Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process Fmea Mahindra and Mahindra Limited Farm Equipment Sector

Caricato da

BALACHANDAR SDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Process Fmea Mahindra and Mahindra Limited Farm Equipment Sector

Caricato da

BALACHANDAR SCopyright:

Formati disponibili

PROCESS FMEA

MAHINDRA AND MAHINDRA LIMITED

FARM EQUIPMENT SECTOR

KEY DATE:- 20.12.04 DATE OF ORIGIN:- 20.12.04

CORE TEAM :AM / RRN / AM / FK DATE: 09.12.16 APPD : FK

AREA/INDIV

PROCESS S C O D R IDUAL

POTENTIAL CAUSE/ CURRENT PROCESS

E L C CURRENT PROCESS CONTROL E P RECOMMENDED RESPONSIB ACTION TAKEN & S O D RPN

REQUIREMENTS POTENTIAL FAILURE MODE POTENTIAL EFFECTS OF FAILURE MECHANISM OF CONTROL

V A C (DETECTION) T N ACTION LE & EFFECTIVE DATE

FAILURE (PREVENTION)

FUNCTION R S U E TARGET

DATE

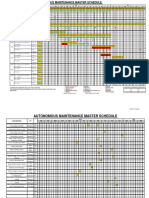

10) Hand hole cover tightening Tightening activity Self certification of hand hole cover

Hand hole cover tightening hand hole cover mounting bolt loose Water entry in clutch housing 7 4 5 140

and hand brake unloading missing fitment

Proper handling of hand brake after Improper handling of Hand brake hung on Self certification of hanging hand

Proper handling of hand brake not done Paint chipp off on hand brake 5 4 5 100

painting hand brake stand provided brake on stand

Demasking of lower link +top link +V.T.U.

Demasking sequence Self certification of demasking thru

20) Demasking plunger+ brake drum+ Differential lock Demasking of parts not done Next stage parts cannot be assembled 5 4 5 100

not adhered self certification card .

shaft

Demasking of VTU top plate breather cap Demasking sequence Self certification of demasking thru

Demasking of parts not done Next stage parts cannot be assembled 5 3 5 75

+Gear shifted lever threaded portion not adhered self certification card .

Demasking of starter motor terminal over

Demasking sequence Self certification of demasking thru

flow injection +tappet cover +gaer shifter + Demasking of parts not done Next stage parts cannot be assembled 5 3 5 75

not adhered self certification card .

difflock plunger

Improper/inaccurate

Jamming / frictional noise of moving parts where grease procedure mentioned

30) Rear, machine area greasing Greasing to be done in all greasing areas Greasing not done 6 greasing by the 3 QP-3 & QP -4 check point 7 126

is required in sop

operator

Excess grease on Cleaning of excess Visual checking for cleaning of

Cleanging of extra grease Spillage of grease on floor Slippage while working on work station 4 tractor and excess grease at stage by cell 4 excess greasing by operatorthru 5 80

grease not removal member self certification

Calculated amount

grease dispensing

Preventive Quantified dispensor for Front

Jamming / frictional noise of moving parts where grease Improper/inaccurate Daily Check point in SOP for machine to be TR/ST

40) Greasing at all defined point Greasing to be done in all greasing areas greasing not done

is required

7

working of grease gun

maintenance of grease 5

ensuring the grease gun functions

5 175

installed & Pusher 25.01.13

Axle installed 7 2 5 70

gun 20.01.13

arrangement for

grease dispensing

Excess grease on Cleaning of excess Visual checking for cleaning of

Cleanging of extra grease Spillage of grease on floor Slippage while working on work station 4 tractor and excess grease at stage by cell 5 excess greasing by operatorthru 7 140

grease not removal member self certification

Stand by grease

dispensing system additonal grease

Stroke of AFB to switch over from FK & KS / dispensing system

Greasing to be done in AFB Less grease applicatiion Noise from AFB 4 Noise from AFB

greasing fixed to 18

5 7 140

one to another 09.12.16 provided 4 2 7 56

incase of low 09.12.16

grease in drum

Checking of oil level by dip stick ,

Mfg & assly Oil filling activity

50)VTU Oil filling Filling of VTU Oil Oil not filling VTU can not opreat 6 <SC> 2 Error detection thru Qp-3 4 48

missing

Inspection , Self certification

Checking of oil level by dip stick ,

Mfg & assly Incorrect machine

Fill correct quantity of VTU Oil Incorrect quanity oil filling in VTU incurrect function of VTU oil 6 auto level setting 2 Error detection thru Qp-3 4 48

setting

Inspection , Self certification

Mfg & assly

Air leakage from nut

Tightening of Drain Plug Less tightening of VTU drain plug Major saftey issue for l/k 6 runner during 2 4 48

tightening of nut

Checking of oil level by gauge,

Mfg & assly Oil filling activity

60) Air cleaner oil filling Filling of Air Cleaner Oil Oil not filling Unclear air can insert of the engine 6 2 Error detection thru Qp-3 4 48

missing

Inspection , Self certification

Checking of oil level by gauge,

Mfg & assly Incorrect machine Auto setting of oil

Fill correct quantity of Air Cleaner Oil Incorrect quanity oil filling in air cleaner Engine can seizue due to less and excess oil 6 2 Error detection thru Qp-3 4 48

setting level.

Inspection , Self certification

Mfg & assly oil quantity revised to

Gears erratic noise coming from tracror while runining & Poka yake visual inspection & QP 3,QP 4 FK & KS /

70) Transmission oil filling . Transmission oil filling . Oil not filling 8 Oil filling acitivity miss 2 4 64 meet the min - max Oil quantity revised for OIB 8 2 4 64

gear wear out implemented check point 09.12.16

level on the dipstick

Mfg & assly

Gears erratic noise coming from tracror while runining & Incorrect machine visual inspection & QP 3,QP 4

Fill correct quantity of transmission oil Incorrect filling of transmission oil 8 Auto level setting 2 7 112

gear wear out setting check point

Mfg & assly

Leakage on Cleaning of oil by cell visual inspection & QP 3,QP 4

No oil on Tractor parts Transmission & VTU Oil on Parts aesthetic look not good possibility of Paint defects , Slippage while 4 6 4 168

testing dispensing unit member check point

DATE C.L CHANGE APPD DATE C.L CHANGE APPD DEPT. SHEET

15.08.15 BZ PFMEA Reviewed with CFT FK TRACTOR ASSY. 01 OF 01

02.08.15 BY Use of IOCL (MTRAC 30) Oil in place of EP90 Oil for 255 DI model(ER15C0003077 ) FK PART / STAGE NAME: OPN / PFMEA NO:

Post Demasking &

04.07.2015 BX Revised for F15 Q-2 FK TR 510

Greasing

OIB Oil Qty revised to 35.5 from 35 Ltr & Stand by grease dispensing

27.06.2015 BW SOP revised for VTU oil quantity from 12 to 11.6 litter FK 09.12.16 CC system FK PART / STAGE NO DATE C/L

AFB Grease Strokes increased from 10 to 18 to eliminate the chances of

06.06.15 BV oil quantity revised FK 09.11.16 CB noise from the sleeve FK 09.12.16 CC

04.06.2015 BU Revised for F15 Q-1 FK 15.10.2015 CA SOP Revised for offline greasing of tie rod at greasing stage FK

TQM-18 (Rev. 01, 03.10.2008)

Potrebbero piacerti anche

- DFX Design For X A Complete Guide - 2020 EditionDa EverandDFX Design For X A Complete Guide - 2020 EditionNessuna valutazione finora

- D10369520ADocumento4 pagineD10369520AQUALITY ControlNessuna valutazione finora

- Daily Bin Cleaning & Washing Check SheetDocumento1 paginaDaily Bin Cleaning & Washing Check Sheetsumeet sharmaNessuna valutazione finora

- BASF Injection Molding Defects PDFDocumento38 pagineBASF Injection Molding Defects PDFSenthil Kumar100% (1)

- MTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Documento9 pagineMTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Sahil WadhwaNessuna valutazione finora

- Bin CleaningDocumento2 pagineBin CleaningRS MANIKANDANNessuna valutazione finora

- F-PD-11 Tool Development Plan (Micro Plan)Documento3 pagineF-PD-11 Tool Development Plan (Micro Plan)Trivesh SharmaNessuna valutazione finora

- AM FormatDocumento73 pagineAM Formathisham_eyesNessuna valutazione finora

- Past Defect History 2021Documento10 paginePast Defect History 2021RahulNessuna valutazione finora

- FIR-garments PDFDocumento4 pagineFIR-garments PDFTarun PariharNessuna valutazione finora

- No: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDDocumento2 pagineNo: Trai/Pd/Mwi/71: Toprun Automotive India PVT LTDubraghuNessuna valutazione finora

- APQPDocumento3 pagineAPQPsam1hi5Nessuna valutazione finora

- Mould Check List / Trial Record: FG Control Tube FG H-TopDocumento8 pagineMould Check List / Trial Record: FG Control Tube FG H-ToprajeshNessuna valutazione finora

- Autocar Ppap Requirements Rev 5Documento17 pagineAutocar Ppap Requirements Rev 5man hoNessuna valutazione finora

- GM FMEA DoneDocumento12 pagineGM FMEA DoneSuraj RawatNessuna valutazione finora

- 03 - SIPOC Diagram - 2009-06-11Documento1 pagina03 - SIPOC Diagram - 2009-06-11Anand RajaNessuna valutazione finora

- 1 7 Supplier Rohs Audit Checklist Audit Report NoDocumento6 pagine1 7 Supplier Rohs Audit Checklist Audit Report Noรอคนบนฟ้า ส่งใครมาให้ สักคนNessuna valutazione finora

- 23.sop - HRDDocumento4 pagine23.sop - HRDrishi gautamNessuna valutazione finora

- Program Name: CE's APQP and Product Launch System (APLS)Documento2 pagineProgram Name: CE's APQP and Product Launch System (APLS)Janaka MangalaNessuna valutazione finora

- QP - NPD - 07 Procedure For Change ManagementDocumento3 pagineQP - NPD - 07 Procedure For Change ManagementMASU BRAKE PADS QANessuna valutazione finora

- Customer Special CharacteristicsDocumento1 paginaCustomer Special Characteristicspundhir12898Nessuna valutazione finora

- Change Details Planed/Un Planned/Ab Normality Corrective Action (As Per 5M Rules) Machine No. & Name Part No. & Part NameDocumento2 pagineChange Details Planed/Un Planned/Ab Normality Corrective Action (As Per 5M Rules) Machine No. & Name Part No. & Part NamePk NimiwalNessuna valutazione finora

- D10414410A CP Rev 00Documento21 pagineD10414410A CP Rev 00Suraj RawatNessuna valutazione finora

- KSS713 - Die Casting Tool Standard - Rev.03Documento17 pagineKSS713 - Die Casting Tool Standard - Rev.03Adrian Doru100% (2)

- Capacity Verification Run at Rate IpaDocumento4 pagineCapacity Verification Run at Rate IpaBES100% (1)

- Product Part Approval Process: Automotive Quality Management SystemDocumento3 pagineProduct Part Approval Process: Automotive Quality Management SystemrajaNessuna valutazione finora

- PP - Injection Mould Component Cost EstimationDocumento7 paginePP - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNessuna valutazione finora

- Process of EB, QB Samples ShipmentDocumento9 pagineProcess of EB, QB Samples ShipmentBự BụngNessuna valutazione finora

- Apqp Time Plan: Risk AnalysisDocumento4 pagineApqp Time Plan: Risk AnalysisRakesh PandeyNessuna valutazione finora

- Pfmea ExampleDocumento5 paginePfmea Exampleesivaks2000Nessuna valutazione finora

- Instructions:: Any ExceptionsDocumento3 pagineInstructions:: Any ExceptionsAkhmad FathoniNessuna valutazione finora

- Injection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Documento1 paginaInjection Molding Condition Sheet For Sumitomo Duz (For Mass Production)Jake Floyd G. FabianNessuna valutazione finora

- Form30TM Advanced Product Quality Planning-APQPDocumento1 paginaForm30TM Advanced Product Quality Planning-APQPShinichi SuzukiNessuna valutazione finora

- Nabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Documento10 pagineNabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Kiran AmboreNessuna valutazione finora

- 16 Major Losses in ProductionDocumento18 pagine16 Major Losses in ProductionAgung Chilmy FirdanaNessuna valutazione finora

- Exemple PPAPDocumento62 pagineExemple PPAPmoezNessuna valutazione finora

- Small Change Form TemplateDocumento2 pagineSmall Change Form TemplatechibugirlNessuna valutazione finora

- SPTR Rev Check ListDocumento5 pagineSPTR Rev Check ListSAKTHIVEL ANessuna valutazione finora

- Poly Carbonate - Injection Mould Component Cost EstimationDocumento7 paginePoly Carbonate - Injection Mould Component Cost EstimationVenkateswaran venkateswaranNessuna valutazione finora

- 5 Why WeldingRobot ToyotaDocumento1 pagina5 Why WeldingRobot ToyotaMickloSoberanNessuna valutazione finora

- F Qa 48 Ppap Readiness Sheet For 0.7lDocumento4 pagineF Qa 48 Ppap Readiness Sheet For 0.7lVikas RaiNessuna valutazione finora

- Appendix - 9 - APQP - Timing - PlanDocumento1 paginaAppendix - 9 - APQP - Timing - PlanChandru JattiNessuna valutazione finora

- Scorpio - N - Accessories Catalogue - Rev - 1.9Documento70 pagineScorpio - N - Accessories Catalogue - Rev - 1.9Kunal GuptaNessuna valutazione finora

- Form Tooling List Approval Tooling (002) Rev 4Documento3 pagineForm Tooling List Approval Tooling (002) Rev 4Kalista BettiNessuna valutazione finora

- Process SheetDocumento8 pagineProcess SheetSuraj RawatNessuna valutazione finora

- Mold SpecificationDocumento1 paginaMold SpecificationVictor Villouta LunaNessuna valutazione finora

- PSW Signature TemplateDocumento1 paginaPSW Signature TemplateKM MuiNessuna valutazione finora

- QCPC - Wide Roller 35,5Documento1 paginaQCPC - Wide Roller 35,5rianNessuna valutazione finora

- D10414410a Fmea CastingDocumento7 pagineD10414410a Fmea CastingSuraj RawatNessuna valutazione finora

- CM InjectDocumento21 pagineCM InjectTiago CerqueiraNessuna valutazione finora

- 6W2H For Side Wrinkles MY17 - RearDocumento4 pagine6W2H For Side Wrinkles MY17 - RearVishvendra Pratap SinghNessuna valutazione finora

- PIEF0158 a-QB Document Check SheetDocumento1 paginaPIEF0158 a-QB Document Check SheetĐỗ Thành NhươngNessuna valutazione finora

- Tool Steel - Material Selection Guide: High Speed SteelsDocumento1 paginaTool Steel - Material Selection Guide: High Speed SteelsAlok Rawat NLMKNessuna valutazione finora

- Gear Box Productivity 30 To 33 Nos Per Hour PDFDocumento2 pagineGear Box Productivity 30 To 33 Nos Per Hour PDFAravindNessuna valutazione finora

- CastingDocumento19 pagineCastingMohd SyafiqNessuna valutazione finora

- Corrective Action 8d-LeakageDocumento1 paginaCorrective Action 8d-LeakageManoj JhajhriaNessuna valutazione finora

- Deviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReportDocumento3 pagineDeviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReporttrungNessuna valutazione finora

- Performance Apprasial ReportDocumento5 paginePerformance Apprasial ReportShami KantNessuna valutazione finora

- PFMEADocumento26 paginePFMEAsmplfbd.qaNessuna valutazione finora

- Step 4: Overall InspectionDocumento8 pagineStep 4: Overall InspectionBALACHANDAR SNessuna valutazione finora

- OS For Domain B 3mu The Killer Virus!Documento5 pagineOS For Domain B 3mu The Killer Virus!BALACHANDAR SNessuna valutazione finora

- Sdfwef 34Documento26 pagineSdfwef 34BALACHANDAR SNessuna valutazione finora

- D 5 T 5 TDocumento3 pagineD 5 T 5 TBALACHANDAR SNessuna valutazione finora

- Sustainability Awareness Behavior Based Safety Industrial Fire HandlingDocumento1 paginaSustainability Awareness Behavior Based Safety Industrial Fire HandlingBALACHANDAR SNessuna valutazione finora

- WRITING TASK 2 You Should Spend About 40 Minutes OnDocumento1 paginaWRITING TASK 2 You Should Spend About 40 Minutes Onasad_chughtaiNessuna valutazione finora

- Level 4 Level 3 Level 2 Level 1 Skill Levels: Concept of Skill-UpDocumento1 paginaLevel 4 Level 3 Level 2 Level 1 Skill Levels: Concept of Skill-UpBALACHANDAR SNessuna valutazione finora

- Basic Heat TreatmentDocumento12 pagineBasic Heat Treatmentpramod_goswamiNessuna valutazione finora

- Fzwced 3 Ew 234 F 2Documento5 pagineFzwced 3 Ew 234 F 2BALACHANDAR SNessuna valutazione finora

- ASTM E 140 Hardness Conversion Tables PDFDocumento21 pagineASTM E 140 Hardness Conversion Tables PDFRiazNessuna valutazione finora

- AlagDocumento31 pagineAlagBALACHANDAR SNessuna valutazione finora

- Kyd 6457 DCDocumento27 pagineKyd 6457 DCBALACHANDAR SNessuna valutazione finora

- ZSXG 3Documento9 pagineZSXG 3BALACHANDAR SNessuna valutazione finora

- 3 RC 4 FDDocumento25 pagine3 RC 4 FDBALACHANDAR SNessuna valutazione finora

- 23 Edqw 3 QwsDocumento2 pagine23 Edqw 3 QwsBALACHANDAR SNessuna valutazione finora

- #Sdvferrf 34Documento12 pagine#Sdvferrf 34BALACHANDAR SNessuna valutazione finora

- Disclosure To Promote The Right To InformationDocumento16 pagineDisclosure To Promote The Right To InformationBALACHANDAR SNessuna valutazione finora

- FV 3 FG 3 GDocumento1 paginaFV 3 FG 3 GBALACHANDAR SNessuna valutazione finora

- Wzwedefr 45 RT 3 FD 3 D 4 DDocumento8 pagineWzwedefr 45 RT 3 FD 3 D 4 DBALACHANDAR SNessuna valutazione finora

- Audit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50Documento1 paginaAudit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50BALACHANDAR SNessuna valutazione finora

- Name of Applicant: Personal DetailsDocumento4 pagineName of Applicant: Personal DetailsBALACHANDAR SNessuna valutazione finora

- #Sdvferrf 34Documento12 pagine#Sdvferrf 34BALACHANDAR SNessuna valutazione finora

- KDHF 577 DFCDocumento1 paginaKDHF 577 DFCBALACHANDAR SNessuna valutazione finora

- MVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014Documento5 pagineMVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014BALACHANDAR SNessuna valutazione finora

- 3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1Documento1 pagina3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNessuna valutazione finora

- PU / Shop Zone Area Description Zone Leader's Name: 3 'S' Zones Details - PlantDocumento1 paginaPU / Shop Zone Area Description Zone Leader's Name: 3 'S' Zones Details - PlantBALACHANDAR SNessuna valutazione finora

- MQS/TPM/3S/1S2S Audit Sheet-Office/F/04 Rev. No.: 00 Rev. Date: 10th April'2013 1Documento1 paginaMQS/TPM/3S/1S2S Audit Sheet-Office/F/04 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNessuna valutazione finora

- 3S' Score Board - PU: Total Plant Level ScoreDocumento1 pagina3S' Score Board - PU: Total Plant Level ScoreBALACHANDAR SNessuna valutazione finora

- 3S' Score Board - PlantDocumento1 pagina3S' Score Board - PlantBALACHANDAR SNessuna valutazione finora

- 3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1Documento1 pagina3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNessuna valutazione finora

- Polaris Predator 90 Owners ManualDocumento153 paginePolaris Predator 90 Owners Manualmilkman951Nessuna valutazione finora

- Operation of DX SeriesDocumento34 pagineOperation of DX SeriesAndrei 26Nessuna valutazione finora

- Mule 4010 Trans 4x4Documento151 pagineMule 4010 Trans 4x4Will DiggNessuna valutazione finora

- 940 Owner's Manual Volvo 940 1 9 9 3: Instruments and Controls ... 1 Body and Interior ... 2Documento204 pagine940 Owner's Manual Volvo 940 1 9 9 3: Instruments and Controls ... 1 Body and Interior ... 2Gudmund SøndergårdNessuna valutazione finora

- TM 1-1520-237-10 - UH.60 - and - EH-60 - Helicopter - 2009Documento902 pagineTM 1-1520-237-10 - UH.60 - and - EH-60 - Helicopter - 2009Wurzel1946100% (1)

- Operating Instructions: Linde Fork Lift TruckDocumento96 pagineOperating Instructions: Linde Fork Lift TruckVictorNessuna valutazione finora

- Army CH-47 Chinook HelicopterDocumento714 pagineArmy CH-47 Chinook HelicopterArmySGT100% (3)

- Manual Comprensora c62hs - CompairDocumento58 pagineManual Comprensora c62hs - CompairJohn Pomahuali100% (1)

- s07 Tramming Axera Robolt Solo 5 enDocumento18 pagines07 Tramming Axera Robolt Solo 5 enAnonymous iu95trpxNNessuna valutazione finora

- DB460 Use & Maintenance ManualDocumento252 pagineDB460 Use & Maintenance ManualJustice MachiwanaNessuna valutazione finora

- Cub CadetDocumento40 pagineCub CadetKen LangNessuna valutazione finora

- MTD ManualDocumento48 pagineMTD ManualJoe SmithNessuna valutazione finora

- Group 40 M191en 05 2015 PDFDocumento38 pagineGroup 40 M191en 05 2015 PDFDavid SolisNessuna valutazione finora

- Igc 2 Element 2 Transport Hazard and Risk Control ReviewerDocumento2 pagineIgc 2 Element 2 Transport Hazard and Risk Control ReviewerJunard M. Lu Hap100% (6)

- Spyder NEWDocumento6 pagineSpyder NEWwchenowethNessuna valutazione finora

- G330 DOOSAN Ingersoll-RandDocumento234 pagineG330 DOOSAN Ingersoll-Randjim perdigonNessuna valutazione finora

- Manual Dieci PDFDocumento303 pagineManual Dieci PDFGabriel Toscariu85% (13)

- Doosan D20S 5 Operation PDFDocumento210 pagineDoosan D20S 5 Operation PDFMohammed Al-hewaimel100% (1)

- Komatsu Wheel Loader Wa500 7 Usa Shop ManualDocumento20 pagineKomatsu Wheel Loader Wa500 7 Usa Shop Manualjewel100% (47)

- Scania SOPSDocumento32 pagineScania SOPSErik Huidobro100% (3)

- BH60M Dumper-202107061742Documento4 pagineBH60M Dumper-202107061742amir sadighiNessuna valutazione finora

- Allison ManualDocumento58 pagineAllison ManualMauricio Gomez Gomez100% (1)

- ZP11 MCE3 SA Service Manual-20180118Documento755 pagineZP11 MCE3 SA Service Manual-20180118Adolfo FuentealbaNessuna valutazione finora

- Tata Sumo Grande MKIIDocumento142 pagineTata Sumo Grande MKIIDevNessuna valutazione finora

- ETM/V 214/216: Operating InstructionsDocumento97 pagineETM/V 214/216: Operating InstructionsVasile DumitruNessuna valutazione finora

- Manua Ford Aspire 97 PDFDocumento254 pagineManua Ford Aspire 97 PDFmasanegraNessuna valutazione finora

- Apc200 Ecm Eci Error CodesDocumento53 pagineApc200 Ecm Eci Error Codescristian faundes67% (3)

- Owners Manual Tata NovusDocumento209 pagineOwners Manual Tata NovusHessa Kansha Rasyida100% (3)

- 05-1 Powershift Trans Specs 5-12130naDocumento23 pagine05-1 Powershift Trans Specs 5-12130naMauricio GonzalezNessuna valutazione finora

- 2013 KTM Power Parts CatalogDocumento74 pagine2013 KTM Power Parts CatalogGeorge IrelandNessuna valutazione finora