Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

40

Caricato da

sebaversaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

40

Caricato da

sebaversaCopyright:

Formati disponibili

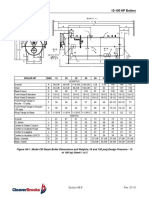

Model 4WG 100 800 HP Boilers

Notes

Section A3-36 Rev. 09-09

Model 4WG 100 800 HP Boilers

SAMPLE SPECIFICATIONS MODEL 4WG HOT WATER BOILERS

PART 1 GENERAL

HOT WATER

Cleaver Brooks Model 4WG

1.01 SCOPE

A. The work to be performed consists of providing all labor, equipment, materials, etc. to

furnish and install new factory assembled steam boiler(s) as described in the

specifications herein.

B. Related Sections include the following:

1. Division 15 Section "Chemical Water Treatment" for feedwater treatment and

connections.

2. Division 15 Section "Breechings, Chimneys, and Stacks" for connections to

breechings, chimneys, and stacks.

3. Division 15 Sections for control wiring for automatic temperature control.

1.02 REFERENCES

A. Product Data: Include rated capacities; shipping, installed, and operating weights;

furnished specialties; and accessories for each model indicated.

B. Shop Drawings: Detail equipment assemblies and indicate dimensions, required

clearances, and method of field assembly, components, and location and size of

each field connection.

C. Wiring Diagrams: Detail wiring for power, signal, and control systems and

differentiate between manufacturer-installed and field-installed wiring.

D. Source Quality Control Tests and Inspection Reports: Indicate and interpret test

results for compliance with performance requirements before shipping.

E. Field Test Reports: Indicate and interpret test results for compliance with

performance requirements.

F. Maintenance Data: Include in the maintenance manuals specified in Division 1.

Include parts list, maintenance guide, and wiring diagrams for each boiler.

1. ASME Section (I or IV) (Power boilers or Heating Boilers)

2. ANSI Z21.13 (Gas Fired Low Pressure Boilers)

3. NFPA 54 (ANSI Z221.3) National Fuel Gas Code

4. FACTORY MUTUAL

5. ASME CSD-1 (Controls and Safety Devices)

6. IRI (Industrial Risks Insurance)

7. UBC (Uniform Building Code)

8. UMC (Uniform Mechanical Code)

9. NEC (National Electrical Code)

10. UL (Underwriters Laboratories)

11. NFPA 85

Section A3-37 Rev. 09-09

Model 4WG 100 800 HP Boilers

1.03 QUALITY ASSURANCE

A. The equipment shall, as a minimum, be in strict compliance with the requirements of

this specification and shall be the manufacturer's standard commercial product

unless specified otherwise. Additional equipment features, details, accessories,

appurtenances, etc. which are not specifically identified but which are a part of the

manufacturer's standard commercial product, shall be included in the equipment

being furnished.

B. The equipment shall be of the type, design, and size that the manufacturer currently

offered for sale and appears in the manufacturer's current catalogue. The equipment

shall be new and fabricated from new materials and shall be free from defects in

materials and workmanship

C. The equipment must fit within the allocated space, leaving ample allowance for

maintenance and cleaning, and must leave suitable space for easy removal of all

equipment appurtenances. Tube pull clearance space from either the front or rear of

boiler must be maintained.

D. All units of the same classification shall be identical to the extent necessary to insure

interchangeability of parts, assemblies, accessories, and spare parts wherever

possible.

E. In order to provide unit responsibility for the specified capacities, efficiencies, and

performance, the boiler manufacturer shall certify in writing that the equipment being

submitted shall perform as specified. The boiler manufacturer shall be responsible for

guarantying that the boiler provides the performance as specified herein.

1.04 SUBMITTALS

A. The contractor shall submit, in a timely manner, all submittals for approval by the

engineer. Under no circumstances shall the contractor install any materials until the

engineer has made final approval on the submittals.

B. The engineer shall review and stamp submittals. Work may proceed and equipment

released for fabrication after contractor receives returned submittals stamped with

"NO EXCEPTIONS TAKEN" or "MAKE CORRECTIONS NOTED".

C. The bidder must submit in writing to the engineer any request for a proposed

deviation, omission, modification, or substitution to this specification for evaluation no

later than ten (10) days prior to the bid date. A request for any substitution shall be

accompanied by technical data, drawings, product samples, and complete data

substantiating compliance of proposed substitution with these specifications. No

materials shall be deemed acceptable if not in strict and full compliance with these

specifications. All bidders must bid solely on the specified materials unless

acceptance by the engineer of a deviation, omission, modification, or substitution is

granted in writing to all bidders prior to the bid date.

D. Shop Drawings - Shop drawings shall be submitted to the engineer for approval and

shall consist of:

1. General assembly drawing of the boiler including product description, model

number, dimensions, clearances, weights, service sizes, etc.

2. Schematic flow diagram of gas valve trains.

3. Schematic wiring diagram of boiler control system of the ladder-type showing all

components, all interlocks, etc. Schematic wiring diagram shall clearly identify

factory wiring and field wiring.

E. Installation Instructions: Manufacturer's printed instructions for installation shall be

submitted to the engineer for approval.

F. Manufacturer's Warranties: Manufacturer's printed warranties, as specified

hereinafter, shall be submitted prior to final acceptance by the engineer.

Section A3-38 Rev. 09-09

Model 4WG 100 800 HP Boilers

G. Manufacturer's Field Service: Manufacturer's printed field service procedures and

reports, as specified hereinafter, shall be submitted prior to final acceptance by the

engineer. Report forms shall contain all information as required to do start-up and

testing as specified in the products section.

1.05 CERTIFICATIONS

A. Manufacturer's Certification: The boiler manufacturer shall certify the following:

1. The products and systems furnished are in strict compliance with the

specifications.

2. The boiler, burner and other associated mechanical and electrical equipment

have all been properly coordinated and integrated to provide a complete and

operable boiler.

3. ASME certification.

4. UL and CSD-1 certification.

5. The equipment furnished has been installed in accordance with the

manufacturer's installation instructions.

6. The specified factory tests have been satisfactorily performed.

7. The specified field tests have been satisfactorily performed.

B. Contractor's Certification: The contractor shall certify the following:

1. The products and systems installed are in strict compliance with the

specifications.

2. The specified field tests have been satisfactorily performed.

C. Boiler Inspectors' Certification: All boiler inspections during hydrostatic testing shall

be performed by an authorized boiler inspector who is certified by the National Board

of Boiler and Pressure Vessel Inspectors and shall be submitted in writing prior to

final acceptance by the engineer.

D. Test Reports: Factory and field test reports as described above and as specified

hereinafter, shall be submitted prior to final acceptance by the engineer.

E. Operation and Maintenance Manuals: Manufacturer's printed operation and

maintenance manuals shall be submitted prior to final acceptance by the engineer.

Operation and maintenance manuals shall contain shop drawings, product data,

operating instructions, cleaning procedures, replacement parts list, maintenance and

repair data, complete parts list, etc.

1.06 DELIVERY, STORAGE, AND HANDLING

A. The contractor shall be responsible for the timely delivery of the equipment to the job

site. The contractor shall be responsible for unloading and rigging of the equipment.

The contractor shall be responsible for protecting the equipment from the weather,

humidity and temperature conditions, dirt, dust, other contaminants, as well as job

site conditions during construction.

B. Equipment shall be unloaded, handled, and stored in accordance with the

manufacturer's handling and storage instructions.

C. The work to be performed consists of providing all labor, equipment, materials, etc. to

furnish and install new factory assembled, low pressure hot water boilers as

described in the specifications herein.

Section A3-39 Rev. 09-09

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocumento5 pagineModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Model CB 15-100 HP BoilersDocumento5 pagineModel CB 15-100 HP BoilerssebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocumento5 pagineModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Model CB 15-100 HP Boilers: LightsDocumento5 pagineModel CB 15-100 HP Boilers: LightssebaversaNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocumento5 pagineModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Documento5 pagineModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Section A5: Model CBL 900-1800 HP BoilersDocumento5 pagineSection A5: Model CBL 900-1800 HP BoilerssebaversaNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocumento5 pagineModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocumento5 pagineModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Features and Benefits: Model CB 15-100 HP BoilersDocumento5 pagineFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Model CB 15-100 HP BoilersDocumento5 pagineModel CB 15-100 HP BoilerssebaversaNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocumento5 pagineModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNessuna valutazione finora

- Model CB 15-100 HP Boilers: Sound LevelDocumento5 pagineModel CB 15-100 HP Boilers: Sound LevelsebaversaNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Model CBL 900-1800 HP BoilersDocumento5 pagineModel CBL 900-1800 HP BoilerssebaversaNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocumento5 pagineModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Model CBL 900-1800 HP Boilers: Engineering DataDocumento5 pagineModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocumento5 pagineModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocumento5 pagineModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNessuna valutazione finora

- Model CBR 125-800 HP BoilersDocumento5 pagineModel CBR 125-800 HP BoilerssebaversaNessuna valutazione finora

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocumento5 pagineModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocumento5 pagineModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 78Documento5 pagine78sebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocumento5 pagineModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNessuna valutazione finora

- Model CBL 900-1800 HP BoilersDocumento5 pagineModel CBL 900-1800 HP BoilerssebaversaNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- 81Documento5 pagine81sebaversaNessuna valutazione finora

- 75Documento5 pagine75sebaversaNessuna valutazione finora

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Documento6 pagineModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNessuna valutazione finora

- General: Model ICB 100-800 HP BoilersDocumento4 pagineGeneral: Model ICB 100-800 HP BoilerssebaversaNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Model ICB 100-800 HP BoilersDocumento4 pagineModel ICB 100-800 HP BoilerssebaversaNessuna valutazione finora

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocumento4 pagineModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaNessuna valutazione finora

- Ac Manufacturing (PDocumento3 pagineAc Manufacturing (Pcardinal_airforce7610Nessuna valutazione finora

- Top Contractors Under Duterte T04 PCIJDocumento86 pagineTop Contractors Under Duterte T04 PCIJIT Account71% (7)

- City Sanitation Plan, UttarakhandDocumento101 pagineCity Sanitation Plan, UttarakhandHarish Kumar Mahavar100% (1)

- ME5286RoboticsToday - 1-RobotArms2017 PDFDocumento5 pagineME5286RoboticsToday - 1-RobotArms2017 PDFchrisNessuna valutazione finora

- CD Changer RetrofitDocumento2 pagineCD Changer RetrofitsacaetanoNessuna valutazione finora

- (BDP-10A) : PG Series Service SchematicDocumento9 pagine(BDP-10A) : PG Series Service Schematicvuqar0979Nessuna valutazione finora

- Construction & MaterialityDocumento178 pagineConstruction & MaterialityHugh Rolland80% (5)

- Soil PollutionDocumento32 pagineSoil PollutionNikhil GautamNessuna valutazione finora

- 36 - TopicsDocumento14 pagine36 - TopicsMohamad MagdyNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Gl1200 BackfiringDocumento4 pagineGl1200 BackfiringPuican IulianNessuna valutazione finora

- Concept Paper On Pottery ClusterDocumento5 pagineConcept Paper On Pottery ClusterBhrigu Bhusan GoswamiNessuna valutazione finora

- 3PL BopDocumento23 pagine3PL BopAkhilNessuna valutazione finora

- Genie Z60Documento2 pagineGenie Z60jishorNessuna valutazione finora

- Bored-Piling Mar2016 PDFDocumento4 pagineBored-Piling Mar2016 PDFrajaNessuna valutazione finora

- FUYP+RZP CieloDocumento19 pagineFUYP+RZP CieloCarlos ManriquezNessuna valutazione finora

- Waterfall Hf3 Ip Us NoticeDocumento2 pagineWaterfall Hf3 Ip Us NoticeVishal SuryawaniNessuna valutazione finora

- Saes A 007 PDFDocumento29 pagineSaes A 007 PDFsindalisindiNessuna valutazione finora

- Chilled Water MSTDocumento9 pagineChilled Water MSTSolymanElsayedSolymanNessuna valutazione finora

- Ece R83Documento253 pagineEce R83sp32483Nessuna valutazione finora

- Glass WoolDocumento44 pagineGlass Woolsmartbond_007Nessuna valutazione finora

- Turlik PDFDocumento38 pagineTurlik PDFMatrix OneNessuna valutazione finora

- ATJ2C-85 (Pindaan2017) Jan2018Documento134 pagineATJ2C-85 (Pindaan2017) Jan2018Shafiq Syazwan100% (23)

- Kysor Service GuideDocumento24 pagineKysor Service GuideAlex Renne ChambiNessuna valutazione finora

- W3400H-installation Operation PDFDocumento202 pagineW3400H-installation Operation PDFphuc100% (1)

- CFPP 4 eDocumento5 pagineCFPP 4 eNicuVisanNessuna valutazione finora

- Catalogo SandvikDocumento149 pagineCatalogo Sandvikojangu100% (1)

- 1140 Impact Manual PDFDocumento60 pagine1140 Impact Manual PDFNdao86Nessuna valutazione finora

- Introduction To Internal Combustion EnginesDocumento19 pagineIntroduction To Internal Combustion EnginesAkhilesh ChoudharyNessuna valutazione finora

- Overhead Set (Travel Method)Documento8 pagineOverhead Set (Travel Method)jengandxb100% (8)

- Transformed: Moving to the Product Operating ModelDa EverandTransformed: Moving to the Product Operating ModelValutazione: 4 su 5 stelle4/5 (1)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDa EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseValutazione: 5 su 5 stelle5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDa EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionValutazione: 4.5 su 5 stelle4.5/5 (2)

- Welding for Beginners in Fabrication: The Essentials of the Welding CraftDa EverandWelding for Beginners in Fabrication: The Essentials of the Welding CraftValutazione: 5 su 5 stelle5/5 (5)

- A Place of My Own: The Architecture of DaydreamsDa EverandA Place of My Own: The Architecture of DaydreamsValutazione: 4 su 5 stelle4/5 (242)

- Building Construction Technology: A Useful Guide - Part 1Da EverandBuilding Construction Technology: A Useful Guide - Part 1Valutazione: 4 su 5 stelle4/5 (3)