Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Performance Data: Model CBLE 100-800 HP Boilers

Caricato da

sebaversaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Performance Data: Model CBLE 100-800 HP Boilers

Caricato da

sebaversaCopyright:

Formati disponibili

Model CBLE 100-800 HP Boilers

PERFORMANCE DATA

The Low Emission Option provides NOx reduction at current published and predicted

fuel-to-steam efficiencies.

Specifying Boiler Efficiency

Cleaver-Brooks offers an industry leading fuel-to-steam boiler efficiency guarantee for

Model CB-LE Firetube Boilers. The guarantee is based on the fuel-to-steam efficiencies

shown in the efficiency tables and the following conditions. The efficiency percent number

is only meaningful if the specific conditions of the efficiency calculations are clearly stated

in the specification (see Cleaver-Brooks publication CB-7768 for a detailed description of

efficiency calculations).

When specifying the efficiencies in the tables, be sure to include the specific guarantee

conditions to maximize the effectiveness of your efficiency specification. If you have any

questions regarding the efficiency specifications, please contact your local Cleaver-

Brooks authorized representative.

Efficiency Specification

The boiler manufacturer shall guarantee that, at the time of startup, the boiler will achieve

fuel-to-steam efficiency (as shown in Table A1-16 and Table A1-17) at 100% firing rate

(add efficiency guarantees at 25%, 50%, and 75% of rating, if required). If the boiler(s)

fail to achieve the corresponding guaranteed efficiency as published, the boiler

manufacturer will rebate, to the ultimate boiler owner, ten thousand dollars ($10,000) for

every full efficiency point (1.0%) that the actual efficiency is below the guaranteed level.

The specified boiler efficiency is based on the following conditions.

1. Fuel specification used to determine boiler efficiency:

Natural Gas

Carbon,% (wt) = 69.98

Hydrogen,% (wt) = 22.31

Sulfur,% (wt) = 0.0

Heating value, Btu/lb. = 21,830

No. 2 Oil

Carbon,% (wt) = 85.8

Hydrogen,% (wt) = 12.7

Sulfur,% (wt) = 0.2

Heating value, Btu/lb. = 19,420

No. 6 Oil

Carbon,% (wt) = 86.6

Hydrogen,% (wt) = 10.9

Sulfur,% (wt) = 2.09

Heating value, Btu/lb. = 18,830

2. Efficiencies are based on ambient air temperature of 80 F, relative humidity of 30%,

and 15% excess air in the exhaust flue gas.

3. Efficiencies are based on manufacturers published radiation and convection losses.

(For Cleaver-Brooks radiation and convection losses, see Boiler Efficiency Facts

Guide, publication number CB-7767).

4. Any efficiency verification testing will be based on the stack loss method.

For efficiencies and stack temperatures at operating pressures not listed, follow these

procedures:

Section A1-24 Rev. 09-09

Model CBLE 100-800 HP Boilers

When the operating steam pressure is between 10 psig and 125 psig, interpolate the

values from the efficiency tables.

When the operating steam pressure is above 125 psig, estimated efficiency can be

calculated as follows:

Example:

Boiler: 350 hp.

Fuel: natural gas.

Operating steam pressure: 200 psig.

Find the fuel-to-steam efficiency at 100% firing rate. From Table A1-16 for a 350 hp boiler

operating at 100% firing rate and an operating steam pressure of 125 psig, the efficiency

is 82.5%.

Using Figure A1-11, note that the stack temperature increases 36 F at the higher

operating pressure. To estimate boiler efficiency, use this rule of thumb: For every 40 F

increase in stack temperature, efficiency decreases by 1%. Since the stack temperature

rise is 36 F, the decrease in the boiler efficiency at 200 psig operating pressure is

calculated as follows: 36/40 =.9%. Therefore, the boiler efficiency at 200 psig operating

pressure is 82.5 -.9 = 81.6%

Emissions

The emission data included in this section consists of typical emission levels for Model

CB boilers equipped with 60, 30, 25, and 20 ppm LE Options when firing natural gas and

No. 2 oil.

Notice

The data in Table A1-18 and Table A1-19 represent typical emission levels only.

Guaranteed emission levels are available from your local Cleaver-Brooks

authorized representative.

Section A1-25 Rev. 09-09

Model CBLE 100-800 HP Boilers

Table A1-16. Predicted Fuel-to-Steam Efficiencies - Natural Gas

OPERATING PRESSURE = 10 psig OPERATING PRESSURE = 125 psig

BOILER HP % OF LOAD % OF LOAD

25% 50% 75% 100% 25% 50% 75% 100%

125 83.3 83.6 83.4 83.2 80.4 80.9 81.0 81.0

150 84.4 84.6 84.5 84.3 81.5 82.0 82.0 82.1

200 85.0 85.3 85.1 84.9 82.2 82.7 82.7 82.7

250 85.0 84.7 84.0 83.3 82.0 82.0 81.6 81.3

300 85.3 85.3 84.6 83.9 82.6 82.7 82.2 81.9

350 85.3 85.7 85.2 84.5 82.6 83.2 82.8 82.5

400 84.5 84.7 84.6 84.4 81.8 82.2 82.4 82.2

500 85.5 85.7 85.5 85.2 82.8 83.2 83.3 83.1

600 85.7 86.0 85.8 85.6 82.9 83.5 83.6 83.5

700 85.7 86.2 86.0 85.7 83.0 83.6 83.6 83.6

750, 800 85.8 86.1 85.9 85.6 83.1 83.6 83.7 83.5

Figure A1-11. Predicted Stack Temperature Increase for Pressure Greater Than 125 psig

Section A1-26 Rev. 09-09

Model CBLE 100-800 HP Boilers

Table A1-17. Predicted Fuel-to-Steam Efficiencies - No. 2 Oil

OPERATING PRESSURE = 10 psig OPERATING PRESSURE = 125 psig

BOILER HP % OF LOAD % OF LOAD

25% 50% 75% 100% 25% 50% 75% 100%

125 86.7 86.9 86.7 86.6 83.7 84.2 84.3 84.3

150 87.8 88.0 87.8 87.6 84.8 85.3 85.3 85.4

200 88.4 88.7 88.4 88.2 85.6 86.0 86.0 86.0

250 88.3 88.1 87.4 86.7 85.3 85.3 84.9 84.7

300 88.6 88.7 88.0 87.3 85.9 86.0 85.5 85.2

350 88.6 89.0 88.5 87.8 85.9 86.6 86.1 85.8

400 87.9 88.1 87.9 87.6 85.1 85.5 85.6 85.5

500 88.9 89.0 88.9 88.6 86.1 86.5 86.6 86.4

600 89.0 89.4 89.2 89.0 86.2 86.8 86.9 86.8

700 89.1 89.5 89.3 89.1 86.3 86.9 87.0 86.9

750, 800 89.2 89.5 89.3 89.0 86.4 86.9 87.0 86.8

Table A1-18. CB-LE Boilers - Natural Gas, Emission Levels

ESTIMATED LEVEL

POLLUTANT

60 ppm 30 ppm 25 ppm 20 ppm 15 ppm 9 ppm

CO ppmA 50/150B 50/150B 50/150B 50/150B 50 50

lb./MMBtu 0.04/0.11 0.04/0.11 0.04/0.11 0.04/0.11 0.04 0.04

NOx ppmA 60 30 25 20 15 9

lb/MMBtu 0.07 0.035 0.03 0.024 0.018 0.011

SOx ppmA 1 1 1 1 1 1

lb/MMBtu 0.001 0.001 0.001 0.001 0.001 0.001

HC/VOC5 ppmA 10 10 10 10 10 10

lb/MMBtu 0.004 0.004 0.004 0.004 0.004 0.004

PM ppmA - - - - - -

lb/MMBtu 0.01 0.01 0.01 0.01 0.01 0.01

A. ppm levels are given on a dry volume basis and corrected to 3% oxygen (15% excess air).

B. CO emission for 60, 30, 25 & 20 ppm system is 50 ppm (0.04 lb/MMBtu) when boiler is operating above 50% of rated

capacity. CO emission is 150 ppm (0.11 lb/MMBtu) when boiler is operating below 50% of rated capacity.

Table A1-19. CB-LE Boilers - No. 2 Oil, Emission Levels

ESTIMATED LEVEL

POLLUTANT

60 ppm LE Option 30, 25, 20 ppm LE Option 15 ppm 9 ppm

A

CO ppm 50 50 50 50

lb/MMBtu 0.039 0.039 0.039 0.039

NOx ppmA 140 90 85 70

lb/MMBtu 0.186 0.120 0.113 0.093

SOx ppmA 278 278 278 278

lb/MMBtu 0.52 0.52 0.52 0.52

HC/VOCs ppmA 4 4 4 4

lb/MMBtu 0.002 0.002 0.002 0.002

PM ppmA - - - -

lb/MMBtu 0.025 0.025 0.025 0.025

A. ppm levels are given on a dry volume basis and corrected to 3% oxygen (15% excess air). BASED ON THE

FOLLOWING CONSTITUENT LEVELS:

Fuel-bound Nitrogen content = 0.015% by weight.

Sulfur content = 0.5% by weight.

Ash content = 0.01% by weight.

Section A1-27 Rev. 09-09

Potrebbero piacerti anche

- GM Passlock II SystemDocumento14 pagineGM Passlock II Systemalmia tronicsNessuna valutazione finora

- SIM BoxingDocumento2 pagineSIM Boxingkrishnakant_75Nessuna valutazione finora

- For Gas Turbine Compressors: Cleanblade Gtc1000 Treatment ProgramDocumento30 pagineFor Gas Turbine Compressors: Cleanblade Gtc1000 Treatment Programsaikatchoudhuri100% (1)

- Acid Gas Sweetening With DEADocumento20 pagineAcid Gas Sweetening With DEAEfer Cuadros BNessuna valutazione finora

- Chiller Estimator 4.0Documento25 pagineChiller Estimator 4.0Dee RajaNessuna valutazione finora

- Data Sheet G3520CDocumento3 pagineData Sheet G3520CIwaiter100% (3)

- Whirlpool Duet HTDocumento96 pagineWhirlpool Duet HTdanny85901100% (2)

- Analysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesDa EverandAnalysis of Engineering Cycles: Thermodynamics and Fluid Mechanics SeriesValutazione: 3 su 5 stelle3/5 (1)

- Exam Flashcards: by Jonathan DonadoDocumento520 pagineExam Flashcards: by Jonathan Donadosolarstuff100% (1)

- J.M. Hurst Cyclic AnalysisDocumento45 pagineJ.M. Hurst Cyclic AnalysisChristian Robinson80% (10)

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantDa EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNessuna valutazione finora

- Esquema Elétrico NGD 9.3Documento2 pagineEsquema Elétrico NGD 9.3LuisCarlosKovalchuk100% (1)

- TSD CogenDocumento5 pagineTSD CogenGaurav SushrutNessuna valutazione finora

- Distillation Optimization-Vapor RecompressionDocumento5 pagineDistillation Optimization-Vapor RecompressionChem.EnggNessuna valutazione finora

- Production of Isopropyl Palmitate-Experimental StudiesDocumento12 pagineProduction of Isopropyl Palmitate-Experimental Studiesikaw_3Nessuna valutazione finora

- Cleaver Brooks - Boiler Book 2011Documento1.140 pagineCleaver Brooks - Boiler Book 2011kennnyp1100% (1)

- BurnerDocumento4 pagineBurnerAhmed Mohamed KhalilNessuna valutazione finora

- 4.1 BoilerDocumento28 pagine4.1 Boilerrashm006ranjanNessuna valutazione finora

- 16.efficiency Management Sytems PresentationsDocumento67 pagine16.efficiency Management Sytems Presentationsrahul100% (1)

- 6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFDocumento31 pagine6-C-RIIMPO301E - Conduct Hydraulic Excavator Operations - Learner Guide - V 1.1 02122019 PDFOwen PerrinNessuna valutazione finora

- Boiler EfficiencyDocumento28 pagineBoiler Efficiencybzkizo_sbbNessuna valutazione finora

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesDa EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNessuna valutazione finora

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersDa EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNessuna valutazione finora

- Energy Audit & Efficiency Improvement of Operating Power PlantsDocumento56 pagineEnergy Audit & Efficiency Improvement of Operating Power Plantsmhdsoleh100% (1)

- Philips Aquatrio FC7070 - 01 Esploso ManualeDocumento9 paginePhilips Aquatrio FC7070 - 01 Esploso ManualeRocco Mangione0% (1)

- Modeling, Analysis and Optimization of Process and Energy SystemsDa EverandModeling, Analysis and Optimization of Process and Energy SystemsNessuna valutazione finora

- 21-3971-CLA - DisenŞo Preliminar Cimentacion - Normal SoilDocumento4 pagine21-3971-CLA - DisenŞo Preliminar Cimentacion - Normal SoilJose ManzanarezNessuna valutazione finora

- Visbreaking Unit PDFDocumento17 pagineVisbreaking Unit PDFMarcos Maldonado100% (1)

- Firing Diagram Based On Design Load PDFDocumento2 pagineFiring Diagram Based On Design Load PDFxaver lawNessuna valutazione finora

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocumento5 pagineModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocumento5 pagineModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNessuna valutazione finora

- CB-7768 Gen - Boiler Efficiency TablesDocumento4 pagineCB-7768 Gen - Boiler Efficiency TablestthennisNessuna valutazione finora

- Turbine Inlet CoolingDocumento6 pagineTurbine Inlet Coolingankarao1969Nessuna valutazione finora

- Boiler Tune Auto ReportDocumento55 pagineBoiler Tune Auto ReportValiNessuna valutazione finora

- Model CBL 900-1800 HP Boilers: Engineering DataDocumento5 pagineModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNessuna valutazione finora

- Tower HMBDocumento26 pagineTower HMBAnkur KoulNessuna valutazione finora

- Model 4WI 100 - 800 HP Boilers: Oil-Fired BurnersDocumento4 pagineModel 4WI 100 - 800 HP Boilers: Oil-Fired BurnerssebaversaNessuna valutazione finora

- Celanova Faza 2 Chilleri: Selection: Compact Screw Compressors CS // CSVDocumento3 pagineCelanova Faza 2 Chilleri: Selection: Compact Screw Compressors CS // CSVSladjan UgrenovicNessuna valutazione finora

- Acetone ProductionDocumento8 pagineAcetone ProductionZahraa GhanemNessuna valutazione finora

- Parameters Influencing Boiler Efficiency: IssueDocumento11 pagineParameters Influencing Boiler Efficiency: IssueJohn NgwokeNessuna valutazione finora

- Model CB 15-100 HP Boilers: LightsDocumento5 pagineModel CB 15-100 HP Boilers: LightssebaversaNessuna valutazione finora

- G3412 - 450 KW Performance DataDocumento3 pagineG3412 - 450 KW Performance DataJacob De CasillasNessuna valutazione finora

- G3520E Data SheetDocumento3 pagineG3520E Data SheetIwaiter100% (2)

- Model CBLE 100-800 HP Boilers: 2.4 Efficiency GuaranteeDocumento4 pagineModel CBLE 100-800 HP Boilers: 2.4 Efficiency GuaranteesebaversaNessuna valutazione finora

- Model CB Boilers 15-100 HP: Dimensions and RatingsDocumento9 pagineModel CB Boilers 15-100 HP: Dimensions and RatingsMauricio RojasNessuna valutazione finora

- Model CB Boilers 15-100 HP: Dimensions and RatingsDocumento10 pagineModel CB Boilers 15-100 HP: Dimensions and Ratingsleonel lopezNessuna valutazione finora

- 92742-87559 Rev00 - Performance NBWB100ADocumento1 pagina92742-87559 Rev00 - Performance NBWB100AJosé Pedro MagalhãesNessuna valutazione finora

- 7.lecture Note On Air Standard CyclesDocumento66 pagine7.lecture Note On Air Standard Cyclessujit kcNessuna valutazione finora

- Boiler Room SavingsDocumento79 pagineBoiler Room SavingsmrfxitNessuna valutazione finora

- Simulation of A Visbreaking UnitDocumento5 pagineSimulation of A Visbreaking UnitPablo PaganiNessuna valutazione finora

- Allyl KlorürDocumento8 pagineAllyl KlorürYiğit ErkulNessuna valutazione finora

- Energy Tips - Steam: Consider Installing High-Pressure Boilers With Backpressure Turbine-GeneratorsDocumento4 pagineEnergy Tips - Steam: Consider Installing High-Pressure Boilers With Backpressure Turbine-GeneratorsArini RizalNessuna valutazione finora

- Obtencion de AcetonaDocumento7 pagineObtencion de AcetonaLiz Laureano RodriguezNessuna valutazione finora

- Combustion Basics: The Chemistry of CombustionDocumento6 pagineCombustion Basics: The Chemistry of CombustionhozipekNessuna valutazione finora

- Vol III Part A EditedDocumento24 pagineVol III Part A EditedAravind ShankarNessuna valutazione finora

- Dokumen - Tips - Cbex de Boiler Book Cbex de Features and Benefits 3 The Cleaver Brooks Cbex deDocumento19 pagineDokumen - Tips - Cbex de Boiler Book Cbex de Features and Benefits 3 The Cleaver Brooks Cbex decarlosNessuna valutazione finora

- Cbex Elite: Boiler Book 09/2019Documento22 pagineCbex Elite: Boiler Book 09/2019Luis Miguel Rios CuentasNessuna valutazione finora

- Practical TBPDocumento8 paginePractical TBPHalben A Nerway0% (1)

- GE Energy: Gas Turbine (60Hz)Documento2 pagineGE Energy: Gas Turbine (60Hz)Rolando Antonio Cuenca PironaNessuna valutazione finora

- Supplementary Paper 4 - Set B Regn No: - NameDocumento16 pagineSupplementary Paper 4 - Set B Regn No: - NameAnuj ShahiNessuna valutazione finora

- Gas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyDocumento3 pagineGas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyEzequiel Juarez BenítezNessuna valutazione finora

- Air Fuel MonitorDocumento8 pagineAir Fuel Monitoraxell AxelzonNessuna valutazione finora

- Y.pabbI - 28 July 15 - EE ImpOperatg PlantsDocumento56 pagineY.pabbI - 28 July 15 - EE ImpOperatg Plantsamerie joy onateNessuna valutazione finora

- 4.1 Boiler - OutputDocumento29 pagine4.1 Boiler - OutputAnonymous gUa0hp4ffNessuna valutazione finora

- Siemens-Gas-Turbine-SGT-600 Operation With Varying Fuel Properties LADocumento8 pagineSiemens-Gas-Turbine-SGT-600 Operation With Varying Fuel Properties LARasoul gholinia kiviNessuna valutazione finora

- LabsimDocumento29 pagineLabsimteja boddu2Nessuna valutazione finora

- Process Simulator Training: Pt. Indonesia PowerDocumento27 pagineProcess Simulator Training: Pt. Indonesia PowerhendriNessuna valutazione finora

- Model CB 15-100 HP Boilers: LightsDocumento5 pagineModel CB 15-100 HP Boilers: LightssebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocumento5 pagineModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNessuna valutazione finora

- Model CB 15-100 HP BoilersDocumento5 pagineModel CB 15-100 HP BoilerssebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: Sound LevelDocumento5 pagineModel CB 15-100 HP Boilers: Sound LevelsebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocumento5 pagineModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNessuna valutazione finora

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Documento5 pagineModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocumento5 pagineModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNessuna valutazione finora

- Section A5: Model CBL 900-1800 HP BoilersDocumento5 pagineSection A5: Model CBL 900-1800 HP BoilerssebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocumento5 pagineModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNessuna valutazione finora

- Model CBL 900-1800 HP BoilersDocumento5 pagineModel CBL 900-1800 HP BoilerssebaversaNessuna valutazione finora

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocumento5 pagineModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNessuna valutazione finora

- Features and Benefits: Model CB 15-100 HP BoilersDocumento5 pagineFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNessuna valutazione finora

- Model CB 15-100 HP BoilersDocumento5 pagineModel CB 15-100 HP BoilerssebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocumento5 pagineModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNessuna valutazione finora

- Model CBR 125-800 HP BoilersDocumento5 pagineModel CBR 125-800 HP BoilerssebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocumento5 pagineModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNessuna valutazione finora

- Model CBL 900-1800 HP Boilers: Engineering DataDocumento5 pagineModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocumento5 pagineModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNessuna valutazione finora

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocumento5 pagineModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaNessuna valutazione finora

- General: Model ICB 100-800 HP BoilersDocumento4 pagineGeneral: Model ICB 100-800 HP BoilerssebaversaNessuna valutazione finora

- Model CBL 900-1800 HP BoilersDocumento5 pagineModel CBL 900-1800 HP BoilerssebaversaNessuna valutazione finora

- Model ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizeDocumento4 pagineModel ICB 100-800 HP Boilers: Table A4-14. Model ICB Steam Boiler Safety Valve Outlet SizesebaversaNessuna valutazione finora

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocumento4 pagineModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaNessuna valutazione finora

- Model ICB 100-800 HP BoilersDocumento4 pagineModel ICB 100-800 HP BoilerssebaversaNessuna valutazione finora

- Model ICB 100-800 HP BoilersDocumento4 pagineModel ICB 100-800 HP BoilerssebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Documento6 pagineModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNessuna valutazione finora

- Model ICB 100-800 HP BoilersDocumento4 pagineModel ICB 100-800 HP BoilerssebaversaNessuna valutazione finora

- Research ArticleDocumento9 pagineResearch ArticlesebaversaNessuna valutazione finora

- Chapter 7 Notes Computer OrganizationDocumento20 pagineChapter 7 Notes Computer OrganizationsriNessuna valutazione finora

- Intermec CS40 SpecsDocumento8 pagineIntermec CS40 Specsss1222Nessuna valutazione finora

- KST GlueTech 44 enDocumento80 pagineKST GlueTech 44 enLeandro RadamesNessuna valutazione finora

- Teradata Installation: Installation Steps For WindowsDocumento4 pagineTeradata Installation: Installation Steps For WindowsjupudiguptaNessuna valutazione finora

- Ude My For Business Course ListDocumento51 pagineUde My For Business Course ListShehroz BhuttaNessuna valutazione finora

- Session 5 PDFDocumento26 pagineSession 5 PDFToufic HageNessuna valutazione finora

- Eje Delantero BMW F10Documento94 pagineEje Delantero BMW F10Daniel Muñoz SotomayorNessuna valutazione finora

- Fast, Accurate Data Management Across The Enterprise: Fact Sheet: File-Aid / MvsDocumento4 pagineFast, Accurate Data Management Across The Enterprise: Fact Sheet: File-Aid / MvsLuis RamirezNessuna valutazione finora

- ENOVIA V6 Product PortfolioDocumento32 pagineENOVIA V6 Product PortfolioARUN PATILNessuna valutazione finora

- Acceleration GrpahDocumento14 pagineAcceleration GrpahRAFAEL TORRESNessuna valutazione finora

- Module002 LaboratoryExercise002Documento2 pagineModule002 LaboratoryExercise002Joaquin SmithNessuna valutazione finora

- Nuevo CvuDocumento1 paginaNuevo CvuJesús GonzálezNessuna valutazione finora

- Tharmal Analysis BasicsDocumento56 pagineTharmal Analysis BasicsNetoNessuna valutazione finora

- " " Reach: Ordering InformationDocumento8 pagine" " Reach: Ordering InformationTrong TranNessuna valutazione finora

- Selenium-75 Sources and Source Holders: ApplicationsDocumento2 pagineSelenium-75 Sources and Source Holders: ApplicationsTanpreet SinghNessuna valutazione finora

- How To Measure MTFDocumento64 pagineHow To Measure MTFamtcorporationNessuna valutazione finora

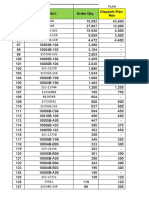

- Order Qty Vs Dispatch Plan - 04 11 20Documento13 pagineOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNessuna valutazione finora

- Tutorial - 05 - Excavation Settle 3DDocumento13 pagineTutorial - 05 - Excavation Settle 3DAlejandro Camargo SanabriaNessuna valutazione finora

- E 7016 Product-SheetDocumento1 paginaE 7016 Product-SheetAlireza TakrimiNessuna valutazione finora