Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2.26 Cofined Space

Caricato da

Mohamed Mouner0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

14 visualizzazioni12 pagineConfined space

Copyright

© © All Rights Reserved

Formati disponibili

PDF o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoConfined space

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

14 visualizzazioni12 pagine2.26 Cofined Space

Caricato da

Mohamed MounerConfined space

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF o leggi online su Scribd

Sei sulla pagina 1di 12

ess SAFETY SAFETY AND HEALTH

JA MANAGEMENT SYSTEM (5-STAR)

2.26 CONFINED SPACE

First Version

August 10" 2017 OHSAS

Adoption by:

faa

Khalaf Alrashdan ‘Ziyad M. Al Shiha

Industrial Security ED CEO of Saudi Electricity Co.

Sx S-STAR SAFETY.

Contents

1 PURPOSE .

2 SCOPE vor

8 DEFINITIONS «occ.

4 RESPONSIBILITY AND ACCOUNTABILITY ....

5 COMPETENT AND AUTHORIZED PERSONNEL

6 CONFINED SPACE IDENTIFICATION ..

7 CONFINED SPACE REQUIREMENTS .

8 WORK INSIDE CONFINED SPACES..

9, MEDICAL FITNESS ..

10 TRAINING AND COMPETANCY ....::.ecssesssseses

11 RECORDS & DOCUMENT RETENTION ......

12 WORK FLOW aos sesneseeen

1 APPENDIX ..

Appendix A - Example: Confined Space Register

Appendix B - Summary for Work Flow for Confined Space Entry

2.8 Risk Assessment | Safety & Health Management System (5-Star)

sox

SEC 5-STAR SAFETY

DA

1 Purpose

This guideline establishes salety requirements and standards that needto be applied before any work is

performed in confined spaces 60 that the risks associated with contined spaces are assessed. that contol

Measures are implemented in accordance withthe hierarchy of controls and those measures are taken to

prevent injury, illness and isease to persons who might be expased torisks arising from those activites in

Saudi Electrical Company and all companies that belong tot,

2Scope

This Element applies to all employees (direct hire and contractors working under direct supervision) at all Sauci

Electrical Company Entities, as well as Visitors (Orientation only). All Confined Space Entry work shall meet the

requirements as set forth in this standard,

3 Definitions

Acceptable entry conditions - means the conditions that shall exist in a confined space to allow entry and to

ensure that authorized entrant can safely enter into and work within the confined space.

‘Asphyxiant gases - means gases thal can cause unconsciousness or death by suffocation through direct

‘oxygen displacement (physical asphyxiant or interference with the body’ ably lo absorb of transport oxygen

to the tissues (chemical asphyxiant).

Competent person - means any person who has in respect ofthe work or task tobe performed the required

knowledge, training and experience and, where applicable, qualifications, speciic to that work or task.

Confined space entry programme - means the authorized manager's overaf programme for controling and,

here appropriate, for protecting his employees from confined space hazards and for regulating employee's

entry into confined spaces.

Confined space - means an enclosed or partially enclosed space that is at atmospheric pressure during

Ceccupancy and is nol intended or designed primarily as a place of work, and ~

‘) slab at any time to ~

(iy have an atmosphere which contains potentially harmful levels of contaminants;

{ij nave an oxygen detcianey or excess; or

(i) cause enguliment; and

b) could have restricted means for entry and exit

Explosive (flammable) range - means the cange of flammable vapour.air or gas-air mixture between the Lower

Explosive Limit (LEL) and Upper Explosive Limit (VEL).

Forced air ventilation - means the use of mechanical devices, such as fans or air movers (ventures), to

produce a safe atmosphere within a confined space.

Hazardous atmosphere - means almosphere that may expose employees to the risk of death, incapecitation,

impairment of abilty to se-rescue (thal is e=cape unaided from a confined space), injury or acute illness from

Cone or more ofthe following causes —

b) oxygen content below 19.5 % or above 23.6 % by volume (al sea level)

©) accumulation o flammable or explosive gas greater than 10 % ofits LEL;

4d) accumulation of oxic gas equal to or exceeding is permissible exposure limit (PEL); or

e) any other atmospheric condition that is immediately dangerous to life or health (|DLH)

Hot work - means fire, heat ar spark producing operation such as welding, thermal or oxygen culting, grinding,

dling, blasting, heating and deaning operation using high temperature steam.

Inert atmosphere - means an atmosphere with high level of asphyxiant gases, which contain litle or no oxygen

and primarily consist of inert or nen-reaclive gases or gases that have a high threshold before they react.

Medical certificate of fitness - A medical cerificate of fitness issued by a medical practitioner,

Permit to work - means the vilten ex printed document that is provided by the authorized manager to allow

and control entry into a confined space.

Permit system - moans the SEC Business Units specific writen procedures for proparing and issuing permits

{or entry and for returning the confined space to service folowing termination of entry.

Prohibited condition. means any condition in a confined space that is rot allowed by the permit during the

period when entry is authorized.

Purging - means the method by which the contaminants are displaced f"0m a confined space;

Rescue services - means the service provided by a trained team to rescue persons from confined spaces;

Shall - The term *shall” as used in this document is intended to desorbe the mandatory requirements,

2.8 Risk Assessment | Safety & Health Management System (5-Star) 2-11

sia

SEC 5-STAR SAFETY

A

4 RESPONSIBILITY AND ACCOUNTABILITY

4.1 Saudi Electricity Company, its subsidiaries, and contractors shall teke all reasonably practicable steps to

prevent confined space entry incidents. The delegated manager shall be responsible for safaty and health

intheir designated area of responsibilty

4.2 Each Department, Division, Aliate, Subsidiary and Contractor shall develop and implement management

systems thal accomplish the requirements of this standard in accordance with the SEC 5 Star Safety

Management System Element requirements,

4.3 Position(s) shall be assigned by the SEC Department, Divisions, Affliates, Subsidiaries and Contractor

‘management with the responsibilty to ensure compliance of this standard in accordance with 5 Star Safety

Management System Element §.1 Manager/Managers designated as Responsible for Health and Safety.

4.4 Roles and responsibilities of al other positions/funetions that are responsible to support implementation of

this Element shall be clearly identified, documented and communicated.

4.8 Supervisors shall ensure all employees are familiar wih confined spaces and those who are required to

work in the confined spaces are trained and competent with this procedure and lead by example in the

correct application and enforcement of the procedure,

4.5 No person shall enter a confined space unless they have read, understood the requirements and signed

‘onto a permit for entry held by the supervisor of the work. Every person shall sign off the permit immediately

upon leaving the confined space.

5 COMPETENT AND AUTHORIZED PERSONNEL,

5.1 Competent Person: An employee who by virtue of training and expeienee is capable of authorizing

Confined Space entry, determining atmospheric conditions, and validating an entry permit. This

authorization is delegated by site management and shall also include the authority to cancel or terminate

teniry at his or her discretion if hazardous conditions arise or are suspected.

5.1 Permit issuer — An employee who is trained as an entry supervisor and an authorized gas tester, and

authorized by the manager to issue and close the permit lo work. He cannot be the same person who

‘supervises the confined space entry activity,

5.2 Confined Space Attendant (also referred to as "standby personnet’): An employee trained in basic rescue

techniques, hazard recognition, communication methods, and contra of Confined Space entrants,

5.8 Confined Space Worker/Entrant: An employee authorized to workin a Confined Space who has received

‘appropriate training fo perform his or her assigned duties under the entry permit program. Entrants shall be

provided the opportunity witness atmosphere monitoring and equipment calibration data,

5.4 Rescue Team: A team of rescue personnel, either in-plant or members of an outside organization, with

the responcibilty to respond to Confined Space emergencies and perform advanced rescue ff and when

required.

6 CONFINED SPACE IDENTIFICATION

Each location shail identify by definition, any confined space and erect signs at the entry points denoting

that itis a confined space - "DANGER --- CONFINED SPACE. 00 NOT ENTER”, or using other similar

meaning and in both Arabic and English, and that a permit is required prior to entry. Where signage is

impractical, other means of highlighting the dangers need to be used or the space needs to be locked to

prevent inadvertent entry

A confined space register shall be developed and maintained al each facilly, site and project where any

confined space has been identified. Appendix 1- Example Confined Space Register.

2.8 Risk Assessment | Safety & Health Management System (5-Star) 3-11

ee

A

7 CONFINED SPACE REQUIREMENTS

7.4 Confined Space Entry Program

‘confined space entry program and procedures shall be develop, documented and communicated by the

authorized manager fo all employees that enter of work at Identified confined spaces. Appendix 2- Flow

Chart ‘Summary of Procedures for Confined Space Entry’ can assist in its development.

7.2 Risk Contral Measures

Prior to any person entering a confined space, the responsible manager, supervisor, aré person in contro!

‘of the work shal jointly undertake a risk assessment line with the 5 Slar Safely Management System GI2.8

Risk Assessment.and ensure that where practicable all potential hazatds are adequately controlled:

‘+ If there may be a risk fo the health and safely of persons cecupying the canfined space or working upon

its surface; or

‘+ No entry is ta be made and no work Is to be carried out within a confined space or upon the outside

surface of @ confined space:

+ When a risk of fire or explosion exists,

‘+ Subject to review ofthe risk assessment responsible person shall authorise the confined spaces entry

Permit for wark in a confined space being castied aut, in accordance withthe following Confined Space

entry process:

1) Initiate the Confined Space entry permit and issue relevant instructions;

2) Isolate the Confined Space and release eny stored energies:

3) Lock and Tag out

4) PurgoWventilate and atmospherically test the Confined Space (where necessary);

5) Check that all nazardous energies are either controls or etminated;

6) Complete the Confined Space entry permit

7) Inform perscanel atthe Confined Space enity requirements;

8) Displayed the entry permit in a prominent place to facilitate sigring and clearance;

9) Barvicaded and display appropriate signage and danger tags;

10) Standby person is avaiable and in place:

11) Communication equipment is working;

12) Enlty to the Confined Space is permitted and work or actviyis performed and completed;

13) All personne! leave the Confined space and remove thai personal Lock and Danger Tag ote.

14) Final inspection and the ‘all clea’ given forthe Confined Space to relurn to service

The entry permit shall state the period ofits validity and shall be revaldated whenever it becomes evident

that the duration of work will involve one of the following:

‘+ Acchange in the person responsible forthe direct control of the work in a confined space;

+ A.significant break in work continuity; and

+ Assigniticant change in atmosphere or work to be performed,

Atmospheric testing and monitoring is to be carried out consistent with the hazards identified and the risk

assessment

A copy should be retained by the Site Manager.

Business Units shall apply their specific Permit to Work Systems in line with the requitements of the 5 Star

Salety Management System GI5.21 Mechanical Work Permit and Gi §.21.1 Electrical Work Permit.

2.8 Risk Assessment | Safety & Health Management System (5Star) ait

. '5-STAR SAFETY

Contractors shall comply with the business unit Confined Space eniry permit to work requitements

7.8 Safe System of Work

Sate systems of work shall be developed for all confined space erties. The authorized manager is

responsible to develop, implement and communicated the system to af personnel involved in contined

space entry and relevant stakeholders. To be effective, a safe system of work needs tobe in writing, in he

form ef a procedure and flowchart and communicated and understood.

Specific safe work method statements or procedures shall be developed for work activities that are more

hazardous when cesried out in.a confined space than elsewhere. These activities would include hot work

(cutting and welding), chemical cleaning, steam cleaning and abrasive blasting.

cua +

Fane Exact

f

7.4 Appointment of supervisor

‘Supervisors shall be appointed to oversee all confined space work. I is thelr responsibilty to ensure all the

necessary precautions are taken and that the safe system of works being followed. It is the responsibilty of

the relevant manager to appoint a suitably trained and experienced supervisor.

The degree of supervision will be based on the findings of the rise assessment. In some cases, periodic

‘checks may be sufficient ifthe work is low risk and routine.

It is more likely that the level of risk wil require a competent person to supervise the work and remain

present while the work is being undertaken.

7.5 Communications

‘The responsible person shall ensure that communication and, where practicable, observation belween

those in the confined space and the slana-by person(s) are capable of being constantly maintained.

‘Communication can be achieved, dependent on the conditions existing in the confined space, in a number

cof ways, including voice, radio, hand signals and other appropriate means, For example, where visual or

‘ral communication is not possible, then a system of rope signals could be devised.

Microwave, long wave or low frequency radio equipment can be used in some confined spaces where

normal radio is unsuitable,

Equipment to be used in potentially flarnmable or explosive atmospheres shall be specially protected so

they do not present a source of ignition.

2.8 Risk Assessment | Safety & Health Management System (5-Star) 5-11

Sit SAFETY

DA

7.6 Testing the air and provision of ventilation

The risk assessment may highlight a need to check that the atmosphere is free from both toxic and

flammable vapors and that there is an adequate concentration of oxygen prior o entry. A competent person

Using @ suitable gas detector, which is correctly calibrated, shal cary cut testing. Where the risk

assessment indicates that conditions may change, or as a further precaution, continuous monitoring of the

air may be necessary. Test results shall be recorded on the permit i enter.

Note: The acceptable oxygen concentration range is between 19.5% and 21%, Work shall not be

undertaken if the oxygen concentration is outside this range.

‘Where itis not practicable to provide a safe oxygen level, or atmospheric contaminants cannot be

measured at or reduced to safe levels, no person is to enter the confined space unless they are equipped

wilh suitable personal protective equipment including air supplied respiratory protective equipment.

7.7 Isolation requirements

All potentially hazardous energy sources such as electrical, mechanical, hydraulic, pneumatic, chemical, or

thermal shall be de-energized and locked out prior to entry to the canfined space so that equipment cannot

be tuned on accidentally. Refer to the 5 Star Safety Management System GI 2.2 Lock Out /Tag Out/ Try

‘Out for requirements of isolating energy sources.

Business units shall apply their spectic Log Out/ Tag Out system where relevant. C

Contractors shall comply with the business unit requirements for Log Out / Tag Out

7.8 Emergency Arrangements

No confined space work shall be undertaken unless there are formal written emergency plans in place for

the rescue of persons in an emergency. Account needs to be taken not only of accidents arising out of

specified risks, but also any other accident in which a person may need to be recovered.

To be suitable and sulficient, rescue shall include consideration of:

+ Rescue and resuscitation equipment;

Raining the alarm and rescue;

Safeguarding the rescuer,

Fire safety;

Controt of plant;

First aid;

Public emergency services;

Training,

itis the responsiblity of the relevant manager to ensure an assessment of the emergency requirements has

been made. It is the supervisor's responsibiliy to ensure any measures deemed necessary are in place and.

tested prior to any confined space entry.

7.8.4 Retrieval System

Each authorized entrant shall wear a full body harness with a retrieval line attached except as modified

below:

+ The retrieval line does not have to be altached to the entrant if t would increase the overall risk of

teniry or would not contribute to the rescue of the entrant. However, precautions shall be taken so

that the task can be performed as safely as without the retrieval line.

+ Wristlats can be used ifthe location determines the use of ahamess is infeasible or creales a

greater hazard,

Note: A retrieval line shall always be used by and attached to the salety hamoss of each authorized entrant

tentering the confined space where a hazardous atmosphere or a potential for engulfment is determined to

exist.

2.8 Risk Assessment | Safety & Heath Management Sytem (5Star) oa

y i 'S-STAR SAFETY

‘Amechanical device shall be readily available to retrieve personnel from vertical-type confined spaces more

than 5 feet deep.

8 WORK INSIDE CONFINED SPACES.

8.1 Electrical Equipment

+ Portable electric equipment and lighting used in confined spaces shall be operated at 18 volts ot

less.

‘+ 110-volt equipment and lights may be used if protected by a ground-fault circuit interrupter (GFCI)

which is positiened outside the confined space. Portable lights outfited with protective guards over

the bulbs shall be provided.

‘+ When a step-down transformer is used, the transformer shall be left outside the space.

‘+ Inaddition, the equipment shall be fitted with a flexible supply cable of heavy-duty type. Cables

shall be located, suspended or guarded to minimize accidental damage.

Where a flammable atmosphere is tkely to exist, all portable electrical equipment euch as lamp, torch light

and other electrical instruments shall be explosion proof and intrinsically safe

8.2 Hot Work

+ Hot work in, or on the exterior surfaces of, an occupied confined space shall not commenced until a

hot work permit has been issued and shail be performed in accordance with the Business Unit "Hot

Work Procedure’

+The hot work permit shall cetty that appropriate precautions have been carried out and lst the

frequency of any tests necessary to ensure that safe conditions are maintained.

‘+ When the confined space or a space adjacent thereto has contained a flammable liquid, vapor or

{gas the permit shall only be issued ater inspection and testng have ensured that the following

factors have been considered:

‘9 The concentration of flammable vapors or gases in the atmosphere:

‘©The liquid and solid residues have been removed as necessary to prevent the release of

flammable substances that will raise the concentration of iammable substances in the

atmosphere; and

‘©The concentration of flammable vapor or gas within any piping within the confined space or

connected to it

‘+ Welding and burning equipment, other than torches, hoses, and electrical welding leads, shall not

'be taken into the confined space. The gas cylinders or welding machines shall be left outside of the

‘space and chocked if on wheels

‘+ Ensure all leads that shall enter vessels and tanks are routed through a nozzle or opening other

than the access, wherever possible.

‘+ When gas cutting or welding is no longer needed on the job, or ifthe job is to be left unattended for

an extended period of time, the gas supply shal be cut off at the cylinders. If hoses are left running

into the confined space, they shall then be disconnected from the gauges and properly sisted, to

prevent tripping hazards and hose damage.

‘+ Open-end fuel, gas and oxygen hoses shall be immediately removed from the space when they are

disconnected from the torch or other gas-consuming device,

‘+ The lookout shall be instructed on how to quickly secure arc and oxy-acetylene welding equipment

in case this equipment is involved in an accident inside the space.

‘+ Only appropriate tools and equipment for the work being done and the potential hazards present

may be used (i.e. explosion-proof, air-operated, non-sparking).

8.3 Bonding and Grounding

To reduce the possibiity of static electricity build up, when using electrical and other equipment

2.8 Risk Assessment | Safety & Health Management System (5-Star) Ta

pe 5-STAR SAFETY

proper bonding and grounding procedures shail be followed,

8.4 Ventilation

Hf welding is required in @ Confined Space, mechanical ventiation may be required that can provide an

‘adequate volumetric rato of fresh arin the vicinity of the workers) 4

‘The ventilation power supply shall be tagged with an Information Tag to prevent accidental disconnection.

Mechanical ventilation systems, where applicable, shall be set at 1C0% outside air. Where possible, open

‘additional manholes to increase air circulation. Use portable blowers augment natural ciculation i

needed.

Alter a suitable ventilating period, repeat the testing. Entry sha not begin unt testing has demonstrated

that the hazardous atmosphere has been eliminated,

8.5 Personal Protective Equipment

Personal protective equipment such as goggles, respirators, boots, hardhats, gioves, and protective clothing

shall be worn when the entry supervisor determines them necessary

If tests indicate that the confined space contains a hazardous atmosphere, employees shall not enter unless.

authorized by their entry supervisor and then only if wearing appropriate respiratory protection,

Where required, a lifeline attached to a full body harness shall be used by all entrants during entry into

and whilst inside a confined space

9. MEDICAL FITNESS.

Al authorized entrants intending to work in confined space shall be carted physically and mentally fit

determined by an occupational health doctor (OHD) t0 detect the following

+ history ofits, blackouts or fainting attacks;

+ heart disease or heart disorder;

+ chronic airway diseases such as asthma, bronchitis, or a shortness of breath on exertion;

+ deatness:

1+ Meniere's disease or disease Involving giddiness or loss of balance;

‘+ claustrophobia or other mental disorder;

‘+ neurological and Musculo-Skeletat Disorder such as back pain or joint trouble that limits mobility in

‘confined spaces;

+ condition that limit movement in confined space such as gross cbesily, pregnancy and physical

handicap;

+ metabolic diseases;

‘+ serious defect in eyesight; and

‘+ any other disease or condition that may affect or endanger the ferson’s safety and health whilst working

in contined space

Following the health surveillance, the occupational health doctor (OHD) stall issue a health fitness certificate

valid for a period not exceeding two (2) years,

2.8 Risk Assessment | Safety & Health Management System (5-Star) au

i 5-STAR SAFETY

10 TRAINING AND COMPETANCY

‘Training shail be provided to all employees drectly affected with working in confined spaces, to ensure they

acquire the competency, understanding, knowledge, and skils necessary for the safe work performance in

spaces,

Training shall be provided to every affected employee:

+ before the employee is first assigned duties under this standard,

‘+ belore there is a change in assigned duties;

‘+ whenever there is a change in confined space operations that presents a hazard which an employee

has not previously been trained; and

‘+ whenever the authorized manager has reasons to believe elther that there are deviations from the

confined space entry procedures or that there are inadequacies in the employee's knowledge or use of

these procedures,

Specialize training Is reauired for employees involved in confined-space work such as authorized entrants,

sland-by persons, authorized gas tester and entry supervisor

11 RECORD KEEPING

‘The following records shall be kept end maintained:

+ Entry permits for one month;

+The current recorded risk assessment reports for workin a confined space;

+ Training Records

‘This document shall be kept in the Safety and Health Management System (5-Star) files end made available

for auditing purposes.

12 WORK FLOW

13 APPENDIX

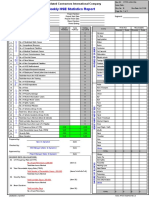

APPENDIX A ~ EXAMPLE: CONFINED SPACE REGISTER

APPENDIX B ~ SUMMARY OF WORK FLOW FOR CONFINED SPACE ENTRY

2.8 Risk Assessment | Safety & Health Management System (5-Star) 9-41

EC 5-STAR SAFETY

DA

APPENDIX A- EXAMPLE: CONFINED SPACE REGISTER

sh

1011

| wecoregorgent

| sgiemoteantence

| 38 venmnade

—

al

spaces

‘ened

pence

omens!

¥

eeccjoumausog |

Zoneds pouyjuos v eds o1n 5}

2.8 Risk Assessment | Safety & Health Management System (5-Star)

*

YSEC5-STAR SAFETY

APPENDIX B ~ SUMMARY OF WORK FLOW FOR CONFINED SPACE ENTRY

AMIN 39VdS G3NLINOD Hos SaUNGRIOd JO AUVINWNNS,

wt

2.8 Risk Assessment | Safety & Health Management System (5-Star)

Potrebbero piacerti anche

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- 1.2 Lighting Natural and ArtificialDocumento3 pagine1.2 Lighting Natural and ArtificialMohamed MounerNessuna valutazione finora

- Pp0707-Wmp-f01 Waste Log - (Non-Hazardous Waste)Documento1 paginaPp0707-Wmp-f01 Waste Log - (Non-Hazardous Waste)Mohamed MounerNessuna valutazione finora

- 1.1 Buildings and FloorsDocumento4 pagine1.1 Buildings and FloorsMohamed Mouner100% (1)

- Pp704-Sec-f08 Property Loss or Damage ReportDocumento1 paginaPp704-Sec-f08 Property Loss or Damage ReportMohamed MounerNessuna valutazione finora

- Pp704-Sec-f07 CCC Security ChecklistDocumento5 paginePp704-Sec-f07 CCC Security ChecklistMohamed MounerNessuna valutazione finora

- Pp704-Sec-f05 Material 'Loading Notes' (Waybill)Documento2 paginePp704-Sec-f05 Material 'Loading Notes' (Waybill)Mohamed MounerNessuna valutazione finora

- Pp704-Sec-f04 Stores Requisition of MaterialsDocumento2 paginePp704-Sec-f04 Stores Requisition of MaterialsMohamed MounerNessuna valutazione finora

- Hse Statistics Report Pp701 Hse f04 Rev.bDocumento1 paginaHse Statistics Report Pp701 Hse f04 Rev.bMohamed Mouner100% (1)

- Pp704-Sec-f02 Identification Badge LogDocumento2 paginePp704-Sec-f02 Identification Badge LogMohamed MounerNessuna valutazione finora

- Material Gate Pass: Security Plan Procedure Attachment No. 3Documento2 pagineMaterial Gate Pass: Security Plan Procedure Attachment No. 3Mohamed MounerNessuna valutazione finora

- 2.25 Working at HightDocumento21 pagine2.25 Working at HightMohamed MounerNessuna valutazione finora

- BACS 4 Hr. HSE Induction - FinalDocumento191 pagineBACS 4 Hr. HSE Induction - FinalMohamed MounerNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)