Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

United States Patent: (72) 3,195,589 7/1965 Houda, Jr..................... 141/82 X

Caricato da

Mustafa ŞEN0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

26 visualizzazioni6 pagineaerosol patent

Titolo originale

Us 3604477

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoaerosol patent

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

26 visualizzazioni6 pagineUnited States Patent: (72) 3,195,589 7/1965 Houda, Jr..................... 141/82 X

Caricato da

Mustafa ŞENaerosol patent

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 6

United States Patent [11] 3,604,477

[72] Inventor Hans Grothoff 3,195,589 7/1965 Houda, Jr..................... 141/82 X

Am Krabben 7,58911 Valbert, Germany 3,21 1,191 10/1965 Honisch ...... -- 141/20

[21] Appl. No. 798,884 3,213,903 10/1965 Armstrong.. 141/20 X

[22] Filed Feb. 13, 1969 Primary Examiner—Laverne D. Geiger

[45] Patented Sept. 14, 1971 Assistant Examiner—Edward J. Earls

[32] Priority Feb. 13, 1968 Attorney–Michael S. Striker

[33] Germany

[31] P 1601 260.5

ABSTRACT: The metering cylinder of an apparatus for ad

mitting gaseous or liquefied propellant into aerosol packages

[54] APPARATUS FOR FILING AEROSOL PACKAGES accommodates a reciprocable plunger which is hollow and is

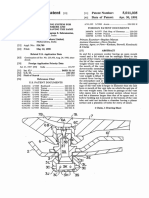

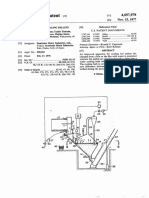

21 Claims, 1 Drawing Fig. connected to the piston of a pneumatic cylinder. The metering

[52] U.S. Cl........................................................ 141/20, cylinder is separably connected with a filling head and is pro

141/82, 222/131, 222/144.5, 222/146 C, 417/228 vided with an internal annular space for lubricant which sur

[51] Int. Cl............. .............. B65b 31/06 rounds a portion of the plunger. The filling head and the me

[50] Field of Search............................................ 141/3, 20, tering cylinder are provided with jackets for circulating condi

82, 104; 184/24; 230/212,213; 92/144; 222/131, tioning fluid which withdraws heat developing on compression

144.5, 146 C; 417/228 of gaseous propellant. The space for lubricant is flanked by

two annular seals which are respectively installed in the meter

[56] References Cited ing cylinder and in the pneumatic cylinder. The inlet of the

UNITED STATES PATENTS metering cylinder can receive gaseous or liquefied propellant,

759,514 5/1904 Grant........................... 230/213 X depending on the setting of a three-way valve which is in

1,832,252 11/1931 Simmons...................... 184/24 UX stalled in a conduit containing a pump for liquefied propellant

1,971,542 8/1934 Taylor.......... 184/24 X and a valve which regulates the pressure of gaseous propel

lant.

3,604,477

1 2

The novel features which are considered as characteristic of

APPARATUS FOR FILING AFROSOL PACKAGES the invention are set forth in particular in the appended

claims. The improved apparatus itself, however, both as to its

construction and its mode of operation, together with addi

BACKGROUND OF THE INVENTION tional features and advantages thereof, will be best understood

The present invention relates to apparatus for filling aerosol upon perusal of the following detailed description of certain

packages, particularly for introducing gaseous or liquefied specific embodiments with reference to the accompanying

propellants into the containers of such packages. drawing.

In the art of aerosols, liquified propellants are those sub 10 BRIEF DESCRIPTION OF THE DRAWING

stances which are liquid at a pressure of 10 atmospheres su

peratmospheric pressure and at a temperature of 20°C. Such The single FIGURE is a schematic partly elevational and

substances include butane, propane, vinyl chloride and partly sectional view of a filling apparatus which embodies the

fluoridated chlorohydrocarbons such as difluordichlor invention.

methane. The characteristic pressure of gaseous propellants at 15 DESCRIPTION OF THE PREFERRED EMBODIMENTS

a temperature of 20° C. exceeds 40 atmospheres superat

mospheric pressure; these include carbon dioxide, laughing The drawing illustrates an apparatus which is utilized for in

gas and certain inert gases, such as nitrogen. As a rule, troduction of gaseous or liquefied propellants into aerosol

presently known apparatus for filling of aerosol packages with packages 28. The apparatus comprises an upright metering

liquefied propellants are not suited for filling with gaseous 20 cylinder 2 having an annular upper end wall 5 which is

propellants, mainly because the sealing elements for the separably connected to the lower end wall 4 of a second

plunger of the metering cylinder cannot stand extended use

when the plunger is not lubricated by liquefied propellant. cylinder 1. This cylinder 1 forms part of a drive means for a

hollow plunger 6 which is reciprocably received in the meter

Another drawback of conventional apparatus is that there is ing cylinder 2 and extends upwardly through the end walls 4

too much dead space between the metering cylinder and the 25 and 5. The drive means further comprises a piston 3 which is

filling head and that no provision is made to withdraw heat

which develops on compression of gaseous propellants prior reciprocable

nected with

in the interior of the cylinder 1 and is rigidly con

the upper end of the plunger 6. The cylinder 1 is

and during introduction into aerosol packages. of the double-acting type and is operated by compressed air or

SUMMARY OF THE INVENTION other suitable pressurized fluid medium. The conduits which

30 deliver and evacuate fluid from the upper and lower chambers

An object of my invention is to provide an apparatus which of the cylinder 1 are indicated at 12 and 13. The source of

can be used with equal advantage for filling of aerosol pressurized fluid which is connected with he conduits 12 and

packages with gaseous or liquefied fluids. 13 is not shown in the drawing.

Another object of the invention is to provide an apparatus The lower end wall 5a of the metering cylinder 2 is

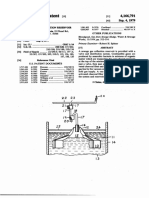

wherein heat developing on compression of gaseous propel 35 separably connected with a filling head 9. A spindle 10 in the

lants is withdrawn in a novel and improved way. upper end wall 11 of the cylinder 1 serves as a means for ad

A further object of the invention is to provide the apparatus justing the stroke of the piston 3 and for thereby determining

with novel means for lubricating the plunger of the metering the amounts of propellant which is introduced into successive

cylinder. packages 28.

An additional object of the invention is to provide an ap 40 In accordance with a feature of my invention, the upper end

paratus wherein the temperature of metering cylinder, its wall 5 of the metering cylinder 2 is provided with an internal

plunger and filling head during admissions of gaseous propel

lants can be regulated and maintained with greater accuracy annular15, e.g.,

space 14 which accommodates a supply of lubricant

oil. The lubricant surrounds a portion of the plunger 6

than in presently known apparatus. and is prevented from penetrating into the cylinders 1, 2 by

Still another object of the invention is to provide an ap 45

paratus which can be rapidly converted from filling of two annular sealing devices 17, 18 which are respectively in

packages with liquefied propellants to filling of packages with stalled in the bottom walls 4 and 5. The material of the sealing

devices 17, 18 must be resistant to the chemical influence of

gaseous propellants, or vice versa.

Another object of the invention is to provide novel condi 50 propellant.

basis of

A satisfactory material is a synthetic plastic on the

polytetrafluorethylene. It is further desirable to em

tioning means for the filling head and metering cylinder of an ploy sealing devices which are automatically held in requisite

apparatus for admission of propellants into aerosol packages.

A further object of the invention is to provide an apparatus sealing engagement with the plunger 6 or to provide means for

which can be designed to fill containers with propellants in tightening

The

the sealing devices 17, 18 when necessary.

plunger 6 is hollow and is provided with one or more

rapid sequence and in such a way that each of a seccession of 55 openings 16 located close to the piston 3. The drawing shows

aerosol packages receives the same amount of gaseous or two openings 16 which are located diametrically opposite

liquefied propellant. each other Such openings permit penetration and evacuation

The improved apparatus comprises a preferably upright me

tering cylinder defining a metering chamber having in its of air which enters the lower chamber of the cylinder 1 by way

lower end wall propellant-admitting inlet means and propel of the conduit 13. The air cools the plunger 6 to thereby

lant-evacuating outlet means, a hollow plunger reciprocably 60 remove some heat which develops on compression of gaseous

extending into the metering chamber, a lubricant-receiving propellant in the metering chamber 19 of the cylinder 2. Cir

annular space preferably provided in the upper end wall of the culation of air into and from the interior of the plunger 6 takes

metering cylinder and surrounding a portion of the plunger, place in automatic response to reciprocation of the piston 3.

The lower end wall 5a of the metering cylinder 2 is provided

annular sealing elements flanking the lubricant-receiving 65 with an inlet 20a for admission of gaseous or liquefied propel

space to seal the supply of lubricant against entry to the meter lant and with an outlet 20 which can admit propellant to an

ing chamber and against escape into the cylinder of a drive annular groove 21 in the bottom end face of the cylinder 2 and

which reciprocates the plunger, a filling head separably con thence into an inlet 23b of the filling head 9. The outlet 20 is a

nected with the lower end wall of the metering cylinder and

having an inlet connected with the outlet means and a nor 70 bore which extends in parallelism with the axis of the cylinder

mally sealed outlet which can receive the valve on the con 22.and This reduces the volume of dead space between the cylinder

the filling head. The filling head 9 is hollow and accom

tainer of a aerosol package, hollow jackets provided on the

filling head and metering cylinder, a source of conditioning modates a stressed helical valve spring 22 which biases a small

fluid, and means for circulating conditioning fluid from the plunger 23 constituting the valve member of the open-and

source, through the jackets and back to the source when the 75 shut valve in the filling head. The valve member 23 is

reciprocable in a cylindrical sleeve 24 of the filling head 9 and

apparatus is used for admission of gaseous propellant.

3,604,477 4

3

its lower end normally bears against a sealing washer 25 in If a package 28 is to receive a metered amount of liquified

stalled in the filling head above a normally sealed outlet 23a. propellant from the source 7, the valve 44 is adjusted so that it

The washer 25 overlies an internal annular shoulder of the connects the conduit 42 with the supply conduit 48. The pump

filling head 9. The lower end portion of the valve member 23 49 then introduces into the metering chamber 19 a predeter

is formed with a recess 26 which can receive the valve 27 of 5 mined amount of liquefied propellant which is free of bubbles.

the aerosol package 28. A sealing ring 29 in the outlet 23a of The conduit 12 thereupon admits pressurized fluid into the

the filling head 9 engages the valve 27 of the package 28 when upper chamber of the cylinder 1 so that the piston 3 moves

such valve extends into the recess 26 to thereby seal the away from the spindle 10 and the plunger 6 expels liquefied

propellant from the atmosphere. The exact construction of the propellant by way of the outlet 20, groove 21, inlet 23b, outlet

10 23a and into the interior of the package 28. The magnitude of

filling head 9 forms no part of the present invention; it is pressure which is required to move the piston 3 downwardly

preferably designed in such a way that it opens rapidly at a depends on the ratio of effective surfaces of piston 3 and

predetermined pressure (e.g., 40 atmospheres superat plunger 6, on the pressure of liquefied propellant in the meter

mospheric pressure) when the apparatus is used for filling of ing chamber 19, and on the force which holds the valve

packages 28 with gaseous propellant and closes rapidly in 15 member 23 of the filling head 9 in closed position. Once the

response to a relatively high constant pressure which is equal pressure in metering chamber 19 exceeds a predetermined

to or approximates the opening pressure. value, the valve member 23 moves to open position (i.e., away

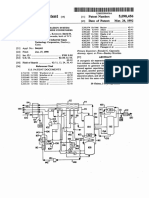

The metering cylinder 2 is provided with a hollow cylindri from the sealing washer 25). When a package is being filled

cal jacket 30 and the filling head 9 is formed with a second with liquefied propellant, the pump 33 is idle because the

hollow jacket 31. These jackets receive water or other suitable 20 cylinder 2 and filling head 9 require no cooling.

conditioning fluid from a source 32, e.g., a tank, by way of a If the apparatus is used for filling of packages 28 with gase

fluid-circulating device which includes conduits 34, 35 con ous propellant which is supplied by the source 8, the valve 44

necting the tank 32 with the jacket 31, a further conduit 36 is adjusted to assume the position shown in the drawing and

which connects the jacket 31 with the lower end of the jacket the pump 33 is started to circulate the conditioning fluid from

30, a return conduit 37 which connects the upper end of the 25 the tank 32, through conduits 34, 35, jacket 31, conduit 36,

jacket 30 with the tank 32, and a pump 33 which is installed jacket 30, return conduit 37 and back to the tank 32. The

between the conduits 34, 35. The apparatus further comprises valve 47 is adjusted to insure that the coil 46 receives gaseous

means for regulating the temperature of conditioning fluid in propellant at a predetermined pressure and such propellant is

the tank 32. Such means includes a thermostat 38 which dips 30 cooled to a predetermined temperature while it flows through

into fluid in the tank 32 and controls a valve 41 installed in a the coil 46. The propellant then flows through the valves 44,

conduit 39 which is connected with a water tap or the like. 43, supply conduit 42 and inlet 20a into the metering chamber

The conduit 39 includes a portion 40 which forms a coil and 19 of the cylinder 2. In contrast to operation during admission

dips into fluid in the tank 32. The thermostat 38 insures that of liquefied propellant, the plunger 6 is held in upper end posi

the water (coolant) which flows through the conduit 39 and its 35 tion for a period of time which depends on the pressure of

coil 40 maintains the temperature of conditioning fluid in tank gaseous propellant at the inlet 20a and the pressure required

32 at a constant value of within a predetermined range of tem to open the valve member 23 in the filling head 9. The pres

peratures. The regulation of temperature of the conditioning sure of gas in the metering chamber 19 rises as a result of heat

fluid is important when the aerosol packages are filled with ing of compressed propellant. When such pressure reaches a

gaseous propellant, i.e., when some of the compression head 40 given value, the valve member 23 moves away from the

must be withdrawn from the metering cylinder 2 and filling washer 25. Propellants in the form of carbon dioxide gas of

head 9. This insures that each of a series of containers 28 laughing gas are heated beyond their critical temperature so

receives the same amount of gaseous propellant because the that it is not necessary to limit their pressure. The temperature

circumstances (as regards the temperature) during filling of 45 of gases which are to be admitted into packages 28 remains

successive containers are the same or nearly the same. above such critical temperature because the interval allotted

The inlet 20a of the metering cylinder 2 is connected with a for filling of a package is very short (e.g., about 1 second) so

supply conduit 42 which contains a one-way valve 43 and in that the gases cannot exchange too much heat with the adjoin

connected with the discharge opening of a three-way valve 44. ing walls of the cylinder 2 and filling head 9. Such heat is

This valve is further connected with a supply conduit 48 which 50 withdrawn by conditioning fluid which is circulated by the

contains a pump 49 and receives liquefied propellant from a pump 33. .

source 7. A source 8 of gaseous propellant is connected with The pressure of gaseous propellant at the inlet 20a can be

the valve 44 by a further supply conduit 45 which contains a varied within a wide range, as long as it does not exceed the

pressure reducing valve 47 and includes a portion 46 which pressure which is required to move the valve member 23 away

forms at least one coil and dips into conditioning fluid and the 55 from closed position. As a rule, the pressure which is required

tank 32. The valve 44 can assume three positions in the first of to open the valve member 23 exceeds 40 atmospheres su

which it connects the conduits 42, 48, in the second of which peratmospheric pressure; this is desirable to reduce the time

which is required to complete the filling of a package 28 with

it connects the conduits 42, 45, and in the third of which it gaseous

seals the conduit 42 from the conduits 45, 48. The drawing propellant. The interval which is required for filling of

shows the valve 44 in a position in which it permits flow of 60 a package can be reduced by increasing the pressure of gase

gaseous propellant from the conduit 45 into the conduit 42. ous propellant during admission into the chamber 19. The

The means for moving aerosol packages 28 into and away amount of gaseous propellant which is admitted into a

from engagement with the filling head 9 comprises a platform package 28 is determined by the stroke of the plunger 6, the

setting of the pressure reducing valve 47, the temperature of

or table 52 which is connected to the upper end of a rod 53

forming part of a piston 50 in a double-acting hydraulic or 65 propellant, the volume of dead space in the apparatus, and the

pneumatic cylinder 51 mounted at a level below the filling 28 pressure required to open the valve member 23. Each package

head. The stroke of the piston 50 is selected in such a way that tainedreceives only a portion of gaseous propellant which is con

the platform 52 can move the valve 27 of a package 28 into operation in the apparatus during filling. This is in contrast to

the outlet 23a of the filling head 9 so that the dome of the 70 It is further with liquefied propellant.

valve 27 is engaged by the sealing ring 29. It is clear that the rapidly heatingdesirable to provide the tank 32 with means for

the conditioning fluid to a desired temperature

package 28 can be supported by a stationary platform and that when the apparatus

the parts 1, 2 and 9 can be moved as a unit up and down to source of hot water isandstarted. Such means may include a

thereby move the head 9 into and away from engagement with similar to the unit including the partsregulating

a second unit which is

38–41 with the excep

the stationary package. 75 tion that its bimetallic thermostat regulates the circulation of

The operation:

3,604,477

5 6

hot water. This enables the operator to rapidly raise the tem having propellant-admitting inlet means and propellant

perature of conditioning fluid to an optimum value when the evacuating outlet means; a hollow internally cooled plunger

apparatus is started. extending into said cylinder and reciprocable therein to

When the plunger 6 completes its downward stroke during thereby change the volume of said metering chamber, said end

expulsion of gaseous propellant from the metering chamber wall of said cylinder sealingly surrounding said plunger and

19, and when the pressure in the filling head 9 decreases to a defining a lubricant-containing annular space which surrounds

value at which the valve member 23 returns to closed position, a portion of said plunger and is sealed from said metering

the apparatus admits pressurized fluid into the lower chamber chamber; drive means for reciprocating said plunger; a filling

of the cylinder 1 so that the piston 3 returns into abutment 10

head connected with said cylinder and having an inlet in com

with the spindle 10. The package 28 on the platform 52 is then munication with said outlet means and a normally sealed out

disengaged from the filling head 9 and replaced with a fresh let, said filling head and said cylinder having hollow jackets; a

package. It is desirable to select a filling head which is first source containing a supply of a conditioning fluid; means

designed in such a way that the valve member 23 opens and for circulating the conditioning fluid from said source and

closes in response to a predetermined pressure; this insures 15

through said jackets; a second source containing a supply of a

that each of a succession of packages 28 receives the same liquefied propellant; and supply conduit means connecting

amount of gaseous propellant. said second source with said inlet means.

Without further analysis, the foregoing will so fully reveal 5. A combination as defined in claim 4, further comprising

the gist of the present invention that others can, by applying pump means provided in said supply conduit means and

current knowledge, readily adapt it for various applications 20 operative to deliver liquefied propellant from said second

without omitting features which fairly constitute essential source to aid inlet means.

characteristics of the generic and specific aspects of my con 6. A combination as defined in claim 5, further comprising

tribution to the art. one-way valve means provided in said conduit means between

What is claimed as new and desired to be protected by Let said pump means and inlet means.

ters Patent is set forth in the appended claims: 25 7. In an apparatus for filling aerosol packages with gaseous

1. In an apparatus for filling aerosol packages with gaseous or liquid propellants, a combination comprising a metering

and liquefied propellants, a combination comprising a meter cylinder having an end wall and defining a metering chamber

ing cylinder defining a metering chamber having propellant having propellant-admitting inlet means and propellant

admitting and propellant-evacuating inlet and outlet means; a evacuating outlet means; a hollow internally cooled plunger

hollow plunger reciprocably received in said chamber, said 30 extending into said cylinder and reciprocable therein to

cylinder further defining a lubricant-containing annular space thereby change the volume of said metering chamber, said end

surrounding a portion of said plunger and sealed from said me wall of said cylinder sealingly surrounding said plunger and

tering chamber: drive means for reciprocating said plunger; a defining a lubricant-containing annular space which surrounds

filling head connected with said cylinder and having an inlet in a portion of said plunger and is sealed from said metering

communication with said outlet means and a normally sealed 35 chamber; drive means for reciprocating said plunger; a filling

outlet, said filling head and said cylinder having hollow head connected with said cylinder and having an inlet in com

jackets; a source of conditioning fluid; means for circulating munication with said outlet means and a normally sealed out

conditioning fluid from said source and through said jackets; a let, said filling head and said cylinder having hollow jackets; a

source of gaseous propellant; supply conduit means connect first source containing a supply of a conditioning fluid; means

ing said propellant source with said inlet means, pressure 40 for circulating the conditioning fluid from said source and

reducing valve means provided in said conduit means; and through said jackets; a second source containing a supply of a

one-way valve means provided in said conduit means between liquefied propellant; a third source containing a supply of

said pressure-reducing valve means and said inlet means, said gaseous propellant; first conduit means connected with said

conduit means comprising a portion extending intermediate 45 inlet means; second conduit means connected with said

said pressure-reducing valve means and said one-way valve second source; third conduit means connected with said third

means and dipping into conditioning fluid in said first men source; and valve means connected with said conduit means

tioned source. and movable between a plurality of positions in one of which

2. A combination as defined in claim 1 wherein said portion said first conduit means is connected with said second conduit

of the supply conduit means forms at least one coil. means and in another of which said first conduit means is con

50 nected with said third conduit means.

3. In an apparatus for filling aerosol packages with gaseous

or liquid propellants, a combination comprising a metering 8. A combination as defined in claim 7, further comprising

cylinder having an end wall and defining a metering chamber one-way valve means provided in said first conduit means,

having propellant-admitting inlet means and propellant pump means provided in said second conduit means, a pres

evacuating outlet means; a hollow internally cooled plunger 55 sure-reducing valve means provided in said third conduit

extending into said cylinder and reciprocable therein to in earls.

thereby change the volume of said metering chamber, said end 9. In an apparatus for filling aerosol packages with fluid

wall of said cylinder sealingly surrounding said plunger and propellants, a combination comprising a metering cylinder

defining a lubricant-containing annular space which surrounds having an end wall and defining a metering chamber having

a portion of said plunger and is sealed from said metering 60 propellant-admitting inlet means and propellant-evacuating

chamber; drive means for reciprocating said plunger; a filling outlet means; a hollow internally cooled plunger extending

head connected with said cylinder and having an inlet in com into said cylinder and reciprocable therein to thereby change

munication with said outlet means and a normally sealed out the volume of said metering chamber, said end wall of said

let, said filling head and said cylinder having hollow jackets; a cylinder sealingly surrounding said plunger and defining a

first source containing a supply of a conditioning fluid; means 65 lubricant-containing annular space which surrounds a portion

for circulating the conditioning fluid from said source and of said plunger and is sealed from said metering chamber;

through said jackets; a second source containing a supply of a drive means for reciprocating said plunger; a filling head con

gaseous propellant; supply conduit means connecting said nected with said cylinder and having an inlet in communica

second source with said inlet means; pressure reducing valve tion with said outlet means and a normally sealed outlet, said

means provided in said conduit means; and one-way valve 70 filling head and said cylinder having hollow jackets; a first

means provided in said conduit means between said pressure source means

containing a supply of a fluid-conditioning medium;

for circulating the conditioning medium from said first

reducing valve means and said inlet means.

4. In an apparatus for filling aerosol packages with gaseous source and through said jackets; a second source containing a

or liquid propellants, a combination comprising a metering 75 supply of a fluid propellant; and supply conduit means con

cylinder having an end wall and defining a metering chamber necting said second source with said inlet means.

3,604,477 8

7

10. A combination as defined in claim 9, wherein said means for circulating the conditioning medium comprises

cylinder further comprises a record end wall which is con second conduit means connecting the interior of one of said

nected with said filling head and is provided with said outlet jackets with the interior of the other jacket.

In earls. 18. A combination as defined in claim 17, wherein said

11. A combination as defined in claim 9, further comprising means for circulating the conditioning medium further com

means for regulating the temperature of conditioning medium prises third conduit means for delivering the conditioning

said first source. medium from said first source to one of said jackets and fourth

12. A combination as defined in claim 11, wherein said conduit means for returning the conditioning medium from

regulating means comprises thermostat means. the other jacket to said first source.

13. A combination as defined in claim 9, wherein said drive 10 19. A combination as defined in claim 9, wherein said me

means comprises a cylinder and piston unit whose piston is tering cylinder comprises a second end wall which is con

rigid with said hollow plunger. nected with said filling head and wherein the outlet means of

14. A combination as defined in claim 9, further comprising said metering cylinder is parallel to the axis of the metering

a pair of annular sealing devices surrounding said plunger at 15

cylinder.

the opposite axial ends of said lubricant-containing space. 20. A combination as defined in claim 9, wherein said drive

15. A combination as defined in claim 14, wherein said means comprises a fluid-operated cylinder and piston unit

drive means comprises a second cylinder and a piston whose piston is rigid with said plunger, said plunger having at

reciprocable in said second cylinder and connected with said least one opening establishing communication between the in

plunger, said second cylinder having an end wall adjacent to 20

terior of the cylinder of said unit and the interior of said

the end wall of said metering cylinder and each of said end plunger whereby the fluid which operates said unit can circu

walls accommodating one of said sealing devices. late between the interior of said plunger and the interior of the

16. A combination as defined in claim 9, wherein said drive cylinder of said unit to internally cool the plunger.

means comprises a second cylinder separably secured to said 21. A combination as defined in claim 20, wherein said

end wall of said metering cylinder, said metering cylinder hav 25 opening is closely adjacent to the piston of said unit.

ing another end wall separably secured to said filling head.

17. A combination as defined in claim 9, wherein said

30

35

40

45

50

55

60

65

70

75

Potrebbero piacerti anche

- The Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattDa EverandThe Steam Engine Explained and Illustrated (Seventh Edition) With an Account of its Invention and Progressive Improvement, and its Application to Navigation and Railways; Including also a Memoir of WattNessuna valutazione finora

- United States Patent (19) : (75) Inventor: Donald J. Hirz, Willowick, OhioDocumento9 pagineUnited States Patent (19) : (75) Inventor: Donald J. Hirz, Willowick, OhioMustafa ŞENNessuna valutazione finora

- Us 5149907Documento7 pagineUs 5149907wewewewNessuna valutazione finora

- Rotary Dryer Steam Distribution SystemDocumento7 pagineRotary Dryer Steam Distribution SystemDouglas TondelloNessuna valutazione finora

- United States PatentDocumento5 pagineUnited States PatentPraveen SinghNessuna valutazione finora

- United States Patent (19) : PerryDocumento11 pagineUnited States Patent (19) : PerryDaniel MilanoNessuna valutazione finora

- United States Patent: Attorney-Pastoriza and KellyDocumento4 pagineUnited States Patent: Attorney-Pastoriza and KellyEnrico FermiNessuna valutazione finora

- Olin BWP Primer Patent - US3062146Documento5 pagineOlin BWP Primer Patent - US3062146orpheus1972Nessuna valutazione finora

- Pressure cookers with improved venting systemDocumento5 paginePressure cookers with improved venting systemgobinath VPNessuna valutazione finora

- Hawkins US5011035Documento5 pagineHawkins US5011035gobinath VPNessuna valutazione finora

- United States Patent (19) : George Et Al. 11 Patent Number: 4,969,525 45) Date of Patent: Nov. 13, 1990Documento9 pagineUnited States Patent (19) : George Et Al. 11 Patent Number: 4,969,525 45) Date of Patent: Nov. 13, 1990Cuenta InformacionNessuna valutazione finora

- Us4232526 PDFDocumento5 pagineUs4232526 PDFFernando TaleroNessuna valutazione finora

- Us4044945a PDFDocumento6 pagineUs4044945a PDF王如意Nessuna valutazione finora

- Thomas Ogle Gas Saver Carburetor PatentDocumento11 pagineThomas Ogle Gas Saver Carburetor Patentfatihy73Nessuna valutazione finora

- United States PatentDocumento5 pagineUnited States PatentAyu NurizzaNessuna valutazione finora

- Us2105625 PDFDocumento4 pagineUs2105625 PDFbelchior alvaroNessuna valutazione finora

- Us 3690255Documento5 pagineUs 3690255wewewewNessuna valutazione finora

- United States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980Documento4 pagineUnited States Patent (19) 11 4,226,186: Peck 45 (Oct. 7, 1980KundanNessuna valutazione finora

- United States Patent (19) : Gazalel, 72 8Documento7 pagineUnited States Patent (19) : Gazalel, 72 8Mihai RobertNessuna valutazione finora

- Patent for Cooling Hot Pellets with Water While Avoiding OxidationDocumento4 paginePatent for Cooling Hot Pellets with Water While Avoiding OxidationVinod Kumar KonagantiNessuna valutazione finora

- Depósito de Gases ResidualesDocumento5 pagineDepósito de Gases ResidualesLuis BejaranoNessuna valutazione finora

- Jan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LDocumento6 pagineJan. 7, 1936. C. N. Pogue 2,026,798: Filed Sept. 27, 1935 2. Sheets-Sheet LJesus ValleNessuna valutazione finora

- United States Patent: UehlingDocumento5 pagineUnited States Patent: UehlingAlex KattamisNessuna valutazione finora

- Venting Apparatus for Tire Mold Improves Air DischargeDocumento9 pagineVenting Apparatus for Tire Mold Improves Air DischargeDaikinllcNessuna valutazione finora

- US patent for positive back seat valve closure systemDocumento5 pagineUS patent for positive back seat valve closure systemTaufik Budi WibowoNessuna valutazione finora

- Us2960824 PDFDocumento5 pagineUs2960824 PDFgrigNessuna valutazione finora

- United States Patent (191: McguganDocumento6 pagineUnited States Patent (191: McguganJamesStenhouseNessuna valutazione finora

- CokeDocumento6 pagineCokeDendy Wahyu RadityaNessuna valutazione finora

- US5231917 - Wobble PistonDocumento5 pagineUS5231917 - Wobble PistondevheadbotNessuna valutazione finora

- Patente Cryoplus Linde Us4617039Documento13 paginePatente Cryoplus Linde Us4617039rubenpeNessuna valutazione finora

- United States Patent Describes Metering Dispenser with Flexible Chamber WallDocumento9 pagineUnited States Patent Describes Metering Dispenser with Flexible Chamber WallRonaldo SantosNessuna valutazione finora

- Patent for ambient air vaporizer with dissimilar materials couplingDocumento12 paginePatent for ambient air vaporizer with dissimilar materials couplingJaime Ocampo SalgadoNessuna valutazione finora

- United States Patent: Primary Examiner-Verlin R. PendegrassDocumento6 pagineUnited States Patent: Primary Examiner-Verlin R. PendegrassSmokeNessuna valutazione finora

- United States PatentDocumento6 pagineUnited States PatentJayaraj VNessuna valutazione finora

- Schema Pneumatique Generateur Haute PureteDocumento8 pagineSchema Pneumatique Generateur Haute PureteMariaNessuna valutazione finora

- Aug. 26, 1969 R. M. Lockwood ETAL 3,462,955: Filed June 29, 1967Documento4 pagineAug. 26, 1969 R. M. Lockwood ETAL 3,462,955: Filed June 29, 1967billy dillpickerNessuna valutazione finora

- Additive Composition For Release of Stuck Drill Pipe - (Fatty Alcohol Propoxylate and SMO Based Pipe Free Agent ExxonMobil)Documento6 pagineAdditive Composition For Release of Stuck Drill Pipe - (Fatty Alcohol Propoxylate and SMO Based Pipe Free Agent ExxonMobil)Pothiraj KrishnanNessuna valutazione finora

- Rotating double shell heat exchange drumDocumento5 pagineRotating double shell heat exchange drumaegosmithNessuna valutazione finora

- Turbofan jet engine afterburner flow mixing assemblyDocumento8 pagineTurbofan jet engine afterburner flow mixing assemblyMuhammed Cm SönmezNessuna valutazione finora

- US6390148 Valvula de LlenadoDocumento8 pagineUS6390148 Valvula de LlenadoFreddy SalinasNessuna valutazione finora

- US1216939Documento3 pagineUS1216939kissaNessuna valutazione finora

- Air Cleaner For Internal Combustion EngineDocumento6 pagineAir Cleaner For Internal Combustion EngineSirDeparnieux100% (1)

- Wash and Humidify Air with Early Air Washer DesignDocumento3 pagineWash and Humidify Air with Early Air Washer DesignPriya TiwariNessuna valutazione finora

- Us4278200 PDFDocumento4 pagineUs4278200 PDF王如意Nessuna valutazione finora

- United States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977Documento16 pagineUnited States Patent (19) 11 4,023,782: Eifer (45) May 17, 1977liNessuna valutazione finora

- United States PatentDocumento12 pagineUnited States PatentsaeedNessuna valutazione finora

- Cryogenic Air Separation System with Dual Feed Air Side CondensersDocumento8 pagineCryogenic Air Separation System with Dual Feed Air Side Condenserssajad yaghootNessuna valutazione finora

- Original: FiledDocumento4 pagineOriginal: FiledwcaskeyNessuna valutazione finora

- US5269336Documento7 pagineUS5269336fjkwznhxj5Nessuna valutazione finora

- H. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Documento4 pagineH. O. Pedersen Etal: 2 Sheets-Sheet 1 Filed March 20, 1962Josh FullerNessuna valutazione finora

- US4219241Documento7 pagineUS4219241aungkyawzoreNessuna valutazione finora

- United States Patent (191: Briickner Et A1Documento6 pagineUnited States Patent (191: Briickner Et A1PeterWangNessuna valutazione finora

- Seal PlateDocumento14 pagineSeal PlateRubén Leal RuizNessuna valutazione finora

- Login Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationDocumento8 pagineLogin Create Account (Free!) View Patents That Cite This Patent Click For Automatic Bibliography GenerationFilipNessuna valutazione finora

- US3094165 Wheeler Manfac-PatentDocumento7 pagineUS3094165 Wheeler Manfac-Patentsoubhadra nagNessuna valutazione finora

- United States Patent 19: Dumain Et AlDocumento10 pagineUnited States Patent 19: Dumain Et AlFi FiyundaNessuna valutazione finora

- Hydrant system reduces aircraft refueling pressure surgesDocumento4 pagineHydrant system reduces aircraft refueling pressure surgessqmiNessuna valutazione finora

- AU2020201626B2Documento59 pagineAU2020201626B2jNessuna valutazione finora

- United States Patent (19) : Siewert (45) May 25, 1976Documento7 pagineUnited States Patent (19) : Siewert (45) May 25, 1976INessuna valutazione finora

- Glue GunDocumento9 pagineGlue GunNaranLoganNessuna valutazione finora

- QTC TechDocumento124 pagineQTC TechMarc DenningerNessuna valutazione finora

- United States Patent (19) : Burger (45) Apr. 24, 1979Documento17 pagineUnited States Patent (19) : Burger (45) Apr. 24, 1979Mustafa ŞENNessuna valutazione finora

- Stock Gear Catalog 2008v3 PDFDocumento20 pagineStock Gear Catalog 2008v3 PDFDaniel Alfredo Chosgo IriarteNessuna valutazione finora

- COST Abstract BookDocumento105 pagineCOST Abstract BookMustafa ŞENNessuna valutazione finora

- Me2301 QBDocumento7 pagineMe2301 QBbalajigandhirajanNessuna valutazione finora

- Study a Fuel Injection Pump and Injector by DismantlingDocumento4 pagineStudy a Fuel Injection Pump and Injector by Dismantlingdhirendra singh50% (2)

- Engine Range en KUBDocumento28 pagineEngine Range en KUBVielis CaloloNessuna valutazione finora

- Dp6h Ufaa62 ProposalDocumento10 pagineDp6h Ufaa62 ProposalFerdinan Tulus Yones TobingNessuna valutazione finora

- The Passat, Model Year 2001: Self-Study Programme 251Documento64 pagineThe Passat, Model Year 2001: Self-Study Programme 251pakaitamasNessuna valutazione finora

- 6 Stroke EngineDocumento12 pagine6 Stroke EngineVanam VenkateshNessuna valutazione finora

- Stihl MS 460 Chainsaw Service ManualDocumento10 pagineStihl MS 460 Chainsaw Service ManualBrianCookNessuna valutazione finora

- Two Stroke Hydrogen Engine 1Documento4 pagineTwo Stroke Hydrogen Engine 1mrhat1234Nessuna valutazione finora

- Evolution engine specificationsDocumento21 pagineEvolution engine specificationsSergey Gaivoronsky67% (6)

- Engine Mechanical ECHO 2002Documento85 pagineEngine Mechanical ECHO 2002Tomas Dominguez100% (1)

- Internal Combustion Engines MCQ PDFDocumento14 pagineInternal Combustion Engines MCQ PDFShakir ullah87% (53)

- Cseelements of Mechanical Engg. L2Documento13 pagineCseelements of Mechanical Engg. L2bhatchinmay7Nessuna valutazione finora

- Year I and Year II Applied Science Modules - Auto & Diesel (New)Documento20 pagineYear I and Year II Applied Science Modules - Auto & Diesel (New)iiamakyraNessuna valutazione finora

- Service Manual Generic Xor 125Documento96 pagineService Manual Generic Xor 125chicharro88100% (2)

- Bhel EsvDocumento4 pagineBhel EsvKarthi Keyan100% (1)

- IC EnginesfinalDocumento136 pagineIC EnginesfinalVarsha SreekumarNessuna valutazione finora

- PK Nag Solution Thermodynamics 1 To 3Documento32 paginePK Nag Solution Thermodynamics 1 To 3Himanshu Arora100% (1)

- F5 T4B Service ManualDocumento393 pagineF5 T4B Service ManualDmicalio SimNessuna valutazione finora

- Million Dollar Copywriting SecretsDocumento79 pagineMillion Dollar Copywriting SecretsEdward Kobani100% (6)

- Lebw6460 00Documento16 pagineLebw6460 00taherNessuna valutazione finora

- Ignition SystemsDocumento19 pagineIgnition Systemshotbuddy723100% (1)

- RT-flex82 Flexview-9520 Rev.00Documento64 pagineRT-flex82 Flexview-9520 Rev.00Gaby Cris100% (2)

- Technical Note 4130ADocumento17 pagineTechnical Note 4130AliosylNessuna valutazione finora

- Newton's laws, aerodynamics, and aircraft performance fundamentalsDocumento34 pagineNewton's laws, aerodynamics, and aircraft performance fundamentalsGirish SreeneebusNessuna valutazione finora

- Pp12aDocumento55 paginePp12aWagih Abd El-AzizNessuna valutazione finora

- QB 114462Documento15 pagineQB 114462vasanthavananNessuna valutazione finora

- Engine Failure AnalyseDocumento76 pagineEngine Failure AnalyseMuhammad Asif100% (1)

- Revision SolutionDocumento19 pagineRevision SolutionHassan Abo NagaNessuna valutazione finora

- EM II, 2 Engleza, PDFDocumento36 pagineEM II, 2 Engleza, PDFAndrei Minca100% (2)

- PC15MR1Documento261 paginePC15MR1PooNessuna valutazione finora

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideDa EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideValutazione: 2 su 5 stelle2/5 (1)

- Asset Integrity Management for Offshore and Onshore StructuresDa EverandAsset Integrity Management for Offshore and Onshore StructuresNessuna valutazione finora

- Flow Analysis for Hydrocarbon Pipeline EngineeringDa EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNessuna valutazione finora

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryDa EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNessuna valutazione finora

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionDa EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionValutazione: 4.5 su 5 stelle4.5/5 (16)

- Industrial Piping and Equipment Estimating ManualDa EverandIndustrial Piping and Equipment Estimating ManualValutazione: 5 su 5 stelle5/5 (7)

- Pipeline Integrity: Management and Risk EvaluationDa EverandPipeline Integrity: Management and Risk EvaluationValutazione: 4.5 su 5 stelle4.5/5 (6)

- Well Control for Completions and InterventionsDa EverandWell Control for Completions and InterventionsValutazione: 4 su 5 stelle4/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataDa EverandPocket Guide to Flanges, Fittings, and Piping DataValutazione: 3.5 su 5 stelle3.5/5 (22)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesDa EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesNessuna valutazione finora

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilDa EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilNessuna valutazione finora

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationDa EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationValutazione: 4.5 su 5 stelle4.5/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisDa EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNessuna valutazione finora

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsDa EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsValutazione: 5 su 5 stelle5/5 (1)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesDa EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesValutazione: 4 su 5 stelle4/5 (2)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsDa EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsNessuna valutazione finora

- Subsea Valves and Actuators for the Oil and Gas IndustryDa EverandSubsea Valves and Actuators for the Oil and Gas IndustryValutazione: 5 su 5 stelle5/5 (1)

- Enhanced Oil Recovery Handout: A Focus on WaterfloodingDa EverandEnhanced Oil Recovery Handout: A Focus on WaterfloodingNessuna valutazione finora

- Petroleum Rock Mechanics: Drilling Operations and Well DesignDa EverandPetroleum Rock Mechanics: Drilling Operations and Well DesignValutazione: 5 su 5 stelle5/5 (1)

- Compression Machinery for Oil and GasDa EverandCompression Machinery for Oil and GasKlaus BrunValutazione: 4 su 5 stelle4/5 (4)