Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Plan

Caricato da

AnilkumarGopinathanNair0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

20 visualizzazioni1 paginaIWE syllabus plan

Copyright

© © All Rights Reserved

Formati disponibili

ODS, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoIWE syllabus plan

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato ODS, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

20 visualizzazioni1 paginaPlan

Caricato da

AnilkumarGopinathanNairIWE syllabus plan

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato ODS, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

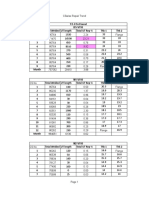

Module 1 Welding Processes and Equipment

Subsection Topic Days Planned Date Actual Date

1.1 General introduction to welding technology 1

1.2 Oxy-gas Welding and related processes 2

1.3 Electrotechnics, a review 2

1.4 The arc 2

1.5 Power sources for arc welding 3

Revision 1

1.6 Introduction to gas shielded arc welding 1

1.7 TIG Welding 2

1.8.1 MIG/MAG 2

1.8.2 Flux Cored Arc Welding 1

1.9 MMA Welding 2

1.10 Submerged-Arc Welding 2

1.11 Resistance Welding 2

Revision 1

1.12.1 Laser; Electron Beam; Plasma 2

1.12.2 Other Welding Processes, 2

1.13 Cutting, Drilling and other edge preparation processes 3

1.14 Surfacing and Spraying 3

Revision 1

1.15 Fully mechanised processes and robotics 2

1.16 Brazing and soldering 2

1.17 Joining processes for plastics 2

1.18 Joining processes for ceramics and composites 2

Revision 2

45 Days

Module 2 Materials and their behavior during welding

2.1 Structure and properties of metals 1

2.2 Phase Diagrams and Alloys 2

2.3 Iron – carbon alloys 2

2.4 Manufacture and classification of steels 2

2.5 Behavior of structural steels in fusion welding 3

Revision 1

2.6 Cracking phenomena in welded joints 4

2.7 Fractures and different kinds of fractures 3

2.8 Heat treatment of base materials and welded joints 3

2.9 Structural (unalloyed) steels 1

2.10 High strength steels 2

2.11 Application of structural and high strength steels 1

2.12 Creep and creep resistant steels 3

Revision 1

2.13 Steels for cryogenic applications 3

2.14 Introduction to corrosion 4

2.15 Stainless and heat resistant steels 4

Revision 1

2.16 Introduction to wear and protective layers 3

2.17 Cast irons and steels 4

2.18 Copper and copper alloys 5

Revision 1

2.19 Nickel and nickel alloys 4

2.20 Aluminium and aluminium alloys 4

2.21 Titanium and other metals and alloys 4

Revision 1

2.22 Joining dissimilar materials 5

2.23 Destructive testing of materials and welded joints 5

Revision 1

78 Days

Module 3 Construction and design

3.1 Basic theory of structural systems 2

3.2 Fundamentals of the strength of materials 3

3.3 Joint design for Welding and Brazing 3

3.4 Basics of weld design 3

Revision 1

3.5 Behaviour of welded structures under different types of loading 2

3.6 Design of welded structures with predominantly static loading 2

3.7 Behaviour of welded structures under cyclic loading 4

3.8 Design of cyclic loaded welded structures 3

3.9 Design of welded pressure equipment 5

Revision 1

3.10 Design of aluminium alloys structures 5

3.11 Introduction to fracture mechanics 3

37 Days

Module 4 Fabrication, applications engineering

4.1 Introduction to quality assurance in welded fabrication 2

4.2 Quality control during manufacture 2

4.3 Residual Stresses and Distortion 3

4.4 Plant facilities, welding jigs and fixtures 2

4.5 Health and Safety 2

4.6 Measurement, Control and Recording in Welding 2

4.7 Imperfections and Acceptance Criteria 3

4.8 Non Destructive Testing 3

4.9 Economics and Productivity 3

4.10 Repair Welding 3

4.11 Reinforcing-steel welded joints 3

28 Days

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- DC TruLaser 3030 L20 2009 11 Inch D648en-USDocumento373 pagineDC TruLaser 3030 L20 2009 11 Inch D648en-USGeraldine75% (4)

- Pipe FittingsDocumento48 paginePipe Fittingskumarmvsn100% (2)

- Photos of Defects Found in RadiographyDocumento14 paginePhotos of Defects Found in RadiographyKavipriyan KaviNessuna valutazione finora

- Jis G4303 Standard English VersionDocumento27 pagineJis G4303 Standard English VersionAnonymous uHWYnQOL550% (2)

- Astm A48-A48m-03Documento6 pagineAstm A48-A48m-03kimolocknarNessuna valutazione finora

- WeldDocumento22 pagineWeldAnilkumarGopinathanNairNessuna valutazione finora

- SL No Date Stock Long/Short Buy Price Sell Price Qty Leverage Profit/LossDocumento27 pagineSL No Date Stock Long/Short Buy Price Sell Price Qty Leverage Profit/LossAnilkumarGopinathanNairNessuna valutazione finora

- Trading Book - AGDocumento7 pagineTrading Book - AGAnilkumarGopinathanNairNessuna valutazione finora

- Item Approx Price ActualDocumento2 pagineItem Approx Price ActualAnilkumarGopinathanNairNessuna valutazione finora

- EuclidDocumento15 pagineEuclidAnilkumarGopinathanNairNessuna valutazione finora

- Trading Book - DSDocumento9 pagineTrading Book - DSAnilkumarGopinathanNairNessuna valutazione finora

- Daily Attendance Report July 2018Documento9 pagineDaily Attendance Report July 2018AnilkumarGopinathanNairNessuna valutazione finora

- Address To ApplyDocumento1 paginaAddress To ApplyAnilkumarGopinathanNairNessuna valutazione finora

- Weld 1Documento18 pagineWeld 1AnilkumarGopinathanNairNessuna valutazione finora

- Unit-1 5S & EHS ScoreDocumento1 paginaUnit-1 5S & EHS ScoreAnilkumarGopinathanNairNessuna valutazione finora

- Daily ExpenseDocumento33 pagineDaily ExpenseAnilkumarGopinathanNairNessuna valutazione finora

- Img 412114601Documento1 paginaImg 412114601AnilkumarGopinathanNairNessuna valutazione finora

- Weld 1Documento18 pagineWeld 1AnilkumarGopinathanNairNessuna valutazione finora

- Supplier Kpi From Ved - Purc, Stores & LogDocumento18 pagineSupplier Kpi From Ved - Purc, Stores & LogAnilkumarGopinathanNairNessuna valutazione finora

- UT Performance March 2018 GraphDocumento12 pagineUT Performance March 2018 GraphAnilkumarGopinathanNairNessuna valutazione finora

- Daily Attendance Report July 2018Documento9 pagineDaily Attendance Report July 2018AnilkumarGopinathanNairNessuna valutazione finora

- Supplier Kpi From Vs - Fab, NDT & QCDocumento4 pagineSupplier Kpi From Vs - Fab, NDT & QCAnilkumarGopinathanNairNessuna valutazione finora

- UT Performance 8-05-2018Documento13 pagineUT Performance 8-05-2018AnilkumarGopinathanNairNessuna valutazione finora

- WEEK 22 LS Repair TrendDocumento2 pagineWEEK 22 LS Repair TrendAnilkumarGopinathanNairNessuna valutazione finora

- Requirement For LS SAW ProcessDocumento1 paginaRequirement For LS SAW ProcessAnilkumarGopinathanNairNessuna valutazione finora

- UT Performance 24-04-2018Documento13 pagineUT Performance 24-04-2018AnilkumarGopinathanNairNessuna valutazione finora

- UT Performance 13-04-2018.odsDocumento151 pagineUT Performance 13-04-2018.odsAnilkumarGopinathanNairNessuna valutazione finora

- UT Performance 13-04-2018.odsDocumento151 pagineUT Performance 13-04-2018.odsAnilkumarGopinathanNairNessuna valutazione finora

- WEEK 22 LS Repair TrendDocumento2 pagineWEEK 22 LS Repair TrendAnilkumarGopinathanNairNessuna valutazione finora

- UT Performance 5-05-2018Documento13 pagineUT Performance 5-05-2018AnilkumarGopinathanNairNessuna valutazione finora

- Deputy Manager - Ied SGM - IedDocumento2 pagineDeputy Manager - Ied SGM - IedAnilkumarGopinathanNairNessuna valutazione finora

- Unit-1 5S & EHS ScoreDocumento2 pagineUnit-1 5S & EHS ScoreAnilkumarGopinathanNairNessuna valutazione finora

- Copy of Copy of Copy of Copy of WEEK 29 COMPLETEDDocumento58 pagineCopy of Copy of Copy of Copy of WEEK 29 COMPLETEDAnilkumarGopinathanNairNessuna valutazione finora

- ISO 15614-1 2012 190 ISO 15609-1 2004 98 ISO 9606-1 2013 190 ISO 14732 2013 164 ISO 4063 2010 190 Total 832Documento1 paginaISO 15614-1 2012 190 ISO 15609-1 2004 98 ISO 9606-1 2013 190 ISO 14732 2013 164 ISO 4063 2010 190 Total 832AnilkumarGopinathanNairNessuna valutazione finora

- Bay: Section No: Date: Cs No O/S Amps Voltage Welder Id M/C No Remarks Bevel Width Bevel Depth No of Pass Travel Speed Welding MonitorDocumento1 paginaBay: Section No: Date: Cs No O/S Amps Voltage Welder Id M/C No Remarks Bevel Width Bevel Depth No of Pass Travel Speed Welding MonitorAnilkumarGopinathanNairNessuna valutazione finora

- ISO 1461 - American Galvanizer's AssociationDocumento3 pagineISO 1461 - American Galvanizer's AssociationBurcu YıldızNessuna valutazione finora

- Surface Treatments and CoatingsDocumento4 pagineSurface Treatments and Coatingsmightym85Nessuna valutazione finora

- The Effects of Contaminants On The Gas Nitriding of Nitralloy-135Documento61 pagineThe Effects of Contaminants On The Gas Nitriding of Nitralloy-135saltbathNessuna valutazione finora

- ASTM A 802 Standard Practice For Steel Castings, Iron Castings, Surface Acceptance, Visual ExaminationDocumento10 pagineASTM A 802 Standard Practice For Steel Castings, Iron Castings, Surface Acceptance, Visual Examinationpsanches25100% (1)

- Design and Analysis of Riser For Sand CastingDocumento16 pagineDesign and Analysis of Riser For Sand Castingrpadhra8803Nessuna valutazione finora

- Bas Sus B - 5Documento1 paginaBas Sus B - 5Partha Sarathi GhoshNessuna valutazione finora

- Air Vee BendingDocumento4 pagineAir Vee Bendinganil chejaraNessuna valutazione finora

- Mil HDBK 694aDocumento106 pagineMil HDBK 694ahardik033Nessuna valutazione finora

- Pro Railing 2017Documento90 paginePro Railing 2017Peter DavidsonNessuna valutazione finora

- IRON-MIG 201-221-221P EngDocumento4 pagineIRON-MIG 201-221-221P Engg4okk8809Nessuna valutazione finora

- Lincoln Strip Cladding Presentation April 2011Documento26 pagineLincoln Strip Cladding Presentation April 2011Renny DevassyNessuna valutazione finora

- 04 QuizDocumento5 pagine04 QuizMani MuruganNessuna valutazione finora

- 6243 02 Que 20080117Documento16 pagine6243 02 Que 20080117UncleBulgariaNessuna valutazione finora

- 07 Thermal Moisture ProtDocumento19 pagine07 Thermal Moisture ProtErika RafaelNessuna valutazione finora

- Part 9 FencingDocumento13 paginePart 9 FencingElvis GrayNessuna valutazione finora

- CYANEX ® 272 ExtractantDocumento16 pagineCYANEX ® 272 ExtractantEnis SevimNessuna valutazione finora

- 01 Machinability 4 in 1 PageDocumento14 pagine01 Machinability 4 in 1 PagedsdvdNessuna valutazione finora

- Sequential Leaching For The Production of Alumina From A Nigerian ClayDocumento7 pagineSequential Leaching For The Production of Alumina From A Nigerian ClayPuturrú De Fuá100% (1)

- Electric Heating&weldingDocumento28 pagineElectric Heating&weldingChiranjeevi PithaniNessuna valutazione finora

- Metrode Instructions For 625 Wires D20Documento5 pagineMetrode Instructions For 625 Wires D20haran2000Nessuna valutazione finora

- MILLER - PlasmarezaciDocumento28 pagineMILLER - PlasmarezaciIvan DulicNessuna valutazione finora

- Book of Spindles Part 2 PDFDocumento44 pagineBook of Spindles Part 2 PDFnirmalmthp100% (1)

- Reflectror MWF330 Tempo-3Documento2 pagineReflectror MWF330 Tempo-3Edgar SeguraNessuna valutazione finora

- Punch Tonnage Chart: Tonnage Required To Punch Round Holes in ASTM A-36 Structural SteelDocumento1 paginaPunch Tonnage Chart: Tonnage Required To Punch Round Holes in ASTM A-36 Structural Steelsmartcad60Nessuna valutazione finora

- KnurlingDocumento2 pagineKnurlingSounak BanerjeeNessuna valutazione finora