Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Clarification On Uneven Base Metal Thickness

Caricato da

g_sanchetiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Clarification On Uneven Base Metal Thickness

Caricato da

g_sanchetiCopyright:

Formati disponibili

Frs|uljkwhg#pdwhuldo#olfhqvhg#wr#Xqlyhuvlw|#ri#Wrurqwr#e|#Wkrpvrq#Vflhqwlilf/#Lqf1#+zzz1whfkvwuhhw1frp,1##Wklv#frs|#grzqordghg#rq#534803:046#3:=69=6:#03833#e|#dxwkrul}hg#xvhu#orjdq#dkovwurp1##Qr#ix

ASME BPVC.IX-2015

QW-202 TYPE OF TESTS REQUIRED (c) Qualification for Fillet Welds. WPS qualification for

QW-202.1 Mechanical Tests. The type and number fillet welds may be made on grooveweld test coupons

of test specimens that shall be tested to qualify a groove using test specimens specified in (a) or (b). Filletweld

weld procedure are given in QW-451, and shall be re- procedures so qualified may be used for welding all thick-

moved in a manner similar to that shown in Figures nesses of base metal for all sizes of fillet welds, and all dia-

QW-463.1(a) through QW-463.1(f). If any test specimen meters of pipe or tube in accordance with Table

required by QW-451 fails to meet the applicable accep- QW-451.4. Nonpressureretaining fillet welds, as defined

tance criteria, the test coupon shall be considered as in other Sections of the Code, may as an alternate be qual-

failed. ified with fillet welds only. Tests shall be made in accor-

dance with QW-180. Limits of qualification shall be in

When it can be determined that the cause of failure is

accordance with Table QW-451.3.

not related to welding parameters, another test coupon

may be welded using identical welding parameters. QW-202.3 Weld Repair and Buildup. WPS qualified

Alternatively, if adequate material of the original test on groove welds shall be applicable for weld repairs to

coupon exists, additional test specimens may be removed groove and fillet welds and for weld buildup under the

as close as practicable to the original specimen location to following provisions:

replace the failed test specimens. (a) There is no limitation on the thickness of base me-

When it has been determined that the test failure was tal or deposited weld metal for fillet welds.

caused by an essential or supplementary essential vari-

(b) For other than fillet welds, the thickness range for

able, a new test coupon may be welded with appropriate

base metal and deposited weld metal for each welding

changes to the variable(s) that was determined to cause

process shall be in accordance with QW-451, except there

the test failure. If the new test passes, the essential and

need be no upper limit on the base metal thickness pro-

supplementary variables shall be documented on the

vided qualification was made on base metal having a

PQR.

thickness of 11/2 in. (38 mm) or more.

When it is determined that the test failure was caused

by one or more welding related factors other than essen- QW-202.4 Dissimilar Base Metal Thicknesses. WPS

tial or supplementary essential variables, a new test cou- qualified on groove welds shall be applicable for produc-

pon may be welded with the appropriate changes to the tion welds between dissimilar base metal thicknesses

welding related factors that were determined to cause provided:

the test failure. If the new test passes, the welding related (a) the thickness of the thinner member shall be within

factors that were determined to cause the previous test the range permitted by QW-451

failure shall be addressed by the organization to ensure

(b) the thickness of the thicker member shall be as

that the required properties are achieved in the produc-

follows:

tion weldment.

(1) For PNo. 8, PNo. 41, PNo. 42, PNo. 43, PNo.

Where qualification is for fillet welds only, the require-

44, PNo. 45, PNo. 46, PNo. 49, PNo. 51, PNo. 52,

ments are given in QW-202.2(c); and where qualification

PNo. 53, PNo. 61, and PNo. 62 metal, there shall be no

is for stud welds only, the requirements are given in

limitation on the maximum thickness of the thicker pro-

QW-202.5.

duction member in joints of similar PNumber materials

provided qualification was made on base metal having a

QW-202.2 Groove and Fillet Welds thickness of 1/4 in. (6 mm) or greater.

(a) Qualification for Groove Full Penetration Welds. (2) For all other metal, the thickness of the thicker

Grooveweld test coupons shall qualify the thickness member shall be within the range permitted by

ranges of both base metal and deposited weld metal to QW-451, except there need be no limitation on the maxi-

be used in production. Limits of qualification shall be in mum thickness of the thicker production member pro-

accordance with QW-451. WPS qualification for groove vided qualification was made on base metal having a

welds shall be made on groove welds using tension and thickness of 11/2 in. (38 mm) or more.

guidedbend specimens. Notchtoughness tests shall be More than one procedure qualification may be required

made when required by other Section(s) of the Code. to qualify for some dissimilar thickness combinations.

The WPS shall be qualified for use with groove welds

within the range of essential variables listed. QW-202.5 Stud Welding. Procedure qualification

(b) Qualification for Partial Penetration Groove Welds. tests for stud welds shall be made in accordance with

Partial penetration groove welds shall be qualified in ac- QW-192. The procedure qualification tests shall qualify

cordance with the requirements of QW-451 for both base the welding procedures for use within the range of the es-

metal and deposited weld metal thickness, except there sential variables of Table QW-261. For studs welded to

need be no upper limit on the base metal thickness pro- other than PNo. 1 metals, five additional welds shall be

vided qualification was made on base metal having a made and subjected to a macrotest, except that this is

thickness of 11/2 in. (38 mm) or more. not required for studs used for extended heating surfaces.

30

Potrebbero piacerti anche

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Faculdade Estadual de Engenharia Química de Lorena - FAENQUILDocumento56 pagineFaculdade Estadual de Engenharia Química de Lorena - FAENQUILLuis Gustavo PachecoNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- SSPC-SP 1 Solvent Cleaning PDFDocumento2 pagineSSPC-SP 1 Solvent Cleaning PDFbhadresh_prajapati_188% (8)

- Acid Cleaning ReportDocumento1 paginaAcid Cleaning Reportg_sanchetiNessuna valutazione finora

- Theory of Earth's Magnetism and Its Relation To Ship DeviationDocumento28 pagineTheory of Earth's Magnetism and Its Relation To Ship DeviationMaster Irvin100% (1)

- Compound Document Structure Manufacturers Record Book Index (Mri) 17052048-QA-MRB-068-V3006-001 SectionsDocumento4 pagineCompound Document Structure Manufacturers Record Book Index (Mri) 17052048-QA-MRB-068-V3006-001 Sectionsg_sanchetiNessuna valutazione finora

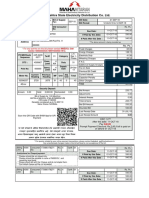

- Mseb Electricity BillDocumento1 paginaMseb Electricity Billg_sanchetiNessuna valutazione finora

- Fatigue of RiserDocumento55 pagineFatigue of RiserDao DungNessuna valutazione finora

- HIC Testing As Per NACE MR 0275Documento3 pagineHIC Testing As Per NACE MR 0275g_sancheti100% (1)

- Calculation of Hydrodynamic Pressures On Walls of Rectangular TankDocumento12 pagineCalculation of Hydrodynamic Pressures On Walls of Rectangular TankPrakash Singh Rawal100% (1)

- Purge With NitrogenDocumento5 paginePurge With Nitrogendeion29100% (1)

- Boiler Manual Umpp PDFDocumento53 pagineBoiler Manual Umpp PDFRanjanaWajeNessuna valutazione finora

- Branch Timings - YES Bank April19 PDFDocumento112 pagineBranch Timings - YES Bank April19 PDFg_sanchetiNessuna valutazione finora

- Coupon Code:HDFCTC500: Additional Rs.500 Off On Rs.2000 and AboveDocumento14 pagineCoupon Code:HDFCTC500: Additional Rs.500 Off On Rs.2000 and Aboveg_sanchetiNessuna valutazione finora

- 4.1 Weldwell ElectrodesDocumento10 pagine4.1 Weldwell Electrodesg_sanchetiNessuna valutazione finora

- Travel Expenses SheetDocumento2 pagineTravel Expenses Sheetg_sanchetiNessuna valutazione finora

- Auditing Welds Under ASME IX PDFDocumento21 pagineAuditing Welds Under ASME IX PDFkbldamNessuna valutazione finora

- Branch Timings - YES Bank April19 PDFDocumento112 pagineBranch Timings - YES Bank April19 PDFg_sanchetiNessuna valutazione finora

- MHADA Pune BookletDocumento109 pagineMHADA Pune Booklethrishikeshsp50% (2)

- EPF Name Change FormDocumento1 paginaEPF Name Change Formg_sanchetiNessuna valutazione finora

- Magnetism in ss304Documento1 paginaMagnetism in ss304g_sanchetiNessuna valutazione finora

- 94C58000001B5.Filename - Monday Breakout 9 John Hartnett Welding EconomicsDocumento53 pagine94C58000001B5.Filename - Monday Breakout 9 John Hartnett Welding EconomicsgcldesignNessuna valutazione finora

- The Stainless Steel FamilyDocumento5 pagineThe Stainless Steel Familyvvk557Nessuna valutazione finora

- Health and Safety in WeldingDocumento46 pagineHealth and Safety in Weldingegn2007Nessuna valutazione finora

- AWS Weld Symbol ChartDocumento1 paginaAWS Weld Symbol ChartExsan OthmanNessuna valutazione finora

- 20 MN V6Documento1 pagina20 MN V6g_sanchetiNessuna valutazione finora

- Flanges SnapsDocumento1 paginaFlanges Snapsg_sanchetiNessuna valutazione finora

- Doubts To Be ClarifiedDocumento2 pagineDoubts To Be Clarifiedg_sanchetiNessuna valutazione finora

- Wise MoneyDocumento20 pagineWise Moneyg_sanchetiNessuna valutazione finora

- Tolerances 10Documento1 paginaTolerances 10g_sanchetiNessuna valutazione finora

- Mack WeldingDocumento4 pagineMack Weldingg_sanchetiNessuna valutazione finora

- Control On Chemical Analysis and Cleanliness For SS310 Filler WireDocumento1 paginaControl On Chemical Analysis and Cleanliness For SS310 Filler Wireg_sanchetiNessuna valutazione finora

- E+H Flange Serration PhotosDocumento4 pagineE+H Flange Serration Photosg_sanchetiNessuna valutazione finora

- Caustic PermagnateDocumento3 pagineCaustic Permagnateg_sanchetiNessuna valutazione finora

- Shell Omala S4 WE 220: Performance, Features & BenefitsDocumento3 pagineShell Omala S4 WE 220: Performance, Features & BenefitsPro.MechanicNessuna valutazione finora

- Aquatic Adaptations - Poonam SinghDocumento46 pagineAquatic Adaptations - Poonam Singhaksahu01234Nessuna valutazione finora

- User's Manual: ULTRA CFR Nd:YAG Laser SystemDocumento55 pagineUser's Manual: ULTRA CFR Nd:YAG Laser SystemLeonardo PantojaNessuna valutazione finora

- Electroysis WorksheetDocumento2 pagineElectroysis WorksheetericaNessuna valutazione finora

- Form 2208 - Page 1: Surface Pump Installation DataDocumento3 pagineForm 2208 - Page 1: Surface Pump Installation DataErich ThomasNessuna valutazione finora

- Striling Engine.1Documento17 pagineStriling Engine.1elangandhiNessuna valutazione finora

- AnsaryDocumento40 pagineAnsarydhamodharan24Nessuna valutazione finora

- Conical Shell FootingDocumento6 pagineConical Shell FootingHari AppathuraiNessuna valutazione finora

- Pollet - Importancia de Parametros de Ultrasonido TintasDocumento12 paginePollet - Importancia de Parametros de Ultrasonido TintasFabricio CarrilloNessuna valutazione finora

- 7 MultiphaseFreeSurfaceFilmDocumento25 pagine7 MultiphaseFreeSurfaceFilmJesthyn VC100% (1)

- Damage and Failure For Ductile MetalsDocumento10 pagineDamage and Failure For Ductile Metalsp_rameshreddy2006Nessuna valutazione finora

- Zone-2 Hazardous Area Classification-Hazard Distance For Open Well Ventilated AreaDocumento30 pagineZone-2 Hazardous Area Classification-Hazard Distance For Open Well Ventilated AreaRonak MotaNessuna valutazione finora

- Failure Analysis ReportDocumento24 pagineFailure Analysis ReportThirukkumaranBalasubramanianNessuna valutazione finora

- Tray Dryer Final ReportDocumento13 pagineTray Dryer Final ReportHaziq AzliNessuna valutazione finora

- Ds Medaprot 100Documento1 paginaDs Medaprot 100faridNessuna valutazione finora

- Unit V - Unid End Questions - EMDocumento6 pagineUnit V - Unid End Questions - EMNaresh JonnaNessuna valutazione finora

- Fluid Mechanics ExerciseDocumento8 pagineFluid Mechanics ExerciseJjrlNessuna valutazione finora

- CH 4 Review Delection and Stiffness1Documento12 pagineCH 4 Review Delection and Stiffness1Anas TubailNessuna valutazione finora

- 2023 July Nov ME TA RevDocumento4 pagine2023 July Nov ME TA RevMd IsmayeelNessuna valutazione finora

- Lewatit® MonoPlus S 108-EN-GBDocumento4 pagineLewatit® MonoPlus S 108-EN-GBsimontin23Nessuna valutazione finora

- Calibration of Concrete Damage Material Model in LS-DynaDocumento14 pagineCalibration of Concrete Damage Material Model in LS-DynaEuNessuna valutazione finora

- Nho2 BCBNVDocumento4 pagineNho2 BCBNVavijitjhakassNessuna valutazione finora

- Essential in WeldingDocumento3 pagineEssential in WeldingBelle SantosNessuna valutazione finora

- Self-Healing Concrete With Crystalline AdmixtureDocumento8 pagineSelf-Healing Concrete With Crystalline AdmixtureAlexander HierroNessuna valutazione finora

- Belt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationDocumento8 pagineBelt Conveyor Idler: Read These Instructions Carefully Before Starting InstallationKenji LacambraNessuna valutazione finora

- Reservoir Souring Mechanisms and PreventionDocumento20 pagineReservoir Souring Mechanisms and PreventionmaxjuliNessuna valutazione finora