Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tensioners

Caricato da

Valentin LupascuCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tensioners

Caricato da

Valentin LupascuCopyright:

Formati disponibili

PRODUCT SPECIFICATIONS

The following pages contain engineering

data and product specifications for T-Max

Tensioners.

TO DOWNLOAD FILES SELECTION

For CAD drawings of T-Max Tensioners,

please click on the part number to begin the LIGHT DUTY

download process. You will have the choice ROTARY TENSIONERS

of a 2D AutoCAD ver. 12 .dwg or a 3D .igs file.

RT0500

RT1000

RT1600

HEAVY DUTY

ROTARY TENSIONERS

RT4000

LINEAR TENSIONERS

CT1100, 2100, 3100

CT1200, 2200, 3200

CT1400, 2400, 3400

LT1000, 2000, 3000

SELECTION CHART

COMMON

ROTARY ASSEMBLIES

OVERHUNG LOAD

INFORMATION

FREQUENTLY ASKED

QUESTIONS

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

How to Select a Tensioner

Selecting a tensioner can be difficult because there is no cut-and-dried method for

determining the amount of force a tensioner should develop. The size and type of

tensioner (belt or chain) are determined based on knowing the drive parameters and

power requirements, speed, torque, cycles, etc. These guidelines are suggestions to assist

the designer. If there is any doubt, spring force determination should be made in

consultation with the belt or chain manufacturer.

V-belt Drives Light Duty

The RT0500, RT1000, RT1600-L and RT1600 series are best suited for single groove

drives using 3L, A/4L or B/5L cross section belts.

V-belt Drives Heavy Duty

RT4000 series tensioners are designed for use on drives with two to four belts B/5V

and one to two belts C cross sections.

Synchronous Belt Drives

Automatic tensioners are not usually used on power transmitting synchronous

belt drives, but are acceptable for use on drives strictly for motion transfer. If an

automatic tensioner is desired for a power transmitting drive, consult the belt

manufacturer for recommendations.

Chain Drives

Click here for selection chart.

Idler Guidelines

Always mount idler on the slack side of the drive, with preferred mounting on

the inside slack side.

Follow the belt manufacturers recommended minimum idler diameter.

Optimum location for the tensioner is where the idler provides nearly equal arcs

of contact on both the driveR and driveN sheaves or sprockets.

Keep overhung load to a minimum.

For assistance, contact Fenner Drives application engineering group.

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Light-Duty Rotary Tensioners

BODY

Rugged, die-cast aluminum or high-strength, lightweight glass-

reinforced nylon.

BEARINGS

Oil-impregnated, sintered bronze bearings are used to provide

smooth, reliable movement at all wear points. Bearings are

positioned by a press-fit and never need lubrication.

SPRINGS

Alloy steel, accurately wound compression springs are used

to provide consistent tensioning force. Grease-lubricated to

ensure not only quiet operation, but also long life.

MOUNTING HOLE

Single bolt design for both mounting and tension adjustment.

Rugged, heavy-duty construction

Easy installation and adjustment with single bolt feature

Wide variety of sizes and mounting styles

Improved performance and extended life for most fixed-center drives

Built-in spring mechanism absorbs momentary overloads and reduces vibration

Precision construction from high-quality materials for proven durability

Graduated scale tension adjustment

For corrosive, washdown, or other harsh applications, units are available with

stainless steel springs and center hub

Ideal for use with Fenner Drives Idler Pulleys and Sprockets

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Rotary Tensioners

RT0500

Molded of premium quality, high-strength glass-reinforced nylon

Composite material means lighter weight

Spring forces up to 25 lbs.

Ideally suited for light duty 3L, 4L, 5L and single A V-belt drives

Part A B C D E F G H I Rotation Force

Number (degrees) (lbs.)

RT0500 3.00 0.19 0.57 2.75 4.86 0.90 3/8-16 0.40 1.36 15 10

30 15

45 20

60 25

RT0501 3.00 0.19 0.57 2.75 4.86 0.90 0.40 0.40 1.36 15 10

30 15

45 20

60 25

Notes 1) All dimensions are in inches.

2) Maximum load no more than 1" distance from front face of tensioner to centerline of idler click here for overhung load information.

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

otary Tensioners

RT1000

Die-cast aluminum construction

Spring forces up to 30 lbs.

Part A B C D E F G H I Rotation Force

Number (degrees) (lbs.)

RT1001 3.50 0.25 0.59 2.75 5.31 1.15 3/8-16 3/8-16 1.42 15 16

30 23

45 30

RT1003 3.50 0.25 0.59 2.75 5.31 1.15 0.40 3/8-16 1.42 15 16

30 23

45 30

Notes 1) All dimensions are in inches.

2) Maximum load no more than 1" distance from front face of tensioner to centerline of idler click here for overhung load information.

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Rotary Tensioners

RT1600

Die-cast aluminum construction

Extended arm length

Spring forces up to 26 lbs.

Part A B C D E F G H I Rotation Force

Number (degrees) (lbs.)

RT1601-L 6.37 0.25 0.59 2.75 8.24 1.12 3/8-16 3/8-16 1.42 15 10

30 13

45 16

RT1603-L 6.37 0.25 0.59 2.75 8.24 1.12 0.40 3/8-16 1.42 15 10

30 13

45 16

RT1601 6.37 0.25 0.59 2.75 8.24 1.12 3/8-16 3/8-16 1.42 15 20

25 23

35 26

RT1603 6.37 0.25 0.59 2.75 8.24 1.12 0.40 3/8-16 1.42 15 20

25 23

35 26

Notes 1) All dimensions are in inches.

2) Maximum load no more than 1" distance from front face of tensioner to centerline of idler click here for overhung load information.

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Heavy-Duty Rotary Tensioners

ARM

Heavy duty, stamped steel construction with unique offset to

position idler load over bearings, thereby reducing overhung

loads. 0.510" thru-holes for idler mounting.

HOUSING & BASE

Rugged, die-cast aluminum construction.

BEARINGS

Incorporates two 6203 ball bearings to provide high

overhung load capacity.

MOUNTING HOLES

Single bolt design for mounting and tension adjustment.

Available as "-13 tapped or 0.510" thru-hole for " bolt.

SPRING

Alloy steel torsional wrapped spring which may be reversed

to allow bi-directional use.

DIRECTIONAL ARROW

Ensures proper installation must always point toward belt

or chain being tensioned.

The industrys first heavy-duty tensioner for multiple belt drives

Rugged, heavy-duty construction for heavy load applications

Designed for use with multiple belts or strands of chain

Unique arm design keeps load centered over bearings

No elastomeric tension members to cold-flow, fatigue or take

a compression set

Torsion spring absorbs momentary overloads and reduces vibration

Ideal for use with nylon multiple groove V- and flat belt idler pulleys,

only from Fenner Drives

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Rotary Tensioners

RT4000

Heavy duty stamped steel arm

Die-cast aluminum construction

Spring forces up to 90 lbs.

Part Rotation(3) Force(3)

Number A A1 B C D E F G H I J K M M1 (degrees) (lbs.)

RT4000 4.50 5.40 0.49 1.19 4.00 8.58 2.24 1/2 - 13 0.51 2.60 2.15 2.46 2.35 3.25 0 - 90 0 - 90

RT4001 4.50 5.40 na 1.19 4.00 8.58 2.24 0.51 0.51 2.60 2.15 2.46 2.35 3.25 0 - 90 0 - 90

Notes 1) All dimensions are in inches.

2) Maximum load no more than 1" distance from front face of tensioner arm to centerline of idler click here for overhung load information.

3) Dimension A: 1 rotation = 1 lb. force. Dimension A1: 1 rotation = .83 lb. force.

4) Requires a 3-15/16 fixed head, hook style spanner wrench for tensioning.

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Linear Tensioners

UHMW HEAD

Self-lubricating properties are ideal for chain drives.

MOUNTING BLOCK

Aluminum triangular mounting block has tapped or

thru-holes for mounting chain sprockets.

BEARINGS

Oil-impregnated, sintered bronze bearings for

smooth, reliable movement at all wear points.

Bearings are positioned by a press-fit and never

need lubrication.

BODY

Rugged, die-cast aluminum with thick wall sections

and machined interface surfaces.

SPRINGS

Alloy steel, accurately wound compression springs

are used to provide consistent tensioning force.

Grease-lubricated to ensure not only quiet opera-

tion, but also long life.

MOUNTING SLOT

Single bolt for mounting and for tension adjustment.

Die-cast aluminum construction

Easy installation and adjustment with single bolt feature

Wide variety of sizes and mounting styles

Improved performance and extended life for most fixed-center drives

Built-in spring mechanism absorbs momentary overloads and reduces vibration

Precision construction from high-quality materials for proven durability

Can be used in a host of industrial applications

For corrosive, washdown, or other harsh applications, units are available with

stainless steel springs

Fully automatic straight-line take up

Ideal for use with Fenner Drives Idler Sprockets

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Chain Tensioners

CT1100, CT2100 and CT3100

Large arc-shaped head guides the roller chain

Head made from UHMW its self-lubricating properties

are ideal for chain drives

Spring forces up to 200 lbs.

CT Travel Force

Series (inches) ( lbs.)

1100-L 1.10 5 - 30 Common Dimensions

1100 0.85 15 - 40 Series A C D E G H

2100 1.25 20 - 60

CT1100 2.36 1.89 2.95 5.66 0.41 5.50

3100 1.65 45 - 115

CT2100 2.95 2.36 3.54 6.48 0.49 5.50

3100-H 1.00 30 - 200

CT3100 3.54 2.95 4.25 7.60 0.57 5.50

3196 1.00 45 - 115

Single Chain Double Chain Triple Chain

Part No. Chain B M Part No. Chain B N Part No. Chain B O

CT1101-L #35 0.98 0.79 CT1103-L #35 0.98 0.63 CT1105-L #35 0.98 1.02

CT1101 #35 0.98 0.79 CT1103 #35 0.98 0.63 CT1105 #35 0.98 1.02

CT1102 #40 0.98 0.79 CT1104 #40 0.98 0.81 CT1106 #40 0.98 1.36

CT2101 #50 1.18 0.87 CT2103 #50 1.18 0.98 CT2105 #50 1.18 1.63

CT2102 #60 1.18 0.87 CT2104 #60 1.18 1.37

CT3101 #80 1.38 0.98 CT3103 #80 1.38 1.81

CT3102 #100 1.38 0.98

CT3102-H #100 1.38 0.98

CT3196 #81X 1.38 1.75

Notes 1) All dimensions are in inches.

2) These tensioners can be used on chain sizes up to #160 (click here for tensioner selection chart).

Contact Fenner Drives application engineering group for head dimensions.

3) Fenner Drives can build tensioners with spring forces other than those listed.

Contact Fenner Drives application engineering group.

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

thirteen

Chain Tensioners CT1200, CT2200 and CT3200

Small arc-shaped head for when space is limited

Head made from UHMW its self-lubricating properties

are ideal for chain drives

Spring forces up to 200 lbs.

CT Travel Force

Series (inches) ( lbs.) Common Dimensions

1200-L 1.10 5 - 30 Series A C D E G

1200 0.85 15 - 40

CT1200 2.36 1.89 2.95 5.66 0.41

2200 1.25 20 - 60

CT2200 2.95 2.36 3.54 6.48 0.49

3200 1.65 45 - 115

CT3200 3.54 2.95 4.25 7.60 0.57

3200-H 1.00 30 - 200

Single Chain Double Chain Triple Chain

Part No. Chain B M Part No. Chain B N Part No. Chain B O

CT1201-L #35 0.98 0.79 CT1203-L #35 0.98 0.63 CT1205-L #35 0.98 1.02

CT1201 #35 0.98 0.79 CT1203 #35 0.98 0.63 CT1205 #35 0.98 1.02

CT1202 #40 0.98 0.79 CT1204 #40 0.98 0.81 CT1206 #40 0.98 1.36

CT2201 #50 1.18 0.86 CT2203 #50 1.18 0.98 CT2205 #50 1.18 1.75

CT2202 #60 1.18 0.86 CT2204 #60 1.18 1.37

CT3201 #80 1.38 0.98 CT3203 #80 1.38 1.81

CT3202 #100 1.38 0.98

CT3202-H #100 1.38 0.98

Notes 1) All dimensions are in inches.

2) These tensioners can be used on chain sizes up to #160 (click here for tensioner selection chart).

Contact Fenner Drives application engineering group for head dimensions.

3) Fenner Drives can build tensioners with spring forces other than those listed.

Contact Fenner Drives application engineering group.

Chain Tensioners

CT1400, CT2400, and CT3400 Fixed

An economical tensioner when automatic tensioning is not required

Slotted frame for quick and precise adjustment in any direction

Head made from UHMW its self-lubricating properties are ideal

for chain drives

For single and double chain applications

Part No. A B C D E F G H M N Chain

CT1401 1.56 0.59 2.87 0.39 5.60 1.18 0.41 0.39 0.79 #35

CT1402 1.56 0.59 2.87 0.39 5.60 1.18 0.41 0.39 0.79 #35

CT1403 1.56 0.59 2.87 0.39 5.60 1.18 0.41 0.39 0.79 #40

CT1404 1.56 0.59 2.87 0.39 5.60 1.18 0.41 0.39 0.95 #40

CT2401 1.97 0.71 3.35 0.47 6.50 1.42 0.51 0.47 0.86 #50

CT2402 1.97 0.71 3.35 0.47 6.50 1.42 0.51 0.47 1.11 #50

CT2403 1.97 0.71 3.35 0.47 6.50 1.42 0.51 0.47 0.86 #60

CT2404 1.97 0.71 3.35 0.47 6.50 1.42 0.51 0.47 1.53 #60

CT3401 2.36 0.77 3.23 0.51 6.68 1.57 0.51 0.55 0.98 #80

CT3402 2.36 0.77 3.23 0.51 6.68 1.57 0.51 0.55 1.98 #80

Note All dimensions are in inches.

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Linear Tensioners

LT1000, LT2000, and LT3000

Ideal for use with Fenner Drives Roller Chain Idler Sprockets

Spring forces up to 200 lbs.

Part Travel Force

Number A B C D E F G H J (inches) (lbs.)

LT1001-L 2.36 0.98 1.80 2.91 5.40 0.40 0.42 3/8 - 16 0.79 1.10 5 - 28

LT1001 2.36 0.98 1.80 2.91 5.40 0.40 0.42 3/8 - 16 0.79 .85 15 - 38

LT1002 2.36 0.98 1.80 2.91 5.40 0.40 0.42 0.40 0.79 .85 15 - 38

LT2001 2.95 1.18 2.36 3.54 6.89 0.47 0.49 1/2 - 13 0.98 1.25 20 - 57

LT2002 2.95 1.18 2.36 3.54 6.89 0.47 0.49 0.51 0.98 1.25 20 - 57

LT3001 3.54 1.38 2.95 4.25 8.27 0.55 0.57 1/2 - 13 1.18 1.65 45 - 109

LT3002 3.54 1.38 2.95 4.25 8.27 0.55 0.57 0.51 1.18 1.65 45 - 109

LT3002-H 3.54 1.38 2.95 4.25 8.27 0.55 0.57 0.51 1.18 1.00 30 - 200

Notes 1) All dimensions are in inches.

2) Maximum load no more than 1" distance from front face of tensioner to centerline of idler click here for overhung load information.

3) Fenner Drives can build tensioners with spring forces other than those listed.

Contact Fenner Drives application engineering group.

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Tensioner Selection Chart

for Roller Chain Drives

Rotary and Linear Tensioners Single Chain

Chain Size #35 #40 #50 #60 #80 #100 #120 #140 #160

RT0500 X X X

RT1600-L X X X

RT1600 X X X X X

RT1000 X X X X X

RT4000 X X X

LT/CT1000-L X X X

LT/CT1000 X X X X X X

LT/CT2000 X X X X

LT/CT3000 X X X X

LT/CT3000-H X X

Rotary and Linear Tensioners Double Chain

Chain Size #35 #40 #50 #60 #80 #100 #120 #140 #160

RT0500 X X

RT1600-L X X

RT1600 X X X X

RT1000 X X X X

RT4000 X X

LT/CT1000-L X X

LT/CT1000 X X X X X

LT/CT2000 X X X

LT/CT3000 X X

LT/CT3000-H X X X

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Common Rotary

Assemblies

For a complete solution to your tensioning needs, weve

made it as simple as can be. Well take any of the tensioners

and idlers listed below and assemble them right at the factory.

You just tell us the tensioner/idler combo you need, and well

put it together and send it to you ready to install, just like

you see in the illustration.

For additional assembly options, consult factory.

V-belt Pulley Assemblies

Rotary Tensioner Idler Groove Pulley Dim. A*

Part Numbers Part No. Profile Diameter

RT0500, RT1001, RT1601-L VA3001** 4L/A 3.0 1.68

RT0500, RT1001, RT1601-L VA4001** 4L/A 4.0 1.68

RT1601-L VA5001 B 5.0 1.68

RT4000, RT4001 VA5001 B 5.0 1.69

RT4000, RT4001 VA6250 B 6.25 1.64

RT4000, RT4001 V2B6280 B/5V 6.28 2.18

RT4000, RT4001 V3B6280 B/5V 6.28 2.55

RT4000, RT4001 V4B6280 B/5V 6.28 2.94

Flat Belt Pulley Assemblies

Rotary Tensioner Idler Pulley Pulley Dim. A*

Part Numbers Part No. Dia. Width

RT0500, RT1001 FA2750 2.00 1.09 1.93

RT0500, RT1001 FA3002 2.50 1.02 1.93

RT0500, RT1001 FA3502 3.00 1.00 1.93

RT0500, RT1001 FA4501 4.00 1.09 1.93

RT1001 FA5501 5.00 1.02 1.93

RT1601-L, RT1601 FA2750 2.00 1.09 1.93

RT1601-L, RT1601 FA3002 2.50 1.02 1.93

RT1601-L, RT1601 FA3502 3.00 1.00 1.93

RT1601-L, RT1601 FA4501 4.00 1.09 1.93

RT1601-L, RT1601 FA5501 5.00 1.02 1.93

RT4000, RT4001 FA2750 2.00 1.09 1.94

RT4000, RT4001 FA3002 2.50 1.02 1.94

RT4000, RT4001 FA3502 3.00 1.00 1.94

RT4000, RT4001 FA4501 4.00 1.09 1.94

RT4000, RT4001 FA5501 5.00 1.02 1.94

RT4000, RT4001 F1B6280 6.00 1.23 2.19

RT4000, RT4001 F2B6280 6.00 2.10 2.63

RT4000, RT4001 F3B6280 6.00 2.91 2.94

RT4000, RT4001 F4B6280 6.00 3.85 3.47

Chain Sprocket Assemblies

Rotary Tensioner Idler Chain Number Dim. A*

Part Numbers Part No. Type Teeth

RT0500, RT1001, RT1601-L, RT1601 CS3502 35 19 1.68

RT0500, RT1001, RT1601-L, RT1601 CS4002 40 17 1.68

RT0500, RT1001, RT1601-L, RT1601 CS5002 50 15 1.68

RT1001, RT1601 CS6002 60 13 1.68

RT1001, RT1601 CS8002 80 12 1.68

* Dim. A = Most compact assembly, and minimizes overhung load for optimal performances. Click here for overhung load information.

** Available with specially sealed bearing and CAP plug for high pressure washdown applications.

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Overhung Load Information

Figure 1 Figure 2

Correct Incorrect

To receive a full measure of performance from Overhung load is directly related to the tensioner

the tensioner/idler assembly, it is important to mounting location. Although it is easy to move

keep overhung loads to a minimum. Figure 1 the idler further away from the tensioner arm to

illustrates a properly designed tensioner/idler achieve correct alignment with the driveR and

assembly where the overhung load is no more driveN, this is NOT the correct thing to do.

than one inch from the centerline of the idler When considering a tensioner/idler assembly the

to the face of the tensioner arm. idler should be mounted close to the tensioner

Figure 2 illustrates a poorly designed tension- arm and then the tensioner/idler assembly position

er/idler assembly. Note the distance from the determined. In some instances it may be necessary

idler to the tensioner is excessive. This arrange- to fabricate a new mounting bracket or add plates,

ment will introduce excessive load on the idler spacers, channel, etc. to an existing bracket to

mounting bolt, tensioner arm and the bushing position the assembly allowing for correct align-

in the tensioner body. The result will be poor ment of the idler with the driveR and driveN

performance and premature failure of the ten- components.

sioner. If in doubt, contact Fenner Drives application

engineering group for assistance.

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Q

When should I use a rotary versus linear

tensioner?

A linear moves in a straight line and a rotary swings in

Q On my belt or chain drive, where should

the tensioner/idler be located?

Always install the tensioner/idler on the slack side

A

Frequently Asked Questions

A

an arc. Sometimes mounting location, drive configura- of the drive.

tion, etc. will not permit the use of one versus the

Q

other. The application should be closely reviewed to

determine which tensioner is best suited. We can help Where is the best place on my V-belt drive

you determine which is best for your application just to locate a tensioner/idler?

give us a call. Preferably, a tensioner/idler should be located on

A

the inside of the drive. Optimum placement would

Q

be where it provides nearly equal arc of contacts on

Which tensioner is the best one for my both the driveR and driveN pulleys.

application?

Q

Generally, the rotary style is primarily used on belt

Where do I position the tensioner on my

A

drives, although it can also be used with chain drives.

The CT linear tensioner with the UHMW head is the

most popular on chain drives.

chain drive?

The tensioner should be located on the slack or sag

A side of the chain and outside the perimeter of the

Q

chain strand.

Can I use the tensioner/idler on the backside

of a belt?

Yes. Although a backside idler increases wrap angle

A

and power transmission capacity, it does introduce a

reverse or back bend in the belt that will shorten belt

life. Consult with the belt manufacturer for minimum

Q I am using chain other than standard ANSI

roller chain. Can I get the UHMW head on

a CT linear tensioner to match my chain?

Consult Fenner Drives application engineering group.

pulley diameter and location.

A In many instances we have been able to design and

furnish a special UHMW head.

Q

My drive reverses where do I locate the

tensioner/idler?

Spring-loaded tensioners should never be used on

Q Do I need to periodically grease the springs?

In most cases, no. The springs are pre-lubricated at

A

reversing drives. If they are, when the drive reverses the factory and the unit is assembled. However, on

the slack side becomes the tight side and vice versa.

A tensioner designed for the slack side would then

have inadequate spring force to maintain belt tension.

A occasion an application may dictate the need for re-

lubrication. Contact Fenner Drives application engi-

neering group. We may be able to design a tensioner

with a fitting that will allow this.

Q

How do I determine what size tensioner/idler

I need for my belt drive?

Selection of the proper size tensioner can be made Q Where should I position the tensioner in

the chain span?

A

using the guidelines specified in this catalog. Consult

with the belt manufacturer, who can determine the

right amount of spring force based on the application

and drive parameters.

A

Unless a chain guide is being used, the tensioner

should be located an equal distance from the driveR

and driveN sprockets.

Q

I have some contaminants in my application

will they have any effect on the tensioner?

Q My chain drive appears to have excessive

slack will a tensioner help this problem?

Usually, under normal conditions chain slack should

Our tensioners are made from glass filled nylon or not exceed 4% of the span. For unusual conditions

A

aluminum. Although many chemicals/oils will not

affect them, they are not resistant to all. Contact

Fenner Drives application engineering group with

the contaminants present and well make a recom-

A

such as heavy loads, frequent starts/stops, etc. it should

not exceed 2% of the span. Excessive chain slack usual-

ly occurs on drives with long spans. Typically a span

greater than 50P (P = chain pitch) will require

mendation. a tensioner.

1.800.243.3374 info@fennerdrives.com CONTACT Fenner Drives

Potrebbero piacerti anche

- Guide to Load Analysis for Durability in Vehicle EngineeringDa EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonValutazione: 4 su 5 stelle4/5 (1)

- TensionersDocumento20 pagineTensionersSuresh KumarNessuna valutazione finora

- Catalogo Redutor MecanicoDocumento152 pagineCatalogo Redutor MecanicoGabriel SizaNessuna valutazione finora

- Correas DentadasDocumento48 pagineCorreas DentadassantiagoNessuna valutazione finora

- ContiTech Power Transmission SystemsDocumento87 pagineContiTech Power Transmission SystemsRamírez Vilca JulioNessuna valutazione finora

- Chap 2 DesignDocumento49 pagineChap 2 DesignFareedMohmed100% (1)

- How Timing Belt WorksDocumento7 pagineHow Timing Belt WorksParas ThakurNessuna valutazione finora

- Design and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainDa EverandDesign and Analysis of Composite Structures for Automotive Applications: Chassis and DrivetrainNessuna valutazione finora

- TH Alpha 2005 GBDocumento94 pagineTH Alpha 2005 GBSimon VanhumbeeckNessuna valutazione finora

- Plant Maintenance A Complete Guide - 2020 EditionDa EverandPlant Maintenance A Complete Guide - 2020 EditionNessuna valutazione finora

- 18Documento5 pagine18John RobinNessuna valutazione finora

- Accesorios Roscados para PlásticosDocumento32 pagineAccesorios Roscados para PlásticosjbertralNessuna valutazione finora

- Continuous casting The Ultimate Step-By-Step GuideDa EverandContinuous casting The Ultimate Step-By-Step GuideNessuna valutazione finora

- Torque TighteningDocumento2 pagineTorque TighteningAnonymous fbeCwgBFY100% (1)

- Belt Tensioning ProcedureDocumento2 pagineBelt Tensioning Procedureanguyen22153319Nessuna valutazione finora

- Design of Shaft KeysDocumento29 pagineDesign of Shaft KeysNagarajuRbNessuna valutazione finora

- Bolt Tightening PDFDocumento20 pagineBolt Tightening PDFblahblahNessuna valutazione finora

- Drivedesign LightpowerDocumento110 pagineDrivedesign LightpowerMirescu Robert-AlexandruNessuna valutazione finora

- Battery Management Systems For Electric Vehicles: Bachelor of TechnologyDocumento25 pagineBattery Management Systems For Electric Vehicles: Bachelor of TechnologyJatin YadavNessuna valutazione finora

- Radial Stackups - Concentric Components ExampleDocumento5 pagineRadial Stackups - Concentric Components ExampleGeorge HerreraNessuna valutazione finora

- MES Die Castings Design and Specification Guide: Delivery Engineered SolutionsDocumento12 pagineMES Die Castings Design and Specification Guide: Delivery Engineered SolutionsRafał Lesiczka100% (1)

- BL Miniature CatalogDocumento40 pagineBL Miniature Catalogchabane_148549Nessuna valutazione finora

- GDTDocumento38 pagineGDTAntonio CervantesNessuna valutazione finora

- Pistol Correction ChartDocumento1 paginaPistol Correction ChartScribbleBabyNessuna valutazione finora

- Moment of InertiaDocumento10 pagineMoment of InertiasenthilcaeNessuna valutazione finora

- CuñaDocumento20 pagineCuñaJulian Granados RicoNessuna valutazione finora

- Grinding Process BoreDocumento22 pagineGrinding Process Boremaulikgadara50% (2)

- Pte Mag PDFDocumento68 paginePte Mag PDFhollowNessuna valutazione finora

- Home About Us Software Services Training Download Pricing Bolting InfoDocumento9 pagineHome About Us Software Services Training Download Pricing Bolting Infopaeg6512Nessuna valutazione finora

- Permaglide Glijlagers LRDocumento76 paginePermaglide Glijlagers LRVitor GodoyNessuna valutazione finora

- Study of CNC Lathe MachineDocumento18 pagineStudy of CNC Lathe MachineGODWIN GNessuna valutazione finora

- Dayco-Timing Belt Training - Entrenamiento Correa DentadaDocumento9 pagineDayco-Timing Belt Training - Entrenamiento Correa DentadaDeiby CeleminNessuna valutazione finora

- Drive Components CatalogDocumento720 pagineDrive Components CatalogAbadNessuna valutazione finora

- Arena Basic Functional Training Manual - R75.1 - June2021Documento334 pagineArena Basic Functional Training Manual - R75.1 - June2021Nori Sri SouryNessuna valutazione finora

- Training at CaparoDocumento36 pagineTraining at Caparopilaniabhupesh_81404Nessuna valutazione finora

- GD&T Training BrochureDocumento5 pagineGD&T Training BrochurePritam PolekarNessuna valutazione finora

- Boston ReducersDocumento356 pagineBoston ReducersVicente Banda ZuñigaNessuna valutazione finora

- 2nd UnitDocumento60 pagine2nd UnitPradeepvenugopalNessuna valutazione finora

- Berg The Theory and Application of Precision Mechanical Components 1965 PDFDocumento177 pagineBerg The Theory and Application of Precision Mechanical Components 1965 PDFAndré PonceNessuna valutazione finora

- Design Guide - Stepper Motor Linear Actuators 101Documento16 pagineDesign Guide - Stepper Motor Linear Actuators 101DerekNessuna valutazione finora

- Tolerance Variance Analysis WP PDFDocumento22 pagineTolerance Variance Analysis WP PDFNirmalan GanapathyNessuna valutazione finora

- Optibelt Industrial Power Transmission CatalogDocumento192 pagineOptibelt Industrial Power Transmission CatalogNarcisNessuna valutazione finora

- GD&TDocumento74 pagineGD&Tgary311098Nessuna valutazione finora

- Ch-8.2 Screw Thread ManufacturingDocumento18 pagineCh-8.2 Screw Thread ManufacturingPrateek Bayal0% (2)

- Geometric Dimensioning and TolerancingDocumento30 pagineGeometric Dimensioning and TolerancingLenti TiborNessuna valutazione finora

- Rotex InchDocumento31 pagineRotex InchDwi Hermanto SetiawanNessuna valutazione finora

- Timingbelts PDFDocumento45 pagineTimingbelts PDFIndra DamarNessuna valutazione finora

- Connecting Rod FailureDocumento4 pagineConnecting Rod FailureaxleburnerNessuna valutazione finora

- Reaction Injection MoldingDocumento8 pagineReaction Injection MoldingAmeer_Takashim_9385Nessuna valutazione finora

- Snap - Fits Design Guide by DistrupolDocumento4 pagineSnap - Fits Design Guide by DistrupolNeleNessuna valutazione finora

- Gam Spiral Bevel Gearbox CatalogDocumento75 pagineGam Spiral Bevel Gearbox CatalogServo2GoNessuna valutazione finora

- Du Dub PDFDocumento55 pagineDu Dub PDFSURESH100% (1)

- Bearing Types-Mechanical EngineersDocumento26 pagineBearing Types-Mechanical EngineersGadNessuna valutazione finora

- Berger Lahr - Linear Tables PDFDocumento16 pagineBerger Lahr - Linear Tables PDFofanNessuna valutazione finora

- FrigosorbDocumento1 paginaFrigosorbValentin LupascuNessuna valutazione finora

- Silko Blast ChillersDocumento7 pagineSilko Blast ChillersValentin LupascuNessuna valutazione finora

- Chilling FoodDocumento9 pagineChilling FoodValentin LupascuNessuna valutazione finora

- Heatcraft Condensing UnitsDocumento12 pagineHeatcraft Condensing UnitsValentin LupascuNessuna valutazione finora

- Refrigeration Theory PDFDocumento48 pagineRefrigeration Theory PDFValentin LupascuNessuna valutazione finora

- Engine Driven RefrigerationDocumento2 pagineEngine Driven RefrigerationValentin LupascuNessuna valutazione finora

- Centrifugal Fans GREENHECKDocumento10 pagineCentrifugal Fans GREENHECKValentin LupascuNessuna valutazione finora

- Plastic Hinge Length and Depth For Piles in Marine Oil Terminals Including Nonlinear Soil PropertiesDocumento10 paginePlastic Hinge Length and Depth For Piles in Marine Oil Terminals Including Nonlinear Soil PropertiesGopu RNessuna valutazione finora

- SemDocumento583 pagineSemMaria SantosNessuna valutazione finora

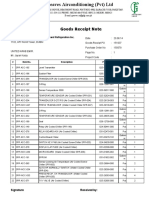

- Goods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateDocumento4 pagineGoods Receipt Note: Johnson Controls Air Conditioning and Refrigeration Inc. (YORK) DateSaad PathanNessuna valutazione finora

- Capacity Analysis of Kashmir Highway IslamabadDocumento71 pagineCapacity Analysis of Kashmir Highway Islamabadm saadullah khanNessuna valutazione finora

- Aristotle Metaphysics Lambda Accessed 201111 Classicalk LibraryDocumento19 pagineAristotle Metaphysics Lambda Accessed 201111 Classicalk Librarygijsbo2000Nessuna valutazione finora

- Emcee Script For Recognition DayDocumento3 pagineEmcee Script For Recognition DayRomeo Jr. LaguardiaNessuna valutazione finora

- Empowerment Technology Lesson 4 PDFDocumento18 pagineEmpowerment Technology Lesson 4 PDFqueenless eightyoneNessuna valutazione finora

- MidsemDocumento6 pagineMidsemAravind SomasundaramNessuna valutazione finora

- CUIT 201 Assignment3 March2023Documento2 pagineCUIT 201 Assignment3 March2023crybert zinyamaNessuna valutazione finora

- CKRE Lab (CHC 304) Manual - 16 May 22Documento66 pagineCKRE Lab (CHC 304) Manual - 16 May 22Varun pandeyNessuna valutazione finora

- KSP Solutibilty Practice ProblemsDocumento22 pagineKSP Solutibilty Practice ProblemsRohan BhatiaNessuna valutazione finora

- Sensor de Temperatura e Umidade CarelDocumento1 paginaSensor de Temperatura e Umidade CarelMayconLimaNessuna valutazione finora

- Biosynthesis and Characterization of Silica Nanoparticles From RiceDocumento10 pagineBiosynthesis and Characterization of Silica Nanoparticles From Riceanon_432216275Nessuna valutazione finora

- 19 71 Hydrologic Engineering Methods For Water Resources DevelopmentDocumento654 pagine19 71 Hydrologic Engineering Methods For Water Resources DevelopmentMartha LetchingerNessuna valutazione finora

- Per Dev Dlp-1-2 - 3 SelfDocumento6 paginePer Dev Dlp-1-2 - 3 SelfMonisa SocorinNessuna valutazione finora

- Summative Test in Foundation of Social StudiesDocumento2 pagineSummative Test in Foundation of Social StudiesJane FajelNessuna valutazione finora

- FPGA Implementation For Humidity and Temperature Remote Sensing SystemDocumento5 pagineFPGA Implementation For Humidity and Temperature Remote Sensing SystemteekamNessuna valutazione finora

- 2011 Frequency AllocationsDocumento1 pagina2011 Frequency Allocationsculeros1Nessuna valutazione finora

- Combinational Logic-Part-2 PDFDocumento25 pagineCombinational Logic-Part-2 PDFSAKSHI PALIWALNessuna valutazione finora

- SD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore FacilitiesDocumento33 pagineSD-NOC-MAR-202 - Rev00 Transfer of Personnel at Offshore Facilitiestho03103261100% (1)

- Turbine Start-Up SOPDocumento17 pagineTurbine Start-Up SOPCo-gen ManagerNessuna valutazione finora

- 00.diesel Engine Power Plant Design PDFDocumento4 pagine00.diesel Engine Power Plant Design PDFmardirad100% (1)

- T54125ADocumento64 pagineT54125ARaúl FroddenNessuna valutazione finora

- Bombas KMPDocumento42 pagineBombas KMPReagrinca Ventas80% (5)

- Use The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficeDocumento5 pagineUse The Analysis ToolPak To Perform Complex Data Analysis - Excel - OfficedakingNessuna valutazione finora

- TinkerPlots Help PDFDocumento104 pagineTinkerPlots Help PDFJames 23fNessuna valutazione finora

- The Data Driven AuditDocumento34 pagineThe Data Driven AuditMon compte Mon compteNessuna valutazione finora

- Mathematics4 q4 Week4 v4Documento11 pagineMathematics4 q4 Week4 v4Morales JinxNessuna valutazione finora

- GE Uno Downlight Backlit BLDocumento2 pagineGE Uno Downlight Backlit BLChen KengloonNessuna valutazione finora

- QSMT Chapter 1Documento5 pagineQSMT Chapter 1Rachelle Mae SalvadorNessuna valutazione finora