Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Piping Design Brochure

Caricato da

parthiv0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

125 visualizzazioni2 paginepip

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentopip

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

125 visualizzazioni2 paginePiping Design Brochure

Caricato da

parthivpip

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Celosia Technologies

Certificate Course in Piping Design Engineering

Program Overview

This is a comprehensive program which covers in depth all major

topics related to Piping Engineering with live examples

Who should attend :

B.E / Diploma in Mechanical, Chemical, Industrial Production

Duration :

6-8 weeks

What you will learn

Plant layout fundamentals.

Components used in piping systems -

fittings,flanges and valves.

Terminology and symbols used in plant layout.

Plot plans,elevations and 3D models.

Equipments used in process plants.

P&IDs.

Piping design and engineering principles.

Piping material specifications.

Piping codes.

Piping G.As isometrics and

Bill of materials.

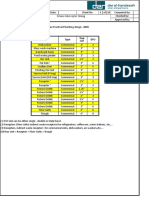

Syllabus :

Fundamentals of Plant engineering and introduction to Piping basics

Project types,Project phases,Structure of EPC engineering organization,Pipe sizes,Pipe schedule nos,Pipe

manufacturing methods,classifications and abbreviations.

Pipe fittings

Classification selection and application of elbows, tees, bends, reducers, O-lets, pipe nipples, couplings, weld caps

and plugs.

Flanges,Gaskets and bolts

Flange types and application, P-T ratings, flange facing types and applications, gasket ,bolt types and selection.

Valves

Type of valves and functions, P-T ratings, valve trim, valve materials and applicable codes.

Piping speciality items

Various type of SP items and their applications

Codes and standards

Relevant codes for piping from ASME, API, BS, AISI, ASTM, IS DIN, MSS-SP etc..

Piping and valve material specifications

Material selection, pipe wall thickness calculations, P-T ratings, branch tables and PMS applications.

Process mechanical equipments

Description of the various static and rotary equipments used in the plant with vendor drawings.

Pipe rack

Rack width considerations, pipe grouping and arrangements on the rack, future space requirements and pipe spacing.

Preparation of plot plan, equipment layout and piping GA drawings

Plot plan requirements and development, overall plot plan and unit plot plans,equipment layout

guidelines,piping GA layout guidelines,accessability maintainability and material handling considerations on

layouts,practical examples of pipe routing for various equipments.

Piping Isometrics, BOM and MTO

Preparation of isometrics,bill of materials and material take off with practical exercises.

Piping supports

Type of supports -primary, secondary, rest, anchor, line stop guide, clamp and shoe type supports, trunnion, spring

type and special type supports.

Piping stress analysis

Introduction to stress analysis and objectives, type of loads, failure theories, critical line selection criteria.

Mock project

To Enrol now : #1204, 1st Floor,

Contact : 9148769480. 9916997490 16th main, BTM layout 2nd stage,

Mail : info@celosiatech.com Near Udupi Gardens,

celosia.tech@gmail.com Bangalore - 560076.

Web : www.celosiatech.com

Potrebbero piacerti anche

- Piping DesignDocumento4 paginePiping DesignTerry YongNessuna valutazione finora

- Piping Design: Two Weeks Job Oriented Certificate Course OnDocumento8 paginePiping Design: Two Weeks Job Oriented Certificate Course OncontgautamNessuna valutazione finora

- Pipe Flange and Gaskets BasicsDocumento3 paginePipe Flange and Gaskets BasicsEhab AbowardaNessuna valutazione finora

- Job DetailsDocumento1 paginaJob DetailsvijaykmjNessuna valutazione finora

- Process Piping DraftingDocumento3 pagineProcess Piping DraftingtsplinstNessuna valutazione finora

- Master process piping design and stress analysisDocumento13 pagineMaster process piping design and stress analysisGaurav PanjwaniNessuna valutazione finora

- Process Piping Design & Construction As Per ASME B 31.3 PDFDocumento12 pagineProcess Piping Design & Construction As Per ASME B 31.3 PDFDRASTINessuna valutazione finora

- Process Piping Detailed Engineering - Design & DraftingDocumento11 pagineProcess Piping Detailed Engineering - Design & DraftingJohn Mickel100% (2)

- PG PipingMainDocumento7 paginePG PipingMainAnh Vân TrầnNessuna valutazione finora

- Imran Hussain MechanicalDocumento5 pagineImran Hussain MechanicalImran HussainNessuna valutazione finora

- Piping Engineering.nDocumento6 paginePiping Engineering.nAjay KumarNessuna valutazione finora

- PG Diploma in Piping Design and Autocad Training CourseDocumento4 paginePG Diploma in Piping Design and Autocad Training CourseWin LinnNessuna valutazione finora

- Piping Engineering Course OverviewDocumento2 paginePiping Engineering Course Overviewmayur_lanjewar0% (1)

- Introduction to Piping Design FundamentalsDocumento44 pagineIntroduction to Piping Design FundamentalsSairaj JakalNessuna valutazione finora

- Introduction To Piping Design CourseDocumento91 pagineIntroduction To Piping Design CourseSayed Abo ElkhairNessuna valutazione finora

- Sylabus For Piping TrainingDocumento5 pagineSylabus For Piping TrainingDilip YadavNessuna valutazione finora

- Depps - Abu DhabiDocumento10 pagineDepps - Abu Dhabiamli22Nessuna valutazione finora

- PG Diploma in Piping Design, Engineering & ConstructionDocumento7 paginePG Diploma in Piping Design, Engineering & Constructionagata_101Nessuna valutazione finora

- CERTIFICATE COURSE IN PIPING DESIGNDocumento2 pagineCERTIFICATE COURSE IN PIPING DESIGNparthivNessuna valutazione finora

- Plant Layout and IsometricDocumento46 paginePlant Layout and IsometricJenny Azzahra100% (1)

- Piping DesigningDocumento28 paginePiping DesigningAnil PalNessuna valutazione finora

- STATIC EQUIPMENT AND PRESSURE VESSEL DESIGN COURSE CONTENTSDocumento3 pagineSTATIC EQUIPMENT AND PRESSURE VESSEL DESIGN COURSE CONTENTSPrasanna kumar subudhiNessuna valutazione finora

- Process Piping Design & EngineeringDocumento4 pagineProcess Piping Design & Engineeringtibi1000Nessuna valutazione finora

- Institute of Structural EngineeringDocumento2 pagineInstitute of Structural EngineeringSuvidya Institute of TechnologyNessuna valutazione finora

- CV Firdaus 2011Documento4 pagineCV Firdaus 2011KakDausNessuna valutazione finora

- MD Shahnawaz: About MeDocumento4 pagineMD Shahnawaz: About Memohammad shameer mallickNessuna valutazione finora

- Be An Expert in Piping Design & LayoutDocumento40 pagineBe An Expert in Piping Design & LayoutSathish100% (3)

- Process Design & EngineeringDocumento14 pagineProcess Design & Engineeringramms_73100% (2)

- Piping Design and Detailed EngineeringDocumento3 paginePiping Design and Detailed EngineeringsdNessuna valutazione finora

- Gujarat Technological University: W.E.F. AY 2018-19Documento3 pagineGujarat Technological University: W.E.F. AY 2018-19Hardik SonvaneNessuna valutazione finora

- To Be A Piping Designer You Should KnowDocumento7 pagineTo Be A Piping Designer You Should KnowQusroo AhmedNessuna valutazione finora

- V Logidasan-Piping DesignDocumento7 pagineV Logidasan-Piping DesignRanjith KumarNessuna valutazione finora

- Mechanical Engineer with 3+ years experience seeking challenging positionDocumento6 pagineMechanical Engineer with 3+ years experience seeking challenging positiondavidgeorge143Nessuna valutazione finora

- Piping Design CourseDocumento5 paginePiping Design CourseClaudio SotoNessuna valutazione finora

- Piping EngineeringDocumento5 paginePiping Engineeringpriyampatel21Nessuna valutazione finora

- Sam SurendranDocumento2 pagineSam SurendranSumantrra ChattopadhyayNessuna valutazione finora

- Certificate in Process Plant Layout & Piping DesignDocumento3 pagineCertificate in Process Plant Layout & Piping DesignShamsol AriffinNessuna valutazione finora

- Process Piping Design & Engineering Per ASME B 31.3Documento16 pagineProcess Piping Design & Engineering Per ASME B 31.3naveenbaskaran1989Nessuna valutazione finora

- Amit Nayak Resume - Technical Lead Piping - 07.12.23Documento5 pagineAmit Nayak Resume - Technical Lead Piping - 07.12.23Sumantra ChattopadhyayNessuna valutazione finora

- Piping EngineeringDocumento2 paginePiping EngineeringSuvidya Institute of TechnologyNessuna valutazione finora

- Resume - Soham Mukhopadhyay PDFDocumento5 pagineResume - Soham Mukhopadhyay PDFArup NaskarNessuna valutazione finora

- Production Engineering: Jig and Tool DesignDa EverandProduction Engineering: Jig and Tool DesignValutazione: 4 su 5 stelle4/5 (9)

- Reflow Soldering: Apparatus and Heat Transfer ProcessesDa EverandReflow Soldering: Apparatus and Heat Transfer ProcessesNessuna valutazione finora

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDa EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsDa EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNessuna valutazione finora

- Which Process?: A Guide to the Selection of Welding and Related ProcessesDa EverandWhich Process?: A Guide to the Selection of Welding and Related ProcessesNessuna valutazione finora

- Design of Steel-Concrete Composite Structures Using High-Strength MaterialsDa EverandDesign of Steel-Concrete Composite Structures Using High-Strength MaterialsNessuna valutazione finora

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADa EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANessuna valutazione finora

- The Engineer's Guide to Plant Layout and Piping Design for the Oil and Gas IndustriesDa EverandThe Engineer's Guide to Plant Layout and Piping Design for the Oil and Gas IndustriesValutazione: 4 su 5 stelle4/5 (16)

- Advances in Additive Manufacturing ProcessesDa EverandAdvances in Additive Manufacturing ProcessesNessuna valutazione finora

- 3D Concrete Printing Technology: Construction and Building ApplicationsDa Everand3D Concrete Printing Technology: Construction and Building ApplicationsNessuna valutazione finora

- Arctic Pipeline Planning: Design, Construction, and EquipmentDa EverandArctic Pipeline Planning: Design, Construction, and EquipmentNessuna valutazione finora

- Grease interceptor sizing calculation sheetDocumento12 pagineGrease interceptor sizing calculation sheetparthivNessuna valutazione finora

- Remove Oil Grease Water 40Documento6 pagineRemove Oil Grease Water 40Sai PrasathNessuna valutazione finora

- Fawsec Campus-Plum&FP Calc1Documento26 pagineFawsec Campus-Plum&FP Calc1parthivNessuna valutazione finora

- Plumbing FixturesDocumento15 paginePlumbing FixturesparthivNessuna valutazione finora

- Fire Training ManualDocumento72 pagineFire Training ManualDQueen WarDhaniNessuna valutazione finora

- Optimize Plumbing Calculations for Sump Pits, Ejector PumpsDocumento83 pagineOptimize Plumbing Calculations for Sump Pits, Ejector PumpsparthivNessuna valutazione finora

- Spetic and Perculating Pit Calc.Documento1 paginaSpetic and Perculating Pit Calc.كرم عمروNessuna valutazione finora

- Pressure Drop & Water HeatersDocumento22 paginePressure Drop & Water HeatersparthivNessuna valutazione finora

- Design Data BaseDocumento17 pagineDesign Data BaseparthivNessuna valutazione finora

- Water Dosing Calculation BookDocumento12 pagineWater Dosing Calculation BookSugumar Panneer SelvamNessuna valutazione finora

- Mannings Formula SpreadsheetDocumento18 pagineMannings Formula SpreadsheetparthivNessuna valutazione finora

- Discussion Paper Fixture Unit Rating Systems July 2015Documento2 pagineDiscussion Paper Fixture Unit Rating Systems July 2015parthivNessuna valutazione finora

- Pressure Drop & Water HeatersDocumento22 paginePressure Drop & Water HeatersparthivNessuna valutazione finora

- Booster 1Documento5 pagineBooster 1NghiaNessuna valutazione finora

- CL - Petece Enviro Engineers PDFDocumento2 pagineCL - Petece Enviro Engineers PDFparthivNessuna valutazione finora

- Discussion Paper Fixture Unit Rating Systems July 2015Documento5 pagineDiscussion Paper Fixture Unit Rating Systems July 2015parthivNessuna valutazione finora

- Product Information For The Product Group: (Parkdeckabläufe Aus Gusseisen)Documento2 pagineProduct Information For The Product Group: (Parkdeckabläufe Aus Gusseisen)parthivNessuna valutazione finora

- U02 Manual: RevisionDocumento8 pagineU02 Manual: RevisionparthivNessuna valutazione finora

- Grundfosliterature 4055021Documento32 pagineGrundfosliterature 4055021parthivNessuna valutazione finora

- U02 Manual: RevisionDocumento8 pagineU02 Manual: RevisionparthivNessuna valutazione finora

- Australian Building Code Board discusses updating fixture unit rating systemsDocumento66 pagineAustralian Building Code Board discusses updating fixture unit rating systemstehtehtehNessuna valutazione finora

- Eaching High-Rise Plumbing DesignDocumento19 pagineEaching High-Rise Plumbing Designm_salah20202000Nessuna valutazione finora

- MEP Design ReviewDocumento1 paginaMEP Design ReviewparthivNessuna valutazione finora

- Unilift KP 150, KP 250, KP 350: Installation and Operating InstructionsDocumento14 pagineUnilift KP 150, KP 250, KP 350: Installation and Operating InstructionsparthivNessuna valutazione finora

- Product Information For The Product Group: (Parkdeckabläufe Aus Gusseisen)Documento2 pagineProduct Information For The Product Group: (Parkdeckabläufe Aus Gusseisen)parthivNessuna valutazione finora

- Product Information For The Product Group: (Parkdeckabläufe Aus Gusseisen)Documento2 pagineProduct Information For The Product Group: (Parkdeckabläufe Aus Gusseisen)parthivNessuna valutazione finora

- Water Dosing Calculation BookDocumento12 pagineWater Dosing Calculation BookSugumar Panneer SelvamNessuna valutazione finora

- Fire protection system updates KSA plantDocumento16 pagineFire protection system updates KSA plantparthivNessuna valutazione finora

- Water Softener CalculationsDocumento1 paginaWater Softener CalculationsparthivNessuna valutazione finora

- Grease interceptor sizing calculation sheetDocumento12 pagineGrease interceptor sizing calculation sheetparthivNessuna valutazione finora

- 6 Acop v. OmbudsmanDocumento1 pagina6 Acop v. OmbudsmanChester Santos SoniegaNessuna valutazione finora

- Node NO Slot NO CH No. Tag Name Address Signal Description: All Valve Fault Take From LogicDocumento103 pagineNode NO Slot NO CH No. Tag Name Address Signal Description: All Valve Fault Take From Logicash_captchajobsNessuna valutazione finora

- 2011 REV SAE Suspension Kiszco PDFDocumento112 pagine2011 REV SAE Suspension Kiszco PDFRushik KudaleNessuna valutazione finora

- ID Analisis Persetujuan Tindakan Kedokteran Informed Consent Dalam Rangka Persiapan PDFDocumento11 pagineID Analisis Persetujuan Tindakan Kedokteran Informed Consent Dalam Rangka Persiapan PDFAmelia AmelNessuna valutazione finora

- Power Efficiency Diagnostics ReportDocumento16 paginePower Efficiency Diagnostics Reportranscrib300Nessuna valutazione finora

- NPTEL Web Course On Complex Analysis: A. SwaminathanDocumento19 pagineNPTEL Web Course On Complex Analysis: A. SwaminathanMohit SharmaNessuna valutazione finora

- 1Z0-062 Exam Dumps With PDF and VCE Download (1-30)Documento6 pagine1Z0-062 Exam Dumps With PDF and VCE Download (1-30)Humberto Cordova GallegosNessuna valutazione finora

- Science Q4 Lesson BDA EarthquakeDocumento41 pagineScience Q4 Lesson BDA EarthquakeAnaLizaD.SebastianNessuna valutazione finora

- CSCE 3110 Data Structures and Algorithms NotesDocumento19 pagineCSCE 3110 Data Structures and Algorithms NotesAbdul SattarNessuna valutazione finora

- Zaranda Finlay 684 Manual Parts CatalogDocumento405 pagineZaranda Finlay 684 Manual Parts CatalogRicky Vil100% (2)

- Steam Turbine and Governor (SimPowerSystems)Documento5 pagineSteam Turbine and Governor (SimPowerSystems)hitmancuteadNessuna valutazione finora

- Copywirting Secrets From The BibleDocumento14 pagineCopywirting Secrets From The BibleRAY EDWARDS100% (2)

- Shilpa PPT FinalDocumento51 pagineShilpa PPT FinalDrakeNessuna valutazione finora

- Panda CheatsheetDocumento17 paginePanda CheatsheetAdevair JuniorNessuna valutazione finora

- DBM CSC Form No. 1 Position Description Forms 1feb.222019Documento2 pagineDBM CSC Form No. 1 Position Description Forms 1feb.222019Jemazel Ignacio87% (30)

- Request For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarDocumento1 paginaRequest For Information (Rfi) : Luxury Villa at Isola Dana-09 Island - Pearl QatarRahmat KhanNessuna valutazione finora

- MTD Microwave Techniques and Devices TEXTDocumento551 pagineMTD Microwave Techniques and Devices TEXTARAVINDNessuna valutazione finora

- StarletDocumento16 pagineStarletMohsen SirajNessuna valutazione finora

- Ts 391 IltDocumento5 pagineTs 391 IltFunnypoumNessuna valutazione finora

- 38-St. Luke - S vs. SanchezDocumento25 pagine38-St. Luke - S vs. SanchezFatzie MendozaNessuna valutazione finora

- Susan Abbotson - Critical Companion To Arthur Miller - A Literary Reference To His Life and Work-Facts On File (2007) PDFDocumento529 pagineSusan Abbotson - Critical Companion To Arthur Miller - A Literary Reference To His Life and Work-Facts On File (2007) PDFTaha Tariq0% (1)

- Coronary artery diseases reviewDocumento43 pagineCoronary artery diseases reviewKeputrian FKUPNessuna valutazione finora

- March 29, 2013 Strathmore TimesDocumento31 pagineMarch 29, 2013 Strathmore TimesStrathmore TimesNessuna valutazione finora

- Matching a Vendor's HRSG in THERMOFLEXDocumento30 pagineMatching a Vendor's HRSG in THERMOFLEXRafraf EzdineNessuna valutazione finora

- Computer Science Practical File WorkDocumento34 pagineComputer Science Practical File WorkArshdeep SinghNessuna valutazione finora

- Part 1 - Cutlip and Center's Effective Public Relations. 11th Ed.Documento127 paginePart 1 - Cutlip and Center's Effective Public Relations. 11th Ed.Duyen Pham75% (4)

- Family health assessment nursing problemsDocumento8 pagineFamily health assessment nursing problemsMari MazNessuna valutazione finora

- PNB V. Se, Et Al.: 18 April 1996 G.R. No. 119231 Hermosisima, JR., J.: Special Laws - Warehouse Receipts LawDocumento3 paginePNB V. Se, Et Al.: 18 April 1996 G.R. No. 119231 Hermosisima, JR., J.: Special Laws - Warehouse Receipts LawKelvin ZabatNessuna valutazione finora

- JEdwards PaperDocumento94 pagineJEdwards PaperHassan Hitch Adamu LafiaNessuna valutazione finora