Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

HT Chart For ASME Material-Sec I

Caricato da

MurugananthamParamasivamTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

HT Chart For ASME Material-Sec I

Caricato da

MurugananthamParamasivamCopyright:

Formati disponibili

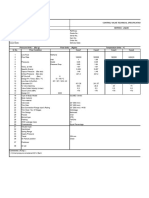

PWHT CYCLE TIME AS PER ASME CODES FOR ASME MATERIALS

P # & Material PWHT

ASME Sec 1

Sr # P# Gr # Grade Temperature Min Ref: Table PW Soaking time Ref: Table PW-39-1 Heating rate Thickness Limits Ref: Table PW- Governing Thickness for Preheat Temperature

Cooling rate Ref: A-101-1

39-1 to PW 39-13 to PW-39-13 Ref : A-101.1 39-1 to 39-13 PWHT(Socket Welding) Ref A 100.4

1 SA 36 ,SA 53 ,SA 106 Gr B 1) For less than 2" Thickness, as 1) For less than 2" Thickness, as

per manufacturer recomondation per manufacturer recomondation

2 SA234 WPB, SA 283 GR A

or Applicable Material or Applicable Material 1) Above 19.00 MM

1

3 SA 333 Gr 6, sa 350 Gr Lf1 specification. specification. 2) Shall be extended up to 25.00

Up to 2" Thick 1Hr /Inch (25 MM) , But 1) 10C for All other materials.

2) For Above 2" Thickness it is 2) For Above 2" Thickness it is MM Provided minimum Preheat

For Group 1,2 & 3 , Minimum = Minimum 15 Minutes. Above 2" Thick 2) 80C for material has both

4 1 SA420 WPL6, SA 516 GR 60 2Hr + 15 Minutes for Each Additional

abvoe 425C should not exceed abvoe 425C should not exceed 95C is applied.

595C C>0.30 & Thickness at Joint >

Inch ( 25.0 mm) 335C/Hr divided by Thickness in 335C/Hr divided by Thickness in 3) Up to 38.00 MM , if Preheat

5 SA 105, SA 216 WCB,SA 234 WPC 25.00 MM

Inch, but in no case shall be more Inch, but in no case shall be more 120C applied , CE 0.45 & Single

than 335C/Hr. than 335C/Hr. layer thickness 6.00 MM

6 2 A 350 GR LF2,SA 516 GR 70

3) It should not be less than 55C 3) It should not be less than 55C

7 SA 671 GR CC 70 CD 70 /Hr. /Hr.

8 A 204 GR A, SA209 GR T1B

1) For T > 16.00 MM

9 1 SA 213 T2,SA 234 WP1, SA 335 P1 1) See PW-41

Up to 2" Thick 1Hr /Inch (25 MM) , 2) For other conditions see PW39-2. 1) 10C for All other materials.

2) For fillet weld Throat thickness >

For Group 1,2 & 3 , Minimum = But Minimum 15 Minutes. Above 3) For Gr 3 material, Applicable for All 2) 80C for material has either T.S

10 3 SA 356 GR 2, SA 691 CM-65 SAME AS P1 Material Same as P1 Material

Thickness.

13.00 MM

595C 2" Thick 2Hr + 15 Minutes for Each > 70 Ksi or Thickness at Joint >

3) If C 0.25% & Prehaet applied is

11 A 182 GR F2, GR F1 , SA 204 GR C Additional Inch ( 25.0 mm) 4) Same as item# 2 & 3 mentioned in 16.00 MM

95 C

2 Governing Thickness

12 SA 336 GR F1

13 A 182 FL12, CL.1,2

1) Up to 2" Thick 1Hr /Inch (25 MM) ,

14 A 213 T11 / T 12 1) See PW-41

But Minimum 15 Minutes. 1) For T > 16.00 MM 1) 10C for All other materials.

1 2) For fillet weld Throat thickness >

For Group 1, & 2 Minimum = 2) Above 2" to 5" Thick 1Hr /Inch 2) For other conditions see PW39-3. 2) 120C for material has either

15 A 234 WP11 / 12 Cl.1,SA 335 P11 3) For Above 5" 5Hr Plus 15 Min for

SAME AS P1 Material Same as P1 Material

3) Same as item# 2 & 3 mentioned in

13.00 MM

650C T.S > 60 Ksi or Thickness at Joint >

3) If C 0.15% & Prehaet applied is

16 4 A 335 P12 ,SA 336 GR F12/F11 Each Additional Thickness of 25.00 Governing Thickness 13.00 MM

120 C

MM

17 2 A 333 GR 4

18 A 148 90 -60

3 Not given

19 A 668 Cl.kb, ka, kc

20 SA 182 F22, Cl.1 , Cl.3, F21

21 SA 213 T21 & T 22, SA 217 GR WC9

22 SA 234 WP22, Cl.1,

23 5A 1 A 335 GR P21 & 22 1) Up to 2" Thick 1Hr /Inch (25

24 A 336 F22 Cl.1 & Cl.3, SA 336 F21 CL.1 MM) , But Minimum 15 1) See PW-41

1) Cr 3.0%, C 0.15% & Min

Minutes. 2) For fillet weld Throat thickness >

25 SA 369 FP21 & 22, SA 369 FP21 & 22 Preheat apllied is 150 C , then

2) Above 2" to 5" Thick 1Hr 13.00 MM

675 C SAME AS P1 Material Same as P1 Material Thickness 16.00 MM. 3) If C 0.15% & Prehaet applied is

26 A 691 2.25 CR, Cl.1 & 2 /Inch

2) Other wise applicable for All 150 C. 1) 205C for material has either

3) For Above 5" 5Hr Plus 15

27 A 182 F5a , F5 & F9, SA 234 EP5 & WP9 Thickness and materials 4) If Cr 3.0% , Then T > 13.00 mm T.S > 60 Ksi or both Cr >6 .0%

Min for Each Additional

&Thickness at Joint > 13.00 MM

28 A 213 T5c, T5, T5b &T 9 Thickness of 25.00 MM

2) 150 C for All other materials

29 1 A 335 GR P5, 5b & 5c , P9

30 A 336 F5, F5a & F9 ,369 GR FP5 &FP9

5B

31 SA 387 5 Cl.1 & 2 , SA 691 5 CR, Cl.1 & 2

32 A 213 T91

33 2 A 217 GR C12A Not Given NA NA NA NA NA

34 A 356 GR 12A

35 A 182 F 3V, F3 VCb,F22V

35 5C 1 A 336 F3VCb , F3V & F22V Not Given NA NA NA NA NA Not given

37 A 508 22 Cl.3 & 3V ,SA 542 22 Cl3 & 3V

38 SA-182 F6a Cl 1,2,3 & 4, F6b

39 6 1,2 & 3 SA217 CA15,SA240 Type 410, 429 760C Same as P5A Materail SAME AS P1 Material Same as P1 Material See notes of Table PW-39-6 See Notes of Table PW-39-6 205 C for ALL Thickness

40 SA268 Type 410, SA 336 F6,SA 351 CA15

41 SA182 F430,SA 240 Type 405,409,410S

7 1&2 730C Same as P5A Materail SAME AS P1 Material Same as P1 Material See notes of Table PW-39-7 See Notes of Table PW-39-7 None

42 SA240 S44400,SA268 Type 439

43 A 182 FR , SA 203 Gr A,B, SA 234 WPR

44 A 333 GR 7 & GR 9, SA 334 GR 7 & 9

9A 1 Not Given

45 A 350 GR LF5, Cl 1&.2 , SA 350 GR LF9

46 SA 714 Gr v, Tp.E , Gr V NA NA NA NA NA NA

47 A 203 Gr D , Gr. E & F

48 9B 1 A 333 GR 3 , SA 334 GR 3 Not Given

49 A 350GR LF3 , SA 765 III

50 SA 479 S32550

10 1 Not Given NA NA NA NA NA NA

51 SA 815 S 32760

52 Alloy S31803 1020C to 1100C As per material spec As per Material spec As per material spec As per material spec As per Material spec NA

53 Alloy S32550

10H 1

54 Alloy S32750 Not Given NA NA NA NA NA NA

55 All others

1) Up to 2" Thickness ,1 Hr /

56 SA 240 XM-33,27,SA268 TP446

Inch, bt Min 15 Mints. 150 C, But interpass should be

10 I 1 675C SAME AS P1 Material See note 4 ALL Thickness NA

2) For T Above 2" , it is 1 Hr between 175C to 230C

57 SA479 XM-27,SA 268 & 731 XM-27,33 /Inch

1) Up to 5" Thickness, it is 1Hr

58 SA 182 F91,A217 CA12A,SA234WP91

/Inch , but minumum 30

1) 205C for material has either

Minutes.

59 15 E 1 SA336 F91,SA369F91,A356 12A 730C - 775C SAME AS P1 Material Same as P1 Material See notes of Table PW-39-5 See notes of Table PW-39-5 T.S > 60 Ksi or both Cr >6 .0%

2) Above 5" 5Hr Plus 15

&Thickness at Joint > 13.00 MM

Minutes for each addition of 1" 2) 150 C for All other materials

60 A691 91,EN10222-2 X10CrMoVNb9-1

Thick .

1 The above table is prepared based on ASME Code edition 2010 addenda 2011a

Prepared by

A.Ayyanar 21 March 2013 1 of 1

Potrebbero piacerti anche

- Manpower Supply Agreement PDFDocumento3 pagineManpower Supply Agreement PDFMurugananthamParamasivam71% (7)

- Ielts Simon EbookDocumento51 pagineIelts Simon EbookMurugananthamParamasivamNessuna valutazione finora

- Pig Receiver Data Sheet 91303 - 8 InchDocumento4 paginePig Receiver Data Sheet 91303 - 8 InchSinaNessuna valutazione finora

- AGMA 9002-A86 Inch Bore and ANSI B17.1 Square Keyway TolerancesDocumento6 pagineAGMA 9002-A86 Inch Bore and ANSI B17.1 Square Keyway TolerancesEmmanuel García100% (1)

- 350W AmplifierDocumento5 pagine350W AmplifiermoisesNessuna valutazione finora

- Stratification OT 3536-22 ScrubberDocumento31 pagineStratification OT 3536-22 ScrubberbecemNessuna valutazione finora

- VP 3209 e 031a 02 0013 Rev.dDocumento254 pagineVP 3209 e 031a 02 0013 Rev.dSuryaprakashNessuna valutazione finora

- Rahul Girkar ResumeDocumento4 pagineRahul Girkar ResumerahulNessuna valutazione finora

- ESR0055024ACAL1004 0cDocumento24 pagineESR0055024ACAL1004 0ckayaltharanNessuna valutazione finora

- Flange Mawp Reduction PV Elite PDFDocumento8 pagineFlange Mawp Reduction PV Elite PDFDarshan PanchalNessuna valutazione finora

- Cyclic Service - Intergraph CADWorx & AnalysisDocumento2 pagineCyclic Service - Intergraph CADWorx & Analysisisrar khanNessuna valutazione finora

- D99 0017 Ef16001 33F1 Fe 8250 Rev 02 PDFDocumento3 pagineD99 0017 Ef16001 33F1 Fe 8250 Rev 02 PDFendoguNessuna valutazione finora

- 3D Stress CriteriaDocumento5 pagine3D Stress CriteriaFernando DiezNessuna valutazione finora

- 338033-4604-45ES-0005-07 (Carbon Steel Vessels - Technical Specification) PDFDocumento9 pagine338033-4604-45ES-0005-07 (Carbon Steel Vessels - Technical Specification) PDFjdgh1986Nessuna valutazione finora

- Ring Joint DimensionsDocumento1 paginaRing Joint DimensionsDuane HodgsonNessuna valutazione finora

- 16 B 06 HDocumento20 pagine16 B 06 HVaibhav Bhoir0% (1)

- Arz 104 Wood 125141Documento1 paginaArz 104 Wood 125141youcef islaNessuna valutazione finora

- P Niveda Priya B.T: IotechnologyDocumento2 pagineP Niveda Priya B.T: IotechnologyNiveNessuna valutazione finora

- DC S3-1301 REV.0 OriginalDocumento93 pagineDC S3-1301 REV.0 OriginalPeja JusohNessuna valutazione finora

- Microsoft Word - Material Selection GuidelinesDocumento3 pagineMicrosoft Word - Material Selection Guidelinesarjun SinghNessuna valutazione finora

- Calculated MAWP MAPDocumento4 pagineCalculated MAWP MAPhataefendiNessuna valutazione finora

- Calcs 4Documento19 pagineCalcs 4Syariful Maliki NejstaršíNessuna valutazione finora

- Pig Launcher Data Sheet 91303 - 8 InchDocumento4 paginePig Launcher Data Sheet 91303 - 8 InchSinaNessuna valutazione finora

- 8-1280-13 Pipe Class HF-1Documento4 pagine8-1280-13 Pipe Class HF-1Jesus MendezNessuna valutazione finora

- T12026 SACM 0002 N 0 - ProposalDocumento81 pagineT12026 SACM 0002 N 0 - ProposalSubrata DasNessuna valutazione finora

- Technical TQL Log - R0Documento4 pagineTechnical TQL Log - R0Jonathan ThimotyNessuna valutazione finora

- 898 FK BrochureDocumento12 pagine898 FK BrochuremahmoodvahidNessuna valutazione finora

- Pressure Vessel Design Old (Eugyene F Megysey)Documento31 paginePressure Vessel Design Old (Eugyene F Megysey)David FonsecaNessuna valutazione finora

- Astm F436.04 PDFDocumento6 pagineAstm F436.04 PDFWelington Volpatto MoraisNessuna valutazione finora

- Desalinated Water TankDocumento34 pagineDesalinated Water Tankhgagselim2012Nessuna valutazione finora

- Pressure Vessel Manual-M.asgaRZADEGANDocumento79 paginePressure Vessel Manual-M.asgaRZADEGANH BNessuna valutazione finora

- Spreaer Beam&Lifting Line Beam p3Documento2 pagineSpreaer Beam&Lifting Line Beam p3Sabrang LorNessuna valutazione finora

- Expansion Bellow Tech ComparisonDocumento10 pagineExpansion Bellow Tech ComparisonSabariMechyNessuna valutazione finora

- Bilge Keels PDFDocumento3 pagineBilge Keels PDFUtpalSahaNessuna valutazione finora

- 6261 - 4803 - 029 - Attachment-20 - Mandatory Spare Part List - XX PDFDocumento34 pagine6261 - 4803 - 029 - Attachment-20 - Mandatory Spare Part List - XX PDFharmlesdragon100% (1)

- Material and Equipment Standard For Large Welded Low Pressure Storage Tanks M-Me-110Documento17 pagineMaterial and Equipment Standard For Large Welded Low Pressure Storage Tanks M-Me-110Javeed A. KhanNessuna valutazione finora

- Mechanical Datasheet of Black Product (Fuel Oil) Road Tanker Unloading Pump (P-332, P-336)Documento4 pagineMechanical Datasheet of Black Product (Fuel Oil) Road Tanker Unloading Pump (P-332, P-336)Gop MangukiyaNessuna valutazione finora

- Toaz - Info Lifting Lug Calculation On Dish End PRDocumento156 pagineToaz - Info Lifting Lug Calculation On Dish End PRandry4jcNessuna valutazione finora

- Example E4.3.1Documento6 pagineExample E4.3.1Dario100% (1)

- BTP2B-EPCIC-BTJTB-M-TDS-0003 Rev.X PDFDocumento7 pagineBTP2B-EPCIC-BTJTB-M-TDS-0003 Rev.X PDFandrianoNessuna valutazione finora

- Purchase Spec. For Nozzles Swage (Sa106b)Documento4 paginePurchase Spec. For Nozzles Swage (Sa106b)Daison PaulNessuna valutazione finora

- LiquidDocumento2 pagineLiquidsiddhesh_guessNessuna valutazione finora

- Tbe For Osbl (SBS)Documento5 pagineTbe For Osbl (SBS)benidbb100% (3)

- Void 004-Permeate Water Storage TankDocumento55 pagineVoid 004-Permeate Water Storage TankUday UdmaleNessuna valutazione finora

- V 21302 - Rev.2 CDocumento133 pagineV 21302 - Rev.2 Cpandiangv100% (1)

- Stock Specifications - Plates - S355G10 MDocumento2 pagineStock Specifications - Plates - S355G10 Macadjournals. comNessuna valutazione finora

- PV Elite Örnek PDFDocumento223 paginePV Elite Örnek PDFakın ersözNessuna valutazione finora

- Gpcoewg Gecol: Document Cover SheetDocumento32 pagineGpcoewg Gecol: Document Cover Sheettanmaymajhi09_796764Nessuna valutazione finora

- Equivalent PressureDocumento1 paginaEquivalent PressureSarfaraz KhanNessuna valutazione finora

- Long Weld Necks 900 Rating DimensionDocumento1 paginaLong Weld Necks 900 Rating DimensionsriNessuna valutazione finora

- Load Cell DatasheetDocumento2 pagineLoad Cell DatasheetArulsaminathan100% (2)

- A869-6-44-0005 PMS For RevampDocumento950 pagineA869-6-44-0005 PMS For RevampMastram HatheshNessuna valutazione finora

- FVCDocumento0 pagineFVCsmileya_vpNessuna valutazione finora

- Technical - Query - JIND - 2april2020 (Ed. LAPI)Documento1 paginaTechnical - Query - JIND - 2april2020 (Ed. LAPI)Nyayu SitimayaNessuna valutazione finora

- 8-12 X 3000 M Spherical LPG Storage TankDocumento1 pagina8-12 X 3000 M Spherical LPG Storage Tankevrim77100% (1)

- Sick Tanker Unloading PumpDocumento3 pagineSick Tanker Unloading PumpSumantrra ChattopadhyayNessuna valutazione finora

- Tall Vertical ColumnsDocumento2 pagineTall Vertical ColumnsMas Arman TewoNessuna valutazione finora

- 26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002Documento33 pagine26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002ogyriskyNessuna valutazione finora

- Erg (1) T 01 378 07Documento58 pagineErg (1) T 01 378 07nazar750Nessuna valutazione finora

- ZeCor TechBulletin PDFDocumento2 pagineZeCor TechBulletin PDFjavoidea696526Nessuna valutazione finora

- Salt Spray and Cyclic Corrosion Testing PDFDocumento2 pagineSalt Spray and Cyclic Corrosion Testing PDFJorge Enrique Salas RoblesNessuna valutazione finora

- Dimensioning A Heat Exchanger Flange: About P3 EngineeringDocumento22 pagineDimensioning A Heat Exchanger Flange: About P3 EngineeringVilas AndhaleNessuna valutazione finora

- HT Chart For ASME Material-B31.3Documento1 paginaHT Chart For ASME Material-B31.3MurugananthamParamasivamNessuna valutazione finora

- HT Chart For ASME Material-B31.3 PDFDocumento1 paginaHT Chart For ASME Material-B31.3 PDFMurugananthamParamasivamNessuna valutazione finora

- Api 653Documento1 paginaApi 653BashMohandesssNessuna valutazione finora

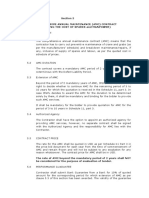

- Section 5 Comprehensive Annual Maintenance (Amc) Contract (Incuding The Cost of Spares and Manpower)Documento5 pagineSection 5 Comprehensive Annual Maintenance (Amc) Contract (Incuding The Cost of Spares and Manpower)MurugananthamParamasivamNessuna valutazione finora

- A312 A312mDocumento10 pagineA312 A312made faruroziNessuna valutazione finora

- Qa QC CoordinatorDocumento2 pagineQa QC CoordinatorMurugananthamParamasivamNessuna valutazione finora

- UserGuide - 510 - 570 - 653 PDFDocumento25 pagineUserGuide - 510 - 570 - 653 PDFMurugananthamParamasivamNessuna valutazione finora

- EOI Frame Agreement Construction Field Engineering and Inspection Services Web Version Final 07022013 0Documento4 pagineEOI Frame Agreement Construction Field Engineering and Inspection Services Web Version Final 07022013 0MurugananthamParamasivamNessuna valutazione finora

- General Terms and Conditions For Contracts For Work and LabourDocumento4 pagineGeneral Terms and Conditions For Contracts For Work and LabourMurugananthamParamasivamNessuna valutazione finora

- 12e451 3Documento3 pagine12e451 3MurugananthamParamasivamNessuna valutazione finora

- 103 Instructions To Bidders and RFQ Terms and ConditionsDocumento4 pagine103 Instructions To Bidders and RFQ Terms and ConditionsMurugananthamParamasivamNessuna valutazione finora

- 343 - 2014-04-12-10-38-16 - 1397279296 (1) MeconDocumento1 pagina343 - 2014-04-12-10-38-16 - 1397279296 (1) MeconMurugananthamParamasivamNessuna valutazione finora

- Vocabulary TermDocumento4 pagineVocabulary TermMurugananthamParamasivamNessuna valutazione finora

- Itt Mecon RFTDocumento10 pagineItt Mecon RFTMurugananthamParamasivamNessuna valutazione finora

- Worldwide Technical Recruitment Services - 2012 Lettersize, 1Documento2 pagineWorldwide Technical Recruitment Services - 2012 Lettersize, 1MurugananthamParamasivamNessuna valutazione finora

- 103 Instructions To Bidders and RFQ Terms and ConditionsDocumento4 pagine103 Instructions To Bidders and RFQ Terms and ConditionsMurugananthamParamasivamNessuna valutazione finora

- Addendum 001 Request For Bid Traffic Signal Parts RFB 2-150310KH1Documento2 pagineAddendum 001 Request For Bid Traffic Signal Parts RFB 2-150310KH1MurugananthamParamasivamNessuna valutazione finora

- Requirements For Welders RecruitmentDocumento2 pagineRequirements For Welders RecruitmentMurugananthamParamasivamNessuna valutazione finora

- TemplateDocumento2 pagineTemplateMurugananthamParamasivamNessuna valutazione finora

- Hydrogen-Induced Cracking Along The Fusion Boundary of Dissimilar Metal WeldsDocumento7 pagineHydrogen-Induced Cracking Along The Fusion Boundary of Dissimilar Metal WeldsMurugananthamParamasivamNessuna valutazione finora

- Defects or ProblemDocumento4 pagineDefects or ProblemMurugananthamParamasivamNessuna valutazione finora

- Vocabulary and DefinitionsDocumento14 pagineVocabulary and DefinitionsMurugananthamParamasivamNessuna valutazione finora

- Hydrogen-Induced Cracking Along The Fusion Boundary of Dissimilar Metal WeldsDocumento7 pagineHydrogen-Induced Cracking Along The Fusion Boundary of Dissimilar Metal WeldsMurugananthamParamasivamNessuna valutazione finora

- Defects in Overlay1Documento2 pagineDefects in Overlay1MurugananthamParamasivamNessuna valutazione finora

- HT Chart For ASME Material-B31.3 PDFDocumento1 paginaHT Chart For ASME Material-B31.3 PDFMurugananthamParamasivamNessuna valutazione finora

- Hydrogen-Induced Cracking (HIC) : Failures in Sour Gas EnvironmentsDocumento1 paginaHydrogen-Induced Cracking (HIC) : Failures in Sour Gas EnvironmentsMurugananthamParamasivamNessuna valutazione finora

- Vocabulary and DefinitionsDocumento14 pagineVocabulary and DefinitionsMurugananthamParamasivamNessuna valutazione finora

- Selection of Welding Process WRT MaterialDocumento1 paginaSelection of Welding Process WRT MaterialMurugananthamParamasivamNessuna valutazione finora

- Dissimilar Weld Filler Metal SelectionDocumento1 paginaDissimilar Weld Filler Metal SelectionMurugananthamParamasivamNessuna valutazione finora

- Shaper Gear CuttingDocumento4 pagineShaper Gear Cuttingnevadablue100% (4)

- ASTM E1417 Penetrant Testing - 9 PDFDocumento11 pagineASTM E1417 Penetrant Testing - 9 PDFbikaNessuna valutazione finora

- Mazda rx7Documento3 pagineMazda rx7Jon WestNessuna valutazione finora

- Catalogo GIACOMINIDocumento45 pagineCatalogo GIACOMINIIsrael Silva Hgo.Nessuna valutazione finora

- Empaque Espirometalicos PDFDocumento50 pagineEmpaque Espirometalicos PDFgregorioNessuna valutazione finora

- Power Factor Regulator User's Guide: A Brief Ov Erv IewDocumento4 paginePower Factor Regulator User's Guide: A Brief Ov Erv Iewsincan200779Nessuna valutazione finora

- K.analysis of The Articulated Robotic Arm (TITLE DEFENCE)Documento22 pagineK.analysis of The Articulated Robotic Arm (TITLE DEFENCE)sky4sterNessuna valutazione finora

- Ball ValvesDocumento4 pagineBall ValvesIgde Agung ChandraNessuna valutazione finora

- Wanyiri S K - Traffic Congestion in Nairobi CBDDocumento65 pagineWanyiri S K - Traffic Congestion in Nairobi CBD1man1bookNessuna valutazione finora

- Current Electricity All DerivationsDocumento11 pagineCurrent Electricity All DerivationsRonit VaskarNessuna valutazione finora

- 80312A-ENUS Error LogDocumento10 pagine80312A-ENUS Error LogSafdar HussainNessuna valutazione finora

- Cat Reforming Part 2 3 PDF FreeDocumento68 pagineCat Reforming Part 2 3 PDF FreeLê Trường AnNessuna valutazione finora

- Ee BD ManualDocumento37 pagineEe BD Manualsergey62Nessuna valutazione finora

- InsulinDocumento6 pagineInsulinJorelle-Nickolai RodriguezNessuna valutazione finora

- Info02e5 Safety ValveDocumento2 pagineInfo02e5 Safety ValveCarlos GutierrezNessuna valutazione finora

- Sqldatagrid Symbol User'S Guide: ArchestraDocumento36 pagineSqldatagrid Symbol User'S Guide: ArchestraAde SuryaNessuna valutazione finora

- Excel ExercisesDocumento37 pagineExcel ExercisesBERNIELLE DAVE FALDASNessuna valutazione finora

- Ups and Stabilizer Assembling UnitDocumento28 pagineUps and Stabilizer Assembling UnitIPro PkNessuna valutazione finora

- Verilog Implementation of Reed - Solomon CodeDocumento16 pagineVerilog Implementation of Reed - Solomon CodeManik Prabhu ChillalNessuna valutazione finora

- lfb10 Call PointDocumento1 paginalfb10 Call PointOmar AhmedNessuna valutazione finora

- Distance Measuring EquipmentDocumento12 pagineDistance Measuring Equipmentमेनसन लाखेमरूNessuna valutazione finora

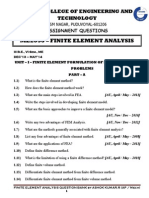

- Assignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Documento85 pagineAssignment Booklet Me2353 Finite Element Analysis Dec 2013 May 2014Ashok Kumar Rajendran100% (9)

- Firestop HILTIDocumento44 pagineFirestop HILTIronaldo aguirreNessuna valutazione finora

- Features General Description: 1.5A Low Dropout Linear Regulator With Programmable Soft-StartDocumento15 pagineFeatures General Description: 1.5A Low Dropout Linear Regulator With Programmable Soft-StartSivaNessuna valutazione finora

- Fourier Series - MATLAB & Simulink PDFDocumento7 pagineFourier Series - MATLAB & Simulink PDFWanderson Antonio Sousa SilvaNessuna valutazione finora

- Operating & Installation Instructions NA-FS10V7 NA-FS95V7Documento32 pagineOperating & Installation Instructions NA-FS10V7 NA-FS95V7Kis NermalNessuna valutazione finora

- 240-109607332 Eskom Plant Labelling Abbreviation StandardDocumento638 pagine240-109607332 Eskom Plant Labelling Abbreviation StandardiabhuaNessuna valutazione finora

- Detailed Lesson Plan in IctDocumento4 pagineDetailed Lesson Plan in IctJai AidamusNessuna valutazione finora