Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Part 7. Refrigeration Equipment - Chapter 4. Combination Absorption-Centrifugal System

Caricato da

Karthikeyan Sankarrajan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

16 visualizzazioni1 paginaCentrifugal Compressor Power Requirement

Titolo originale

Centrifugal Compressor Power Requirement

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCentrifugal Compressor Power Requirement

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

16 visualizzazioni1 paginaPart 7. Refrigeration Equipment - Chapter 4. Combination Absorption-Centrifugal System

Caricato da

Karthikeyan SankarrajanCentrifugal Compressor Power Requirement

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Part 7. Refrigeration Equipment | Chapter 4.

Combination Absorption-centrifugal System

load in proportion to the instantaneous load, while the

steam pressure regulator maintains a steam flow balance

between the centrifugal and absorption machines and

consequently a minimum system steam rate.

ENGINEERING PROCEDURE

Selecting the equipment for a combination system is

a matter of achieving the required performance with the

minimum owning and operating costs. Equipment

selecting is essentially a trial-and-error process. The Base the determination of steam rate upon an

following method is recommended to provide a assumed one-third-system load on the centrifugal and a

satisfactory system. two-thirds system load on the high temperature side a

leaving water temperature may be determined. From

PERFORMANCE Chart 11 an approximate brake horsepower per ton of

The required performance consists of load or refrigeration may be assumed for the centrifugal.

tonnage, chilled water temperature and quantity or rise The required turbine performance is abstained from

(F). The load or tonnage is determined by using normal the turbine supplier and includes the following:

methods. Chilled water rises of 15-20 F is suggested for 1. Curves relation speed, horsepower and steam

minimum system steam rate and pressure drop thru the consumption from full to minimum load of the

chillers. Chilled water temperature selection should not centrifugal.

be arbitrary, but should be as high as design permits. 2. Curves relating turbine exhaust steam quality to

Recommended condenser water quantities are turbine horsepower, speed or steam

approximately 3 gpm per ton for the centrifugal and 3.5 consumption.

gpm per ton for the absorption machine. 3. There are no turbine performance characteristics

which are typical of all turbines. Chart 12 shows

TURBINE STEAM RATE the performance of two typical back pressure

Determine the expected single stage turbine steam turbines for centrifugal refrigeration machine

rate and exhaust steam quality for the specified inlet duty.

steam conditions (pressure and superheat) and 13 psig

back pressure. (This allows 1 psi pressure loss for the DISTRIBITION OF DESIGN CAPACITY AND MIMUMUM

steam piping between the turbine exhaust and the SYSTEM STEAM RATE

absorption machine inlet, assuming the absorption Calculate the centrifugal machine proportion of the

machine and turbine are close-coupled.) system design load. This is determined from the formula:

Potrebbero piacerti anche

- Smacna Duct Fitting Loss TableDocumento2 pagineSmacna Duct Fitting Loss TableKarthikeyan Sankarrajan75% (4)

- Essentials of Steam Turbine Design and Analysis: Back To BasicsDocumento9 pagineEssentials of Steam Turbine Design and Analysis: Back To BasicsJohn AnthoniNessuna valutazione finora

- Cummins 4BT - 6BT Engine Parts Catalogue - Diesel Engine, Diesel Engine Parts, Generator Set ExporterDocumento3 pagineCummins 4BT - 6BT Engine Parts Catalogue - Diesel Engine, Diesel Engine Parts, Generator Set ExporterRicardo Rodriguez100% (7)

- Prac 5 Without AnswersDocumento4 paginePrac 5 Without AnswersTitsarosal ThomasNessuna valutazione finora

- Combined Cycle - ArticleDocumento7 pagineCombined Cycle - Articlemgkvpr100% (1)

- Scramjets: Fuel Mixing and Injection SystemsDa EverandScramjets: Fuel Mixing and Injection SystemsNessuna valutazione finora

- Shaft DesignDocumento13 pagineShaft DesignKarthikeyan SankarrajanNessuna valutazione finora

- IPC Loading UnitsDocumento3 pagineIPC Loading UnitsTaqui Mubeen67% (3)

- Grease Trap TypesDocumento1 paginaGrease Trap TypesKarthikeyan SankarrajanNessuna valutazione finora

- Fittings - K ValueDocumento2 pagineFittings - K ValueKarthikeyan SankarrajanNessuna valutazione finora

- Purolite Ion Exchange Resins For Use in Nuclear PowerDocumento34 paginePurolite Ion Exchange Resins For Use in Nuclear PowerWalid Fattah100% (1)

- LP1 TKZ 10XXX M M1a Man 8405 CDocumento27 pagineLP1 TKZ 10XXX M M1a Man 8405 CPhong DoNessuna valutazione finora

- Chilled Water Pumps Training ManualDocumento23 pagineChilled Water Pumps Training Manualsarmad009Nessuna valutazione finora

- ReactorsDocumento70 pagineReactorsMusa KaleemNessuna valutazione finora

- Ch2 - Gas TurbinesDocumento37 pagineCh2 - Gas TurbinesShaktivell Letchumanan100% (1)

- 02gas tURBINES - A PDFDocumento38 pagine02gas tURBINES - A PDFAdib ShaidanNessuna valutazione finora

- Boost Engine Power with Turbochargers and SuperchargersDocumento38 pagineBoost Engine Power with Turbochargers and SuperchargersSudarshan SudhuNessuna valutazione finora

- Thermoeconomic Evaluation of Combined Cycle Cogeneration Systems - MakaleDocumento8 pagineThermoeconomic Evaluation of Combined Cycle Cogeneration Systems - Makaley_durNessuna valutazione finora

- How CCPPs Work to Generate Power EfficientlyDocumento11 pagineHow CCPPs Work to Generate Power EfficientlyPGPalomaNessuna valutazione finora

- Analysis of Inlet Air Temperature Effect On Gas Turbine Compressor PerfornanceDocumento9 pagineAnalysis of Inlet Air Temperature Effect On Gas Turbine Compressor PerfornanceRafraf Ezdine100% (1)

- Power Plant: Lec. (7) Dr. Omar M. AliDocumento10 paginePower Plant: Lec. (7) Dr. Omar M. AliBalen KarimNessuna valutazione finora

- M15 PDFDocumento28 pagineM15 PDFMartha Escobar RojasNessuna valutazione finora

- Jet Propulsion Lecture Gas Turbine Cycle Components EfficiencyDocumento32 pagineJet Propulsion Lecture Gas Turbine Cycle Components Efficiencyswai singhNessuna valutazione finora

- Process Efficiencies: Net inDocumento4 pagineProcess Efficiencies: Net inWillRoseroNessuna valutazione finora

- Turbines and ExpandersDocumento8 pagineTurbines and ExpandersMusa KaleemNessuna valutazione finora

- Shiv Pratap PatelDocumento19 pagineShiv Pratap PatelShubham JeengarNessuna valutazione finora

- Heat Engines Vol 2 Chapter 3 PDFDocumento23 pagineHeat Engines Vol 2 Chapter 3 PDFtarunNessuna valutazione finora

- Gujarat Technological University: L.D. College of Engineering AhmedabadDocumento31 pagineGujarat Technological University: L.D. College of Engineering AhmedabadRaumil ManiarNessuna valutazione finora

- Vapour Compression For Propane-Propylene SplittersDocumento3 pagineVapour Compression For Propane-Propylene SplittersJohnNessuna valutazione finora

- University of Karbala Department of Mechanical Lecture Notes - Power Plants by Fadhel Al-MousawiDocumento27 pagineUniversity of Karbala Department of Mechanical Lecture Notes - Power Plants by Fadhel Al-Mousawiحامد عبد الشهيد حميد مجيد100% (1)

- Brayton Cycle Reheat Regen RecollingDocumento14 pagineBrayton Cycle Reheat Regen RecollingDaxit LodaliyaNessuna valutazione finora

- CH - 4Documento31 pagineCH - 4fedila jemal100% (1)

- Thermodynamics Project PDFDocumento32 pagineThermodynamics Project PDFDaniyal NisarNessuna valutazione finora

- Lab Refrigeration N Cooling TowerDocumento21 pagineLab Refrigeration N Cooling TowerShahran IezzatNessuna valutazione finora

- Ch-6-W-12-Gas TurbinesDocumento50 pagineCh-6-W-12-Gas TurbinesArkew Bogale100% (2)

- Sistem Irreversibel Turbin GasDocumento6 pagineSistem Irreversibel Turbin GasAndri susantoNessuna valutazione finora

- CH 01 Propul ThermoDocumento16 pagineCH 01 Propul ThermoWilliams LabeNessuna valutazione finora

- Choudari Et Al. (2012) - Distillation Optimization Vapor RecompressionDocumento5 pagineChoudari Et Al. (2012) - Distillation Optimization Vapor Recompressionvazzoleralex6884Nessuna valutazione finora

- Vapour Cycle Thermodynamics TutorialDocumento13 pagineVapour Cycle Thermodynamics TutorialDavid ChikuseNessuna valutazione finora

- Gpsa 15Documento28 pagineGpsa 15David Cortez Peralta100% (1)

- Gas Turbine IntroductionDocumento84 pagineGas Turbine IntroductionMohammad Akram100% (2)

- EES AppendixADocumento7 pagineEES AppendixAhardik10888Nessuna valutazione finora

- Waste heat recovery feasibility studyDocumento43 pagineWaste heat recovery feasibility studyajithvinuNessuna valutazione finora

- Brayton Cycle GuideDocumento23 pagineBrayton Cycle GuideKelly AnwarNessuna valutazione finora

- Figure 1. Rankine CycleDocumento17 pagineFigure 1. Rankine CycleJikni NobleNessuna valutazione finora

- Gas Turbines for Aircraft Propulsion AnalysisDocumento49 pagineGas Turbines for Aircraft Propulsion AnalysisDk DamoNessuna valutazione finora

- Chap 1 - Steam Power PlantDocumento60 pagineChap 1 - Steam Power PlantMuhammad Qusyairi100% (2)

- Gas TurbineDocumento43 pagineGas TurbineMuhammad Qusyairi50% (2)

- Turbocharger Test Stand With A Hot Gas Generator For High - Performance Supercharging SystemsDocumento4 pagineTurbocharger Test Stand With A Hot Gas Generator For High - Performance Supercharging SystemsintelligentloveNessuna valutazione finora

- Turbojet Cycle Design: Universidad Carlos III de MadridDocumento9 pagineTurbojet Cycle Design: Universidad Carlos III de MadridTolgahan ŞahinNessuna valutazione finora

- Airframe and Powerplant ReviewerDocumento45 pagineAirframe and Powerplant ReviewerBobby SereNessuna valutazione finora

- RegenerationDocumento8 pagineRegenerationMohamed KhalilNessuna valutazione finora

- 1214meij02 PDFDocumento15 pagine1214meij02 PDFAnonymous 9JYURINessuna valutazione finora

- Comparison Between Single&multi Shaft Turbine PDFDocumento12 pagineComparison Between Single&multi Shaft Turbine PDFcobrasrkNessuna valutazione finora

- Chapter 8B - Gas Power Plant Brayton CycleDocumento17 pagineChapter 8B - Gas Power Plant Brayton CycleBF3nobel100% (1)

- Vapor Power CyclesDocumento18 pagineVapor Power CyclesParmeshwarPaulNessuna valutazione finora

- Chapter 8 - SolutionDocumento43 pagineChapter 8 - SolutionIzaNessuna valutazione finora

- Al-Weshahi Et Al Validation of Simulation Model For Cogeneration Power and Waer Desalination PlantDocumento10 pagineAl-Weshahi Et Al Validation of Simulation Model For Cogeneration Power and Waer Desalination PlantSrinivas RajanalaNessuna valutazione finora

- Transition To Turbopropeller-Powered AirplanesDocumento14 pagineTransition To Turbopropeller-Powered AirplanesAditya Sinha100% (1)

- Comparison Between SingleDocumento14 pagineComparison Between Singlesevero97Nessuna valutazione finora

- Module 2 Gas Turbines PDFDocumento31 pagineModule 2 Gas Turbines PDFafaq ahmad khanNessuna valutazione finora

- Gasturb Project: Submitted By: Dev Prakash (16AE30001)Documento9 pagineGasturb Project: Submitted By: Dev Prakash (16AE30001)dev burmanNessuna valutazione finora

- 06 Gas Turbine Power PlantDocumento31 pagine06 Gas Turbine Power PlantRishav niroulaNessuna valutazione finora

- Chapter 3 Gas Power CyclesDocumento42 pagineChapter 3 Gas Power CyclesAmirul HazzmiNessuna valutazione finora

- Twisted Tube TechnologyDocumento5 pagineTwisted Tube TechnologylpczyfansNessuna valutazione finora

- Turbine Inlet Air CoolingDocumento4 pagineTurbine Inlet Air Coolingkrazylion100% (2)

- Machines DesignDocumento7 pagineMachines DesignKarthikeyan SankarrajanNessuna valutazione finora

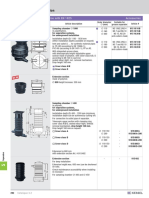

- Led Bollard Light: Item Code: EL-S-BOL-LEDDocumento1 paginaLed Bollard Light: Item Code: EL-S-BOL-LEDKarthikeyan SankarrajanNessuna valutazione finora

- Stress DesignDocumento11 pagineStress DesignKarthikeyan SankarrajanNessuna valutazione finora

- Health Facility GuidelinesDocumento51 pagineHealth Facility GuidelinesAshok Kumar Pillai100% (1)

- Refrigerant Dehumidification Technology: Technical Bulletin 1Documento12 pagineRefrigerant Dehumidification Technology: Technical Bulletin 1Karthikeyan SankarrajanNessuna valutazione finora

- Brake DesignDocumento2 pagineBrake DesignKarthikeyan SankarrajanNessuna valutazione finora

- Seasonal Energy Efficien..Documento6 pagineSeasonal Energy Efficien..Karthikeyan SankarrajanNessuna valutazione finora

- Method statement for testing and commissioningDocumento1 paginaMethod statement for testing and commissioningKarthikeyan SankarrajanNessuna valutazione finora

- Sewerage CalculatorDocumento5 pagineSewerage CalculatorKarthikeyan SankarrajanNessuna valutazione finora

- Air Flow Velocity in DuctsDocumento2 pagineAir Flow Velocity in DuctsKarthikeyan SankarrajanNessuna valutazione finora

- SMACNA - HVAC-Systems-Duct-Design1990 260Documento1 paginaSMACNA - HVAC-Systems-Duct-Design1990 260Karthikeyan Sankarrajan100% (1)

- Water Regulations Advisory Scheme Ltd. (Wras) Material ApprovalDocumento2 pagineWater Regulations Advisory Scheme Ltd. (Wras) Material ApprovalKarthikeyan SankarrajanNessuna valutazione finora

- F.A.Q. Picv: General Valve QuestionsDocumento9 pagineF.A.Q. Picv: General Valve QuestionsKarthikeyan SankarrajanNessuna valutazione finora

- Led Top Pole Light: Item Code: LL-POLETOP-LEDDocumento1 paginaLed Top Pole Light: Item Code: LL-POLETOP-LEDKarthikeyan SankarrajanNessuna valutazione finora

- For Underground Installation: Grease SeparatorsDocumento1 paginaFor Underground Installation: Grease SeparatorsKarthikeyan SankarrajanNessuna valutazione finora

- Lux LevelDocumento1 paginaLux LevelKarthikeyan SankarrajanNessuna valutazione finora

- Typical Kv valve sizing chartDocumento1 paginaTypical Kv valve sizing chartKarthikeyan SankarrajanNessuna valutazione finora

- 00 HVAC CalcDocumento52 pagine00 HVAC Calcibson045001256Nessuna valutazione finora

- Underground coalescence separatorDocumento1 paginaUnderground coalescence separatorKarthikeyan SankarrajanNessuna valutazione finora

- Part 11. Air-Water System - Chapter 1. Induction Unit SystemDocumento1 paginaPart 11. Air-Water System - Chapter 1. Induction Unit SystemKarthikeyan SankarrajanNessuna valutazione finora

- Part 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Documento1 paginaPart 10. All-Air Systems - Chapter 4. Dual-Duct System: Table 1 Summarizes The Cooling Load Requirements of 2)Karthikeyan SankarrajanNessuna valutazione finora

- Air Duct Design Friction Loss ChartDocumento1 paginaAir Duct Design Friction Loss ChartKarthikeyan SankarrajanNessuna valutazione finora

- Halton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Documento4 pagineHalton: - High Heat and High Grease Emissions? Not To Worry With Mist On Demand!Karthikeyan SankarrajanNessuna valutazione finora

- Recommended Duct VelocitiesDocumento1 paginaRecommended Duct VelocitiesKarthikeyan Sankarrajan100% (1)

- NTi Audio AppNote XL2 Noise CurvesDocumento13 pagineNTi Audio AppNote XL2 Noise CurvesdjossNessuna valutazione finora

- 19 6 6 Wildpoldsried AlcaldeDocumento20 pagine19 6 6 Wildpoldsried AlcaldeFabricio NoriegaNessuna valutazione finora

- Thermozorb Heatless Regenerative Air Dryer: TZ22 - TZ903Documento2 pagineThermozorb Heatless Regenerative Air Dryer: TZ22 - TZ903Емил ГавриловNessuna valutazione finora

- TIGAS Haldor TopsoeDocumento25 pagineTIGAS Haldor TopsoeGabriele CentiNessuna valutazione finora

- The Effect of Elevated Inlet Air Temperature and Relative Humidity On Cogeneration SystemDocumento11 pagineThe Effect of Elevated Inlet Air Temperature and Relative Humidity On Cogeneration SystemAdrian Arauco CarhuasNessuna valutazione finora

- 3KW Solar Power System Quotation and SpecificationDocumento1 pagina3KW Solar Power System Quotation and Specificationfarrelsyafira100% (1)

- Modeling and Stability Analysis of Distributed GenerationDocumento8 pagineModeling and Stability Analysis of Distributed Generationrudreshsj86Nessuna valutazione finora

- Boiler Specification With MountingsDocumento9 pagineBoiler Specification With MountingsKrishna RajuNessuna valutazione finora

- Compressor Oils: Compressor Oils Are Fluids Used For Lubrication of Moving Metal Parts of Gas (Air) CompressorsDocumento3 pagineCompressor Oils: Compressor Oils Are Fluids Used For Lubrication of Moving Metal Parts of Gas (Air) Compressorsspyros_peiraiasNessuna valutazione finora

- Desert - Scientists May Have Found One Answer To The Problem of Water ShortagesDocumento3 pagineDesert - Scientists May Have Found One Answer To The Problem of Water ShortagesMam SawNessuna valutazione finora

- Exam 1 - 2009Documento3 pagineExam 1 - 2009yaprak dönerNessuna valutazione finora

- Catalogo Técnico DVM SamsungDocumento90 pagineCatalogo Técnico DVM Samsungfabioleite06Nessuna valutazione finora

- PC160LC-8 - Parts BookDocumento422 paginePC160LC-8 - Parts BookHugo Silva100% (2)

- Management of DC Supply Failure.05.07.2020Documento66 pagineManagement of DC Supply Failure.05.07.2020ntpc bgtppNessuna valutazione finora

- Manual Boiler EZ-G - SG - EngDocumento72 pagineManual Boiler EZ-G - SG - EngjokoNessuna valutazione finora

- System Component: 3.1. Selection of The Heat Exchanger (Air Handling Unit)Documento1 paginaSystem Component: 3.1. Selection of The Heat Exchanger (Air Handling Unit)Skill IndiaNessuna valutazione finora

- Optimize Steam Power Cycle EfficiencyDocumento48 pagineOptimize Steam Power Cycle EfficiencyHafiz ShamNessuna valutazione finora

- Design and Performance Evaluation of A Dual-Operation Condenser Using R-134ADocumento17 pagineDesign and Performance Evaluation of A Dual-Operation Condenser Using R-134AAhmed AlhamdiNessuna valutazione finora

- Chapter 1 7Documento76 pagineChapter 1 7Ian ReyesNessuna valutazione finora

- Dual Power Generation Solar Plus Windmill System Chapter 1 FinaleDocumento11 pagineDual Power Generation Solar Plus Windmill System Chapter 1 FinaleBlackStar Code 27Nessuna valutazione finora

- TRANSMISSION SCHEMES FOR EVACUATION OF POWER FROM GENERATION PROJECTSDocumento53 pagineTRANSMISSION SCHEMES FOR EVACUATION OF POWER FROM GENERATION PROJECTSRagavanNessuna valutazione finora

- Boiler Mountings and AccessoriesDocumento12 pagineBoiler Mountings and AccessoriesGokulAgNessuna valutazione finora

- HRSG StartupDocumento19 pagineHRSG Startuptpplant100% (1)

- R Randen Engg - Bhushan - Valves Enq - 18Documento3 pagineR Randen Engg - Bhushan - Valves Enq - 18Vinayak PujariNessuna valutazione finora

- Spare Parts Catalogue - January 2015Documento17 pagineSpare Parts Catalogue - January 2015Yury KovalevNessuna valutazione finora

- Reducing Rear Pass Temperature by Varying Burner Tilt AngleDocumento9 pagineReducing Rear Pass Temperature by Varying Burner Tilt AngleMayank ManishNessuna valutazione finora

- 15 - 005 Low Load Operation For S1600 Gendrive EnginesDocumento1 pagina15 - 005 Low Load Operation For S1600 Gendrive EnginesjamesNessuna valutazione finora