Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

AKH - Catalogo

Caricato da

Sapta WaeTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

AKH - Catalogo

Caricato da

Sapta WaeCopyright:

Formati disponibili

Side Channel Pumps

Self-priming, segmental type

AKH 1101 6103

Technical data

Capacity: from 0,2 up to 35 m/h

Head: from 6 up to 144 m

Speed: 1450 rpm (max. 1800 rpm)

Temperature: max. 120 C

Casing pressure: PN 16

Shaft sealing: stuffing box or mechanical seal

Flange connections: DIN 2501 / PN 16

Direction of rotation: clockwise

(when seen from the drive end)

Application Construction

The Sterling SIHI AKH pump is a self-priming side channel Casing pressure

pump capable of handling gas along with the medium and Maximum 16 bar from -40 C up to +120 C.

operates at a low noise level. The AKH is suitable for trouble

free handling of clean or turbid liquids without any abrasive

particles. Please observe

Technical rules and safety regulations:

The performance curve steepness admits a precise regulation Casing pressure = inlet pressure + delivery head at minimum

of the pressure with a small change in capacity. pump capacity.

The AKH pump has been developed for a broad range of

medium duty applications in: Position of branches

Chemical industry, Suction and discharge branch point radially upwards.

Petro-Chemical industry,

Oil industry,

Machinery and automobile industry , Flanges

Food industry,

Building trades, The flanges correspond to DIN EN 1092-2 / PN 16.

Plastic and rubber industry, Flange design as per DIN 2512 with groove or drilled

Surface treatment, according to ANSI 150 or 300 lbs is basically possible.

Ship yards.

Bearing

Either by one grease lubricated ball bearing and one liquid

Design surrouned sleeve bearing (design A) or by two grease

lubricated ball bearings (design B). The ball bearings are

Pumps of the series AKH have a segmental type construction according to DIN 625. The first grease filling is done in the

with open vane wheel impellers. The pump construction is factory.

either with one liquid surrounded slide bearing and one ball

bearing or in a more industrial construction by using a double

ball bearing design. Direction of rotation

Clockwise, when looking at the pump from the drive end.

The program comprises 6 sizes with up to 4 stages (an Anti-clockwise is possible.

extension with 5 or 6 stages is possible for certain sizes).

The performance curves of the AKH are identical for all the

material designs. Shaft sealing

The applied hydraulic components are from our Modular Side The shaft can be sealed by either a stuffing box or a standard

Channel system (interchangeability of parts). mechanical seal.

Sterling Fluid Systems Pumping Technology AKH-00 2003

Material design AKH

Cast iron

Pos Components Material design

0A 0B 0F

1060 Suction casing

1070 Discharge casing

EN-GJL-250

1090

1140 Intermediate piece

1141

2100 Shaft X 20 Cr 13

2350 Vane wheel impeller CuZn40Al2 G-X 3 CrNiMoCuN 26 6 3 3 PAEK

0241 Bearing bush EK 2203

Stainless steel and Bronze

Pos Components Material design

2H* 3B 4B 4F

1060 Suction casing

EN-GJL-250 GC-CuSn 12

1070 Discharge casing

G-X 6 CrNiMo 18 10

1090

1140 Intermediate piece G-Sn Bz 16

1141

2100 Shaft X 5 CrNiMo 17 12 2

G-Cu Sn chrome G-Cu Sn chrome

2350 Vane wheel impeller plated plated G-X 3 CrNiMoCuN 26 6 3 3 PAEK

0241 Bearing bush EK 2203

* The construction of the AKH in material 2H is conform the construction of the AKH in Cast iron (see the next page)

Casing seal General comments

The casing can be sealed with a liquid sealing compound or Side Channel pumps with the same hydraulic construction

soft Teflon. are manufactured in series as:

AOH Low duty pump with oval flanges, PN 10

Drive

CEH High duty pump, PN 40

By electric motor, type of construction IM B3. Also available with magnetic coupling

CEB Vertical tank mounted pump, PN 25 with magnetic

coupling

CEV Vertical tank mounted pump, PN 25 with mechanical

seal (replacement for CVGP)

AEH High duty pump, PN 40

Also available with magnetic coupling

Technical documents about these pump series will be readily

supplied on request.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 2 / 20

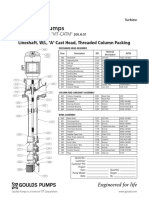

Sectional drawing and parts list AKH (typical)

AKH in Cast iron (0A, 0B, 0F, 2H)

1070 1060

2350 2100

Design A

(only for sizes 1100 up to 5100)

1140

0241 1141 1090 4330

Pos. Components

0241 Bearing bush

1060 Suction casing

1070 Discharge casing

1090 Suction intermediate piece

1140 Discharge intermediate piece

1141 Discharge intermediate piece Design B

1800 Mounting flange

2100 Shaft

2350 Vane wheel impeller

3500 Bearing housing

4330 Mechanical seal

4610 Stuffing box Stuffing box (available for all material designs)

AKH in Bronze (3B) and Stainless steel (4B and 4F)

1070 1060 2100

2350 3500

4610

1800

Design A

(only for Stainless steel in sizes 1200 up to 5100)

1141 1090

0241 1140 4330

Design B

All possible design combinations can be found in the delivery program

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 3 / 20

Performance range AKH

General conditions

Liquid: Water

Density: 1 kg/dm3

Viscosity: 1 cSt

Temperature: 20 C

Atmospheric pressure: 1013 mbar

Characteristic tolerances

Capacity 10% - Delivery head 10% - Power + 10%

For designs with a mechanical seal or a casing seal of soft Teflon, the tolerance for the delivery head is extended by 2% each.

Measuring standard

According to ISO 5198

150 n = 1450 rpm

H

(m)

100

1100* 1200 3100 3600 4100 5100 6100

50

0

0,2 0,4 0,6 0,8 1 2 4 6 8 10 20 40

Q

* only for cast iron design (m3/h)

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 4 / 20

Dimension chart, Pump set drawing and Performance curves

AKH 1100 in cast iron (0A, 0B, 0F, 2H)

H

(m) w

1450 rpm 119

100 110 57,5

4 a 145

25

80 1103 4

G

60

1102

40

1101 50

20 G

m2 m1

0

f1

P v e1

(kW) w1

1,2

1104

1103 14x4

0,8 115

1102

85

0,4 11j5

1101 100 4 DN25

0

NPSH 90 13 12,6

(m) h3

2 13 36 d

1

0,2 0,4 0,6 0,8 1,0 1,2 1,4 1,6 c

Q 120 e2

(m3/h)

156 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head is

extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m 1 m 2 w* w1

1101 0.37 71 P007 B68 14 35 120 317 20 15 350 285 110 53 125 182 146 627 570

1102 0.55 80 P007 B68 15 38 120 317 20 15 350 285 110 53 125 182 146 661 570

1103 0.75 80 P008 B68 17 45 154 297 20 15 400 265 120 53 130 216 180 695 640

1.1 90S 48 753

1104 0.75 80 P008 B68 19 50 188 297 20 15 400 265 120 53 130 250 214 729 640

1.1 90S P210 55 300 25 19 420 260 115 155 787 650

* Design B - dimensions depend upon the motor brand.

The weight of the pump in design A will be approximately 1 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 5 / 20

Dimension chart, Pump set drawing and Performance curves

AKH 1200 in cast iron (0A, 0B, 0F, 2H)

H

(m) w

12 1450 rpm 119

04

100 57,5 145

a

25

120

80 3 4

G

60 1202

40

1201

50

G

20

m2 m1

0

f1

P v e1

(kW) w1

1,6 1204

1,2 1203 14x4

115

0,8 1202

85

1201 11j5

0,4 100 4 DN25

0

NPSH 90 13 12,6

(m) h3

3

2 13 36 d

1

0,5 1,0 1,5 2,0 2,5

Q

(m3/h) c

120 e2

156 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head is

extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m1 m2 w* w1

0.37 71 35 627

1201 P007 B68 14 120 317 20 15 350 285 110 53 125 182 146 570

0.55 80 37 661

0.55 80 38

1202 P007 B68 15 120 317 20 15 350 285 110 53 125 182 146 661 570

0.75 80 39

0.75 80 45 695

1203 P008 B68 17 154 297 20 15 400 265 120 53 130 216 180 640

1.1 90S 48 753

1204 1.1 90S P210 B68 19 52 188 300 25 19 420 260 115 53 155 250 214 787 650

1.5 90L P241 59 330 480 290 125 730

* Design B - dimensions depend upon the motor brand.

The weight of the pump in design A will be approximately 1 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 6 / 20

Dimension chart, Pump set drawing and Performance curves

AKH 3100 in cast iron (0A, 0B, 0F, 2H)

H 31 w

140 04 1450 rpm

125

(m) 310 70 a 159

120 3

40

100 4

G

3102

80

60

3101

40 55

G

20 m2 m1

0

f1

v e1

P

(kW) 3104 w1

3103

3

3102 18x4

2 140

3101 100

1 16j5

112 5 DN32

0

NPSH

(m) 15 18,1

112

2 h3

1 13 47 d

1 2 3 4

Q

(m3/h) c

160 e2

218 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head is

extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m1 m2 w* w1

3101 0.75 80 P008 B68 22 50 145 297 20 15 400 265 120 56 152 214 178 706 640

1.1 90S 56 764

1.1 90S 55

P008 B68 297 20 15 400 265 120 152 764 640

3102 1.5 90L 23 59 145 56 214 178

2.2 100L P241 B80 70 330 25 19 480 290 125 177 805 730

2.2 100L 73

3103 P241 B80 26 185 330 25 19 480 290 125 56 177 254 218 845 730

3 100L 74

2.2 100L 80

885

3104 3 100L P272 B80 29 81 225 360 25 19 540 320 140 56 177 294 258 730

4 112M 99 906

* Design B - dimensions depend upon the motor brand.

The weight of the pump in design A will be approximately 2,5 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 7 / 20

Dimension chart, Pump set drawing and Performance curves

AKH 3600 in cast iron (0A, 0B, 0F, 2H)

H w

(m) 36

04 1450 rpm 125

100 70 a 159

360 40

3

80 4

G

60 3602

40

3601

55

G

20

m2 m1

0

f1

P v e1

(kW) w1

5

3604

4 18x4

3603

3 140

3602

2 16j5

100

3601

1 112 5 DN32

0

NPSH 112 15 18,1

(m) h3

2

13 47 d

1

4 5 6 7 Q c

(m3/h) 160 e2

218 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head is

extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m1 m2 w* w1

3601 0.75 80 P008 B68 22 50 145 297 20 15 400 265 120 56 152 214 178 706 640

1.1 90S 56 764

1.5 90L P008 B68 59 297 20 15 400 265 120 152 764 640

3602 23 145 56 214 178

2.2 100L P241 B80 70 330 25 19 480 290 125 177 805 730

2.2 100L 70

845

3103 3 100L P241 B80 26 73 185 330 25 19 480 290 125 56 177 254 218 730

4 112M 74 866

3 100L 81 885

P272 B80 360 19 540 320 140 177 820

3604 4 112M 29 99 225 25 56 294 258 906

5.5 132S P015 B95 126 361 15 600 325 160 182 982 920

* Design B - dimensions depend upon the motor brand.

The weight of the pump in design A will be app. 2,5 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 8 / 20

Dimension chart, Pump set drawing and Performance curves

AKH 4100 in cast iron (0A, 0B, 0F, 2H)

H w

(m) 1450 rpm 157

41 75

120 04 a 205

45

100 410 4

3 G

80

4102

60

40 4101 55

G

20 m2 m1

0

f1

v e1

P w1

(kW) 4104

6

4103 18x4

150

4 4102

110

19j5

2 4101

132 6 DN40

0

NPSH 132 20 21,5

(m) h3

4

13 47 d

2

0

6 7 8 9 10 11 12

Q c

(m3/h) 160 e2

218 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head is

extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m1 m2 w* w1

4101 1.5 90L P241 B68 28 69 155 330 25 19 480 290 125 42 197 195 159 852 730

2.2 100L B80 76 893

2.2 100L 86

4102 3 100L P272 B80 34 87 210 360 25 19 540 320 140 42 197 250 214 948 820

4 112M 105 969

4103 4 112M P015 B80 40 116 265 361 25 15 600 325 160 42 182 305 269 1024 920

5.5 132S B95 137 1100

4 112M P015 B80 121 600 160 182 1079 920

4104 5.5 132S P017 B95 45 158 320 361 25 15 700 325 200 42 192 360 324 1155 1100

7.5 132M 168 1181

* Design B - dimensions depend upon the motor brand.

The weight of the pump in design A will be approximately 3 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 9 / 20

Dimension chart, Pump set drawing and Performance curves

AKH 5100 in cast iron (0A, 0B, 0F, 2H)

H w

51

(m) 03 1450 rpm 168

100 82,5

a 217

50

80 5102 4

G

60

5101

40

55

G

20

m2 m1

0

f1

P v e1

(kW)

5103 w1

10

5102 18x4

8

165

6 24j5

125

5101 140

4 5 DN50

2

0 20 26,9

150

h3

NPSH

(m) 13 47 d

4

2 c

10 12 14 16 18 Q 20 160 e2

(m3/h) 218 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head is

extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m1 m2

w* w1

5101 3 100L P272 B80 36 89 170 360 25 19 540 320 140 48 215 220 185 931 820

4 112M 107 952

5.5 132S P015 143 361 25 15 600 325 160 200 1103

5102 7.5 132M B95 46 153 245 48 295 260 1129 920

11 160M P344 216 450 30 24 660 400 180 240 1221

7.5 132M P015 178 361 25 15 700 325 210 1204 1100

B95

5103 11 160M P385 55 262 320 490 30 24 740 440 200 48 240 370 335 1296 1140

15 160L B110 283 1358

* Design B - dimensions depend upon the motor brand.

The weight of the pump in design A will be app. 4 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 10 / 20

Dimension chart, Pump set drawing and Performance curves

AKH 6100 in cast iron (0A, 0B, 0F, 2H)

H w

(m) 61 1450 rpm

03 188 a 251

120 65

4

100 610 G

2

80

60 6101

40 65

G

20 m2 m1

0

f1

P v e1

(kW) w1

6103

20

18x4

16 6102 185

12 145

28j5

6101 150

8 8 DN65

4

0

150 20 30,9

NPSH h3

(m)

15 50 d

6

4

2

15 20 25 30 Q 35 c

(m3/h) 200 e2

250 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head is

extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m 1 m 2 w * w1

6101 5.5 132S P015 B95 54 152 190 361 25 15 600 325 160 63 200 276 220 1102 920

7.5 132M 161 1128

6102 11 160M P385 B95 65 272 280 490 30 24 740 440 200 63 240 366 310 1310 1140

15 160L B110 293 1372

6103 18.5 180M P436 B110 76 317 370 540 30 24 840 490 215 63 260 456 400 1524 1270

22 180L B125 337

* Dimensions depend upon the motor brand.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 11 / 20

Dimensiom chart, Pump set drawing and Performance curves

AKH 1200 in Bronze and Stainless steel (3B, 4B and 4F)

H

(m) w

120 1450 rpm 124 a 150

100 4

25

120 4

80 3

60 1202

40 50

1201 G

20 m2 m1

0 f1

v e1

P w1

(kW)

1,6 1204

14x4

1,2 1203 115

1202 85

0,8

11j5

1201 100 4 DN25

0,4

0

90 11 12,6

NPSH h3

(m)

3 13 36 d

2

1

0,5 1,0 1,5 2,0 2,5 c

Q e2

(m3/h) 120

156 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head

is extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c de1 e2 v f1 h3 m 1 m 2 w* w1

0.37 71 P007 36 317 350 285 110 125 637 570

1201 B68 15 120 20 15 87 256 214

0.55 80 P008 42 297 400 265 120 130 671 640

0.55 80 43

1202 P008 B68 16 120 297 20 15 400 265 120 87 130 256 214 671 640

0.75 80 44

0.75 80 P008 46 297 20 15 400 265 120 130 705 640

1203 B68 18 154 87 290 248

1.1 90S P241 54 330 25 19 480 290 125 155 763 730

1204 1.1 90S P241 B68 20 56 188 330 25 19 480 290 125 87 155 324 282 797 730

1.5 90L 60

* Design B - dimensions depend on the motor brand.

The weight of the pump in design A (only available in Stainless steel) will be approximately 1 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 12 / 20

Dimensiom chart, Pump set drawing and Performance curves

AKH 3100 in Bronze and Stainless steel (3B, 4B and 4F)

H w

31 1450 rpm

140 04 189

146 a

(m)

120 310 40

3

4

100

3102

80

60

3101 55

40 G

m2 m1

20

0 f1

v e1

P w1

(kW) 3104

3 3103

18x4

2 3102 140

100

1 3101 16j5

118 5 DN32

0

NPSH 112 15 18,1

(m)

2 h3

13 36 d

1

1 2 3 4

Q c

(m3/h) 160 e2

196 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head

is extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m1 m2 w* w1

3101 0.75 80 P241 B68 26 58 150 330 25 19 480 290 125 99 177 308 268 762 730

1.1 90S 62 820

1.1 90S 63

P241 B68 330 480 290 125 820 730

3102 1.5 90L 27 67 150 25 19 99 177 308 268

2.2 100L P272 B80 78 360 540 320 140 861 820

2.2 100L 82

3103 P272 B80 31 190 360 25 19 540 320 140 99 177 348 308 901 820

3 100L 83

2.2 100L 96

P272 360 19 540 320 140 177 941 820

3104 3 100L B80 34 97 230 25 99 388 348

4 112M P015 109 361 15 600 325 160 162 962 920

* Design B - dimensions depend on the motor brand.

The weight of the pump in design A (only available in Stainless steel) will be approximately 2,7 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 13 / 20

Dimensiom chart, Pump set drawing and Performance curves

AKH 3600 in Bronze and Stainless steel (3B, 4B and 4F)

H w

(m) 36

04 1450 rpm 146 a 189

100 40

360 4

3

80

60 3602

40 55

3601 G

20 m2 m1

0 f1

v e1

P w1

(kW)

5

3604 18x4

4 140

3603

3

3602 100

2 16j5

3601 118 5 DN32

1

0

NPSH 112 15 18,1

(m) h3

3 13 36 d

2

1 c

4 5 6 7 Q 160 e2

(m3/h) 196 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head

is extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m1 m2 w* w1

3601 0.75 80 P241 B68 26 58 150 330 25 19 480 290 125 99 177 308 268 762 730

1.1 90S 62 820

1.5 90L P241 B68 67 330 480 290 125 820 730

3602 27 150 25 19 99 177 308 268

2.2 100L P272 B80 78 360 540 320 140 861 820

2.2 100L 82

901

3103 3 100L P272 B80 31 83 190 360 25 19 540 320 140 99 177 348 308 820

4 112M 101 922

3 100L 87 360 19 540 320 140 177 941

P272 B80 820

3604 4 112M 34 109 230 361 25 15 600 325 160 99 162 388 348 962

5.5 132S P015 B95 131 182 1038 920

* Design B - dimensions depend on the motor brand.

The weight of the pump in design A (only available in Stainless steel) will be approximately 2,7 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 14 / 20

Dimensiom chart, Pump set drawing and Performance curves

AKH 4100 in Bronze and Stainless steel (3B, 4B and 4F)

H w

(m) 1450 rpm

149 a 197

41

120 04 45

4

100 410

3

80

4102

60

55

40 4101 G

m2 m1

20

0 f1

v e1

w1

P

(kW)

4104

6 18x4

4103

150

4 4102 110

19j5

4101 132 6 DN40

2

0

132 20 21,5

NPSH h3

(m)

4 13 47 d

2

0

5 6 7 8 9 10 11 12 c

Q 160 e2

(m3/h) 218 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head

is extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m1 m2 w* w1

4101 1.5 90L P241 B68 33 74 160 330 25 19 480 290 125 92 197 303 263 841 730

2.2 100L P272 B80 85 360 540 320 140 882 820

2.2 100L 92

4102 3 100L P272 B80 39 93 215 360 25 19 540 320 140 92 197 358 318 937 820

4 112M 109 958

4103 4 112M P015 B80 44 118 270 361 25 15 600 325 160 92 182 413 373 1013 920

5.5 132S P017 B95 157 700 200 192 1089 1100

4 112M B80 140 1068

4104 5.5 132S P017 B95 50 163 325 361 25 15 700 325 200 92 192 468 428 1144 1100

7.5 132M 173 1170

* Design B - dimensions depend on the motor brand.

The weight of the pump in design A (only available in Stainless steel) will be approximately 3,2 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 15 / 20

Dimensiom chart, Pump set drawing and Performance curves

AKH 5100 in Bronze and Stainless steel (3B, 4B and 4F)

H 510 w

(m) 3 1450 rpm 163 a 217

100 50

4

80 5102

60

5101

40 55

G

20 m2 m1

0 f1

v e1

P w1

(kW) 5103

10 18x4

8 5102 165

125

6 24j5

140 8 DN50

5101

4

2

150 20 26,9

0

h3

NPSH 13 47 d

(m)

4

2 c

160 e2

11 12 14 16 18 Q 20 218 b2

(m3/h)

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head

is extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 w*m1 m2 w1

5101 3 100L P272 B80 45 98 175 360 25 19 540 320 140 99 215 329 293 931 820

4 112M 121 952

5.5 132S 168 361 25 15 700 325 210 1103 1100

P017

5102 7.5 132M B95 55 178 250 200 99 404 368 1129

11 160M P385 262 490 30 24 740 440 240 1221 1140

7.5 132M P017 217 361 25 15 700 325 210 1204 1100

B95 200

5103 11 160M P385 64 271 325 490 30 24 740 440 99 240 479 443 1296 1140

15 160L P436 B110 283 540 840 490 215 1358 1270

* Design B - dimensions depend upon the motor brand.

The weight of the pump in design A (only available in Stainless steel) will be app. 4,2 kg less.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 16 / 20

Dimensiom chart, Pump set drawing and Performance curves

AKH 6100 in Bronze and Stainless steel (3B, 4B and 4F)

H w

(m) 610 1450 rpm

3 182 a 251

120 65

4

100

610

2

80

60

6101

40 65

G3/8

20 m2 m1

0 f1

v e1

P w1

(kW)

6103

20

18x4

16 6102 185

12 145

28j5

6101 165 8 DN65

8

4

0 150 20 30,9

NPSH h3

(m) 15 50 d

6

4

2 c

15 20 25 30 Q 35

(m3/h) 200 e2

250 b2

General: Values are valid for water = 1 kg/dm3 and = 1 cSt.

Characteristic tolerances: Capacity 5% - Delivery head 5% - Power + 10%.

For designs with a mechanical seal or casing seal of soft Teflon, the tolerance for the delivery head

is extended by 2% each.

Pump Motor Base Coupling Weight

size kW size plate pump set a b2 c d e1 e2 v f1 h3 m1 m2

w* w1

6101 5.5 132S P017 B95 62 175 195 361 25 15 700 325 160 117 210 388 328 1101 1100

7.5 132M 182 1127

6102 11 160M P385 B95 75 282 285 490 30 24 740 440 200 117 240 478 418 1309 1140

15 160L P436 B110 294 540 840 490 215 1371 1270

6103 18.5 180M P487 B110 87 342 375 610 30 24 940 550 240 117 280 568 508 1523 1420

22 180L B125 362

* Dimensions depend upon the motor brand.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 17 / 20

Notes

It is the policy of Sterling Fluid Systems to seek continually for ways to improve its products

and the right is reserved to alter specifications at anytime without prior notice.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 18 / 20

Sterling SIHI Side Channel pumps

Sterling Fluid Systems offers an extensive Side Channel pump range under its brand name Sterling

SIHI. Sterling Fluid Systems has more than 80 years of experience in manufacturing, installation and

support of Side Channel pumps. The Sterling SIHI Side Channel pumps can be found in a wide

application range for the:

Chemical market

Pharmaceutical industry

Petrochemical industry

Food industry

Ship yards

LPG industry

and many more ...

The Sterling SIHI Side Channel pump range

1000

CEH

AEH

AEHL

100 ADHL

CDHL

Delivery head (m)

AOH ASH

AKH

10 AKL

AKV

AOL

DRV

0 10 20 30 40

Capacity (m3/h)

The benefits of the Sterling SIHI Side Channel pumps

Self priming

Gas handling

High-resistant materials

Performance curve characteristics

High efficiency

Low NPSHR value

Modular hydraulic system

The Sterling SIHI Side Channel pumps comply with the highest demands of our customers and

are the best solution for the handling of liquid under critical physical conditions.

Sterling Fluid Systems Pumping Technology AKH-00 / 2003 Page 19 / 20

Sterling Fluid Systems (Europe)

www.sterlingfluidsystems.com/europe

Sterling Fluid Systems (Austria) Sterling Fluid Systems (Belgium) Sterling Fluid Systems (Chech Republic)

Wien Groot-Bijgaarden Olomouc

Telephone: +43 (0)1 680 050 Telephone: +32 (0)2 481 7711 Telephone: +420 (0)587 433 651

Fax: +43 (0)1 680 0521 Fax: +32 (0)2 481 7737 Fax: +420 (0)587 433 653

E-Mail: sales_austria@sterlingsihi.de E-Mail: sales@sterlingfluidsystems.be E-Mail: sterling@sterling.cz

Sterling Fluid Systems (France) Sterling SIHI (Germany) Sterling Fluid Systems (Italy)

Trappes Itzehoe Monza

Telephone: +33 (0)1 34 82 39 00 Telephone: 49 (0)4821 77101 Telephone: +39 (0)039 2824 1

Fax: +33 (0)1 34 82 39 61 Fax: 49 (0)4821 771274 Fax: +39 (0)039 2824 220

E-Mail: sterlingsihi@easynet.fr E-Mail: sales@sterlingsihi.de E-Mail: sterlingitaly@sidro.it

Sterling Fluid Systems (Greece) Sterling Fluid Systems (Hungary) Sterling Fluid Systems (Romania)

Athens Veszprm Bucuresti

Telephone: +302 (0)10 9570783 Telephone: +36 (0)88 40 66 33 Telephone: +40 (0)21 610 7188

Fax: +0302 (0)10 9568121 Fax: +36 (0)88 40 66 35 Fax: +40 (0)21 210 8287

E-Mail: sales_greece@sterlingsihi.de E-Mail: sales_hungary@sterlingsihi.de E-Mail: sales_romania@sterlingsihi.de

Sterling Fluid Systems (Netherlands) Sterling Fluid Systems (Polska) Sterling SAT

Beverwijk Warszawa Dgeling, Germany

Telephone: +31 (0)251 263 232 Telephone: +48 (0)22 849 7097 Telephone: +49 (0)4821 9000-0

Fax: +31 (0)251 226 309 Fax: +48 (0)22 849 6726 Fax: +49 (0)4821 9000-501

E-Mail: info@sihi.nl E-Mail: sterling@sterling.pl E-Mail: sat@sterlingsat.com

Sterling Fluid Systems (Schweiz) Sterling Fluid Systems (Spain) Sterling Fluid Systems (UK)

Schaffhausen Madrid Altrincham/Cheshire

Telephone: +41 (0)52 6440606 Telephone: +34 (0)91 709 1310 Telephone: +44 (0)161 9286371

Fax: +41 (0)52 6440616 Fax: +34 (0)91 715 9700 Fax: +44 (0)161 9252129

E-Mail: info@sterlingfluid.ch E-Mail: mibsa@stnet.es E-Mail: uksales@sterlingfluid.com

Sterling Fluid Systems (Americas)

www.sterlingfluidsystems.com/americas

Sterling Fluid Systems (USA) Sterling Fluid Systems (Canada)

Grand Island Guelph

Telephone: (1) 716 773 6450 Telephone: (1) 519 824 4600

Fax: (1) 716 773 2330 Fax: (1) 519 824 7250

E-Mail: mail@sihi.com E-Mail: mail@sihi.com

Sterling Fluid Systems (Asia)

www.sterlingfluidsystems.com/asia

Sterling Fluid Systems (Asia) SIHI (Australia) Sterling Fluid Systems (China)

Singapore Bayswater Shanghai

Telephone: (65) 68630 828 Telephone: (61) 3 9720 1500 Telephone: (8621) 6336 3488/6326 4171/6326 4062

Fax: (65) 68630 868 Fax: (61) 3 9720 4076 Fax: (8621) 63268487

E-Mail: asia.marketing@sterlingasia.com.sg E-Mail: sfsaus@ozemail.com.au E-Mail: asia.marketing@sterlingasia.com.sg

Sterling Fluid Systems (Malaysia) Sterling Fluid Systems (Philippines) Sterling Fluid Systems (Thailand)

Selangor Darul Ehsan Muntinlupa City Bangkok

Telephone: (60) 3 8070 0198/99 Telephone: (63) 2 809 4908 Telephone: (66) 2 319 2567

Fax: (60) 3 8070 0240 Fax: (63) 2 807 2013 Fax: (66) 2 319 25673/4

E-Mail: sfsmsia@tm.net.my E-Mail: asia.marketing@sterlingasia.com.sg E-Mail: sfsthai@sterlingthai.co.th

www.sterlingfluidsystems.com

Potrebbero piacerti anche

- GouldsDocumento11 pagineGouldsKaren Isabel Ambiado Rivas100% (1)

- TAP DRILL CHART: RECOMMENDED DRILLS FOR TAP SIZESDocumento1 paginaTAP DRILL CHART: RECOMMENDED DRILLS FOR TAP SIZESArup MohajanNessuna valutazione finora

- Fraction Decimal ChartDocumento1 paginaFraction Decimal ChartancadorsNessuna valutazione finora

- Inquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteDocumento5 pagineInquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteCik MinnNessuna valutazione finora

- Prueba Del Amperaje Máximo de Cable Blindado No4 CentriliftDocumento6 paginePrueba Del Amperaje Máximo de Cable Blindado No4 CentriliftRaifel MoralesNessuna valutazione finora

- Boletin Non ClogDocumento12 pagineBoletin Non ClogulisesgeNessuna valutazione finora

- SMR 301 WP Installation ManualDocumento19 pagineSMR 301 WP Installation ManualCarlos de la VegaNessuna valutazione finora

- Rolo Id PumpDocumento17 pagineRolo Id Pumpsri717Nessuna valutazione finora

- 10 Mezclado y Agitacion de LIquidosDocumento19 pagine10 Mezclado y Agitacion de LIquidosakarcz6731Nessuna valutazione finora

- Protech Bearing Isolator Seal TheoryDocumento8 pagineProtech Bearing Isolator Seal TheorySanjoy Kr. DeyNessuna valutazione finora

- Stray Current Corrosion in Submersible PumpsDocumento5 pagineStray Current Corrosion in Submersible PumpsMachineryengNessuna valutazione finora

- 3231Documento40 pagine3231Jorge Patiño100% (1)

- Catalogo EagleBurgmann API 682 3ra Edición (58 E) PDFDocumento30 pagineCatalogo EagleBurgmann API 682 3ra Edición (58 E) PDFRobert VillavicencioNessuna valutazione finora

- 1 Magnetic-Drive-PumpsDocumento19 pagine1 Magnetic-Drive-PumpsMuzammil PiyarjiNessuna valutazione finora

- 80261-01 r1 Technical Data Sheet, AquaBold High Pressure Pump, 4x6x9Documento1 pagina80261-01 r1 Technical Data Sheet, AquaBold High Pressure Pump, 4x6x9pablolz712100% (1)

- Clyde Pumps WEIR API Brochures For Barrel Pumps EtcDocumento22 pagineClyde Pumps WEIR API Brochures For Barrel Pumps EtcSSudhakarNessuna valutazione finora

- Tolerance FinderDocumento4 pagineTolerance FinderAmit100% (2)

- 2007-019 Centrilift Cable Splice TapeDocumento1 pagina2007-019 Centrilift Cable Splice TapeLuis MendozaNessuna valutazione finora

- 3604 SMN-JWR PDFDocumento7 pagine3604 SMN-JWR PDFsaharaNessuna valutazione finora

- 2020 Style 688 Split SealtekDocumento8 pagine2020 Style 688 Split SealtekdiamsamNessuna valutazione finora

- Michael M. Calistrat: Safety, Application, and Service Factors As Applied To Shaft Couplings byDocumento8 pagineMichael M. Calistrat: Safety, Application, and Service Factors As Applied To Shaft Couplings byronny_fernandes363Nessuna valutazione finora

- Magnetic Drive Pumps Product GuideDocumento32 pagineMagnetic Drive Pumps Product GuideJean-francois RosierNessuna valutazione finora

- ISOMAG - Pump - Zone - Reprint-Bearing Protection DevicesDocumento5 pagineISOMAG - Pump - Zone - Reprint-Bearing Protection DevicesChandra SimanjuntakNessuna valutazione finora

- BIWDocumento62 pagineBIWingpochoNessuna valutazione finora

- Creating Larger Forces With Differential Roller Screws: Carlos GonzalezDocumento1 paginaCreating Larger Forces With Differential Roller Screws: Carlos GonzalezfbahsiNessuna valutazione finora

- Sugar CaneMill V5.1Documento7 pagineSugar CaneMill V5.1uksraj100% (1)

- Ku Reprint Ps April2007Documento2 pagineKu Reprint Ps April2007keyur1109Nessuna valutazione finora

- Reactors Ppt4Documento55 pagineReactors Ppt4DanishNessuna valutazione finora

- ITT Gould PumpsDocumento2 pagineITT Gould PumpsBilly ZununNessuna valutazione finora

- BR MiningDocumento12 pagineBR MiningSteven TremolNessuna valutazione finora

- IECEx CML 14.0047X 0 PDFDocumento7 pagineIECEx CML 14.0047X 0 PDFINSTECH ServicesNessuna valutazione finora

- Agitadores PlentyDocumento16 pagineAgitadores Plentyrolando tapiaNessuna valutazione finora

- Submersible Pumps: The Supplier of Choice for Difficult ApplicationsDocumento10 pagineSubmersible Pumps: The Supplier of Choice for Difficult ApplicationsKarina MedinaNessuna valutazione finora

- Mark 3 ASME Pumps PDFDocumento94 pagineMark 3 ASME Pumps PDFInf IngNessuna valutazione finora

- VTP October 22Documento8 pagineVTP October 22Hidroterm Plantas Electricas-Bombas De Agua-Maquinaria Pesada100% (1)

- Solar Steam GenerationDocumento15 pagineSolar Steam GenerationSebastian MontecinoNessuna valutazione finora

- Cone Strainer PDFDocumento5 pagineCone Strainer PDFmohammad100% (1)

- Goulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610Documento40 pagineGoulds Model 3700/3710: High Temperature/High Pressure Process Pumps Designed and Built To Meet Requirements of API-610sebasNessuna valutazione finora

- Z22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USDocumento2 pagineZ22 DoubleSuctionAxiallysplitSingleStageCentrifugalPump60HzUS E10118 USediNessuna valutazione finora

- ASME Guide Heat-Transfer-Surfaces-GuideDocumento8 pagineASME Guide Heat-Transfer-Surfaces-Guidealejandro carmona henaoNessuna valutazione finora

- CpkoDocumento24 pagineCpkoDeepak SparkleNessuna valutazione finora

- Steam Trap TesterDocumento4 pagineSteam Trap TesterISMAEL RAMIREZNessuna valutazione finora

- Printable Fastener Tools PDFDocumento32 paginePrintable Fastener Tools PDFColumbia Gomez0% (1)

- PumpingDocumento68 paginePumpingbbmoksh100% (1)

- TECHNICAL Layne Engineering ManualDocumento34 pagineTECHNICAL Layne Engineering ManualAnonymous CMS3dL1TNessuna valutazione finora

- Archimedys Technical Data - Metric - GB 11264 PDFDocumento43 pagineArchimedys Technical Data - Metric - GB 11264 PDFAnonymous Cxriyx9HIXNessuna valutazione finora

- C9MDocumento1 paginaC9MГоран ЈараковићNessuna valutazione finora

- Orion Double AdjustmentDocumento2 pagineOrion Double AdjustmentEmnNessuna valutazione finora

- Vertical Solid Shaft (VSS), High Thrust, TEFCDocumento9 pagineVertical Solid Shaft (VSS), High Thrust, TEFCeliahudNessuna valutazione finora

- KTR Magnetic Coupling CatalogDocumento10 pagineKTR Magnetic Coupling CatalogHyungTae JangNessuna valutazione finora

- Goulds Pump Curves 3175Documento3 pagineGoulds Pump Curves 3175RichNessuna valutazione finora

- Pressure Dam Bearings USEFULDocumento16 paginePressure Dam Bearings USEFULAmna ChaudaryNessuna valutazione finora

- Valves Overview Service enDocumento12 pagineValves Overview Service enBalraj PadmashaliNessuna valutazione finora

- FLOWSERVE CPXV AP73611BDocumento48 pagineFLOWSERVE CPXV AP73611Broyert80Nessuna valutazione finora

- Dynamic Seal in The Fertilizer Industry 11-09Documento9 pagineDynamic Seal in The Fertilizer Industry 11-09Souvik Singha RoyNessuna valutazione finora

- Type OHH Pump API610 9 Ed. (ISO 13709) : File Name / OHH Sales Presentation - PPT 11/21/2001 1Documento20 pagineType OHH Pump API610 9 Ed. (ISO 13709) : File Name / OHH Sales Presentation - PPT 11/21/2001 1Jorge OportoNessuna valutazione finora

- Goulds LF 3171: Low Flow, High Head Vertical Sump PumpDocumento4 pagineGoulds LF 3171: Low Flow, High Head Vertical Sump PumpPaul CastroNessuna valutazione finora

- ITT Goulds Pumps For Sugar FactoryDocumento12 pagineITT Goulds Pumps For Sugar FactoryhareudangNessuna valutazione finora

- Arc Welding and Gas Welding Processes ExplainedDocumento23 pagineArc Welding and Gas Welding Processes ExplainedRaghu ChowdaryNessuna valutazione finora

- Side Channel Pump Technical Data and PerformanceDocumento6 pagineSide Channel Pump Technical Data and Performancewakgeng marwahNessuna valutazione finora

- IMO MSC 88 SlidesDocumento6 pagineIMO MSC 88 SlidesSapta WaeNessuna valutazione finora

- STM partVI PDFDocumento8 pagineSTM partVI PDFSapta WaeNessuna valutazione finora

- ABS Rules for Steel Vessels Under 90mDocumento91 pagineABS Rules for Steel Vessels Under 90mGean Antonny Gamarra DamianNessuna valutazione finora

- ABS Rules for Steel Vessels Under 90mDocumento91 pagineABS Rules for Steel Vessels Under 90mGean Antonny Gamarra DamianNessuna valutazione finora

- STM PartixDocumento7 pagineSTM PartixSapta WaeNessuna valutazione finora

- KARET PACKING-Layout1new PDFDocumento1 paginaKARET PACKING-Layout1new PDFSapta WaeNessuna valutazione finora

- Autocad ShortcutsDocumento13 pagineAutocad ShortcutsKriscel CaraanNessuna valutazione finora

- Marine Air CondDocumento1 paginaMarine Air CondSapta WaeNessuna valutazione finora

- GRP NewCatalogue PDFDocumento80 pagineGRP NewCatalogue PDFtUNNessuna valutazione finora

- Lloyds Marine Pollution Checklist (R2)Documento0 pagineLloyds Marine Pollution Checklist (R2)Dimitris PaliktoglouNessuna valutazione finora

- Cargo Inspectors - Safe Working Practices PDFDocumento5 pagineCargo Inspectors - Safe Working Practices PDFSapta WaeNessuna valutazione finora

- SOLAS Training Manual OdtDocumento11 pagineSOLAS Training Manual OdtSapta WaeNessuna valutazione finora

- GRP NewCatalogue PDFDocumento80 pagineGRP NewCatalogue PDFtUNNessuna valutazione finora

- Vacuum Book EDocumento71 pagineVacuum Book EChristian Vargas100% (5)

- STM PartiDocumento15 pagineSTM PartiSapta WaeNessuna valutazione finora

- STM PartiDocumento15 pagineSTM PartiSapta WaeNessuna valutazione finora

- Pub ISMDocumento22 paginePub ISMMohanakrishnan RajasekaranNessuna valutazione finora

- I have known the sea too long to respect its decencyDocumento2 pagineI have known the sea too long to respect its decencyqualiman1Nessuna valutazione finora

- 6.1 Reporting & Quality Control Procedures (DOC & SMC)Documento1 pagina6.1 Reporting & Quality Control Procedures (DOC & SMC)gunnery02Nessuna valutazione finora

- 1.1 Object of The InstructionsDocumento4 pagine1.1 Object of The InstructionsEduSoftNessuna valutazione finora

- STM partVI PDFDocumento8 pagineSTM partVI PDFSapta WaeNessuna valutazione finora

- STM PartviiDocumento8 pagineSTM PartviiSapta WaeNessuna valutazione finora

- New Construction Survey Guide eDocumento40 pagineNew Construction Survey Guide egeorgekc77Nessuna valutazione finora

- Bojean CurvesDocumento9 pagineBojean CurvesjaishanakarNessuna valutazione finora

- Bojean CurvesDocumento9 pagineBojean CurvesjaishanakarNessuna valutazione finora

- Faddeev-Popov Ghosts: Physics 230A, Spring 2007, Hitoshi MurayamaDocumento3 pagineFaddeev-Popov Ghosts: Physics 230A, Spring 2007, Hitoshi MurayamaSapta WaeNessuna valutazione finora

- Faddeev-Popov Ghosts: Physics 230A, Spring 2007, Hitoshi MurayamaDocumento3 pagineFaddeev-Popov Ghosts: Physics 230A, Spring 2007, Hitoshi MurayamaSapta WaeNessuna valutazione finora

- 1.1 Object of The InstructionsDocumento4 pagine1.1 Object of The InstructionsEduSoftNessuna valutazione finora

- Main Deck Hafar PDFDocumento1 paginaMain Deck Hafar PDFSapta WaeNessuna valutazione finora

- ETEN4001 Tute1 2017Documento3 pagineETEN4001 Tute1 2017Orlando CalderasNessuna valutazione finora

- Aceros PoscoDocumento35 pagineAceros PoscoregistrosegNessuna valutazione finora

- Determine COP of a Heat Pump/Refrigeration MachineDocumento2 pagineDetermine COP of a Heat Pump/Refrigeration MachineJeremy Tay0% (2)

- 2D Compressible Viscous-Flow Solver On Unstructured Meshes With Linear and Quadratic Reconstruction of Convective FluxesDocumento77 pagine2D Compressible Viscous-Flow Solver On Unstructured Meshes With Linear and Quadratic Reconstruction of Convective FluxeshityouNessuna valutazione finora

- Movement of The EarthDocumento21 pagineMovement of The EarthAqilah Taufik100% (1)

- Extraction in Chemical Technology PrincipleDocumento24 pagineExtraction in Chemical Technology PrincipleFatima ZaharaNessuna valutazione finora

- Newtons Second LawDocumento2 pagineNewtons Second LawTalina FlowerNessuna valutazione finora

- InterpolationDocumento7 pagineInterpolationElianne GabbayNessuna valutazione finora

- Design of Rotating Electrical Machines2Documento531 pagineDesign of Rotating Electrical Machines2alirozNessuna valutazione finora

- FMDocumento4 pagineFMvishalNessuna valutazione finora

- Secondary or Machining ProcessDocumento49 pagineSecondary or Machining ProcessHar QuinNessuna valutazione finora

- The Effect of Vehicle Noise On Automatic Speech Recognition SystemsDocumento4 pagineThe Effect of Vehicle Noise On Automatic Speech Recognition SystemsadityaNessuna valutazione finora

- High Frequency Circuit Design CourseDocumento5 pagineHigh Frequency Circuit Design CourseadauNessuna valutazione finora

- International Journal of Mechanical Sciences: Chong Li, Hui-Shen Shen, Hai Wang, Zhefeng YuDocumento10 pagineInternational Journal of Mechanical Sciences: Chong Li, Hui-Shen Shen, Hai Wang, Zhefeng Yuali_biscoeatNessuna valutazione finora

- Research Paper in MicrowavesDocumento10 pagineResearch Paper in MicrowavesManoling PanopioNessuna valutazione finora

- G-Snack Evolution Rev05Documento2 pagineG-Snack Evolution Rev05whaleNessuna valutazione finora

- Practice FinalDocumento26 paginePractice Finalchaseutd123Nessuna valutazione finora

- AkzoNobel EBS 481 FQ tcm54-30339Documento1 paginaAkzoNobel EBS 481 FQ tcm54-30339Nissim Hazar CasanovaNessuna valutazione finora

- Astm E837-08Documento17 pagineAstm E837-08jodakiNessuna valutazione finora

- B 21 - B 21M - 14Documento8 pagineB 21 - B 21M - 14Ahmed BilalNessuna valutazione finora

- Thermodynamics Level 1: Temperature Scale and Work Done in Different ProcessesDocumento7 pagineThermodynamics Level 1: Temperature Scale and Work Done in Different ProcessesViren Patel50% (2)

- 694-3 - R10KDocumento5 pagine694-3 - R10KJosé AdelinoNessuna valutazione finora

- PLC Simulation ReportDocumento62 paginePLC Simulation ReportAsraful Goni NirabNessuna valutazione finora

- Prepared By: Ms. Ethel D. Nabor, LPTDocumento29 paginePrepared By: Ms. Ethel D. Nabor, LPTJohn Ralf T. TorrejosNessuna valutazione finora

- 26 - Jaxa-Rozen Cold Work Stainless Steell PDFDocumento13 pagine26 - Jaxa-Rozen Cold Work Stainless Steell PDFSergio MuñozNessuna valutazione finora

- Introduction To Chemical Engineering Thermodynamics - 7th Ed - Smith, Van Ness & Abbot PDFDocumento709 pagineIntroduction To Chemical Engineering Thermodynamics - 7th Ed - Smith, Van Ness & Abbot PDFmangelmp78% (18)

- Co2 Removal Membrane TechnologyDocumento32 pagineCo2 Removal Membrane TechnologyhecalsieNessuna valutazione finora

- Simple Lifting Machines MyDocumento14 pagineSimple Lifting Machines MyAkash SinghNessuna valutazione finora

- BMP Assignment IIDocumento3 pagineBMP Assignment IIShahminan ShahNessuna valutazione finora