Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BSM Series Complete PDF

Caricato da

georgica pandelicaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BSM Series Complete PDF

Caricato da

georgica pandelicaCopyright:

Formati disponibili

BSM Series

Brushless Servo Motor Manual

ICPE SA - SPLAIUL UNIRII, NR. 313, SECTOR 3 - 030138 BUCURESTI - ROMANIA

Tel / Fax : 004 / 021 / 3467233, e-mail: servo@icpe.ro, web: www.icpe.ro/dept03

Use of Motors

Servo motors are intended to drive machinery. As such, they must be part of a controlled system

that includes a transistorized electronic amplifier. They are not intended for direct connection to

the power supply or for use with thyristor drives. Instructions in the amplifier and control system

manuals must be observed; this document does not replace those instructions.

Unless specified otherwise, servo motors are intended for use in a normal industrial

environment without exposure to excessive or corrosive moisture or abnormal ambient

temperatures. The exact operating conditions may be established by referring to the

data for the motor. The mating of motors to machinery is a skilled operation;

disassembly or repair must not be attempted. In the event that a motor fails to operate

correctly, contact the place of purchase for return instructions.

Safety Notes

There are some possible hazards associated with the use of motors. The following precautions

should be observed. Specific Warnings and Cautions are listed inside the back cover.

Installation and Maintenance: Installation and maintenance or replacement must be carried out

by suitably qualified service personnel, paying particular attention to possible electrical and

mechanical hazards.

Flying leads: Ensure that flying or loose leads are suitably restrained, to prevent snagging or

entan-glement, before carrying motors with such leads.

Generation: If the motor is driven mechanically, it may generate hazardous voltages at its power

input terminals. The power connector must be suitably guarded to prevent a possible shock

hazard.

Loose motors: When running an unmounted motor, ensure that the rotating shaft is adequately

guarded and the motor is physically restrained to prevent it from moving. Remove the key which

otherwise could fly out when the motor is running.

Damaged cables: Damage to cables or connectors may cause an electrical hazard. Ensure there

is no damage before energizing the system.

Supply: Servo motors must not be directly connected to a power supply; they require an

electronic drive system. Consult the instructions for the drive system before energizing or using

the motor.

Brakes: The brakes that are included on motors are holding brakes only and are not to be used as

a mechanical restraining device for safety purposes.

Safety requirements: The safe incorporation of this product into a machine system is the

responsi-bility of the machine designer, who should comply with the local safety requirements at

the place where the machine is to be used. In Europe this is likely to be the Machinery Directive.

Mechanical connection: Motors must be connected to the machine with a torsionally rigid

coupler or a reinforced timing belt. Couplers which are not rigid will cause difficulty in

achieving an accept-able response from the control system. Couplings and pulleys must be tight

as the high dynamic performance of a servo motor can easily cause couplings to slip, and thereby

damage the shaft and cause instability. Care must be taken in aligning couplings and tightening

belts so that the motor is not subjected to significant bearing loads, or premature bearing wear

will occur. Once connected to a load, tuning will be affected. A system tuned without a load will

probably require retuning once a load is applied.

Connectors: Motor power connectors are for assembly purposes only. They should not be

connected or disconnected while power is applied.

ICPE SA - SPLAIUL UNIRII, NR. 313, SECTOR 3 - 030138 BUCURESTI - ROMANIA

Tel / Fax : 004 / 021 / 3467233, e-mail: servo@icpe.ro, web: www.icpe.ro/dept03

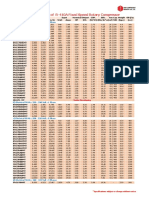

size A B C D E F H K K1 M O P R S1 S2 T1 T2 U U1

J6 k6 h9 h9

0.1 40 63 5,8 9 24 2,5 55 118 151 55 8 74 M3.10 39 39 7,2 3 3 14

0.2 40 63 5,8 9 24 2,5 55 143 176 55 8 74 M3.10 39 39 7,2 3 3 14

0.3 40 63 5,8 9 24 2,5 55 163 196 55 8 74 M3.10 39 39 7,2 3 3 14

0.4 40 63 5,8 9 24 2,5 55 183 216 55 8 74 M3.10 39 39 7,2 3 3 14

0.5 40 63 5,8 9 24 2,5 55 254 287 55 8 74 M3.10 39 39 7,2 3 3 14

1.1 80 100 7 14 30 3 88 132 173 82 10 115 M4.12 36 36 11,1 5 5 20

1.2 80 100 7 14 30 3 88 152 193 82 10 115 M4.12 36 36 11,1 5 5 20

1.3 80 100 7 14 30 3 88 172 213 82 10 115 M4.12 36 36 11,1 5 5 20

1.4 80 100 7 14 30 3 88 192 233 82 10 115 M4.12 36 36 11,1 5 5 20

1.5 80 100 7 14 40 3 88 222 263 82 10 115 M4.12 36 36 11,1 5 5 20

2.1 95 115 9 19 40 3 105 198 238 105 12 135 M6.15 39 39 15,5 6 6 30

2.2 95 115 9 19 40 3 105 228 268 105 12 135 M6.15 39 39 15,5 6 6 30

2.3 95 115 9 19 40 3 105 248 288 105 12 135 M6.15 39 39 15,5 6 6 30

2.4 95 115 9 19 40 3 105 293 333 105 12 135 M6.15 39 39 15,5 6 6 30

3.1 130 165 11 24 50 3,5 145 280 323 145 12 188 M8.25 39 39 19,9 8 8 40

3.2 130 165 11 24 50 3,5 145 320 363 145 12 188 M8.25 39 39 19,9 8 8 40

3.3 130 165 11 24 50 3,5 145 440 483 145 12 188 M8.25 39 39 19,9 8 8 40

ICPE SA - SPLAIUL UNIRII, NR. 313, SECTOR 3 - 030138 BUCURESTI - ROMANIA

Tel / Fax : 004 / 021 / 3467233, e-mail: servo@icpe.ro, web: www.icpe.ro/dept03

J

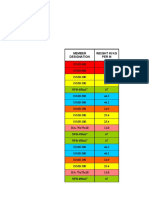

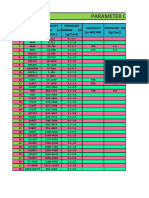

Size Dim. PN(kW) MN(Nm) Mo[Nm] Mom[Nm] In[A] Io[A] 2 m[kg] m+BR[kg] R[Ohm ] L[mH] kE[V]] kT[Nm/A]

[kgcm ]

BSM 55 - 0020 - 3 0.1 0.04 0.13 0.2 0.8 0.3 0.4 0.05 0.83 1.2 122 66.5 30 0.50

BSM 55 - 0050 - 3 0.2 0.13 0.35 0.5 1 0.9 1.2 0.1 1.3 1.6 18,3 13 26 0.43

BSM 55 - 0070 - 3 0.3 0.19 0.5 0.7 2.8 1.2 1.6 0.15 1.6 1.8 11.9 14.3 28 0.46

BSM 55 - 0070 - 6 0.3 0.19 0.5 0.7 2.8 0.7 0.9 0.15 1.6 1.8 32 28 47 0.78

BSM 55 - 0085 - 3 0.4 0.29 0.74 0.85 3.4 1.7 1.9 0.2 1.9 2.2 8.9 9.3 28 0.46

BSM 55 - 0085 - 6 0.4 0.29 0.74 0.85 3.4 0.9 1.1 0.2 1.9 2.2 28 23 50 0.83

BSM 55 - 0150 - 3 0.5 0.54 1.35 1.5 6 3.1 3.4 0.33 2.8 3.1 3.8 4.6 28 0.46

BSM 55 - 0150 - 6 0.5 0.54 1.35 1.5 6 1.7 1.9 0.33 2.8 3.1 13.7 13.9 51 0.84

BSM 88 - 0100 - 3 1.1 0.23 0.66 1 4 1.6 2.4 0.3 2 2.8 6.3 14.3 26 0.43

BSM 88 - 0100 - 6 1.1 0.23 0.66 1 4 1.0 1.4 0.3 2 2.8 18.4 39 44 0.73

BSM 88 - 0170 - 3 1.2 0.38 1.1 1.7 6.2 2.3 3.6 0.68 2.9 3.7 3.3 9.2 30 0.50

BSM 88 - 0170 - 6 1.2 0.38 1.1 1.7 6.2 1.4 2.2 0.68 2.9 3.7 7.7 24 50 0.83

BSM 88 - 0260 - 3 1.3 0.63 1.8 2.6 10.4 3.8 5.5 1 3.7 4.5 1.7 6 30 0.50

BSM 88 - 0260 - 6 1.3 0.63 1.8 2.6 10.4 1.9 2.8 1 3.7 4.5 5.2 16.7 59 0.98

BSM 88 - 0350 - 3 1.4 0.92 2.5 3.5 14 4.8 6.6 1.4 4.3 5.5 1.1 4.3 33.5 0.55

BSM 88 - 0350 - 6 1.4 0.92 2.5 3.5 14 3.1 4.3 1.4 4.3 5.5 2.8 10.8 52 0.86

BSM 88 - 0420 - 3 1.5 1.21 3.2 4.2 16.8 6.2 8.1 1.8 5.4 6.7 0.8 3.2 33 0.55

BSM 88 - 0420 - 6 1.5 1.21 3.2 4.2 16.8 3.7 4.8 1.8 5.4 6.7 2.4 9.3 55 0.91

BSM 105 - 0450 - 3 2.1 1.34 3.5 4.5 18 6.4 8.2 2.4 6 6.9 1 5.5 35 0.58

BSM 105 - 0450 - 6 2.1 1.34 3.5 4.5 18 3.7 4.8 2.4 6 6.9 2.8 13.6 60 0.99

BSM 105 - 0650 - 3 2.2 2.01 5.2 6.5 26 11.1 13.8 3.2 7.6 9.5 0.4 2.3 30 0.50

BSM 105 - 0650 - 6 2.2 2.01 5.2 6.5 26 4.9 6.1 3.2 7.6 9.5 2 11.3 68 1.12

BSM 105 - 0750 - 3 2.3 2.72 6.8 7.5 30 13.0 14.4 3.6 8.5 11.4 0.47 1.9 33 0.55

BSM 105 - 0750 - 6 2.3 2.72 6.8 7.5 30 7.1 7.9 3.6 8.5 11.4 1.5 8.4 60 0.99

BSM 105 - 1000 - 6 2.4 3.48 8.7 10 40 10.3 11.8 4.5 16 19 0.8 4.4 54 0.89

BSM 145 - 1500 - 6 3.1 4.02 11 15 30 12.0 16.4 5.3 19.5 24 0.6 6.1 58 0.96

BSM 145 - 2000 - 6 3.2 5.03 15 20 40 18.5 26.5 6.7 22 28 0.3 3.2 48 0.79

BSM 145 - 3000 - 6 3.3 8.38 22 30 60 22.0 29.3 11.2 30 34 0.3 3.8 65 1.08

ICPE SA - SPLAIUL UNIRII, NR. 313, SECTOR 3 - 030138 BUCURESTI - ROMANIA

Tel / Fax : 004 / 021 / 3467233, e-mail: servo@icpe.ro, web: www.icpe.ro/dept03

Torque v. speed

7

Momax

5

Torque [Nm]

Intermittent torque

3

2

Mn

Mo

1

Continuous torque

0

0 1000 2000 3000 4000 5000 6000 7000

n [rpm]

M[Nm] - S1 M[Nm] - peak torque

nN - Nominal speed

PN - Nominal power

M N - Nominal torque

Mo - Static torque - continuous standstill torque

Momax - Maximum static torque - maximum intermittent static torque

IN - Nominal current (± 10%)

Io - Static current (± 10%)

J - Moment of inertia including resolver (without brake)

m - Weight of the motor (weight of the motor with brake)

R - Line to line motor resistance (25°C) (± 10%)

L - Line to line motor inductivity (± 20%)

kE - Electromotive force [V] at 1000 rpm (± 10%)

kT - Torque constant (± 10%)

ICPE SA - SPLAIUL UNIRII, NR. 313, SECTOR 3 - 030138 BUCURESTI - ROMANIA

Tel / Fax : 004 / 021 / 3467233, e-mail: servo@icpe.ro, web: www.icpe.ro/dept03

Connectors Data

Power Power Resolver Resolver

Connector Cable Connector Cable

Pin Signal Pin Signal

1 PHASE R 1 1 Sin + WHITE

2 GROUND SHIELD 2 Sin - BROWN

+GROUND

3 PHASE S 2 3 Cos + GREEN

4 PHASE T 3 4 Cos - YELLOW

A Brake Red 5 PTC RED

(+24V)

B Brake (0V) Blue 6 PTC BLUE

C Open 7 Carrier - PINK

D Open 8 Carrier + GREY

9 Open Open

10 Open Open

11 Open Open

12 Open Open

ICPE SA - SPLAIUL UNIRII, NR. 313, SECTOR 3 - 030138 BUCURESTI - ROMANIA

Tel / Fax : 004 / 021 / 3467233, e-mail: servo@icpe.ro, web: www.icpe.ro/dept03

Resolver data

Specification Size 0, 1, 2 Size 3

Primary Rotor Rotor

Speed One One

Power supply condition (*) 4 Vrms/7KHz 4Vrms/5kHz

Input current (typical) 35 mA 25 mA

Transformation ratio .5 ± 5% .5 ± 5%

Phase Shift 5o 5o

Rotor resistance 21 Ω 20Ω

Stator resistance 74 Ω 58 Ω

(*)

Resolver can be used with other input voltages and frequencies, but the give input power must

not be exceeded.

Voltage variation Winding Diagram

Shaft loading

The following table provides guidelines for 20 000 hour – rated speed: 3000 RPM.

Motor type Radial Axial force

Radial load force applied force (N) (N)

at center of shaft extension

Size 0 220 80

Size 1 250 90

Axial load force

Size 2 300 100

Size 3 570 200

ICPE SA - SPLAIUL UNIRII, NR. 313, SECTOR 3 - 030138 BUCURESTI - ROMANIA

Tel / Fax : 004 / 021 / 3467233, e-mail: servo@icpe.ro, web: www.icpe.ro/dept03

Brake Motor Application Guidelines

The brakes offered as options on these servo motors are holding brakes. They are designed to

hold the motor shaft at 0 RPM for up to the rated brake holding torque. The brakes are

permanent magnet type, and release when voltage is applied to the brake coil.

The brakes are not designed for stopping rotation of the motor shaft. Servo drive inputs should

be used to stop motor shaft rotation. The recommended method of stopping motor shaft rotation

is to command the servo drive to decelerate the motor to 0 RPM, and engage the brake after the

servo drive has decelerated the motor to 0 RPM.

If system main power fails, the brakes can withstand use as stopping brakes. However, use of the

brakes as stopping brakes creates rotational mechanical backlash that is potentially damaging to

the system, increases brake pad wear and reduces brake life. The brakes are not designed nor are

they intended to be used as a safety device.

A separate power source is required to disengage the brake. This power source may be controlled

by the servo motor controls, in addition to manual operator controls.

Motor type Size 0 Size 1 Size 2 Size 3

Holding Torque Nm 1.2 3.2 6 12

Coil Current (at 24 V c.c. ± 10%) A 0.37 0.42 0.55 0.75

Motor Installation

Observe the following installation guidelines and those in the Product Notice:

WARNING: Motors and linkages must be securely mounted for a

system to be operational. Disassembled equipment should be

appropriately iden-tified (tagged-out) and access to electrical

power restricted (locked-out).

Failure to observe these safety procedures could result in personal

injury and damage to equipment.

1. Do not run motors that are not properly mounted. Attach all power and data cables

after the motor is mounted.

2. Mount motors with connectors pointing downward and use a drip loop in the cable to

keep liquids flowing away from the connectors.

3. Consider motor case temperature if necessary to safeguard operator and

maintenance staff. Maximum case temperature is approximately 100°C for a motor

used at continuous rating in a 40°C ambient temperature.

4. The installer must comply with all local regulations and should use equipment and

installation practices that promote electromagnetic compatibility and safety.

ICPE SA - SPLAIUL UNIRII, NR. 313, SECTOR 3 - 030138 BUCURESTI - ROMANIA

Tel / Fax : 004 / 021 / 3467233, e-mail: servo@icpe.ro, web: www.icpe.ro/dept03

Preventing Electrical Noise

ElectroMagnetic Interference (EMI), commonly called “noise”, may adversely impact motor

performance by inducing stray signals. Effective techniques to counter EMI include filtering the

AC power, shielding and separating signal carrying lines, and practicing good grounding

techniques. Effective AC power filtering can be achieved through the use of isolated AC power

transformers or properly installed AC line filters. Physically separate signal lines from motor

cabling and power wiring; do not parallel signal wires with motor or power wires or route signal

wires over the vent openings of servo drives. Ground all equipment using a single-point parallel

ground system that employs ground bus bars or straps. If necessary, use electrical noise

remediation techniques to mitigate EMI in “noisy” environments.

Knowledgeable cable routing and careful cable construction improves system electromagnetic

com-patibility (EMC). General cable build and installation guidelines include:

1. Keep wire lengths as short as physically possible.

2. Route signal cables (encoder, serial, analog) away from motor and power wiring.

3. Separate cables by 1 foot minimum for every 30 feet of parallel run.

4. Ground both ends of the encoder cable and twist the signal wire pairs.

5. Use shielded motor cables when necessary to prevent electromagnetic interference (EMI)

with other equipment.

Couplings and Pulleys

Mechanical connections to the motor shaft, such as couplings and pulleys, require a rigid

coupling or a reinforced timing belt. The high dynamic performance of servo motors can cause

couplings, pulleys or belts to loosen or slip over time. A loose or slipping connection will cause

system instability and may damage the motor shaft and keyway. All connections between the

system and the servo motor shaft must be rigid to achieve acceptable response from the system.

Connections should be periodically inspected to verify the rigidity.

When mounting couplings or pulleys to the motor shaft, ensure that the connections are properly

aligned and that axial and radial loads are within the specifications of the motor. The section

“Load Force Ratings” provides guidelines to achieve 20,000 hours of bearing life.

ICPE SA - SPLAIUL UNIRII, NR. 313, SECTOR 3 - 030138 BUCURESTI - ROMANIA

Tel / Fax : 004 / 021 / 3467233, e-mail: servo@icpe.ro, web: www.icpe.ro/dept03

Product Identification Information

Motor Part Number Identification

BSM 88 -0260 - 3- BR

BR =With brake

BSM Series

FRAME SIZE

STALL TORQUE

e.g. 0260=2.6 Nm

WINDING VOLTAGE

3=325 VDC

6=565 VDC

NOTE: the sealing kit is available only for motors under 3000 rpm.

Mating Connectors Part Numbers

Connector Type Part Number

Power – Crimp BSTA078FR19230005000

Resolver – Crimp ASTA035FR11190005000

Disposal or Warranty Return of Motors

Motors may contain environmentally regulated materials, such as lead solder and circuit boards.

When disposing of a motor, please recycle motors per regulations at your location. You may

choose to return a motor for disposal by contacting your supplier. Please contact the source that

supplied the motor for warranty, non-warranty, or disposal work.

For more information refer to our web site: servo@icpe.ro

ICPE SA - SPLAIUL UNIRII, NR. 313, SECTOR 3 - 030138 BUCURESTI - ROMANIA

Tel / Fax : 004 / 021 / 3467233, e-mail: servo@icpe.ro, web: www.icpe.ro/dept03

Potrebbero piacerti anche

- Lonne Marine Motors - Lowres Rev1 2015Documento12 pagineLonne Marine Motors - Lowres Rev1 2015이정재Nessuna valutazione finora

- ABB, (Degree of Protection IP55, V 380V F 50Hz KW R/min A - NM - % - KG MDocumento3 pagineABB, (Degree of Protection IP55, V 380V F 50Hz KW R/min A - NM - % - KG MDar MudasirNessuna valutazione finora

- AC MotorsDocumento3 pagineAC MotorsDar MudasirNessuna valutazione finora

- AC MotorsDocumento3 pagineAC MotorsDar MudasirNessuna valutazione finora

- Micromaster 440 KatalogDocumento2 pagineMicromaster 440 KatalogchochoroyNessuna valutazione finora

- Low Voltage: General Performance IE3 Premium Efficiency Cast Iron MotorsDocumento12 pagineLow Voltage: General Performance IE3 Premium Efficiency Cast Iron MotorsHEMANT RAMJINessuna valutazione finora

- Type 2 Coordination SiemensDocumento2 pagineType 2 Coordination SiemensDILEEPNessuna valutazione finora

- Catalog Standard Motor LTS PDFDocumento20 pagineCatalog Standard Motor LTS PDFYogesh BadheNessuna valutazione finora

- Tabel A1.15. Valorile Funcţiei CF ( (, L /H)Documento1 paginaTabel A1.15. Valorile Funcţiei CF ( (, L /H)murujrNessuna valutazione finora

- Siemens 3TS Type 2 Fuse Protected DOLDocumento1 paginaSiemens 3TS Type 2 Fuse Protected DOLJitendra SaliNessuna valutazione finora

- Our Product Range As Per NS-40:2042 As Per Below Mentioned Chart Wall Thickness and Weight Chart of PE-100 As Per NS-40:2042Documento7 pagineOur Product Range As Per NS-40:2042 As Per Below Mentioned Chart Wall Thickness and Weight Chart of PE-100 As Per NS-40:2042Sherpa DanurpuNessuna valutazione finora

- Final IE3 Motors Brochure July 2019Documento12 pagineFinal IE3 Motors Brochure July 2019medanite ashebirNessuna valutazione finora

- R410a Fixed Speed RotaryDocumento2 pagineR410a Fixed Speed RotaryashokindeedNessuna valutazione finora

- Victaulic Couplings Data TableDocumento4 pagineVictaulic Couplings Data Tablejlinhares.engNessuna valutazione finora

- Frameless 12.09.06 RO PDFDocumento5 pagineFrameless 12.09.06 RO PDFserb dumitruNessuna valutazione finora

- M (Dan.M) B (Cm) H (Cm) A (Cm) A Α Rn Kí Hiệu H (Cm) M M M M M M M M M M M M M M M M M M M M M M M M M M M M MDocumento6 pagineM (Dan.M) B (Cm) H (Cm) A (Cm) A Α Rn Kí Hiệu H (Cm) M M M M M M M M M M M M M M M M M M M M M M M M M M M M MPHONHO660Nessuna valutazione finora

- 123bnhg - GFT KoiDocumento675 pagine123bnhg - GFT KoiJPDGLNessuna valutazione finora

- 3HP Motor SpecificationDocumento12 pagine3HP Motor SpecificationShadNessuna valutazione finora

- SIEMENS Squirrel Cage Induction Standard Three-Phase MotorsDocumento19 pagineSIEMENS Squirrel Cage Induction Standard Three-Phase MotorsGraphios UtaNessuna valutazione finora

- Table 4: Critical Values For The Student /-Test M.: VLT Ffi% 7syo 85vo - 90% 99.9"/O 600Documento1 paginaTable 4: Critical Values For The Student /-Test M.: VLT Ffi% 7syo 85vo - 90% 99.9"/O 600Yoga SetiadhiNessuna valutazione finora

- Table 4: Critical Values For The Student /-Test M.: VLT Ffi% 7syo 85vo - 90% 99.9"/O 600Documento1 paginaTable 4: Critical Values For The Student /-Test M.: VLT Ffi% 7syo 85vo - 90% 99.9"/O 600leni evayantiNessuna valutazione finora

- Siemens EexdDocumento10 pagineSiemens EexdmithuntcvNessuna valutazione finora

- Formula GeomekDocumento6 pagineFormula Geomekfasedan prosesNessuna valutazione finora

- Special Cables CatalogueDocumento114 pagineSpecial Cables CatalogueAdel ALkhaligyNessuna valutazione finora

- Special Cables CatalogueDocumento114 pagineSpecial Cables CatalogueAdel ALkhaligyNessuna valutazione finora

- Motor type Motor Typ Moteur type Pn kW Nn rpm η % cos J Kgm L dB (A) m kgDocumento1 paginaMotor type Motor Typ Moteur type Pn kW Nn rpm η % cos J Kgm L dB (A) m kgCARMEN DIMITRIUNessuna valutazione finora

- Low Voltage: General Performance IE2 High Efficiency Cast Iron MotorsDocumento12 pagineLow Voltage: General Performance IE2 High Efficiency Cast Iron MotorsRi bionNessuna valutazione finora

- 02 - STD - Bimetal Overload Relay - (2.07 - 2.08)Documento2 pagine02 - STD - Bimetal Overload Relay - (2.07 - 2.08)ThilinaNessuna valutazione finora

- P202301 PR B CS STD 0001Documento16 pagineP202301 PR B CS STD 0001Nitin SakpalNessuna valutazione finora

- MCCB Type2Documento1 paginaMCCB Type2intrudentalertNessuna valutazione finora

- Hindustan Electric Motors (HEM) Price List - January 2021Documento26 pagineHindustan Electric Motors (HEM) Price List - January 2021Dilip KarkiNessuna valutazione finora

- TECO Performance AEEVDocumento4 pagineTECO Performance AEEVSIVARAMANJAGANATHANNessuna valutazione finora

- Spares List &: Maintenance InstructionsDocumento10 pagineSpares List &: Maintenance InstructionsabdiNessuna valutazione finora

- Voltage Drop Calcs-1-Comparison Between 240v, 480v & 2400v SystemsDocumento2 pagineVoltage Drop Calcs-1-Comparison Between 240v, 480v & 2400v Systemsnikkoelbao96Nessuna valutazione finora

- Drill HolesDocumento304 pagineDrill HolesJorge Luis Zegarra OtoyaNessuna valutazione finora

- Objectiv 1Documento8 pagineObjectiv 1Eng. Charles N. KithomeNessuna valutazione finora

- Hex Socket Button Head Cap Screws Partially / Fully ThreadedDocumento3 pagineHex Socket Button Head Cap Screws Partially / Fully ThreadedFoocheong LoiNessuna valutazione finora

- JK Linear Motion JK Linear Motion JK Linear Motion JK Linear MotionDocumento1 paginaJK Linear Motion JK Linear Motion JK Linear Motion JK Linear MotionManikanta Sai KumarNessuna valutazione finora

- No Depth (FT) GR LLD MSFL Nphi Rhob DTDocumento3 pagineNo Depth (FT) GR LLD MSFL Nphi Rhob DTAriya SetiyakiNessuna valutazione finora

- Insert Bearing Flanged Unit With Round 4-Bolt Flange Housing, Set Screws, For Metric ShaftsDocumento4 pagineInsert Bearing Flanged Unit With Round 4-Bolt Flange Housing, Set Screws, For Metric Shaftsmohamadelsb3Nessuna valutazione finora

- Insert Bearing Square Flanged MetricDocumento4 pagineInsert Bearing Square Flanged Metricvineet sharmaNessuna valutazione finora

- HMB From HYSYSDocumento9 pagineHMB From HYSYSmuhammad lukmanNessuna valutazione finora

- ABB NFLP IE3-Catalogue PDFDocumento12 pagineABB NFLP IE3-Catalogue PDFSabir NasimNessuna valutazione finora

- Bill Link Road Chrawani To CG Dhar DSDocumento19 pagineBill Link Road Chrawani To CG Dhar DSErone DougassaNessuna valutazione finora

- Anelli Catalogo REV-2 PDFDocumento12 pagineAnelli Catalogo REV-2 PDFAL_B_RTONessuna valutazione finora

- Model Motor ListrikDocumento5 pagineModel Motor Listrikfillio daveNessuna valutazione finora

- Cross - Iyears Companbs BI Dualitman - O Roa ROE SizeDocumento8 pagineCross - Iyears Companbs BI Dualitman - O Roa ROE SizeNouman MujahidNessuna valutazione finora

- 1 Almo Catalog GeneralDocumento5 pagine1 Almo Catalog GeneralAndy AndyNessuna valutazione finora

- Equipment DimensionsDocumento14 pagineEquipment DimensionsVij Vaibhav VermaNessuna valutazione finora

- SM8S10 ShanghaisemitechDocumento4 pagineSM8S10 ShanghaisemitechneobelhadjNessuna valutazione finora

- JK57HSDocumento3 pagineJK57HSRozel 14100% (1)

- Parameter CalculatorDocumento6 pagineParameter CalculatorAnkit GuptaNessuna valutazione finora

- Hindustan Motors Pricelist-42-106-04-2022Documento31 pagineHindustan Motors Pricelist-42-106-04-2022Venkateshwar DevendlaNessuna valutazione finora

- Engine DataDocumento2 pagineEngine Datajiffy21Nessuna valutazione finora

- Juan Diego Saltarin CaroDocumento7 pagineJuan Diego Saltarin CaroBarrera AfricanoNessuna valutazione finora

- Trial Trench Measurement SheetDocumento7 pagineTrial Trench Measurement Sheetakash nairNessuna valutazione finora

- United States Census Figures Back to 1630Da EverandUnited States Census Figures Back to 1630Nessuna valutazione finora

- British Commercial Computer Digest: Pergamon Computer Data SeriesDa EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNessuna valutazione finora

- Interruptor Bajo Voltaje.2Documento16 pagineInterruptor Bajo Voltaje.2Anderson LopezNessuna valutazione finora

- Report On Ultrasonic Distance MeterDocumento56 pagineReport On Ultrasonic Distance MeterMahesh Jadhav80% (5)

- Exam 4 Set CDocumento4 pagineExam 4 Set Cmarktaborete0Nessuna valutazione finora

- Test Physics Chapter# 12,13,14 (2 Year) NameDocumento1 paginaTest Physics Chapter# 12,13,14 (2 Year) NameStay FocusedNessuna valutazione finora

- UNITROL Control Upgrade - Flyer - ENDocumento2 pagineUNITROL Control Upgrade - Flyer - ENfabyanoNessuna valutazione finora

- Kohler DieselDocumento80 pagineKohler DieselLeigh Galloway50% (2)

- Microset 4 Installation & Operations GuideDocumento54 pagineMicroset 4 Installation & Operations Guideamjadjaved033148Nessuna valutazione finora

- Lab 1Documento7 pagineLab 1E24106610許翰翔Nessuna valutazione finora

- EDC 2 MarksDocumento16 pagineEDC 2 Marksdr mbaluNessuna valutazione finora

- STE TransformerDocumento36 pagineSTE TransformerAgadi SamridhoNessuna valutazione finora

- Power Generation Course OutlineDocumento3 paginePower Generation Course OutlineRao Umar100% (1)

- Electrical Inspection ChecklistDocumento40 pagineElectrical Inspection ChecklistMohamed100% (1)

- Static and Premature Detonation HazardsDocumento7 pagineStatic and Premature Detonation Hazardswerdna67Nessuna valutazione finora

- Steel Vessels Under 90 Meters (295 Feet) in Length 2017: Rules For Building and ClassingDocumento9 pagineSteel Vessels Under 90 Meters (295 Feet) in Length 2017: Rules For Building and Classingamr_tarek_26Nessuna valutazione finora

- Spectrum Analyzer: PurposeDocumento3 pagineSpectrum Analyzer: PurposeAllanki Sanyasi RaoNessuna valutazione finora

- Cu de Luminaria OD-3648CSDocumento3 pagineCu de Luminaria OD-3648CSMari Tere GutierrezNessuna valutazione finora

- Exercises On Loading Effects in Measurement SystemDocumento2 pagineExercises On Loading Effects in Measurement SystemsiennaNessuna valutazione finora

- Wireless Power Transfer Mini ProjectDocumento11 pagineWireless Power Transfer Mini ProjectAsmita shravan chavanNessuna valutazione finora

- Earthing Switch 12kV - 24kV Instruction ManualDocumento19 pagineEarthing Switch 12kV - 24kV Instruction ManualАлександар СтевићNessuna valutazione finora

- Microgrid - ESS Application NoteDocumento11 pagineMicrogrid - ESS Application NoteHalley WanderbakNessuna valutazione finora

- ACDC Dyn Solar CalculatorDocumento5 pagineACDC Dyn Solar CalculatorArul SankaranNessuna valutazione finora

- Physics 1 Honors Formula SheetDocumento11 paginePhysics 1 Honors Formula SheetCody JohnsonNessuna valutazione finora

- LIFEPAK 20 - 20e Service Manual PDFDocumento408 pagineLIFEPAK 20 - 20e Service Manual PDFleopa7850% (2)

- HT Cable Sizing CalculationDocumento3 pagineHT Cable Sizing CalculationBalamurugan Arumugam100% (1)

- DIGITRIP 3000™ Protective Relays - Technical Data - TD1710TE - May 1999 - CUTLER-HAMMER®Documento8 pagineDIGITRIP 3000™ Protective Relays - Technical Data - TD1710TE - May 1999 - CUTLER-HAMMER®pevareNessuna valutazione finora

- Alarm Annunciator Mbas 9400 PDFDocumento1 paginaAlarm Annunciator Mbas 9400 PDFAnonymous SDeSP1Nessuna valutazione finora

- Chapter - 7 Induction - Motor - Part4Documento19 pagineChapter - 7 Induction - Motor - Part4zulkhairi.whaNessuna valutazione finora

- Soft Starter SMC - 50 - 150-Um011 - En-P - Ingles PDFDocumento306 pagineSoft Starter SMC - 50 - 150-Um011 - En-P - Ingles PDFObsol EtoNessuna valutazione finora

- Kelistrikan Di CH Rev.01Documento32 pagineKelistrikan Di CH Rev.01munierNessuna valutazione finora

- Handbook On Oil Cooling Blower (OCB) of Three Phase Eelectric Locomotive-May 2018Documento55 pagineHandbook On Oil Cooling Blower (OCB) of Three Phase Eelectric Locomotive-May 2018Aravind JNessuna valutazione finora