose of Ground

Fault Circuit Interrupting (GFCI) Device

2. Compare and contrast the types of GFCI

3. Test a GFCI

Introduction

Ground-fault circuit interrupters (GFCIs) have been in use for over 40

years, and have proven themselves to be invaluable in the protection of

personnel from the hazard of electric shock. Other types of leakage current

and ground fault protective devices have been introduced for various

applications since the introduction of GFCIs.

The use of some protective devices is specifically required in the

National Electrical Code (NEC) or in the Philippine Electrical Code. Others are

a component of an appliance, as required by the UL standard covering that

appliance. This information sheet will help to understand the purpose and

operation of Ground Fault Circuit Interrupter

WHAT IS A GFCI?

In terms of function and appearance, a floor outlet can be helpful in

many situations. In a conference room, an outlet in the floor under the

conference table makes it much easier to plug in audio visual equipment

without running extension cords to a wall outlet. In the home, the presence

of a floor outlet in the living room aids in arranging the furnishings, since

major seating areas do not have to remain near a wall in order to include the

presence of accent lamps in the grouping.

As with any type of electrical wiring project, it is recommended that the

installation only be conducted by a properly certified electrician.

A ground fault circuit interrupter, called a GFCI or GFI, is an

inexpensive electrical device that can either be installed in your electrical

system or built into a power cord to protect you from severe electrical shocks.

GFCIs have played a key role in reducing electrocutions. Greater use of GFCIs

could further reduce electrocutions and mitigate thousands of electrical burn

and shock injuries still occurring in and around the home each year.

Ground fault protection is integrated into GFCI receptacles and GFCI

circuit breakers for installation into your electrical system, especially for

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 16 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

circuit outlets in particularly vulnerable areas such as where electrical

equipment is near water.

Portable GFCIs are also available to provide on-the-spot ground fault

protection even if a GFCI is not installed on the circuit.

The GFCI is designed to protect people from severe or fatal electric

shocks but because a GFCI detects ground faults, it can also prevent some

electrical fires and reduce the severity of other fires by interrupting the flow

of electric current.

According to the Philippine Electrical Code (PEC), Ground-Fault

Circuit Interrupter (GFCI) is a device intended for the protection of personnel

that functions to de-energize a circuit or portion thereof within an established

period of time when a current to ground exceeds the values established for a

Class A device (Class A ground-fault circuit interrupters trip when the current

to ground has a value in the range of 4 mA to 6 mA. For further information,

see UL 943, Standard for Ground-Fault Circuit Interrupters.

Another definition of a ground-fault circuit interrupter is found in

Article 100 of the National Electrical Code (NEC) and is as follows: “A device

intended for the protection of personnel that functions to de-energize a circuit

or portion thereof within an established period of time when a current to

ground exceeds the values established for a Class A device.” Following this

definition, a Fine Print Note provides additional information on what

constitutes a Class A GFCI device. It states that a Class A GFCI trips when

the current to ground has a value in the range of 4 milliamps to 6 milliamps,

and references UL 943, the Standard for Safety for Ground-Fault Circuit-

Interrupters.

What Is A Ground Fault?

A ground fault is an unintentional electrical path between a power

source and a grounded surface. Ground faults most often occur when

equipment is damaged or defective, such that live electrical parts are no longer

adequately protected from unintended contact. If your body provides a path

to the ground for this current, you could be burned, severely shocked or

electrocuted.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 17 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Below is an illustration of ground fault.

How Do They Work?

A GFCI constantly monitors current flowing through a circuit. If the

current flowing into the circuit differs by a very small amount (as little as

0.006 amperes) from the returning current, the GFCI interrupts power faster

than a blink of an eye to prevent a lethal dose of electricity.

GFCIs are designed to operate before the electricity can affect your

heartbeat. A GFCI works even on two-slot receptacles.

Here's an example: A bare wire inside an appliance touches its metal

case. The case is then charged with electricity. If you touch the appliance

with one hand while another part of your body is touching a grounded metal

object, such as a water faucet, you will get shocked. If the appliance is

plugged into an outlet protected by a GFCI, the power will be shut off before

a fatal shock can occur.

An illustration of how GFCI works

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 18 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

How to Install

Circuit breaker and receptacle-type GFCIs may be installed in your

home by a qualified and skilled electrician. Receptacle-type GFCIs may be

installed by consumers with adequate knowledge and skills to conform to

proper electrical wiring practices and the instructions accompanying the

device. When in doubt about the proper procedure, contact a qualified

electrician; do not attempt to install it yourself.

A portable GFCI gets plugged into a receptacle just like any other

cord-and-plug-connected device.

How to Test

Test every GFCI:

• After installation.

• At least once a month.

• After a power failure.

• According to the manufacturer’s instructions.

If you do not have the instructions follow this procedure:

• Plug a lamp into the outlet and turn the lamp on.

• Press the GFCI’s test button. Did the light go out? If not, the

GFCI is not working or has not been correctly installed. Contact

a qualified electrician to correct the wiring and/or replace the

defective GFCI.

• Press the reset button. Did the light come back on? If not,

replace the GFCI.

Types of GFCIs

A. CIRCUIT BREAKER GFCI

* A circuit breaker with a built-in GFCI may be installed in a panel box to

add protection to the circuits it supplies.

* Protects against both a ground fault and a circuit overload

* Protects the wiring and every outlet, lighting fixture, or appliance on the

branch circuit that it supplies.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 19 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 20 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

B. RECEPTACLE GFCI

* Used in place of the standard duplex receptacle.

* Fits into a standard outlet box and protects against ground-faults for

whatever is plugged into the outlet and other electrical outlets further

"down-stream" in the branch circuit.

* Can even replace older ungrounded, two slot receptacles with new GFCI

receptacles.

Must use supplied label “NO EQUIPMENT GROUND GFCI PROTECTED” to

identify that the receptacle is not grounded.

* The Receptacle Type incorporates a GFCI device within one or more

receptacle outlets. Such devices are becoming popular because of their low

cost.

a. Receptacle GFCI b. Circuit Breaker GFCI

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 21 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Front View of a Receptacle GFCI

Back View of a Receptacle GFCI

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 22 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

C. PORTABLE GFCI

• Used where installed GFCIs are not practical.

• One type contains the GFCI circuitry in a plastic enclosure with plug

blades in the back and receptacle slots in the front. It can be plugged

into a receptacle, then the electrical product is plugged into the GFCI.

• Another type of portable GFCI is an extension cord combined with a

GFCI. It adds flexibility in using receptacles that are not protected by

GFCIs.

• Portable Type GFCIs come in several styles, all designed for easy

transport. Some are designed to plug into existing non-GFCI outlets, or

connect with a cord and plug arrangement. The portable type also

incorporates a no-voltage release device that will disconnect power to

the outlets if any supply conductor is open. Units approved for outdoor

use will be in enclosures suitable for the environment. If exposed to

rain, they must be listed as waterproof.

A. The Cord-Connected Type of GFCI is an attachment plug incorporating the

GFCI module. It protects the cord and any equipment attached to the cord.

B. Plug Type. The attachment plug has a non-standard appearance with test

and reset buttons. Like the portable type, it incorporates a no-voltage release

device that will disconnect power to the load if any supply conductor is open.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 23 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Self-Check 3.1-2

Identification: Identify what is being described. Used the box below for your

choices.

Ground Fault Circuit Interrupter Ground Fault

Circuit Breaker GFCI Receptacle GFCI

Portable GFCI

___________________ 1. It is an inexpensive electrical device that can either be

installed in your electrical system or built into a power cord to protect you

from severe electrical shocks.

___________________ 2. It is an unintentional electrical path between a power

source and a grounded surface.

___________________ 3. A GFCI that protects against both a ground fault and

a circuit overload

___________________ 4. A GFCI that can be used in place of the standard

duplex receptacle.

___________________ 5. A GFCI that is to be used where installed GFCIs are

not practical.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 24 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Answer Key 3.1-2

1. Ground Fault Circuit Interrupter

2. Ground Fault

3. Circuit Breaker GFCI

4. Receptacle GFCI

5. Portable GFCI

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 25 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Information Sheet 3.1-3

FLOOR OUTLETS

Learning Objectives:

After reading this Information Sheet, you must be able to:

1. Describe a floor outlet

2. Identify the types of floor outlets

This information sheet will describe and identify the types of floor outlets

FLOOR OUTLETS

Floor outlets are electrical outlets that are installed into a floor area

rather than into a wall. Often, a floor outlet will be equipped with a metal plate

to protect the outlet and wiring, along with a cover that prevents dust and

other material from collecting in the outlet when the device is not in use.

Outlets of this type are usually found in dens and living rooms of homes, as

well as in conference rooms or other larger gathering areas in offices and

public buildings.

As with any type of outlet, the floor outlet is intended to allow easy

access to electrical current. Because the plug can be placed at any point along

the floor, it is possible to strategically position several outlets within a space,

creating easy access to electricity even when a power source is needed

somewhere other than along a wall. When not in use, covers snap or slide into

place in order to protect the outlets and also to allow the floor to retain a

smooth surface.

Beneath the surface of the floor, the configuration of the floor outlet is

similar to that of a standard wall outlet. The plugs are housed in an outlet

box and normally connected to a central junction box that helps regulate

electric power flow. Wiring runs from the outlet box to the central junction in

the same manner that electrical wiring runs through walls to a central power

source.

While it is possible to use plastic or porcelain plates with a floor outlet,

the general recommendation is to utilize metal plates. Durable metal is much

less likely to be damaged if the outlet is stepped on when not in use. The metal

covers can hold up well to a lot of weight, which will help to keep the general

appearance of the outlet simple and clean. When necessary, the metal plates

can be outfitted with covers that are spring loaded to snap closed when the

outlets are not in use.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 26 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

In terms of function and appearance, a floor outlet can be helpful in

many situations. In a conference room, an outlet in the floor under the

conference table makes it much easier to plug in audio visual equipment

without running extension cords to a wall outlet. In the home, the presence

of a floor outlet in the living room aids in arranging the furnishings, since

major seating areas do not have to remain near a wall in order to include the

presence of accent lamps in the grouping.

Installing a floor outlet is very similar to the installation of a wall outlet.

As with any type of electrical wiring project, it is recommended that the

installation only be conducted by a properly certified electrician.

EXAMPLES of FLOOR OUTLETS

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 27 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

The National Electrical Code requires floor outlets to be a part of an

approved assembly consisting of a metal box, gasket seal, special receptacle

and strong cover plate with a moisture-proof cover. You can't just mount a

regular wall outlet in the floor. The first time someone stepped on it, it would

break. Besides, mopping a floor around an outlet that doesn't have a

moisture-proof cover could cause corroded connections, or worse, give you a

lethal shock.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 28 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Self-Check 3.1-3

True or False: Write the word TRUE if the statement is correct and FALSE if

the state is incorrect. Write your answer on the space before the number.

___________________ 1. Floor outlets are electrical outlets that are installed

into a wall area rather than into a floor.

___________________ 2. Floor outlets are usually found in dens and living

rooms of homes.

___________________ 3. As with any type of outlet, the floor outlet is intended

to allow easy access to electrical current.

___________________ 4. A floor outlet will be equipped with a metal plate to

protect the outlet and wiring, along with a cover that prevents dust and other

material from collecting in the outlet when the device is not in use

___________________ 5. The configuration of the floor outlet is similar to that

of a standard wall outlet.

___________________ 6. While it is possible to use plastic or porcelain plates

with a floor outlet, the general recommendation is to utilize metal plates

___________________ 7. In terms of function and appearance, a floor outlet can

be helpful in many situations.

___________________ 8. Installing a floor outlet is very similar to the installation

of a wall outlet.

___________________ 9. The National Electrical Code requires floor outlets to

be a part of an approved assembly consisting of a metal box, gasket seal,

special receptacle and strong cover plate with a moisture-proof cover.

___________________ 10. It is recommended that the installation only be

conducted by a properly certified electrician.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 29 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Answer Key 3.1-3

1. False

2. True

3. True

4. True

5. True

6. True

7. True

8. True

9. True

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 30 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Information Sheet 3.1.4

CONTROL DEVICES/SWITCHES

Learning Objectives:

After reading this Information Sheet, you must be able to:

1. Describe a control device or a switch

2. Differentiate the types of switches

Introduction

Circuit control devices have many different shapes and sizes, but most

circuit control devices are either SWITCHES, SOLENOIDS, or RELAYS.

In electrical installation, a SWITCH is a device, which can make or

break an electrical circuit or we can say that switch is a controlling device,

which interrupt the flow of current or direct the flow of current in another

direction.

Almost all the electrical wiring systems contain at least one switch,

which is used to make the device ON or OFF. In addition, a switch is used to

control the circuit operation and user may able to activate or deactivate the

whole or certain parts of the connected circuit.

When the contacts of a switch are closed, the switch creates the closed

path for current flow and hence load consumes the power from source. When

the contacts of a switch are open, no power will be consumed by the load as

shown in below figure.

There are numerous switch applications found in wide variety fields

such as home, automobiles, industrial, military, aerospace and so on. In some

applications multi way switching is employed (like building wiring), in such

cases two or more switches are interconnected to control an electrical load

from more than one location.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 31 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Types of Switches

Switches open and close electrical circuits, allowing power to flow

through lights and appliances. At one time, they were pretty simple—just a

toggle you flipped on and off. But things have changed. As our needs for

energy efficiency have evolved and technology has improved, light switches

have undergone a renaissance.

New switches offer a wide range of control, such as full-range dimming,

a delayed fade from on to off, and dimmer switches that remember a range

of preset settings.

Some occupancy sensor switches automatically turn lights on when a

person enters a room and then off when the person exits. Central lighting

controls can be programmed to operate groups or banks of lights throughout

the house as the needs for lighting in various areas change throughout the

day. Lights, fans, and other electrical devices can be controlled with hand-

held, infrared, wireless remotes. And there are switches designed to control

compact fluorescent, fluorescent and halogen lights.

Some switches are operated with keys, timers, or photoelectric eyes

that sense daylight. Other switches are paired up with electrical outlets

(“combination” switches). You say it’s hard to find a switch in the dark? For

that situation, you need a switch with a pilot light. Outdoor switches,

mounted in a special waterproof electrical box, are operated with a lever that

protects against shock.

Switches can be of mechanical or electronic type:

a. Mechanical switches must be activated physically, by moving,

pressing, releasing, or touching its contacts.

b. Electronic switches do not require any physical contact in order to

control a circuit. These are activated by semiconductor action.

Mechanical Switches

Mechanical switches can be classified into different types based on

several factors such as method of actuation (manual, limit and process

switches), number of contacts (single contact and multi contact switches),

number of poles and throws (SPST, DPDT, SPDT, etc.), operation and

construction (push button, toggle, rotary, joystick, etc), based on state

(momentary and locked switches), etc.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 32 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Based on the number of poles and throws, switches are classified into

following types.

The pole represents the number of individual power circuits that can

be switched. Most of the switches are designed have one, two or three poles

and are designated as single pole, double pole and triple pole.

The number of throws represents the number of states to which

current can pass through the switch. Most of the switches are designed to

have either one or two throws which are designated as single throw and

double throw switches.

Electronic Switches

As opposed to mechanical switches which requires the user to make

contact with the switch for activation, an electronic switch does not require

pressure for activation. This can be especially helpful, when a client presents

with limited movement and/or strength.

The electronic switches are generally called as solid state switches

because there are no physical moving parts and hence absence of physical

contacts. Most of the appliances are controlled by semiconductor switches

such as motor drives and HVAC equipment.

There are different types of solid state switches are available in today

market with different sizes and ratings.

Electronic switches are faster in response than mechanical switches

and can be switched automatically by an electronic circuit like microcontroller

or microprocessor. They can also be categories on the basis of current and

voltage rating like mechanical switches.

The question arises here, why we need electronics switch? The answer

of the question is that sometimes, it is necessary that circuit, which makes

decision also turn OFF or ON certain devices based on the decision. If only

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 33 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

mechanical switch is used, then there should be one person present there all

the time to make the device ON and OFF after getting indication message from

the circuit. To eliminate this problem, electronics switches are used then.

They are very much fast and accurate as compared to mechanical switches.

Electronic switches are small in size and do not make noise while switching

operation and they make sure the stability and reliability of the system,

Bipolar Transistors

A transistor either allows the current to pass or it blocks the current as

similar to working of normal switch.

In switching circuits, transistor operates in cut-off mode for OFF or current

blocking condition and in saturation mode for ON condition. The active

region of the transistor is not used for switching applications.

Both NPN and PNP transistors are operated or switched ON when a

sufficient base current is supplied to it. When a small current flows though

the base terminal supplied by a driving circuit (connected between the base

and emitter), it causes to turns ON the collector-emitter path.

And it is turned OFF when the base current is removed and base voltage is

reduced to a slight negative value. Even though it utilizes small base

current, it is capable to carry much higher currents through the collector-

emitter path.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 34 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Power Diode

A diode can perform switching operations between its high and low state

impedance states. Semiconductor materials like silicon and germanium are

used for constructing the diodes.

Usually, power diodes are constructed using silicon in order to operate the

device at higher currents and higher junction temperatures. These are

constructed by joining p and n type semiconductor materials together to

form PN junction. It has two terminals namely anode and cathode.

When the anode is made positive with respect to cathode and by the

application of voltage greater than the threshold level, PN junction is forward

biased and starts conducting (like ON switch). When the cathode terminal is

made positive with respect to anode, PN junction reverse biased and its

blocks the current flow (like OFF switch).

MOSFET

Metal Oxide Semiconductor Field Effect Transistor (MOSFET) is a unipolar

and high frequency switching device. It is a most commonly used switching

device is power electronic applications. It has three terminals namely drain

(output), source (common) and gate (input).

It is a voltage controlled device, i.e., by controlling input (gate to source)

voltage, resistance between the drain and source is controlled which further

determines the ON and OFF state of the device.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 35 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

MOSFETs can be a P-channel or N-channel devices. The N-channel MOSFET

is tuned ON by applying a positive VGS with respect to the source (provided

that VGS should be greater than threshold voltage).

P-channel MOSFET operates in a similar manner of N-channel MOSFET but

it uses reverse polarity of voltages. Both VGS and VDD are negative with

respect the source to switch ON the P- channel MOSFET.

IGBT

IGBT (Insulated Gate Bipolar Transistor) combines the several advantages of

bipolar junction power transistor and power MOSFET. Like a MOSFET, it is

a voltage controlled device and has lower ON state voltage drop (less than

that of MOSFET and closer to power transistor).

It is a three terminal semiconductor high speed switching device. These

terminals are emitter, collector and gate.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 36 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Similar to the MOSFET, IGBT can be turned ON by applying a positive

voltage (greater than the threshold voltage) between the gate and emitter.

IGBT can be turned by reducing the voltage across the gate-emitter to zero.

In most of the case it needs negative voltage to reduce turn OFF losses and

safely turn OFF the IGBT.

SCR

A Silicon Controlled Rectifier (SCR) most widely used high speed switching

device for power control applications. It is a unidirectional device as a diode,

consisting of three terminals, namely anode, cathode and gate.

An SCR is turned ON and OFF by controlling its gate input and biasing

conditions of the anode and cathode terminals. SCR consists of four layers

of alternate P and N layers such that boundaries of each layer forms

junctions J1, J2 and J3.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 37 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

TRIAC

Triac (or TRIode AC) switch is a bidirectional switching device which is an

equivalent circuit of two back to back SCRs connection with one gate

terminal.

Its capability to control AC power in both positive and negative peaks of the

voltage waveform often makes these devices to be used in motor speed

controllers, light dimmers, pressure control systems, motor drives and other

AC control equipments.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 38 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

DIAC

A DIAC (or DIode AC switch) is bidirectional switching device and it consists

of two terminals which are not named as anode and cathode. It means that

a DIAC can be operated in either direction regardless of the terminal

identification. This indicates that the DIAC can be used in either direction.

When a voltage is applied across a DIAC, it either operates in forward

blocking or reverse blocking mode unless the applied voltage is less than the

breakover voltage. Once the voltage is increased more than breakover

voltage, avalanche breakover occurs and device starts conducting.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 39 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Gate Turn-Off Thyristor

A GTO (Gate Turn off Thyristor) is a bipolar semiconductor switching device.

It has three terminals as anode, cathode and gate. As the name implies, this

switching device is capable to turn OFF through gate terminal.

A GTO is turned ON by applying a small positive gate current triggers the

conduction mode and turned OFF by a negative pulse to the gate. GTO

symbol consists of double arrows on the gate terminal which represents the

bidirectional flow of current through gate terminal.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 40 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Self-Check 3.1-4

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 41 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Answer Key 3.1.4

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 42 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Information Sheet 3.1-5

Types of Mechanical Switches

Learning Objectives:

After reading this Information Sheet, you must be able to:

1. Differentiate the types of mechanical switches

2. Determine the types of mechanical switch used for controlling lights

Single Pole Single Throw Switch (SPST)

The simplest and most common light switch is actually referred to by

hardware dealers and electricians as a “single-pole light switch.” With a

single-pole light switch, flipping the lever up completes the circuit, turning

lights or appliances on, and flipping it down breaks the circuit, turning lights

or receptacles off.

This is a simple ON/OFF switch. It is also called as One-Way Switch (in

the US, they called it Two-Way Switch). When a user presses the button of the

switch, then the plates of the switch connect with each other and the current

starts to flow and vice versa.

SPST (Single Pole Single Through) Switch

• This is the basic ON and OFF switch consisting of one input contact and

one output contact.

• It switches a single circuit and it can either make (ON) or break (OFF)

the load.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 43 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

• The contacts of SPST can be either normally open or normally closed

configurations .

A single-pole switch has two terminal screws on the side that receive

the wires of the circuit. (The number of terminal screws identifies the type of

switch.) Some single-pole switches also have a green grounding screw (not

shown) that connects to the circuit’s ground wire. Different brands vary with

the style and configuration and markings of a SPST.

With a single-pole light switch, flipping the lever up completes the

circuit, turning lights or appliances on, and flipping it down breaks the

circuit, turning lights or receptacles off. A single-pole switch has two

terminal screws on the side.

Single Pole Double Throw Switch (SPDT)

This switch has three terminals, one is input contact and remaining two

are output contacts.

• This means it consist two ON positions and one OFF position.

• In most of the circuits, these switches are used as changeover to connect

the input between two choices of outputs.

• The contact which is connected to the input by default is referred as

normally closed contact and contact which will be connected during ON

operation is a normally open contact.

• This button has three pins in which, one pin is used as common and

called a Two-Way Switch (in US, they called it Three-Way Switch). We

can send two different signals to same pin by using this switch. Because

of this functionality, this switch is also called selector switch.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 44 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

• Other switches related to SPDT are SPCO (Single Pole Changeover) and

SPTT (Single Pole Center Off or Single Pole Triple Throw)

SPDT (Single Pole Double Throw) Switch

Double Pole Single Throw Switch (DPST)

This switch consists of four terminals, two input contacts and two output

contacts.

• It behaves like a two separate SPST configurations, operating at the same

time.

• It has only one ON position, but it can actuate the two contacts

simultaneously, such that each input contact will be connected to its

corresponding output contact.

• In OFF position both switches are at open state.

• This type of switches is used for controlling two different circuits at a

time.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 45 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

• Also, the contacts of this switch may be either normally open or normally

closed configurations.

• This switch is basically two SPST switches in one package and can be

operated by a single lever. This switch is mostly used, where we have to

break both ground and lines at the same time.

DPST (Double Pole, Single Throw) Switch

Double Pole Double Throw Switch (DPDT)

This switch is equivalent to two SPDT switches packaged in one pack.

This switch has two common pins and four signal pins. Total four different

combination of singles can be applied to the input pins of this switch.

Another switch, related to DPDT is DPCO (Double Pole Changeover or

Double Pole, Centre Off).

DPDT (Double Pole Double Throw) switch

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 46 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

• This is a dual ON/OFF switch consisting of two ON positions.

• It has six terminals, two are input contacts and remaining four are the

output contacts.

• It behaves like a two separate SPDT configuration, operating at the same

time.

• Two input contacts are connected to the one set of output contacts in

one position and in another position, input contacts are connected to the

other set of output contacts

Three Way Switch

A three-way wall switch is a variation of the standard single-pole switch

that makes it possible to control a ceiling light or other electrical fixture from

two different locations in a room. In a hallway or large room, for example,

installing three-way switches at both ends lets you turn the light fixture on or

off from both locations.

A light or lights can be controlled by more than one switch. The usual

practice in home construction is to use 3-way switches. "3-way" is the

electrician's designation for a single pole double throw (SPDT) switch.

A 3-way switch is shown below.

Here is a typical circuit in its four possible states.:

The switches must create a complete circuit for current to flow and the

bulb to light. When both switches are up, the circuit is complete (top right).

When both switches are down, the circuit is complete (bottom right). If one

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 47 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

switch is up and one is down, the current reaches a dead end, no current

flows and the bulb is off (top left and bottom left).

Note that the above color scheme does NOT reflect wire color. It is

functional coloring intended to illustrate the voltage state of each wire

segment.

• Red indicates a hot wire (120 volts ac).

• Green indicates a neutral wire at ground potential.

• Blue indicates a wire that is floating. "Floating" here means isolated

from hot and neutral by switches and/or light bulbs.

Typical Three Way Switch

Screw Terminals on Three-Way Switches

If you examine a three-way switch, you will notice several differences

when compared to standard single-pole switches. First, the body of the switch

will be thicker and bulkier than a single-pole switch. And the switch toggle lever

will not have the ON-OFF markings found on a single-pole switch. The biggest

difference, though, will be in the screw terminals on the switch.

While standard single-pole switches have two screw terminals on one

side of the switch, plus a third green grounding screw terminal connected to

the metal strap, three-way switches come equipped with another screw

terminal.

If you look over the three-way switch, you will notice that this extra screw

terminal is a darker color than the other two brass-colored terminals.

This is known as the common connection of the switch. Depending on

where the switch will be in the circuit layout, the purpose of this

common connection is to either to deliver electrical current from the power

source (the circuit-breaker box) to one of the switches or to deliver the current

onward from the second switch to the light fixture.

The other two screw terminals on the switch body will be brass-colored. These

are used to connect the circuit wires that run between the two three-way

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 48 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

switches. These are known as the traveler terminals, and the wires running

between the switches are known as traveler wires.

In a circuit situation, normally these traveler wires will have black and

red insulation. When the switches are installed, these traveler wires allow

electrical current to pass between the switches—or they interrupt the circuit

flow to turn the light fixture OFF. At any given moment when the light fixture

is ON, the power may be flowing through either the black or the red traveler

wire. This will vary depending what position the switch toggle levers are in.

Some brands of a three-way switch terminals have labels 0, 1 and 3. Zero

is the common while 2 and 3 are for travelers.

Wire Connections

Three-way switches have different methods of connection, depending on

the brand of the switch. The switch may also have several ways to make the

wire connections. All switches have screws on the side, but some also come

with push-fitting holes or slots to slide the wire into. Still others come with a

quick-mount, spring-loaded slot alongside the screw terminals that are

designed to hold the wires in place.

Although these push fittings or slot-fittings may be the quickest way to

connect a switch, this method is not recommended, as it is generally less

secure.

Professional electricians who want to avoid callbacks always use the

screw terminal connections which rarely come loose.

Wiring Problems in Three-Way Switch Installations

Three-way switches are tricky to install, especially for DIYers who are

replacing a bad switch. One of the most common problems is improper wiring—

connecting the circuit wires to the wrong screw terminals.

It's very easy to mix up three-way switch wiring when replacing a three-

way switch, especially because in older wiring systems the standard color-

coding of wires may look different than it does in newer installations. The best

way to prevent this is to take the time to mark the wires before you remove any

wires from the old switch, The wire connected to the common screw terminal is

the most important to mark. It must always connect to the darkest-colored

terminal screw.

By placing a colored piece of tape or label on the wire, it will be easy to

find when you connect the new switch.

It's also a good idea remove and reconnect one wire at a time when

replacing switches. By doing this one wire at a time, you can ensure you are

connecting the new switch correctly. This can sometimes be difficult, though,

if the circuit wires in the wall box are too short—in this case, marking the wires

is essential.

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 49 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Mechanical Problems with Three-Way Switches

Problems with switches occur when wire connections come loose, or

when the switch itself fails. Switches are mechanical devices that can wear out

after hundreds or thousands of clicks.

If you suspect a loose wire connection, turn off the power to the circuit

at the circuit breaker box before inspecting the wire connections on the switch.

Make sure they are all tight. Also, check any wire nut connections on other

circuit wires in the wall box. For example, there likely will be a neutral wire

connection inside the box (usually these are white wires); make sure this wire

nut connection is also secure. If you find that this neutral wire connection is

made with electrical tape you should replace it with a wire nut.

If a switch makes a sizzling or popping sound when you turn the switch

ON, it means that the switch contacts are becoming worn and aren't making

good contact. This switch should be changed immediately to avoid bigger

electrical problems.

By inspecting your switches periodically, you'll ensure safe and effective

electrical connections.

A typical illustration of a three-way switch

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 50 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Four-Way Switches

Four-way switch configurations are used to control lights with three or

more switches. A 3-way switch is used on each end with one or more 4-way

switches in between the two 3-way switches. They do not have an on/off

position like single pole switches. It is important to understand how these

switches are wired before attempting to troubleshoot or replace.

A four-way switch

Some brands of a four-way switch has terminal labels of 1, 2, 3 and 4.

Always refer to the manufacturers manual before using a 4-way switch.

Conventional 4-Way Switch Wiring

4-way switches have four terminals each with two pairs of travelers (one set

usually black and one set usually brass color). A four-switch configuration

will have two 3-way switches, one on each end and two 4-way switches in the

middle.

In the diagrams below, the first switch (3-way) common terminal connects to

120 volts.

The first switch (3-way) travelers (brass color) connect to one pair of the

second switch (4-way) travelers (black or brass color).

The other pair of the second switch (4-way) travelers connect to one pair of

the third switch (4-way) travelers.

The other pair of the third switch (4-way) travelers connect to one pair of the

fourth switch (3-way) travelers.

The fourth switch (3-way) common terminal connects to the load (lights).

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 51 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 52 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 53 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 54 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Self-Check 3.1-5

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 55 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Answer Key 3.1-5

Electrical Installation and Date Developed: CBLM 1

Maintenance NCII September 2017 Issued by:

Page 56 of

Install Wiring Devices of Floor and Wall

Mounted Outlets, Lighting

Developed by: USTP-CSTE 115

Fixtures/Switches, and Auxiliary Outlets Victor S. Rosales

Maniya B. Arong Revision # 02

Information Sheet 3.1-6

Electronic Operated Switches

Learning Objectives:

After reading this Information Sheet, you must be able to:

1. Differentiate the types of electronic switches

2. Determine the types of electronic switch used for controlling lights

Introduction:

Due to the changing development of technology, there are

variety of brands, types, configurations of electronic switch used for electrical

wiring. Some of these is used for controlling lights and some of these are for

security purpose.

This information sheet is limited only to the types of electronic

switches applicable to the specialization.

Photocells and Timers

Photocells and timers are switches that turn on and off automatically.

Photocells are commonly used to control lighting. Timers are used to control

fans, water pumps, irrigation controls, etc. Photocells and timers have a

wattage rating. Do not exceed the wattage rating for the load on these

switches.

Photocells/Photoswitch

Photocells are a type of switch used to automatically turn on in the morning

(sunrise) and turn off at night (sunset). They are most commonly used to

control lighting. Photocells are better than time switches for lighting because