Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Ok Task A - Steering, Suspension and Brake Systems

Caricato da

Marvin Sarmiento TalimonganTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Ok Task A - Steering, Suspension and Brake Systems

Caricato da

Marvin Sarmiento TalimonganCopyright:

Formati disponibili

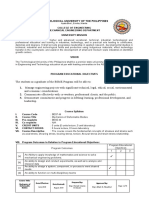

Test Project Automobile Technology

Task A - Steering, Suspension & Brake Systems

TP33 _ RSC_ 2017_ 25%

Submitted by: All Coaches/Judges

Member Region: NCR

TP33_ RSC 2016_pre_NCR

Skill 33 - Automobile Technology

COMPETITOR INSTRUCTION

Competitor Name Country Code Task

Instructions to Competitor

Task Brake, Suspension and Steering Systems

Familiarization Time 15 minutes

Task Duration 3 hours

Total Breaks 15 minutes

MARKING SUMMARY

Possible

Section

Mark

1 Health, Safety and House keeping 4.30

2. Remove / replace Front Strut Assembly 3.00

3. Install Front Strut Assembly 2.50

4. Front Brake Calliper & Disc Brake Measurement 2.40

5. Perform the necessary Wheel Alignment Adjustment 4.50

6. Replace Brake Master Cylinder Assembly 2.40

7. Overhaul front Calliper and check the conditions of all Brake Pads 3.40

8. Hydraulic Brake System Air Bleeding 2.50

Total 25.00

You are required to:

- Observe occupational health & safety standards

- Only ask necessary questions

- Not speak to the public while competing

- Comply with Experts instructions

- Ensure Name on all forms

- Use appropriate tools and procedures

- Complete all instructions on the next page

Remark: Vehicle/Model: Toyota Corolla Model Year 94 - 97

RSC, September 2017, National Capital Region , Philippines 2

Skill 33 - Automobile Technology

COMPETITOR INSTRUCTION

Competitor Name Country Code Task

1. Use safe working procedures at all times.

Ensure that the steering, suspension and brake systems are in a safety

2.

condition.

3. Service front LHS and RHS brake assembly.

Remove and replace Front Strut Assembly with the service tools provided as

4.

instructed by the judge.

5. Remove and replace side tie-rod end with service tools provided.

Perform the wheel alignment adjustment.

6.

Print out and interpret the readings.

7. Replace Brake Master Cylinder Assembly.

7. Overhaul front calliper and check condition of all brake pads.

8. Perform hydraulic Brake System Air Bleeding (using vacuum bleeder).

RSC, September 2017, National Capital Region , Philippines 3

Skill 33 - Automobile Technology

COMPETITOR REPORT SHEET

Competitor Name Country Code Task Report Form

Steering, Suspension

A

& Brake Systems

Brakes System Report Sheet

Front Brake Disc RHS - Measurement

Measured Reading Status Condition

Items

Specification Actual OK Not OK

Disc Std

Round-Out

Max

Disc

Std

Thickness

Min

Brake Pads

Thickness Inner

Outer

RSC, September 2017, National Capital Region , Philippines 4

Skill 33 - Automobile Technology

COMPETITOR REPORT SHEET

Competitor Name Country Code Task Report Form

Steering, Suspension

A

& Brake Systems

Front Brake Disc LHS - Measurement

Measured Reading Status Condition

Items

Specification Actual OK Not OK

Disc Std

Round-Out

Max

n

Disc

Std

Thickness

Min

Brake Pads

Thickness Inner

Outer

RSC, September 2017, National Capital Region , Philippines 5

Skill 33 - Automobile Technology

FORM 5 – MARKING SUMMARY FORM

Competitor Name Country Code Task Marking Scale

Steering, Suspension &

A Brake Systems

MARKING SUMMARY

Possible Actual

Section

Mark Mark

1. Health, Safety and House keeping 4.30

2. Remove / replace Front Strut Assembly 3.00

3. Install Front Strut Assembly 2.50

4. Front Brake Calliper & Disc Brake Measurement 2.40

5. Perform the necessary Wheel Alignment Adjustment 4.50

6. Replace Brake Master Cylinder Assembly 2.40

Overhaul front Calliper and check the conditions of all Brake

7. 3.40

Pads

8. Hydraulic Brake System Air Bleeding 2.50

Task Total 25.00

Time Keeping

Familiarization Competition Breaks

Start Start Start

Stop Stop Stop

Experts Signatures

1 2 3 4

Judge Judge Judge Chief Judge

RSC, September 2017, National Capital Region , Philippines 6

Skill 33 - Automobile Technology

Competitor Name Country Code Task Marking Scheme

Steering, Suspension &

A Brake Systems

MARKING FORM

Health, Safety & 5S House

1. Yes No Actual Comments

Keeping

1.01 Check & prepare all equipment 0.10 0

1.02 Use workshop manual 0.10 0

1.03 Apply logical working procedure 0.10 0

1.04 Check engine oil level 0.10 0

1.05 Check coolant level 0.10 0

1.06 Ramp lowered on stops 0.10 0

1.07 Jacks, pads used 0.10 0 Positioned correctly

1.08 Parking Brake applied to maximum 0.10 0

1.09 Chock tires 0.10 0 Min 2 pcs @ front & rear

1.10 Use fender covers 0.10 0

1.11 Use seat covers 0.10 0

1.12 Use steering wheel cover 0.10 0

1.13 Use gear shift lever cover 0.10 0

1.14 Use floor mats 0.10 0

1.15 Did not wear any metal objects 0.20 0 Wrist watch, bangle etc

During engine starting /

1.16 Voice out to alert others 0.20 0 operating hoist up / down

Use of safety goggle during brake

1.17 0.50 0

bleeding activity

1.18 Proper tools handling 0.50 0 Not dropped >2 x

1.19 Precision tools not dropped 0.50 0

No brake fluid spilled over on any part

1.20 0.50 0

of vehicle body

1.21 Wipe out all initial markings made 0.10 0

1.22 Clean up tools and equipment 0.10 0 * Marks ONLY be awarded when

the task is completed

1.23 Clean up the test models & work area 0.10 0

1.24 Close front engine hood 0.10 0

1.25 Hand over vehicle key to judge 0.10 0

Sub-Total 4.30 0

RSC, September 2017, National Capital Region , Philippines 7

Skill 33 - Automobile Technology

Competitor Name Country Code Task Marking Scale

Steering, Suspension &

A Brake Systems

MARKING FORM

Remove / Replace Front Strut

2. Yes No Actual Remark

Assembly

2.01 Brief judge on the task activity 0.10 0

2.02 Loosen wheel nuts before lifting up 0.10 0

2.03 Raise vehicle to suitable height 0.10 0

2.04 Mark the wheel position/location 0.10 0

2.05 Remove and mark all wheels 0.10 0

2.06 Remove brake hose bracket 0.10 0

Remove Front RHS Strut Assembly &

2.07 0.10 0

Self Locking Nut

2.08 Loosen Flange Nuts 0.10 0

2.09 Remove Strut Assembly (on bench) 0.10 0

2.10 Remove coil spring from Strut (on bench) 0.10 0

- Front coil spring 0.20 0

- Lower Spring ,

0.20 0

Insulator Verbal Inspection report

Verbal - Front s/absorber assembly 0.20 0

Inspection

2.11 - Rubber Spring ,

Report 0.20 0

Bumper

- Absorber Lock Nut 0.20 0

- Dust Seal 0.20 0

Check condition of the Front Strut (on

2.12 0.20 0 Demonstrate procedure

bench)

2.13 Replace the Strut Assembly (on bench) 0.10 0

Reassemble all Components correctly (on

2.14 0.20 0

bench)

Update judge on critical assembling

2.15 0.20 0

points with manual (on bench)

to secure the strut assy.to its

2.16 Temporary tighten the Lock Nut 0.10 0 position

Sub - Total 3.00 0

RSC, September 2017, National Capital Region , Philippines 8

Skill 33 - Automobile Technology

Competitor Name Country Code Task Marking Scale

Steering, Suspension &

A Brake Systems

MARKING FORM

Install one side Front Strut

3. Yes No Actual Remark

Assembly

Install Front Strut Assembly to the vehicle

3.01 0.50 0

and torque nut to specification

3.02 Install & tighten the 3 Flange Nuts 0.40 0

Tighten Front Strut Assembly and torque

3.03 0.50 0

to specifications

3.04 Torque the stabilizer link nut 0.50 0

3.05 Install Wheel Sensor Harness Clip 0.30 0

3.06 Install Brake Hose Bracket 0.30 0

Sub - Total 2.50 0

Front Brake Calliper & Disc -

4. Yes No Actual Comments

Brake Assembly

4.01 Update judge on the task activity 0.10 0 What he planned to do

Temporarily relocate front caliper

4.02 0.10 0 Hook caliper on spring area

assembly via metal hook

Torque all 5 wheel nuts correctly (RHS

4.03 0.10 0 Using correct SST

and LHS)

4.04 Mount brake hose to strut assembly 0.30 0 DTI pointer set accurately

Check run-out of front brake disc (RHS Refer R/M on process

4.05 0.50 0

and LHS)

Measure thickness of brake disc (RHS Indicate 1-5 markings

4.06 0.50 0

and LHS)

Measure thickness of brake pads (RHS

4.07 0.20 0

and LHS)

Install the caliper & torque (RHS and

4.08 0.10 0

LHS)

Re-installed brake pads correctly (RHS

4.09 0.10 0

and LHS)

4.10 Accurate data on report sheet 0.20 0

Fix back all wheels to the initially

4.11 0.10 0

marked position

Tighten the wheel nut to

4.12 0.10 0

recommended specification

Sub - Total 2.40 0

RSC, September 2017, National Capital Region , Philippines 9

Skill 33 - Automobile Technology

Competitor Name Country Code Task Marking Scale

Steering, Suspension &

B Brake Systems

MARKING FORM

Perform the necessary Wheel

5. Yes No Actual Remark

Alignment Adjustment

5.01 Update judge on the task activity 0.10 0

Check tire pressures and correct if

5.02 0.20 0

necessary

Check conditions of wheel bearings (RHS

5.03 0.10 0

and LHS)

5.04 Check joints (RHS and LHS) 0.10 0

5.05 Remove / replace tie-rod end (RHS and 0.10 0

LHS)

Check lower ball joints unloaded (RHS

5.06 0.10 0

and LHS)

5.07 Check vehicle level 0.10 0

5.08 Check wheel base 0.10 0

5.09 Set program on computer alignment 0.10 0

5.10 Mount Wheel Clamps correctly 0.10 0

5.11 Handle Sensors with care 0.30 0

5.12 Mount Sensors correctly 0.10 0

Perform all wheels “run-out”

5.13 0.10 0

compensation

5.14 Position turntable correctly 0.10 0

5.15 Apply parking brake (hand brake) 0.10 0

5.16 Set the turn table to zero 0.10 0

5.17 Position Rear Wheels Slip Plate 0.10 0

5.18 Bounce the car 0.10 0

5.19 Remove the turn table pins 0.10 0

5.20 Set levelling sensor to centre position 0.10 0

5.21 Use brake pedal depressor 0.10 0

5.22 Check Caster Angle 0.10 0

5.23 Check KPI/SAI Angle Ball Joint 0.10 0 Steering Axis Inclination

Centre Steering Wheel Straight ahead

5.24 0.20 0

position

5.25 Lock steering wheel 0.10 0

5.26 Interpret Camber Angle on screen 0.20 0

5.27 Interpret Caster Angle on screen 0.20 0

5.28 Interpret Toe Angle on screen 0.20 0

RSC, September 2017, National Capital Region , Philippines 10

Skill 33 - Automobile Technology

Competitor Name Country Code Task Marking Scale

Steering, Suspension &

B Brake Systems

MARKING FORM

Perform the necessary Wheel

5. Yes No Actual Remark

Alignment Adjustment

5.29 Correct Front Toe Adjustment 0.30 0

5.30 Tighten Tie-rod end lock nut 0.10 0

5.31 Check steering wheel position 0.10 0

5.32 Print out (after adjustment) 0.10 0

5.33 Remove all sensors 0.10 0

5.34 Reset program 0.10 0

5.35 Car lowered to ground 0.10 0

5.36 Remove brake pedal depressor and tools 0.10 0

Sub - Total 4.50 0

Replace Brake Master Cylinder

6. Yes No Actual Remark

Assembly

Recover the brake fluid from the master

6.01 0.4 0 Via the brake bleeder unit assy.

cylinder reservoir

Pumped brake pedal several times to

6.02 0.40 0

remove vacuum from the brake booster

Remove / replace the Brake Master

6.03 0.60 0

Cylinder Assembly

Bleed the brake hydraulic system once

6.04 0.50 0

again

Confirm the status of the brake hydraulic

6.05 0.50 0

system

Sub - Total 2.40 0

RSC, September 2017, National Capital Region , Philippines 11

Skill 33 - Automobile Technology

Competitor Name Country Code Task Marking Scale

Steering, Suspension &

B Brake Systems

MARKING FORM

Overhaul Rear Calliper and

7. check the conditions of all Yes No Actual Comments

Brake Pads

7.01 Update judge on the task activity 0.10 0 What he planned to do

Remove front calliper assembly (left

7.02 0.10 0 Remove rear brake pads

and right side)

Disassemble rear caliper assembly (left

7.03 0.10 0

and right side)

- Caliper piston 0.10 0

- Dust cover 0.10 0

Verbal

Inspect & verify conditions of the

7.04 Inspection - Rubber seal 0.10 0 caliper components

Report

- Caliper bracket 0.10 0

- Sliding mechanism 0.10 0

Reassemble the caliper assembly (left

7.05 0.50 0 Ensure proper marking

and right side)

Update judge on critical assembling

7.06 0.30 0 Refer R/Manual

points with manual

Measure thickness of brake pads (left

7.07 0.30 0

and right side)

Measure thickness of brake disc (left

7.08 0.30 0

and right side)

Re-install brake pads correctly (left and

7.09 0.40 0

right side)

Install caliper and tighten to torque

7.10 0.40 0

(left and right side)

7.11 Accurate info on report sheet 0.40 0

Sub-Total 3.40 0

Hydraulic Brake System

8. Yes No Actual Comments

Bleeding

8.01 Update judge on the task activity 0.40 0 What he planned to do

8.02 Install brake fluid dispenser unit 0.50 0

RSC, September 2017, National Capital Region , Philippines 12

Skill 33 - Automobile Technology

Competitor Name Country Code Task Marking Scale

Steering, Suspension &

B Brake Systems

MARKING FORM

Hydraulic Brake System

8. Yes No Actual Comments

Bleeding

Correct (X) method/procedure

8.03 Perform brake bleeding correctly 0.60 0 (use vacuum bleeder)

8.04 Check functions of brake system 0.60 0

8.05 Update judge on the status 0.40 0 What he planned to do

Sub Total 2.50 0

RSC, September 2017, National Capital Region , Philippines 13

Potrebbero piacerti anche

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionDa EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionValutazione: 5 su 5 stelle5/5 (3)

- Ok Task B - Electrical SystemDocumento10 pagineOk Task B - Electrical SystemMarvin Sarmiento TalimonganNessuna valutazione finora

- Competitor Brake SystemDocumento5 pagineCompetitor Brake Systemasyfai ramadaniNessuna valutazione finora

- ASC 2004 - Automotive B, Brake SystemDocumento7 pagineASC 2004 - Automotive B, Brake Systemelmo simamoraNessuna valutazione finora

- 2017 Smog Check ManualDocumento55 pagine2017 Smog Check ManualJustin DowlerNessuna valutazione finora

- Service Consultant Certified Technician: Erica Lamkin A. KirkDocumento10 pagineService Consultant Certified Technician: Erica Lamkin A. Kirklance jacksonNessuna valutazione finora

- D. Brake SystemDocumento6 pagineD. Brake Systemanang waskitoNessuna valutazione finora

- Body Builder MackDocumento149 pagineBody Builder Mackcristian picado100% (3)

- 94 Chevrolet Diesel SM SuppDocumento433 pagine94 Chevrolet Diesel SM SuppRolf G MichelsenNessuna valutazione finora

- ORGNALBrakesession PlaneDocumento5 pagineORGNALBrakesession Planeyared abebeNessuna valutazione finora

- SOALAN PRAKTIKAL-Akhir WSMP 2022 - Task D - Brake SystemDocumento3 pagineSOALAN PRAKTIKAL-Akhir WSMP 2022 - Task D - Brake Systemamirul rofiqNessuna valutazione finora

- Soal ChasisDocumento2 pagineSoal ChasishengkiNessuna valutazione finora

- Force InductionDocumento17 pagineForce InductionMuhammad Aznan ZakariaNessuna valutazione finora

- Automobile Mechanic-Module 3Documento6 pagineAutomobile Mechanic-Module 3hamayunNessuna valutazione finora

- 2102 APP A Categorisation Manual v5.0Documento160 pagine2102 APP A Categorisation Manual v5.0prestonnippard55Nessuna valutazione finora

- Dot Vehicle Inspection FormsDocumento3 pagineDot Vehicle Inspection FormsJohn Joseph WallsNessuna valutazione finora

- Defender 2.4D Maintenance Check Sheet - MilesDocumento2 pagineDefender 2.4D Maintenance Check Sheet - MilesJose SilvaNessuna valutazione finora

- Parking BrakesDocumento19 pagineParking BrakesCarlos VelázquezNessuna valutazione finora

- 28 Manual de Servicio ToritoDocumento133 pagine28 Manual de Servicio ToritoJulian Uribe HerreraNessuna valutazione finora

- PRAVEEN KUMAR - AS08 - VehicleHomologationandTesting PDFDocumento4 paginePRAVEEN KUMAR - AS08 - VehicleHomologationandTesting PDFpraveenNessuna valutazione finora

- '04 - '07 Prius Technical Service Bulletin: Brake Actuator NoiseDocumento2 pagine'04 - '07 Prius Technical Service Bulletin: Brake Actuator NoisekerirNessuna valutazione finora

- Service 38559Documento2 pagineService 38559Sumeet SawlaniNessuna valutazione finora

- Landrover Freelander 2 Maintenance ScheduleDocumento2 pagineLandrover Freelander 2 Maintenance Schedulevincent_devine777dNessuna valutazione finora

- Annual Truck Inspection SheetDocumento1 paginaAnnual Truck Inspection Sheetw uNessuna valutazione finora

- Coupling Inspection SOP GSE FinalDocumento11 pagineCoupling Inspection SOP GSE FinalPravin Kangne100% (1)

- Smog Check ManualDocumento47 pagineSmog Check ManualJLNessuna valutazione finora

- Discover 125Documento34 pagineDiscover 125Victor Daniel Vazquez PechNessuna valutazione finora

- Boxer 150 - 150X InglesDocumento60 pagineBoxer 150 - 150X InglesPato Erazo67% (6)

- Chery Sqr7080R Service Manual: Chery Automobile Co., LTDDocumento57 pagineChery Sqr7080R Service Manual: Chery Automobile Co., LTDUmar ShamsudinNessuna valutazione finora

- FSM 1989 Tracker 00 General InformationDocumento24 pagineFSM 1989 Tracker 00 General Informationstephanleroux007Nessuna valutazione finora

- CT-100-CT 100B - Ib - TRG NoteDocumento90 pagineCT-100-CT 100B - Ib - TRG Noteramiro idarragaNessuna valutazione finora

- Body Builders Guide PDFDocumento216 pagineBody Builders Guide PDFvo phuongNessuna valutazione finora

- B. STEERING, SUSPENSION AND BRAKE (Yuri)Documento8 pagineB. STEERING, SUSPENSION AND BRAKE (Yuri)Huda Kholif RahmanNessuna valutazione finora

- 6.new Vehicle Delivery Checklist Rev - 13Documento1 pagina6.new Vehicle Delivery Checklist Rev - 13Fahira AfrinaNessuna valutazione finora

- 1994 Jeep Service ManualDocumento1.770 pagine1994 Jeep Service Manualdvalodia100% (1)

- JLR 18 27 10 - 2E - Maintenance Check Sheet - Range Rover Sport (LW) - UK & EU - From 14MY - MilesDocumento2 pagineJLR 18 27 10 - 2E - Maintenance Check Sheet - Range Rover Sport (LW) - UK & EU - From 14MY - MilesmunNessuna valutazione finora

- Operator Skill Assessmentn (Light Vehicle) FormulaDocumento3 pagineOperator Skill Assessmentn (Light Vehicle) Formulaberto hutamaNessuna valutazione finora

- Task C - BrakeDocumento3 pagineTask C - BrakeErwin LastiantoNessuna valutazione finora

- Mclaren Super Series (720S/765Lt) Pdi (Pre-Delivery Inspection)Documento7 pagineMclaren Super Series (720S/765Lt) Pdi (Pre-Delivery Inspection)Haytham AjibNessuna valutazione finora

- Form Inspeksi Alat Berat (Compactor)Documento1 paginaForm Inspeksi Alat Berat (Compactor)HELMY RUSANDYNessuna valutazione finora

- CONTOH PEMURNIAN CoCUDocumento11 pagineCONTOH PEMURNIAN CoCUmuhammad darwishNessuna valutazione finora

- Mitsubishi Motors Lancer Sportback 2010 Owners Manual PDFDocumento658 pagineMitsubishi Motors Lancer Sportback 2010 Owners Manual PDFBLONDEL THIBAULTNessuna valutazione finora

- Formulario de Mantenimiento 1Documento2 pagineFormulario de Mantenimiento 1Marco Arias MartinezNessuna valutazione finora

- 793F T4 Commissioning - Check - ListDocumento3 pagine793F T4 Commissioning - Check - ListErlen PolancoNessuna valutazione finora

- Lks 2018 - A-Tune Up EfiDocumento6 pagineLks 2018 - A-Tune Up EfiahmadbandrexNessuna valutazione finora

- Direct-Hit - Schedules PlanDocumento2 pagineDirect-Hit - Schedules PlangabotoyoNessuna valutazione finora

- General Introduction: Section 1Documento5 pagineGeneral Introduction: Section 1Juan Alfonso Romero HaroNessuna valutazione finora

- 4T40-E Pontiac Sunfire Elec PDFDocumento128 pagine4T40-E Pontiac Sunfire Elec PDFjosue100% (3)

- SI-PAC-007 - Fuel Filter For ROTAX Aircraft EnginesDocumento6 pagineSI-PAC-007 - Fuel Filter For ROTAX Aircraft EnginesMuhammad AhmedNessuna valutazione finora

- 966H Wheel Loader A6GDocumento22 pagine966H Wheel Loader A6GJean Claude EidNessuna valutazione finora

- ASC 2004 - Automotive E, Charging SystemDocumento7 pagineASC 2004 - Automotive E, Charging Systemelmo simamoraNessuna valutazione finora

- 45 AS-F-HSE 045 - Inspection Report TrucksDocumento2 pagine45 AS-F-HSE 045 - Inspection Report TrucksJHUPEL ABARIAL100% (1)

- 2000 Super Duty F-250, F-350, F-450, F-550 Owner GuideDocumento256 pagine2000 Super Duty F-250, F-350, F-450, F-550 Owner GuideMatthew Case100% (6)

- Jeep Wrangler 2004 Repair ManualDocumento20 pagineJeep Wrangler 2004 Repair Manualbillie100% (52)

- Service Manual Payloader Models BC2 BC3 BC4Documento82 pagineService Manual Payloader Models BC2 BC3 BC4Sergio RecabarrenNessuna valutazione finora

- Evaluation of Load-Carrying Capacity of Lubricants Under Conditions of Low Speed and High Torque Used For Final Hypoid Drive AxlesDocumento18 pagineEvaluation of Load-Carrying Capacity of Lubricants Under Conditions of Low Speed and High Torque Used For Final Hypoid Drive AxlesahmedNessuna valutazione finora

- Bearing Inspection SOPDocumento7 pagineBearing Inspection SOPRianAwangga100% (1)

- 001 Identif 1Documento15 pagine001 Identif 1MOHD ZULHILMINessuna valutazione finora

- Vehicle Maintenance ManualDocumento51 pagineVehicle Maintenance ManualIbaadNessuna valutazione finora

- Sae J3213-2023Documento32 pagineSae J3213-20237620383tlNessuna valutazione finora

- Fundamentals OF ElectricityDocumento37 pagineFundamentals OF ElectricityMarvin Sarmiento TalimonganNessuna valutazione finora

- (OK) Auto Electronics and Electrical Related - LAYUGDocumento48 pagine(OK) Auto Electronics and Electrical Related - LAYUGMarvin Sarmiento TalimonganNessuna valutazione finora

- Auto Electronics and Electrical Related Tools, Measuring Instrument, and EquipmentDocumento34 pagineAuto Electronics and Electrical Related Tools, Measuring Instrument, and EquipmentMarvin Sarmiento TalimonganNessuna valutazione finora

- Charging System Installation - RocioDocumento40 pagineCharging System Installation - RocioMarvin Sarmiento TalimonganNessuna valutazione finora

- Espina, Joselito - PRESENTATION - AT10 (Circuit Failures)Documento22 pagineEspina, Joselito - PRESENTATION - AT10 (Circuit Failures)Marvin Sarmiento TalimonganNessuna valutazione finora

- Technological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToDocumento4 pagineTechnological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToMarvin Sarmiento TalimonganNessuna valutazione finora

- I. Vision: College of Industrial TechnologyDocumento6 pagineI. Vision: College of Industrial TechnologyMarvin Sarmiento TalimonganNessuna valutazione finora

- CHED Sample OBE Syllabus AT 1 AUTOMOTIVE ENGINEERING SYSTEMDocumento6 pagineCHED Sample OBE Syllabus AT 1 AUTOMOTIVE ENGINEERING SYSTEMMarvin Sarmiento TalimonganNessuna valutazione finora

- Technological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToDocumento5 pagineTechnological University of The Philippines: The Students As A Graduate of The BSME Program Will Be Able ToMarvin Sarmiento TalimonganNessuna valutazione finora

- Technological University of The PhilippinesDocumento7 pagineTechnological University of The PhilippinesMarvin Sarmiento TalimonganNessuna valutazione finora

- CHED Sample OBE Syllabus AT 2 AUTO MECHANICALDocumento7 pagineCHED Sample OBE Syllabus AT 2 AUTO MECHANICALMarvin Sarmiento TalimonganNessuna valutazione finora

- CHED Sample OBE Syllabus AT 7okDocumento6 pagineCHED Sample OBE Syllabus AT 7okMarvin Sarmiento Talimongan0% (1)

- Vaa-Erd: Technological University of The PhilippinesDocumento6 pagineVaa-Erd: Technological University of The PhilippinesMarvin Sarmiento TalimonganNessuna valutazione finora

- CHED Sample OBE Syllabus AT 3okDocumento6 pagineCHED Sample OBE Syllabus AT 3okMarvin Sarmiento TalimonganNessuna valutazione finora

- Anna Joy Evangelista 2062 Edison ST - Brgy San Isidro Makati CityDocumento2 pagineAnna Joy Evangelista 2062 Edison ST - Brgy San Isidro Makati CityMarvin Sarmiento TalimonganNessuna valutazione finora

- First Gear Technical Institute and Assessment Center Inc.: (Dir. Rolando V. Dela Torre)Documento5 pagineFirst Gear Technical Institute and Assessment Center Inc.: (Dir. Rolando V. Dela Torre)Marvin Sarmiento TalimonganNessuna valutazione finora

- Automotive NC II and Assessment For Driving NC II (Light Vehicle) Driving NC III (StraightDocumento1 paginaAutomotive NC II and Assessment For Driving NC II (Light Vehicle) Driving NC III (StraightMarvin Sarmiento TalimonganNessuna valutazione finora

- FINAL Marking Scheme in CIS Format - v1.3Documento52 pagineFINAL Marking Scheme in CIS Format - v1.3Marvin Sarmiento TalimonganNessuna valutazione finora

- 14264A Construction Mechanic Basic Chapters 14 PDFDocumento77 pagine14264A Construction Mechanic Basic Chapters 14 PDFMarvin Sarmiento TalimonganNessuna valutazione finora

- Assessment Candidates Uli #Documento123 pagineAssessment Candidates Uli #Marvin Sarmiento TalimonganNessuna valutazione finora

- Final ScoreDocumento1 paginaFinal ScoreMarvin Sarmiento TalimonganNessuna valutazione finora

- Talimongan, Marvin S. Mamitag, Renato O.: Prepared By: Approved byDocumento1 paginaTalimongan, Marvin S. Mamitag, Renato O.: Prepared By: Approved byMarvin Sarmiento TalimonganNessuna valutazione finora

- Marking Forms With Aspects Automobile Technology DraftDocumento45 pagineMarking Forms With Aspects Automobile Technology DraftMarvin Sarmiento TalimonganNessuna valutazione finora

- ProReact DSCU 2019 Installation Manual Rev 1-1Documento17 pagineProReact DSCU 2019 Installation Manual Rev 1-1Ionut BucurNessuna valutazione finora

- Y9 2.1 Assessment GridDocumento1 paginaY9 2.1 Assessment GridAlejandroNessuna valutazione finora

- Unit I-Introduction Part-A 1. Define Computers? 2. Define An Analog and A Digital Computer.Documento10 pagineUnit I-Introduction Part-A 1. Define Computers? 2. Define An Analog and A Digital Computer.Thamarai Selvi KoselramNessuna valutazione finora

- SD722 R Manual PDFDocumento78 pagineSD722 R Manual PDFFrank CarrascoNessuna valutazione finora

- LY CNC GuideDocumento15 pagineLY CNC GuideRusoord KitchenNessuna valutazione finora

- Hard Disk DriveDocumento4 pagineHard Disk DriveAbhishek AbhiNessuna valutazione finora

- Guide A - BMW INPA Installation Manual ALL Win OSDocumento60 pagineGuide A - BMW INPA Installation Manual ALL Win OSSorinPetrisor100% (1)

- JM1312-06 SPC R222.321.en-01Documento12 pagineJM1312-06 SPC R222.321.en-01cachit100% (2)

- Woot17 Paper GuriDocumento10 pagineWoot17 Paper Guriaragon1974Nessuna valutazione finora

- Paintstorm Notes V2.02Documento40 paginePaintstorm Notes V2.02Tristan MarlequesterNessuna valutazione finora

- Lab3 - SDRAM - Modified - 2020Documento13 pagineLab3 - SDRAM - Modified - 2020Nguyên Trịnh Vũ ĐăngNessuna valutazione finora

- CCLDocumento13 pagineCCLNasis DerejeNessuna valutazione finora

- Brain Gate Technology: CH - Saikumar Goud 16X01A0567Documento13 pagineBrain Gate Technology: CH - Saikumar Goud 16X01A0567Sai Kumar GoudNessuna valutazione finora

- Distance Warning SystemDocumento26 pagineDistance Warning SystemRajan Babu GoudNessuna valutazione finora

- Definition and Details of Flanges Torque TighteningDocumento4 pagineDefinition and Details of Flanges Torque TighteningFsNessuna valutazione finora

- Tricked Player ContractDocumento6 pagineTricked Player ContractEdward Bailey100% (4)

- Asts Hitachi Wim Wild LRDocumento5 pagineAsts Hitachi Wim Wild LRuamiranda3518Nessuna valutazione finora

- Catalogotamrac 1 PDFDocumento12 pagineCatalogotamrac 1 PDFpepoNessuna valutazione finora

- Tda 7388Documento11 pagineTda 7388Lucas Meister BarichelloNessuna valutazione finora

- NoticeBoard 1990Documento350 pagineNoticeBoard 1990मौर्यवंशी सम्राट आकाशNessuna valutazione finora

- CPUZDocumento8 pagineCPUZRicypeer ArtworkNessuna valutazione finora

- Gnu PlotDocumento3 pagineGnu PlotKapila WijayaratneNessuna valutazione finora

- BGAN Radio Module Technical SpecificationDocumento104 pagineBGAN Radio Module Technical SpecificationAlan TanNessuna valutazione finora

- Usa BL BleDocumento30 pagineUsa BL BleVinsen Teubun LetsoinNessuna valutazione finora

- 17CS44 Module-3 Part-A NotesDocumento21 pagine17CS44 Module-3 Part-A Notesvishwa darshiniNessuna valutazione finora

- RC CodesDocumento12 pagineRC CodesKumar RamNessuna valutazione finora

- Aolait Stage Lighting Quotation SheetDocumento7 pagineAolait Stage Lighting Quotation SheetaolaitberryNessuna valutazione finora

- Alcatel-Lucent 7750 Service RouterDocumento4 pagineAlcatel-Lucent 7750 Service RouterJulieNessuna valutazione finora

- BUSINESS PLAN SampleDocumento22 pagineBUSINESS PLAN Samplecristophel rojoNessuna valutazione finora

- Hitachi 420Documento3 pagineHitachi 420masroork_233% (3)