Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Carbozinc 11 HS PDS

Caricato da

vietrossCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Carbozinc 11 HS PDS

Caricato da

vietrossCopyright:

Formati disponibili

Carbozinc 11 HS

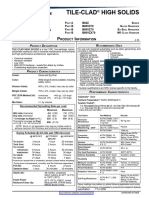

Selection & Specification Data Selection & Specification Data

Generic Type Solvent Based Inorganic Zinc Topcoats Acrylics, Epoxies, Polyurethanes, High Heat Silicones,

Description Ultra-low VOC member of the Carbozinc family Silicates and others as recommended by your

with extraordinary corrosion resistance properties. Carboline sales representative.

Carbozinc 11 HS combines unparalleled performance Not required for certain exposures. A mist-coat/full-coat spray technique

is often required to minimize topcoat bubbling.

characteristics with an ultra-low VOC formulation that

meets some of the most stringent VOC restrictions.

Features Meets Class B slip co-efficient and creep testing Substrates & Surface Preparation

criteria for use on faying surfaces

Rapid cure. Dry to handle in 1 hour at 75F (24C) General Surfaces must be clean and dry. Employ adequate

and 50% relative humidity methods to remove dirt, dust, oil and all other

Low temperature cure down to 15F (-9C) contaminants that could interfere with adhesion of the

High zinc loading coating.

Very good resistance to salting Steel SSPC-SP6 Surface Profile: 1.0-3.0 mils (25-75

May be applied with airless or conventional spray micron). Consult Carboline Technical Service for

Excellent as a lining for solvent storage* (Green appropriate surface preparation guidelines regarding

color only) tank lining applications.

May be used as a weldable pre-construction primer

Exhibits long-term corrosion resistance

Ultra-low VOC level for solvent-based inorganic

Performance Data

zincs Test Method System Results

Color Standard: Green (0300) AASHTO M300 Blasted Steel No blistering or rusting

Special Order: Grey (0700) 1 ct. CZ 11 HS of coating or any

bare steel areas

Finish Flat

ASTM A-325 or 1 ct. CZ 11 HS 0.58 meets

Primer Self Priming A-490 Slip co-efficient requirements for

Service Untopcoated Class B rating

Temperature Continuous: 750F (400C) ASTM B117 Salt Spray Blasted Steel No rusting or blistering;

Non-Continuous: 800F (427C) 1 ct. CZ 11 HS slight rust in scribe,

With recommended high heat topcoats: no creepage at scribe

Continuous: 1000F (538C) after 70,000 hours

Non-Continuous: 1200F (649C) ASTM D3363 1 ct. CZ 11 HS Pencil Hardness 3 H

Dry Film Thickness 2.0 - 3.0 mils (51 - 76 microns) per coat Pencil hardness

0.50-1.00 mils (12-25 microns) per coat for weldable, pre-construction Mixing & Thinning

primer. 2.0-5.0 mils for OEM applications in controlled environments.

Dry film thickness in excess of 6.0 mils (150 microns) per coat is not Mixing Power mix base (Part A), then combine and power

recommended.

mix as follows. Pour zinc filler (Part B) very slowly into

Total Zinc Content 84% by weight premixed base (Part A) with continuous agitation. Mix

in Dry Film until free of lumps. Then add activator (Part C) and

mix for another 2 minutes. Pour mixture through a 30

Solids Content By Volume 75% +/- 2% mesh screen. Sifting zinc through a screen will aid in

Measured in accordance with ASTM D 2697. the mixing process by breaking up or catching dry zinc

lumps. DO NOT MIX PARTIAL KITS. Note: Will not

Theoretical 2 2

1203 ft at 1.0 mils (29.5 m /l at 25 microns) cure without the use of the Activator as defined below.

Coverage Rate 2 2

602 ft at 2.0 mils (14.8 m /l at 50 microns) Thinning Normally not required but may be thinned up to 11 oz

2 2

401 ft at 3.0 mils (9.8 m /l at 75 microns) per 0.72 gal kit or 55 oz per 3.6 gal kit with Thinner

26, 33 or 254. Use of thinners other than those

Allow for loss in mixing and application. supplied by Carboline may adversely affect product

VOC Values Thinner 236 E 38 oz/gal: 2.4 lbs./gal (288 g/l) performance and void product warranty, whether

Thinner 254 8 oz/gal: 2.73 lbs/gal (327 g/l) expressed or implied.

Thinner 26 15.28 oz/gal: 2.95 lbs./gal (354 g/l) For use as a weldable zinc primer to achieve a

Thinner 33 15.28 oz/gal: 2.95 lbs./gal (354 g/l) recommended DFT of 0.50-1.00 mils, thin this product

As Supplied 2.4 lbs./gal (288 g/l) starting with 10% (and up to 30%) with Thinner 236E.

Consult Carboline Technical Service for guidance.

These are nominal values. When used as a pre-construction primer thin

up to 38 oz/gal using exempt Thinner 236 E.

March 2017 0249

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company

to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Page 1 of 2

Carbozinc 11 HS

Mixing & Thinning Curing Schedule

Ratio 0.72 Gal Kit Surface Temp.

* Dry to Handle Dry to Topcoat

Part A (Base): Short fill 1-gal

15 F (-9 C) 16 Hours 7 Days

Part C (Activator): 6.4 fl. oz.

40 F (4 C) 4 Hours 72 Hours

Part B (Zinc Filler): 14.6 lbs

3.6 Gal Kit 60 F (16 C) 2 Hours 36 Hours

Part A (Base): Short fill 5-gal 75 F (24 C) 1 Hours 18 Hours

Part C (Activator): 32 fl. oz. 100 F (38 C) 45.0 Minutes 14 Hours

Part B (Zinc Filler): 73 lbs These times are based on a 3.0 mil (75 micron) dry film thickness. Higher film thickness, insufficient

ventilation or cooler temperatures will require longer cure times and could result in solvent

Pot Life 8 Hours at 75F (24C) and less at higher temps. Pot entrapment and premature failure. Humidity levels below 50% will require longer cure times.

life ends when coating becomes too viscous. Notes: Maximum recoat times are unlimited. Must have a clean, dry surface free of chalk, zinc

salts, etc per typical good painting practices. Consult Carboline Technical Service for specific

information. Also, loose zinc must be removed from the cured film by rubbing with fiberglass or

Application Equipment Guidelines aluminum screen wire when "dry spray/overspray" is evident on the cured film and a topcoat will be

applied. For accelerated curing or where the relative humidity is below 40%, allow an initial 2-hour

Listed below are general equipment guidelines for the application of this product. Job site conditions ambient cure followed by misting with water or steam to keep the coated surface wet for a minimum

may require modifications to these guidelines to achieve the desired results. of 8 hours and until the film achieves a "2H" pencil hardness per ASTM D3363.

Spray Application The following spray equipment has been

(General) found suitable and is available from equipment Cleanup & Safety

manufacturers. Keep material under mild agitation

Cleanup Use Thinner 21 or Isopropyl Alcohol. In case of

during application. If spraying stops for more than

spillage, absorb and dispose of in accordance with

10 minutes, recirculate the material remaining in the

local applicable regulations.

spray line. Do not leave mixed primer in the hoses

during work stoppages. Safety Read and follow all caution statements on this product

data sheet and on the MSDS for this product and use

Conventional Agitated pressure pot equipped with dual regulators,

personal protective equipment as directed.

Spray 3/8 I.D. minimum material hose, with a maximum

length of 50 feet; .070 I.D. fluid tip and appropriate air Ventilation When used in enclosed areas, thorough air circulation

cap. must be used during and after application until the

coating is cured. The ventilation system should be

Airless Spray Pump Ratio: 30:1 (min.)

capable of preventing the solvent vapor concentration

GPM Output: 3.0 (min.)

from reaching the lower explosion limit for the solvents

Material Hose: 3/8 I.D. (min.)

used. Appropriate respirators must be used by all

Tip Size: 0.017-0.021

application personnel.

Output PSI: 2100-2500

Filter Size: 60 mesh

PTFE packings are recommended and available from Packaging, Handling & Storage

the pump manufacturer.

Shelf Life Part A (Base): 12 months at 75F (24C)

Brush For touch-up of areas less than one square foot only. Part B: 24 months at 75F (24C)

Use medium bristle brush and avoid rebrushing. Part C: 24 months at 75F (24C)

Roller Not recommended. *Shelf Life: (actual stated shelf life) when kept at recommended storage

conditions and in original unopened containers.

Application Conditions Shipping Weight 0.72 Gallon Kit - 22 lbs (10 kg)

(Approximate) 3.6 Gallon Kit - 103 lbs (47 kg)

Condition Material Surface Ambient Humidity

Minimum 15 F (-9 C) 15 F (-9 C) 15 F (-9 C) 30% Storage 40 -100F (4-38C).

Temperature & 0-90% Relative Humidity

Maximum 95 F (35 C) 150 F (66 C) 120 F (49 C) 95%

Humidity

This product simply requires the substrate temperature to be above the dew point. Condensation

due to substrate temperatures below the dew point can cause flash rusting on prepared steel and Flash Point Carbozinc 11 HS base: 55F (13C)

interfere with proper adhesion to the substrate. Special application techniques may be required (Setaflash) HS Activator: 90F (33C)

above or below normal application conditions which are as follows: material 60F-85F (16C-29C),

surface & ambient 40F-95F (4C-35C) and humidity 40-90%.

Zinc Filler: N/A

Storage Store Indoors.

This product is solvent based and not affected by excursions below

these published storage temperatures, down to 10F, for a duration of no

more than 14 days. Always inspect the product prior to use to make sure

it is smooth and homogeneous when properly mixed.

March 2017 0249

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to change without prior notice. User must contact Carboline Company

to verify correctness before specifying or ordering. No guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance or injuries resulting from use. Liability, if any, is limited to replacement of products. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE,

EXPRESS OR IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Carboline and Carboguard

are registered trademarks of Carboline Company.

Page 2 of 2

Potrebbero piacerti anche

- D 174 0Documento2 pagineD 174 0Tpoad P-AspetriNessuna valutazione finora

- Pistolas e Sistemas de Pintura CompletoDocumento42 paginePistolas e Sistemas de Pintura CompletoPaulo TeixeiraNessuna valutazione finora

- Four Ball Graxa - D2266-1Documento3 pagineFour Ball Graxa - D2266-1Joel CunhaNessuna valutazione finora

- Sarafil CFL101 Grade Clear Polyester Film Is Designed As Base Film For High Clarity Industrial Applications LikeDocumento2 pagineSarafil CFL101 Grade Clear Polyester Film Is Designed As Base Film For High Clarity Industrial Applications LikeJay AhmadNessuna valutazione finora

- Carbozinc 11: Selection & Specification Data Substrates & Surface PreparationDocumento2 pagineCarbozinc 11: Selection & Specification Data Substrates & Surface PreparationAhmed ElbahrawyNessuna valutazione finora

- Carbozinc 11: Selection & Specification Data Substrates & Surface PreparationDocumento2 pagineCarbozinc 11: Selection & Specification Data Substrates & Surface PreparationClarkFedele27Nessuna valutazione finora

- Carbozinc 11 HS PDSDocumento5 pagineCarbozinc 11 HS PDSEsakki muthuNessuna valutazione finora

- Carbozinc 11Documento2 pagineCarbozinc 11Victor A. Claure Manzoni100% (1)

- Carbozinc 11Documento4 pagineCarbozinc 11DuongthithuydungNessuna valutazione finora

- Carbozinc 11: Selection & Specification DataDocumento5 pagineCarbozinc 11: Selection & Specification DataQuy RomNessuna valutazione finora

- Carbozinc 11 PDSDocumento5 pagineCarbozinc 11 PDSSUBODHNessuna valutazione finora

- Carbozinc 11: Selection & Specification DataDocumento5 pagineCarbozinc 11: Selection & Specification DatajoehodohNessuna valutazione finora

- F13 - Carboguard 893-Zn PDS 10-09Documento2 pagineF13 - Carboguard 893-Zn PDS 10-09naveenbaskaran1989Nessuna valutazione finora

- Zinc PlatingDocumento2 pagineZinc PlatingSathyaraj M SNessuna valutazione finora

- Carbothane 134 HG PDSDocumento2 pagineCarbothane 134 HG PDSKhemaraj Path100% (1)

- Carboline Carbothane 133 HBDocumento5 pagineCarboline Carbothane 133 HBArturo SalinasNessuna valutazione finora

- Carbothane 134 HG PDSDocumento2 pagineCarbothane 134 HG PDSfazeel mohammedNessuna valutazione finora

- Carbothane 133 HB PDS PDFDocumento5 pagineCarbothane 133 HB PDS PDFskNessuna valutazione finora

- Carboguard Low Haps Epoxy: Selection & Specification Data Substrates & Surface PreparationDocumento2 pagineCarboguard Low Haps Epoxy: Selection & Specification Data Substrates & Surface PreparationImran AhmadNessuna valutazione finora

- Carbozinc 11 VOC PDFDocumento2 pagineCarbozinc 11 VOC PDFsrikarmallampatiNessuna valutazione finora

- Carboguard 893 PDSDocumento2 pagineCarboguard 893 PDSNguyễn Thị Châu TâyNessuna valutazione finora

- Carbozinc Data SheetDocumento2 pagineCarbozinc Data SheetIra Purnama SariNessuna valutazione finora

- Carbothane 133 HB: Selection & Specification DataDocumento5 pagineCarbothane 133 HB: Selection & Specification DatalavekushNessuna valutazione finora

- BECKOPOX EM 2120w - Allnex - Bilingual 27 FebDocumento15 pagineBECKOPOX EM 2120w - Allnex - Bilingual 27 FebDhruv Sevak100% (1)

- Carboguard 890 PDSDocumento5 pagineCarboguard 890 PDScrisNessuna valutazione finora

- Carboguard 890 PDSDocumento5 pagineCarboguard 890 PDSAchraf BoudayaNessuna valutazione finora

- Carbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationDocumento2 pagineCarbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationPurwanto ritzaNessuna valutazione finora

- Bitumastic 300 MDocumento2 pagineBitumastic 300 MANIBALLOPEZVEGA100% (1)

- Carbomastic 15 PDSDocumento4 pagineCarbomastic 15 PDSRiyaz Basheer100% (1)

- Sanitile 120 PDSDocumento4 pagineSanitile 120 PDSDuongthithuydungNessuna valutazione finora

- Carbomastic15BNX EngDocumento2 pagineCarbomastic15BNX Engfazeel mohammedNessuna valutazione finora

- Carboguard 60: Selection & Specification Data Substrates & Surface PreparationDocumento2 pagineCarboguard 60: Selection & Specification Data Substrates & Surface PreparationImran AhmadNessuna valutazione finora

- Carbozinc 859Documento2 pagineCarbozinc 859Khemaraj PathNessuna valutazione finora

- C PLATE TdsDocumento1 paginaC PLATE TdsEdwin TacoNessuna valutazione finora

- Fast Clad HB Acrylic: Protective & Marine CoatingsDocumento4 pagineFast Clad HB Acrylic: Protective & Marine CoatingsAna CabreraNessuna valutazione finora

- HMG Epozinc1000Documento2 pagineHMG Epozinc1000ben.ledwidgeNessuna valutazione finora

- WBEpoxyCoating Data SheetDocumento2 pagineWBEpoxyCoating Data SheetkaleshNessuna valutazione finora

- Carboguard 893: Selection & Specification DataDocumento5 pagineCarboguard 893: Selection & Specification DataQuy RomNessuna valutazione finora

- Carboguard 890 EF PDS 9-06Documento2 pagineCarboguard 890 EF PDS 9-06Ckaal74Nessuna valutazione finora

- Anti-Seize Compound TdsDocumento3 pagineAnti-Seize Compound TdskorayNessuna valutazione finora

- Carboguard 893 SG PDSDocumento2 pagineCarboguard 893 SG PDSAhmed ElbahrawyNessuna valutazione finora

- 589enint Greencoat Pural BTDocumento4 pagine589enint Greencoat Pural BTkokrasniqiNessuna valutazione finora

- Phenoline 187 Primer & Finish: Selection & Specification DataDocumento5 paginePhenoline 187 Primer & Finish: Selection & Specification DataQuy RomNessuna valutazione finora

- Carboguard 893 PDSDocumento5 pagineCarboguard 893 PDSUtomoNessuna valutazione finora

- Rebar Primer/Bond-Ci: Cementitious Corrosion Protection and Bonding AgentDocumento2 pagineRebar Primer/Bond-Ci: Cementitious Corrosion Protection and Bonding AgentAbel BerhanemeskelNessuna valutazione finora

- Raven 405FS TDS 060520 V.5.5Documento4 pagineRaven 405FS TDS 060520 V.5.5Larry Wayne Sumpter, JrNessuna valutazione finora

- Carbothane 134 HG PDSDocumento5 pagineCarbothane 134 HG PDSsanthoshkumarplNessuna valutazione finora

- Corotech v157 - Tds en OkfDocumento3 pagineCorotech v157 - Tds en OkfNasreldin SamyNessuna valutazione finora

- Safety-Walk™ Cushion Matting 5270 - 5270E: Technical DataDocumento3 pagineSafety-Walk™ Cushion Matting 5270 - 5270E: Technical DataMichael TadrosNessuna valutazione finora

- Thermaline Heat Shield PDSDocumento2 pagineThermaline Heat Shield PDSKhemaraj Path100% (1)

- Carboline Carboguard 890 PDSDocumento2 pagineCarboline Carboguard 890 PDSSamNessuna valutazione finora

- Phenoline 187 Primer and FinishDocumento2 paginePhenoline 187 Primer and Finish이선엽Nessuna valutazione finora

- Phenoline 187 Finish PDSDocumento2 paginePhenoline 187 Finish PDSalejandroNessuna valutazione finora

- Carbothane 134 HG Polyurethane Coating MSDSDocumento13 pagineCarbothane 134 HG Polyurethane Coating MSDSjgzlzNessuna valutazione finora

- Pintura Epoxica Sherwin Willians Hoja SeguridadDocumento4 paginePintura Epoxica Sherwin Willians Hoja Seguridad1Nessuna valutazione finora

- Carbo L Ag 40 SN eDocumento1 paginaCarbo L Ag 40 SN efadfadg2Nessuna valutazione finora

- Carbomastic 801 PDFDocumento2 pagineCarbomastic 801 PDFkayNessuna valutazione finora

- Flowchem EPN - ENGDocumento2 pagineFlowchem EPN - ENGbassem kooliNessuna valutazione finora

- Carbomastic 15: Selection & Specification Data Substrates & Surface PreparationDocumento2 pagineCarbomastic 15: Selection & Specification Data Substrates & Surface PreparationMarcos MacaiaNessuna valutazione finora

- Gavalnise Vs PaintsDocumento35 pagineGavalnise Vs Paintsian1000100% (2)

- Flat Socket Head Cap ScrewsDocumento8 pagineFlat Socket Head Cap Screwsvietross100% (1)

- 316 316L 317L Spec Sheet PDFDocumento3 pagine316 316L 317L Spec Sheet PDFSaúl L Hdez TNessuna valutazione finora

- Specification Sheet: Alloy 310/310S/310H: (UNS S31000, S31008, S31009) W. Nr. 1.4845Documento2 pagineSpecification Sheet: Alloy 310/310S/310H: (UNS S31000, S31008, S31009) W. Nr. 1.4845Manoj PaneriNessuna valutazione finora

- 08 Attachment 8Documento11 pagine08 Attachment 8vietrossNessuna valutazione finora

- Carbozinc 11 HS PDSDocumento2 pagineCarbozinc 11 HS PDSvietrossNessuna valutazione finora

- Flat Socket Head Cap ScrewsDocumento8 pagineFlat Socket Head Cap Screwsvietross100% (1)

- Iso 8062Documento1 paginaIso 8062Asrar Ahmed100% (2)

- Correlations For Heat Transfer CoefficientsDocumento4 pagineCorrelations For Heat Transfer CoefficientsvietrossNessuna valutazione finora

- Investing WiselyDocumento1 paginaInvesting WiselyvietrossNessuna valutazione finora

- Cotter Pin, Stainless Steel: Page 1 of 1 REV-03 Date: August 4, 2015 Pin - Cot.SsDocumento1 paginaCotter Pin, Stainless Steel: Page 1 of 1 REV-03 Date: August 4, 2015 Pin - Cot.SsD_D_76Nessuna valutazione finora

- 5 14 906kt1000Documento2 pagine5 14 906kt1000vietrossNessuna valutazione finora

- IRS - Comparison of Form 8938 and FBAR RequirementsDocumento8 pagineIRS - Comparison of Form 8938 and FBAR RequirementsvietrossNessuna valutazione finora

- Slug FlowDocumento7 pagineSlug FlowharishtokiNessuna valutazione finora

- CFDDocumento9 pagineCFDvietrossNessuna valutazione finora

- Minimize Your Investment Losses Using Decision TreesDocumento2 pagineMinimize Your Investment Losses Using Decision TreesvietrossNessuna valutazione finora

- Slide Plate ApplicationsDocumento2 pagineSlide Plate ApplicationsvietrossNessuna valutazione finora

- FAGIX Fidelity IncomeDocumento8 pagineFAGIX Fidelity IncomevietrossNessuna valutazione finora

- College SavingsDocumento2 pagineCollege SavingsvietrossNessuna valutazione finora

- HydrogenDocumento6 pagineHydrogenvietrossNessuna valutazione finora

- Ways To Minimize Income Tax in RetirementDocumento2 pagineWays To Minimize Income Tax in RetirementvietrossNessuna valutazione finora

- An Introduction To Air Density and Density Altitude CalculationsDocumento22 pagineAn Introduction To Air Density and Density Altitude CalculationsvietrossNessuna valutazione finora

- 10 Fluid Power LessonsDocumento5 pagine10 Fluid Power LessonsvietrossNessuna valutazione finora

- Health InsurersDocumento2 pagineHealth InsurersvietrossNessuna valutazione finora

- Simple Way To Save On EverythingDocumento2 pagineSimple Way To Save On EverythingvietrossNessuna valutazione finora

- Sight Word SentencesDocumento52 pagineSight Word Sentencesvietross75% (4)

- Surefire Ways To Get Taken by Identity ThievesDocumento3 pagineSurefire Ways To Get Taken by Identity ThievesvietrossNessuna valutazione finora

- College SavingsDocumento2 pagineCollege SavingsvietrossNessuna valutazione finora

- Four High Yielding StocksDocumento2 pagineFour High Yielding StocksvietrossNessuna valutazione finora

- Consumers Guide To Home InsuranceDocumento20 pagineConsumers Guide To Home InsurancevietrossNessuna valutazione finora

- CES Business PresentationDocumento50 pagineCES Business PresentationGary David CrowhurstNessuna valutazione finora

- Pompa CorkenDocumento154 paginePompa Corkenwferry27100% (1)

- Active Directory Interview QuestionsDocumento3 pagineActive Directory Interview QuestionsSameer PatelNessuna valutazione finora

- Seventh Edition Cement Hand BookDocumento6 pagineSeventh Edition Cement Hand Booksatfas50% (2)

- Color Difference Measuring InstrumentsDocumento5 pagineColor Difference Measuring InstrumentsJanine Ellyze EvangelistaNessuna valutazione finora

- Bomba Pioner - ManualDocumento29 pagineBomba Pioner - ManualRodrigoArayaNessuna valutazione finora

- Factors Affecting Four Wheeler Industries in IndiaDocumento54 pagineFactors Affecting Four Wheeler Industries in IndiaRitesh Vaishnav100% (2)

- 40RUM 60Hz PDC V6Documento36 pagine40RUM 60Hz PDC V6hgogoriyaNessuna valutazione finora

- 04 - PGP4108 Drilling FluidsDocumento16 pagine04 - PGP4108 Drilling Fluidsodong anthonyNessuna valutazione finora

- Chapter 9 Mediums of MusicDocumento70 pagineChapter 9 Mediums of MusicAileen Bisnar65% (17)

- Manual Miso WiloDocumento34 pagineManual Miso Wilojesus cuellar50% (2)

- Bus ID No.: E-2896: Passenger InformationDocumento1 paginaBus ID No.: E-2896: Passenger Informationraja mechNessuna valutazione finora

- Digital MarketingDocumento1 paginaDigital Marketingmadhvendra99Nessuna valutazione finora

- Mangesh PatilDocumento3 pagineMangesh Patilcrushboy18Nessuna valutazione finora

- Grade Book Student Progress Report: Dau, An 2011-2012 Lankford, Casey Acts - 7 T1 Percent ActsDocumento7 pagineGrade Book Student Progress Report: Dau, An 2011-2012 Lankford, Casey Acts - 7 T1 Percent ActsdaudinhanNessuna valutazione finora

- Suffolk Library Consultation ResponsesDocumento3.050 pagineSuffolk Library Consultation ResponsesjehargraveNessuna valutazione finora

- Navi Loan Account StatementDocumento1 paginaNavi Loan Account StatementBorah SashankaNessuna valutazione finora

- Modular Prefabricated Residential Construction PDFDocumento90 pagineModular Prefabricated Residential Construction PDFSong Kai YiNessuna valutazione finora

- Bit CoinDocumento7 pagineBit CoinYoga Prima Nanda0% (2)

- TLV JA3 Air Drain TrapDocumento2 pagineTLV JA3 Air Drain TrapMONANessuna valutazione finora

- Pipe Earthing 8Documento2 paginePipe Earthing 8raghavendran raghu75% (4)

- Chartered Process Design Kit DsDocumento2 pagineChartered Process Design Kit DsSandeep SahuNessuna valutazione finora

- Low Impact Development Manual For Michigan September 2008Documento512 pagineLow Impact Development Manual For Michigan September 2008Yadir Rodrìguez NùñezNessuna valutazione finora

- Shell Omala S4 WE 220Documento3 pagineShell Omala S4 WE 220Muhammad SaputraNessuna valutazione finora

- Pitting Trenching Activty eDocumento2 paginePitting Trenching Activty eFARHA NAAZNessuna valutazione finora

- UTM Security With FortinetDocumento76 pagineUTM Security With FortinetNelson Valente GomesNessuna valutazione finora

- Agent-Based Modeling For Decision Making in Economics Under UncertaintyDocumento20 pagineAgent-Based Modeling For Decision Making in Economics Under UncertaintySammy SamuelNessuna valutazione finora

- Eisen: 618B / 818B Series Precision Surface GrindersDocumento2 pagineEisen: 618B / 818B Series Precision Surface GrindersRam ViswanathanNessuna valutazione finora

- Analysis PhaseDocumento63 pagineAnalysis PhaseJoseph Josef0% (1)

- Machines and Equipment For The Production of Autoclaved Aerated ConcreteDocumento9 pagineMachines and Equipment For The Production of Autoclaved Aerated ConcretebalajicaptainNessuna valutazione finora