Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Technical Proposal

Caricato da

olescootCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Technical Proposal

Caricato da

olescootCopyright:

Formati disponibili

TECHNICAL PROPOSAL

Sondex A/S PHE - Design & Datalist

___________________________________________________________________

CETCO E-S24002A/B 14/9/2017

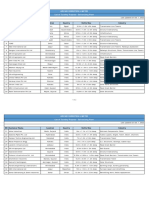

001 PW Cooler Item: 1

_____________________________________________________________________________

PHE-Type S86-IS16-271-TMTL16-LIQUID Hot side Cold side

Flowrate (Note 1) (kg/h) 317468.00 271816.00

Inlet temperature (C) 63.10 32.00

Outlet temperature (C) 40.00 60.00

Pressure drop (bar) 1.01 0.74

Heat exchanged (kW) 8832

Thermodynamic properties: Produced Water Cooling Water

Density (kg/m) 989.00 996.00

Specific heat (kJ/kg*K) 4.34 4.18

Thermal conductivity (W/m*K) 0.66 0.64

Mean viscosity (mPa*s) 0.53 0.59

Wall viscosity (mPa*s) 0.53 0.59

Inlet branch F1 F3

Outlet branch F4 F2

_____________________________________________________________________________

Design of Frame / Plates:

Plate arrangement (passes*channel) 1 x 135 + 0 x 0

Plate arrangement (passes*channel) 1 x 135 + 0 x 0

Number of plates 271

Effective heat surface (m) 242.10

Plate material 0.6 mm TITAN

Gasket material / Max. temp. NITRIL HT SONDER LOCK (S) / 140

Max. design temperature (C) 120.00

Max. Working/test pressure (bar) 12.00 15.60

Max. Differential pressure (bar) 12.00

Approval None

Liquid volume (liter) 729

Frame length (mm) 2095 Max. No. of Plates 289

Net weight (kg) 2167

Frame type IS

Connections HOT side : 6 INCH Fl. cl. with Titan ANSI B16.5 #150

Connections COLD side: 6 INCH Fl. cl. with Titan ANSI B16.5 #150

_____________________________________________________________________________

Category C2L BLUE RAL 5010

Note:

1 The flowrate for cooling water (cold side) will be 271,816 kg/h in order

1)

to meet the required temperature.

2) Connection at both hot side and cold side shall be 6 cladded with titanium

liner.

Sondex A/S Marsvej 5 DK-6000 Kolding

Tel: +45 76306100 Fax: +45 75538968/75505019

100 L1

285

B2 B1

F1 F2

F1-F4 OR B1-B4

DN150 DIN2633

6" CLASS 150 296

CLADDED OR

RUBBERLINED

2350

2350

2254

1694

1694

F1-F4

DN150 DIN2633

F4 F3

6" CLASS 150 B3 B4

UNCLADDED

275

275

7

5

45

50 45

296

2095 50

608 608

80 2045 20

18

18

100

508

608

50

Dimensions Designed by Date Approved by Date Rev. no. Revision Text

without tolerance:

LGK 26-01-2011 FLEB 12-09-2016 02 Changed to EN13445 and thickness of covers changed from 60mm to 45mm

Description:

ISO 2768-m

ISO projektion

SONDEX S86 S87 IS PN16 DN150 DIM DRAWING

FEA (S.L)

LENGTH 600 - 3000 MM

Jernet 9 Rev. date Rev. by Drawing no. Sheet

DK-6000 Kolding 07-09-2016 FLEB S86-S87ISPN16DN150L600-3000-FEA 1 /1

S41/42 - S62 - S79- S86 - S110

Plate Heat Exchangers

Recommended Applications:

The S41/42, S62, S79, S86 and S110 range of Sondex plate heat

exchangers is specially designed for the HVAC area, the geothermal-,

marine-, and heat recovery area as well as the food, industrial and

chemical market.

Design Principle:

The S41/42, S62, S79, S86 and S110 plate range with lengths up to 2,3 m

(7,5 ft) and a long thermal pattern will cover many duties up to 350 m3/h

(1.541 gpm) in a single pass solution, meaning that all the connections

are on the head side. This will ensure easy pipe- and service work, and

by dismantling the exchanger for service, no pipes need to be removed.

The heat transfer is obtained, when the warm medium transfers energy

through the thin, strong flow plates between the channels and delivers

it to the cold opposing medium without mixing the two media.

Counter-current flow creates the optimal efficiency. The plate- and inlet

design allows effective, easy CIP (Cleaning in Place) of all flow surfaces.

Flow plates:

The corrugated herringbone pattern ensures turbulent flow in the

whole effective area. Furthermore, this pattern brings metallic contact

between the plates, and together with Sonder Lock lock devices on

the gaskets, the plate pack is easily assembled.

The plate pack is held firm and safely between the fixed head and

movable follower of the frames.

Data Required for Correct Quotation:

Duty Flow rate Temperature

Copyright Sondex A/S Sondex cannot be held liable for possible errors in any printed materials. Sondex reserves the right to change any data without notice.

Type of media Working pressure Working Temperature

Pressure loss Thermodynamic properties

Above data determines the choice of heat exchanger.

S110

Technical Information

S110 Frame: Construction Standard: Gaskets:

Painted frame, colour RAL 5010 EN13445 (PED 2014/68/EU) The gasket is placed in the closed

S86 (available in other colours) ASME sec VIII, Div. 1 gasket groove, that is formed by

Stainless steel frame, designed for the plates. This design makes the

S79 the food and dairy industry. Connections: plate suitable for high working

Both frames comes with clamping DN150/6 flange in carbon steel, pressures. The plates are strongly

2094 mm (82,4)

bolts placed around the frame edge. rubberlined or cladded with AISI guided during the assembly of the

S62 316 or titanium plate heat exchanger. Materials:

1694 mm (66,7)

Design Pressure: DN100/4, DN125/5 and NBR, EPDM and Viton.

1570 mm 61,8)

Painted frames: 1.0/1.5/2.5 MPa. DN150/6 dairy unions Other materials available on request.

1292 mm 50,9)

(145/217/362 PSI) According to all known standards.

890 mm ( 34,2)

Stainless steel frame: 1.0/1.6 MPa. Extra Equipment:

S41/42

(145/232 PSI) Plate Material: Safety cover in stainless steel

AISI 304/316, 254 SMO and titanium. Insulating jacket

296 mm Intermediate Frames: Also 2 x 0.4 mm Sonder Safe plates, Assembling spanner

(11,6)

Intermediate frames and corner for food and industry. Foundation feet for IS frame

blocks for IS and FS frames in Other materials available on request. Instrument flange

stainless steel. Thermometer and manometer

For exact dimensions of the PHE please

refer to the dimension drawing

Sondex A/S Marsvej 5 DK-6000 Kolding Denmark Tel. +45 76 306 100 Fax +45 75 538 968 / Fax +45 75 505 019 info@sondex.dk www.sondex.net

Potrebbero piacerti anche

- Chapter 1 Feasibility StudyDocumento102 pagineChapter 1 Feasibility Studyolescoot67% (3)

- Chapter 9 Flow in Open ChannelDocumento28 pagineChapter 9 Flow in Open ChannelolescootNessuna valutazione finora

- Notches and WeirsDocumento15 pagineNotches and WeirsolescootNessuna valutazione finora

- Heat Integration - Setting Energy TargetsDocumento30 pagineHeat Integration - Setting Energy TargetsolescootNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- MCQ On Smart GridmisalpavDocumento4 pagineMCQ On Smart GridmisalpavSomnath Hadpe67% (3)

- E-10 Storage Batteries - 1465729800 - E-10Documento10 pagineE-10 Storage Batteries - 1465729800 - E-10nicolas.travailNessuna valutazione finora

- Feyzin Oil Refinery DisasterDocumento8 pagineFeyzin Oil Refinery DisasterDavid Alonso Cedano EchevarriaNessuna valutazione finora

- Nuclear Power PLantDocumento3 pagineNuclear Power PLantibong tiriritNessuna valutazione finora

- Kelly H PM User ManualDocumento20 pagineKelly H PM User ManualmanmonbhaNessuna valutazione finora

- Lecture 29 HodographDocumento10 pagineLecture 29 HodographprasannaNessuna valutazione finora

- Yang-Mills Theory On The Light ConeDocumento14 pagineYang-Mills Theory On The Light Cones4suchiNessuna valutazione finora

- Static Electricity in Fuel Handling FacilitiesDocumento29 pagineStatic Electricity in Fuel Handling Facilitiesbiondimigu100% (1)

- Doordarshan ReportDocumento18 pagineDoordarshan ReportSajal DasNessuna valutazione finora

- Termotehnica Part2Documento95 pagineTermotehnica Part2Cirstea AlexandruNessuna valutazione finora

- CementDocumento11 pagineCementHerdian NafiNessuna valutazione finora

- Reiki Book PDFDocumento108 pagineReiki Book PDFGurpreet Singh Sohal100% (1)

- Asic Lectrical Echnology: Parallel Magnetic CircuitsDocumento10 pagineAsic Lectrical Echnology: Parallel Magnetic CircuitsShivangNessuna valutazione finora

- Dextra Precast Pipe Racks Brochure 2020 ENDocumento5 pagineDextra Precast Pipe Racks Brochure 2020 ENCivix VarixNessuna valutazione finora

- Leroy Somer D510C AVRDocumento54 pagineLeroy Somer D510C AVRabuzer1981Nessuna valutazione finora

- Reports & Indices: Atish Mathur: MATHUR10Documento11 pagineReports & Indices: Atish Mathur: MATHUR10Manasa VarshiniNessuna valutazione finora

- Erturk 2008 Smart Mater. Struct. 17 065016 PDFDocumento15 pagineErturk 2008 Smart Mater. Struct. 17 065016 PDFsuyNessuna valutazione finora

- ShipRight - Design Code For Unmanned Marine Systems - 2017Documento39 pagineShipRight - Design Code For Unmanned Marine Systems - 2017RISHABH JAMBHULKARNessuna valutazione finora

- Pump BasicsDocumento118 paginePump BasicsVinod GuptaNessuna valutazione finora

- Transistor (Ukr)Documento31 pagineTransistor (Ukr)Uday RaiNessuna valutazione finora

- Basics of Petroleum GeologyDocumento23 pagineBasics of Petroleum GeologyShahnawaz MustafaNessuna valutazione finora

- 6120-A - Electric Motors Rated Up To 150KWDocumento7 pagine6120-A - Electric Motors Rated Up To 150KWharmlesdragonNessuna valutazione finora

- Air Break and Air GapDocumento2 pagineAir Break and Air GapZarex BorjaNessuna valutazione finora

- 10 Mechanical Properties of FluidsDocumento8 pagine10 Mechanical Properties of FluidsMokshNessuna valutazione finora

- PHD Thesis On Thermal Power PlantDocumento6 paginePHD Thesis On Thermal Power Plantafkneafpz100% (1)

- Plant Floor Safety Fall 2020 PDFDocumento54 paginePlant Floor Safety Fall 2020 PDFPravivVivpraNessuna valutazione finora

- Client List - Arvind Corrotech Ltd.Documento2 pagineClient List - Arvind Corrotech Ltd.Ricardo Javier Cotamo De la espriellaNessuna valutazione finora

- Test Procedure and Settings of RCCDocumento5 pagineTest Procedure and Settings of RCCkundan kunalNessuna valutazione finora

- Francis Pegler 1.2.17Documento148 pagineFrancis Pegler 1.2.17Kaushaveer GhooraNessuna valutazione finora

- New Holland Engine p11c VC Service ManualDocumento20 pagineNew Holland Engine p11c VC Service Manualdanielle100% (47)