Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Gs Et 29 - A05 2011 - e PDF

Caricato da

carrot123456Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Gs Et 29 - A05 2011 - e PDF

Caricato da

carrot123456Copyright:

Formati disponibili

Translation

Supplementary requirements for the testing and certification of face

shields for electrical works

Status as of 2011-05

GS-ET 29

Expert committee for electrical engineering

Testing and certification body

Gustav-Heinemann-Ufer 130

50968 Kln

GS-ET-29 Face shields for electrical works Page 1 von 26

Status as of 2011-05

The principles set out here will be revised and extended periodically in consideration of

technical progress and the latest findings in the area of occupational safety and health. The

most recent edition shall be binding for testing and certification conducted by the expert

committee for electrical engineering of the testing and certification department at DGUV Test.

This is the English translation of the German test principle. The German original

version is obligatory.

Changes from the edition 2010-02; Rev. 1 (2010-12):

Higher-level Section 4.1 Supplementary optical requirements inserted

Sec. 4.1.2 Diffusion of light and Sec. 4.1.3 Resistance to UV radiation inserted

The supplementary requirements apply in addition to EN 166:2001, in order for compliance

with the PPE Directive 89/686/EEC to be assured.

Note 1:

The tests described in Section 4.2 of the test principles concerning thermal protection were

drawn up with reference to DIN EN 61482-1-2.

Note 2:

The interval between the centre line of the electrode and the calorimeter No. 3 as per Fig. 7

of the test principles was set at 350 mm, based upon practical experience gained with work

on live parts in immediate proximity to the field of vision.

GS-ET-29 Face shields for electrical works Page 2 von 26

Status as of 2011-05

Contents Page

1.0 General 6

1.1 Scope of application 6

1.2 Test and certification procedure 6

2.0 Definitions 6

2.1 Face shields for electricians 6

2.2 Torso 6

2.3 VLT 6

3.0 Requirements and tests 7

3.1 General rules 7

3.2 Documentation to be submitted 7

3.3 Test specimens 7

4.0 Additional requirements/tests 7

4.1 Additional optical requirements 7

4.1.1 Visible light transmittance (380 nm to 780 nm) 7

4.1.1.1 Requirements 8

4.1.1.2 Testing 8

4.1.2 Diffusion of light 9

4.1.3 Resistance to UV radiation 9

4.2 Thermal protection (arc testing) 9

4.2.1 Test arrangement 9

4.2.2 Test chamber 9

4.2.3 Torso 9

GS-ET-29 Face shields for electrical works Page 3 von 26

Status as of 2011-05

4.2.4 Test head with calorimeter 10

4.2.4.1 Arrangement of the sensors 10

4.2.4.2 Sensor measured values 10

4.2.5 Electrical power supply and electrodes 10

4.2.5.1 Electrical test circuit 10

4.2.5.2 Instrumentation in the electrical test circuit 11

4.2.5.3 Electrodes 11

4.2.5.4 Igniter wire 11

4.2.6 Parameters of the electric arc 12

4.2.7 Data recording system 12

4.2.8 Preparation of the test specimen 12

4.2.9 Calibration 13

4.2.9.1 Measurement chain for recording of the temperature 13

4.2.9.2 Calibration of the electrical test circuit and performance

of the test 13

4.2.9.3 Confirmation of the settings of the test arrangement 14

4.2.9.4 Preparation and treatment of the chamber 14

4.2.10 Maintenance and care of the test arrangement 15

4.2.10.1 Care of the sensor surface 15

4.2.10.2 Care of the torso and test head 15

4.2.11 Test method 15

4.2.11.1 Test arrangement 15

4.2.11.2 Number of test specimens 15

4.2.11.3 Test parameters 15

4.2.11.4 Test conditions and initial temperature 16

4.2.11.5 Performance of the test 16

GS-ET-29 Face shields for electrical works Page 4 von 26

Status as of 2011-05

4.2.11.6 Evaluation of the measurement results 17

4.2.11.7 Evaluation of the test results 17

4.3 Additional marking 19

4.4 User information 19

5.0 Annexes 26

5.1 Directives/regulations 26

5.2 Standards 26

GS-ET-29 Face shields for electrical works Page 5 von 26

Status as of 2011-05

1.0 General

1.1 Scope of application

The supplementary requirements apply to Face shields worn by electricians during

work in which a risk of a fault arc exists.

1.2 Test and certification procedure

The test and certification procedure shall be launched once the agreement has been

signed by the contracting parties. The technical documentation listed in Section 3.2

must be submitted together with the agreement.

2.0 Definitions

2.1 Face shields for electrical works

Face shields for electrical works are a form of personal protective equipment which is

worn in front of the face in combination with headgear.

The face shield consists of a transparent protective filter which is either attached to the

frame or held by a surround manufactured from textile materials.

2.2 Torso

The torso is a model of the human upper body which consists of a plate of non-

flammable, non-metal material.

2.3 VLT (visible light transmittance)

The stated visible light transmittance (VLT) makes allowance for the spectral sensitivity

of the average human eye to daylight in accordance with ISO 10527:2006.

GS-ET-29 Face shields for electrical works Page 6 von 26

Status as of 2011-05

3.0 Requirements and tests

3.1 General rules

Unless specified to the contrary in the individual test sections, the tests shall be

performed at an ambient temperature of 20 C 5 K and a relative atmospheric

humidity of 30% to 85%.

The tests shall be conducted in accordance with the manufacturer's rating data.

The measured values shall not differ from the rating data by more than 5%.

3.2 Documentation to be submitted

- The following technical documentation is required for testing:

- User information, including technical data

- Parts lists

- Data sheets of the materials employed

- Product drawings, including dimensions

- Fabrication instructions

3.3 Test specimens

4 test specimens, including headgear, and 3 test specimens (200 x 200 mm)

of the lens are required for the tests for each type of electrician's face shield.

4.0 Additional requirements/tests

4.1 Additional optical requirements

4.1.1 Visible light transmittance (380 nm to 780 nm)

GS-ET-29 Face shields for electrical works Page 7 von 26

Status as of 2011-05

4.1.1.1Requirements

The visible light transmittance1 (VLT) shall be measured by means of the following

light sources on each of three samples2:

a) Standard light type A

b) Fluorescent lamp

c) White-light LED

The lenses are divided into classes in accordance with the D65 standard light source:

Class 0:

Visible light transmittance (D65) 75%

(no information in the user information)

Class 1:

Visible light transmittance (D65) 50% VLT (D65) < 75%

(constraints must be described in the user information)

Class 2:

Visible light transmittance (D65) < 50%

(constraints must be described in the user information)

4.1.1.2Testing

Measurement shall be performed by means of a spectrometer with a resolution of at

least 5 nm (note: the MU rises by 1% compared to a resolution of 1 nm; an interval

of 1 nm should ideally be employed).

The test arrangement for determining the three visual light transmittance (VLT) values

(standard light type A, fluorescent lamp, white-light LED) is shown in Fig. 3.

The dimensions of the lens must be at least 200 x 200 mm.

The visual light transmittance shall be determined at three different positions for both

the left and the right eye. The metering fields for this purpose are shown in Fig. 4.

The test specimen shall be clamped flat in the test arrangement.

Three series of measurements shall be performed for each metering field and light

source.

The mean value of each series shall be employed for evaluation of the VLT.

The measurement uncertainty must be stated.

The test shall be deemed passed when the figure stated by the manufacturer for each

light source lies within the tolerance (+3% / -5%) of the measured test result.

1

Test arrangement, see Fig. 3

2

Each lens may be re-used on each light source

GS-ET-29 Face shields for electrical works Page 8 von 26

Status as of 2011-05

4.1.2 Diffusion of light

For oculars related to Electric arc class 1, DIN EN 166, Sec. 7.1.2.3 applies.

For oculars related to Electric arc class 2, DIN EN 166, Sec. 7.1.2.3 with the

maximum value for welding filters applies.

4.1.3 Resistance to UV radiation

For oculars related to Electric arc class 1, DIN EN 166, Sec. 7.1.5.2 applies.

For oculars related to Electric arc class 2, DIN EN 166, Sec. 7.1.5.2 for

welding filters applies.

If the Light transmittance class according to these Principles of testing,

Sec. 4.1.1.1 changes due to the radiation, then this class must be indicated on

the markings and the necessary information for marking according to these

Principles of testing, Sec. 4.4 must be inserted into the user information.

4.2 Thermal protection (arc testing)

4.2.1 Test arrangement

The test arrangement shall comprise the following elements:

- Test chamber

- Torso

- Test head with calorimeter

- Electrical power supply

- Data recording system

4.2.2 Test chamber

The test chamber as shown in Fig 5 must be manufactured from non-conductive,

heat-resistant material (e.g. plaster of Paris).

4.2.3 Torso

A torso in the form of a plate (H = 500 mm, B = 600 mm, D = min. 10 mm)

manufactured from non-flammable, non-metal material shall be employed

for the test.

The torso shall be arranged such that it remains in position throughout the

duration of the electric arc.

GS-ET-29 Face shields for electrical works Page 9 von 26

Status as of 2011-05

4.2.4 Test head with calorimeter

The test head shall correspond approximately to the 50th percentile of male

adults and shall be manufactured from non-flammable, non-metal material.

Nominal dimensions and design details are stated below and in Fig. 6.

4.2.4.1 Arrangement of the sensors

The sensor shall have a diameter of 60 mm and shall comprise an insulated

mounting and a calorimeter. The calorimeter shall satisfy ISO 9151 and shall

consist of a round disk manufactured from electrolytic copper with a diameter

of 40 mm and a mass of 18 g, and a type T thermoelement (copper-constantan).

The thermoelement shall be manufactured from copper-constantan wire (type T

to IEC 60584-1) and shall be attached such that the constantan wire is located in

the centre of the disk and the copper wire outside the centre. The disk shall be

embedded in an insulated mounting. The sensor shall be fitted into the test plate

such that it is flush with the surface of the latter. The surface of the copper disk,

the purpose of which is to absorb heat, shall be coated with a thin layer of

optically black paint.

4.2.4.2 Sensor measured values

The measured values from the sensors for the temperature rise in C shall be

converted to thermal energy (acting energy) in units of kJ/m2 by multiplication

of the delta temperature values by a constant factor of 5.52 kJ/m2 C.

NOTE: The constant factor is based upon an average value for the thermal

capacity of copper of Cp = 0.385 J/g C (80 C) within the tested

temperature range.

4.2.5 Electrical power supply and electrodes

For the duration of the arc, the electrical power supply must be capable of

delivering a virtually constant alternating voltage and a constant short-circuit

current (symmetrical alternating current component). Alternating currents at

50 Hz and 60 Hz are permissible.

4.2.5.1 Electrical test circuit

The electrical test circuit shall be configured such that under no-load conditions,

a voltage corresponding to the test voltage is generated, and a current

corresponding to the test current would flow were the electrodes to be connected

with no impedance (short-circuit). The arc tests shall be performed in this

configuration.

GS-ET-29 Face shields for electrical works Page 10 von 26

Status as of 2011-05

4.2.5.2 Instrumentation in the electrical test circuit

The test voltage and test current shall be demonstrated by measurements.

The test current (prospective short-circuit current) shall be recorded in the form

of an oscillogram showing the instantaneous values. A graphical representation

shall be produced.

A circuit-breaker, which shall be monitored for the duration of the arc, shall be

employed for making and breaking of the electrical test circuit.

NOTE: No particular requirements apply to making of the test circuit (the angles

affecting the sine wave of the current) and the phase angle or the X/R ratio of the

source impedance; the X/R ratio should if possible be between 1 and 5.

4.2.5.3 Electrodes

The electrodes shall be manufactured from electrical copper and electrical

aluminium rods (with 99.5% Al or electrical Al Mg Si 2.5) (see Fig. 5).

4.2.5.4 Igniter wire

An igniter wire linking the two electrode tips shall be employed for ignition of the

arc. This wire is consumed during testing. Its mass must therefore be kept low,

in order to reduce the number of burns caused by liquid material. A copper wire

with a nominal diameter not exceeding 0.5 mm shall be employed as the igniter

wire.

GS-ET-29 Face shields for electrical works Page 11 von 26

Status as of 2011-05

4.2.6 Parameters of the electric arc

The parameters of the electric arc are defined as follows:

Test voltage: AC 400 V 5%

Test current/arc, class: Class 1: 4 kA 5%

Class 2: 7 kA 5%

Arc duration: 500 ms 5%

Frequency: The test shall be performed at a frequency of (50 1) or

(60 0.12) Hz.

These parameters must be tuned during the tests, in order for the same values

to be employed for all tests within a series. The actual arc voltage and arc

current shall be recorded during the arc duration in each test.

4.2.7 Data recording system

Recording of measured values and data:

The system shall be capable of recording the current and voltage of the electrical

test circuit simultaneously.

The recording frequency shall be at least 5 kHz.

The actual arc current and the actual arc voltage shall be recorded for each arc

test. These values shall be reproduced in graphs within the report.

In addition to the voltage and the current, the two initial values of the calorimeter

shall be recorded. The temperature values must be recorded for at least 30 s

with a scanning rate of at least 50 ms per channel.

4.2.8 Preparation of the test specimen

4.2.8.1 The test head shall be attached to the torso such that it is flush with the transition

to the neck and remains in position throughout the duration of the electric arc

(Fig. 7).

GS-ET-29 Face shields for electrical works Page 12 von 26

Status as of 2011-05

4.2.8.2 The face shield shall be stored for at least 24 hours at a temperature of

between 18 and 28 C and a relative atmospheric humidity of between

45% and 75%.

4.2.8.3 The face shield shall be fitted to the test head together with the headgear

specified by the manufacturer in accordance with the information in the

instruction manual.

4.2.9 Calibration

4.2.9.1 Measurement chain for recording of the temperature

The entire measurement chain, comprising calorimeter and data recording

system, shall be calibrated at regular intervals.

It shall be possible to calibrate several temperature measurement points at

values above 100 C. The data recording system shall be calibrated. Owing

to the characteristics of the tests, several checks of the calibration are

recommended.

4.2.9.2 Calibration of the electrical test circuit and performance of the test

For demonstration of the test conditions, calibration oscillograms of the set

prospective test current and of the test voltage must be recorded with

unchanged test parameters at least for each series of tests.

The reference measurement shall be performed without test specimen; in this

case, the directly acting energy Ei0 is measured.

It shall be demonstrated that in accordance with Fig. 3 of DIN EN 61482-1-2,

the recorded energy Ei0of each sensor on the test plate lies within the range

of the double standard deviation 2 s of the mean value in accordance with

Table 2.

Test current Mean Ei0 Double standard

deviation 2 s

kJ/m2 (cal/cm2) kJ/m2 (cal/cm2)

Class 1: 4 kA 135 (3.2) 56 (1.3)

Class 2: 7 kA 423 (10.1) 78 (1.9)

Table 2: Statistically validated mean values of the directly acting energy

GS-ET-29 Face shields for electrical works Page 13 von 26

Status as of 2011-05

The value of the arc energy shall be determined for each individual test.

A test shall be valid only if the arc energy W arc lies within the range of

the double standard deviation 2 s of the mean value in accordance with

Table 3. Otherwise, the test must be repeated.

Test current Mean value Warc Double standard

deviation 2 s

kJ kJ

Class 1: 4 kA 158 34

Class 2: 7 kA 318 44

Table 3: Values for the permissible arc energy

4.2.9.3 Confirmation of the settings of the test arrangement

The settings of the test arrangement shall be confirmed for each test.

The measured values to be recorded are the arc current, arc duration, arc

energy and arc voltage. The diagram of the arc current shall be recorded in

order to assure the correct phase characteristics. The ambient temperature

and relative atmospheric humidity shall also be recorded. Influences from

wind or air currents shall be prevented.

4.2.9.4 Preparation and treatment of the chamber

The chamber shall be prepared for the test and treated.

Refer to Fig. 5 for the arrangement of the chamber.

The chamber shall be dry.

Prior to testing, the following instructions concerning preparation and treatment

shall be observed:

The "plaster-of-Paris box" shall be dried in an oven for 12 hours at a temperature

of approximately 60 C. It shall be demonstrated that the weight and the

electrical surface resistance have not changed by more than 5% at the end of

preparations.

GS-ET-29 Face shields for electrical works Page 14 von 26

Status as of 2011-05

4.2.10 Maintenance and care of the test arrangement

4.2.10.1 Care of the sensor surface

The surface of each sensor shall be wiped immediately following each test in

order for any decomposition products to be removed which have precipitated

and which could subsequently give rise to faults. Should deposits have collected

and appear to be thicker than a paint coating or to be uneven, the sensor surface

shall be repaired. The sensor shall be cleaned carefully when cold with an

acetone or petroleum solvent which permits gentle treatment. A thin coat of black

high-temperature paint shall be applied to the surface. The same coating shall

be applied to all sensors. It shall be ensured that the coated surface is dry prior

to the beginning of testing.

4.2.10.2 Care of the torso and test head

The torso and test head must remain dry. Where testing is performed outdoors,

the torso and test head must be covered during longer intervals between tests,

in order to prevent solar radiation from causing excessive temperature rises.

4.2.11 Test method

4.2.11.1 Test arrangement

The test chamber, test head and torso shall be arranged as shown in Fig. 7.

4.2.11.2 Number of test specimens4 test specimens shall be tested for each face

shield type.

4.2.11.3 Test parameters

The test parameters are defined for the following two characteristic test classes:

Test class Test current Test voltage Arc duration

kA V AC ms

Class 1 4 5% 400 5% 500 5%

Class 2 7 5% 400 5% 500 5%

Table 4: Test parameters

GS-ET-29 Face shields for electrical works Page 15 von 26

Status as of 2011-05

4.2.11.4 Test conditions and initial temperature

The tests shall be performed at an ambient temperature Ta of between 15 C

and 35 C and a relative atmospheric humidity of 25% to 75%.

The initial temperature of the sensors shall be between 15 C and 35 C.

The ambient temperature Ta and the initial temperature of the sensors To shall

be measured. It must be ensured that the initial temperature of the sensors

(during measurement of the temperature difference by means of the

thermoelements) within series of tests lies within a tolerance of To = Ta 2 C.

Decomposition products must be removed. The active surface of the sensors

shall be renewed frequently by recoating with black paint.

NOTE 1: If necessary, the sensors should be cooled by means of an air jet

or by contact with a cold surface. Should condensed decomposition

products become thicker than the paint coating, the sensor shall be

cleaned, once cool, with an acetone or mineral-oil-based solvent.

The surface shall be recoated with black paint.

The same paint shall be used for all sensors.

NOTE 2: Should suitable equipment be required during outdoor tests in order

to prevent the influence of wind, rain, etc., the tests shall begin not

later than 5 minutes following removal of the item under test from

the pretreatment atmosphere.

4.2.11.5 Performance of the test

The arc shall be ignited within five minutes of removal of the face shield from the

pretreatment atmosphere.

The point at which the arc is ignited must be determined.

The curves for the temperature rise of all sensors in the test series shall be

recorded for the entire exposure time of 30 seconds.

The value pairs (maximum value of the temperature rise Tp at the points in

time indicated in Table 5) shall be determined for each sensor.

GS-ET-29 Face shields for electrical works Page 16 von 26

Status as of 2011-05

4.2.11.6 Evaluation of the measurement results

The acting energy shall be calculated by multiplication of the maximum value of

the temperature rise by the sensor constant 5.52 kJ/m2 C (or 0.132 cal/cm2 C).

Eio = 5.52 (kJ/m2 C) x Tp.o (C)

or Eio = 1.132 (cal/cm2 C) x Tp,o (C)

Eit = 5.52 (kJ/m2 C) x Tp (C)

or Eit = 1.132 (cal/cm2 C) x Tp (C)

The directly acting energy Eio and the four values of the transferred energy Eit

shall be determined, as shall the mean value of the four Eit values and their

corresponding random error range of 95%.

4.2.11.7 Evaluation of the test results

The test shall be deemed passed when, following extinguishing of the fault arc:

- The combustion time of the test specimen is 5 s

- The test specimen does not fuse through

- The test specimen is not fully punctured

- The value pairs of all calorimeters of the test head lie below the relevant -

values stated in Table 5

GS-ET-29 Face shields for electrical works Page 17 von 26

Status as of 2011-05

Time to reach the Heat flow Acting energy Peak temperature

peak value (temperature rise according

temperature to the calorimeter)

2 2

s kW/m kJ/m T C

1 50 50 8.9

2 31 61 10.8

3 23 69 12.2

4 19 75 13.3

5 16 80 14.1

6 14 85 15.1

7 13 88 15.5

8 11.5 92 16.2

9 10.6 95 16.8

10 9.8 98 17.3

11 9.2 101 17.8

12 8.6 103 18.2

13 8.1 106 18.7

14 7.7 108 19.1

15 7.4 111 19.7

16 7.0 113 19.8

17 6.7 114 20.2

18 6.4 116 20.6

19 6.2 118 20.8

20 6.0 120 21.2

25 5.1 128 22.6

30 4.5 134 23.8

Table 5: Resistance of human tissue to heat, second-degree burns

GS-ET-29 Face shields for electrical works Page 18 von 26

Status as of 2011-05

4.3 Additional marking

In addition to marking of the lens in accordance with Section 9.2 of DIN EN 166, the

code for the resistance to fault arcs (8) shall be followed by indication of the fault arc

class (1 or 2) and the visible light transmittance for the standard light type A

(0 or 1 or 2), separated by dashes.

Example: 8 - 1 - 0

The test shall be deemed passed when the marking matches the values determined

in accordance with Sections 4.1 and 4.2.

4.4 User information

In addition to the information required by DIN EN 166 Section 10, the following marking

information must be provided:

- Explanation of the code for the fault arc class by statement of the corresponding

short-circuit current (test current) and of the scope of use.

- Explanation of the code for the visible light transmittance, according to the

classification in accordance with Section 4.1.1.

- In the case of light transmittance classes 1 and 2, the following additional

information is required:

Additional explanations of the constraints, relating to the visible light

transmission with the different light sources.

Additional information concerning the light source required at the workplace

in order for a minimum illumination of 30 lux to be attained behind the

electrician's face shield.

Example:

At a transmittance of 70% for standard light Type A, the value of the additional light

source is at least 39 lux (calculated as follows: 1.3 30 lux = 39 lux).

GS-ET-29 Face shields for electrical works Page 19 von 26

Status as of 2011-05

Wavelength

Fig 1: Spectrum (fluorescent lamp)

Wavelength

Fig 2: Spectrum (white light LED)

GS-ET-29 Face shields for electrical works Page 20 von 26

Status as of 2011-05

Diaphragm 1 Diaphragm 2

Ocular

Light source

Sensor of the

spectrometer

Fig 3 Arrangement for measurement of the visible light transmittance

Where light type A is employed (standard light type A in accordance with DIN 5033):

* D > 20 times the filament diameter, at least 1 m

* B of D

* A and C shall be positioned such that no reflexes are produced on the sensor

Where the fluorescent lamp is used

(typical example: daylight spectrum, manufacturer: OSRAM, type: L/827; see Fig. 1):

* D at least 0.75 m

* B of D

* A and C shall be positioned such that no reflexes are produced on the sensor

Where LED lighting is used

(typical example: manufacturer: LINUS, type: Luxion STAR 065150000 with condenser

and diffusing panel; see Fig. 2):

* D at least 0.5 m

* B of D

* A and C shall be positioned such that no reflexes are produced on the sensor

(if necessary, panel A may be omitted)

Once selected, the intervals are mandatory for the entire series of measurements, and

must be documented.

GS-ET-29 Face shields for electrical works Page 21 von 26

Status as of 2011-05

Upper edge of the flat screen

106

80

MF1 MF2

35

54

MF3 MF4

Ca. 200

45

MF5 MF6

80

Ca. 200

Fig. 4: Metering fields (dimensions in mm)

GS-ET-29 Face shields for electrical works Page 22 von 26

Status as of 2011-05

Front view

Detail

Profile from line A - A

Fig 5: Test chamber

Dimensions in mm

Legend

1 Non-conductive heart-resistand material (e.g. plaster-of-Paris box)

2 Insulating plate, thickness > 15

3 Electrodes diameter 25 (top aluminium, bottom copper)

4 Holes diameter 14, depth 20

GS-ET-29 Face shields for electrical works Page 23 von 26

Status as of 2011-05

Fig. 6: Test head

Dimensions in mm; tolerance: 1.5

Dimension Values [mm]

a 218

b 111

c 175

d 200

e 35

f 93

g 30

h 160

i 80

j 261

k 35

l 105

NOTE: All head dimensions which are not defined may be selected freely; they

should however be oriented towards the 50th percentile of male adults.

GS-ET-29 Face shields for electrical works Page 24 von 26

Status as of 2011-05

Centre of

electrodes Test chamber

86

500

350 5 93

min. 500

Torso

(500 x 600 mm)

(height x width)

Fig. 7: Test arrangement (dimensions in mm)

GS-ET-29 Face shields for electrical works Page 25 von 26

Status as of 2011-05

5.0 Annexes

5.1 Directives

Council Directive 89/686/EEC of 21 December 1989 on the approximation of the

laws of the Member States relating to personal protective equipment

5.2 Standards

EN 166:2001 Personal eye protection-Specifications

ISO 9151:1995-05 Protective clothing against heat and flame

- Determination of heat transmission on exposure to flame

IEC 60584-1:1995-09 Thermocouples

Part 1: Reference tables

EN 61482-1-2:2007 Live working -

Protective clothing against the thermal hazards of an electric

arc Part 1-2 Test methods - Method 2: Determination of arc

protection class of material and clothing by using a

constrained and directed arc

(box test).

ISO 10527: 2006 CIE standard colorimetric observers

GS-ET-29 Face shields for electrical works Page 26 von 26

Status as of 2011-05

Potrebbero piacerti anche

- A Practical Guide to The Wiring Regulations: 17th Edition IEE Wiring Regulations (BS 7671:2008)Da EverandA Practical Guide to The Wiring Regulations: 17th Edition IEE Wiring Regulations (BS 7671:2008)Nessuna valutazione finora

- Practical Power System and Protective Relays CommissioningDa EverandPractical Power System and Protective Relays CommissioningValutazione: 4.5 su 5 stelle4.5/5 (10)

- Field Inspection Testing Electrical EquipmentDocumento21 pagineField Inspection Testing Electrical Equipmentkisan singh100% (2)

- 400kV XLPE CablesDocumento25 pagine400kV XLPE CablespijakzkaraibowNessuna valutazione finora

- VLF Sinus 45 v2 UG enDocumento72 pagineVLF Sinus 45 v2 UG enluis trujilloNessuna valutazione finora

- bs7671 Iee On Site GuideDocumento184 paginebs7671 Iee On Site Guidemigzx95% (19)

- 2912,297 Emc ReportsDocumento64 pagine2912,297 Emc Reportsluis palominoNessuna valutazione finora

- Remote Terminal Unit: Item DescriptionDocumento33 pagineRemote Terminal Unit: Item DescriptionMohd Izham IdrisNessuna valutazione finora

- User Manual: HuksefluxDocumento47 pagineUser Manual: HuksefluxSilvia Guerrero GonzalezNessuna valutazione finora

- Test Report: Report No.: 13A052707E-E Page 1 of 67Documento67 pagineTest Report: Report No.: 13A052707E-E Page 1 of 67Amadeo AntonioNessuna valutazione finora

- IEE On-Site GuideDocumento179 pagineIEE On-Site GuideMahmud Sied100% (5)

- Os10c 5Documento84 pagineOs10c 5Marudavanan SomasundaramNessuna valutazione finora

- Elec Wiring Regs 2007 Rev 01Documento240 pagineElec Wiring Regs 2007 Rev 01Akhtar Abbas Syed100% (2)

- 2003 831 01 - Fiber Optic AttenuatorDocumento51 pagine2003 831 01 - Fiber Optic AttenuatorchopanalvarezNessuna valutazione finora

- 303 Revision of Qualification Procedures For HV and EHV AC Extruded Underground Cable SystemsDocumento92 pagine303 Revision of Qualification Procedures For HV and EHV AC Extruded Underground Cable SystemsepriNessuna valutazione finora

- Transductor Lineal Balluff Perfil Ethernet IP PDFDocumento19 pagineTransductor Lineal Balluff Perfil Ethernet IP PDFGerardo Cruz EspinosaNessuna valutazione finora

- Cable PDDocumento84 pagineCable PDSangamithran DuraiswmayNessuna valutazione finora

- Electrical Installations On Construction SitesDocumento36 pagineElectrical Installations On Construction SitesvozoscribdNessuna valutazione finora

- Ventilation Systems and Components of Nuclear Power Plants: Ohje GuideDocumento17 pagineVentilation Systems and Components of Nuclear Power Plants: Ohje Guideraushan mishraNessuna valutazione finora

- Ventilation System Nuclear Power PlantDocumento17 pagineVentilation System Nuclear Power PlantNandan RajeNessuna valutazione finora

- WELMEC Guide 2.1 v2001 Issue 4Documento31 pagineWELMEC Guide 2.1 v2001 Issue 4Fabio ComunettiNessuna valutazione finora

- Pressure Gauge SelectionDocumento8 paginePressure Gauge Selectionnastyn-1Nessuna valutazione finora

- K16175, K16177 - Manual REV K-ADocumento21 pagineK16175, K16177 - Manual REV K-Amoh_ichwanuddinNessuna valutazione finora

- 400kV GIS - 1512101 R6Documento36 pagine400kV GIS - 1512101 R6waqarNessuna valutazione finora

- Demonstrate Knowledge of Electric Switchboard Testing: Level 4 Credits 3 PurposeDocumento4 pagineDemonstrate Knowledge of Electric Switchboard Testing: Level 4 Credits 3 Purposemagdy473Nessuna valutazione finora

- SIEMENS Transformer TestingDocumento117 pagineSIEMENS Transformer TestingvijayNessuna valutazione finora

- IEC61727 - Characteristics of The Utility Interface - Design Qualification For Invertors PDFDocumento28 pagineIEC61727 - Characteristics of The Utility Interface - Design Qualification For Invertors PDFCliffNessuna valutazione finora

- IEC61727 - Characteristics of The Utility Interface - Design Qualification For InvertorsDocumento28 pagineIEC61727 - Characteristics of The Utility Interface - Design Qualification For InvertorsCliffNessuna valutazione finora

- S1474001-General Requirements For Testing of Pipe SystemsDocumento20 pagineS1474001-General Requirements For Testing of Pipe SystemsBhawyesh KumarNessuna valutazione finora

- User S ManualDocumento16 pagineUser S ManualYacine YaninaNessuna valutazione finora

- Instruction ManualDocumento26 pagineInstruction ManualFabiano TavaresNessuna valutazione finora

- PDP 03 Tuv Introduction IecDocumento28 paginePDP 03 Tuv Introduction Iecdestro57Nessuna valutazione finora

- Raychem Im h57754 Misurfacesnowmeltingcom en - tcm432 55954 PDFDocumento100 pagineRaychem Im h57754 Misurfacesnowmeltingcom en - tcm432 55954 PDFNagaraj RamNessuna valutazione finora

- Functional Specification: Electric Network Control System With Programmable Logic ControllersDocumento35 pagineFunctional Specification: Electric Network Control System With Programmable Logic ControllersHalim KazdarNessuna valutazione finora

- 8474L 000 JSD 1510 002 0Documento8 pagine8474L 000 JSD 1510 002 0danhlakisu1Nessuna valutazione finora

- S Met CT - 00Documento8 pagineS Met CT - 00HARINessuna valutazione finora

- Norsok Standard E-002Documento31 pagineNorsok Standard E-002mjinspectorNessuna valutazione finora

- Regulations For Electrical InstallationsDocumento135 pagineRegulations For Electrical InstallationsGILBERTO ALTUNARNessuna valutazione finora

- 48TMSS18R0Documento45 pagine48TMSS18R0yasirNessuna valutazione finora

- Mil STD 331dDocumento291 pagineMil STD 331dNicolasSuchNessuna valutazione finora

- 14 - EMC Report CSA 4th edition-E41867-00-00VKDocumento61 pagine14 - EMC Report CSA 4th edition-E41867-00-00VKAlejandro Barrientos PreciadoNessuna valutazione finora

- Nea Smart - R Basis 230 VDocumento16 pagineNea Smart - R Basis 230 Valexand3r2008Nessuna valutazione finora

- E-001 - Electrical Systems Ed5, Jul2007Documento112 pagineE-001 - Electrical Systems Ed5, Jul2007Dragoslav DzolicNessuna valutazione finora

- E 001Documento65 pagineE 001Alessandro MoroniNessuna valutazione finora

- Practical Industrial Data Networks: Design, Installation and TroubleshootingDa EverandPractical Industrial Data Networks: Design, Installation and TroubleshootingValutazione: 5 su 5 stelle5/5 (2)

- Process Tomography: Principles, Techniques and ApplicationsDa EverandProcess Tomography: Principles, Techniques and ApplicationsNessuna valutazione finora

- Offshore Electrical EngineeringDa EverandOffshore Electrical EngineeringValutazione: 3.5 su 5 stelle3.5/5 (5)

- Patch Clamping: An Introductory Guide to Patch Clamp ElectrophysiologyDa EverandPatch Clamping: An Introductory Guide to Patch Clamp ElectrophysiologyValutazione: 4 su 5 stelle4/5 (2)

- Principles and Applications of Thermal AnalysisDa EverandPrinciples and Applications of Thermal AnalysisPaul GabbottValutazione: 4 su 5 stelle4/5 (1)

- Practical Electrical Network Automation and Communication SystemsDa EverandPractical Electrical Network Automation and Communication SystemsValutazione: 3.5 su 5 stelle3.5/5 (4)

- Dynamometer: Theory and Application to Engine TestingDa EverandDynamometer: Theory and Application to Engine TestingNessuna valutazione finora

- Digital Circuit Testing: A Guide to DFT and Other TechniquesDa EverandDigital Circuit Testing: A Guide to DFT and Other TechniquesNessuna valutazione finora

- Tunnelling and Negative Resistance Phenomena in SemiconductorsDa EverandTunnelling and Negative Resistance Phenomena in SemiconductorsNessuna valutazione finora

- TechInfo01 IT System FA enDocumento6 pagineTechInfo01 IT System FA encarrot123456Nessuna valutazione finora

- A Note On Determination of Sample Size For A Likert Scale: Jinwoo Park, Misook JungDocumento6 pagineA Note On Determination of Sample Size For A Likert Scale: Jinwoo Park, Misook Jungcarrot123456Nessuna valutazione finora

- Status Indicators: AppendixDocumento3 pagineStatus Indicators: Appendixcarrot123456Nessuna valutazione finora

- DD Hvac Lesson4 TutorialDocumento3 pagineDD Hvac Lesson4 Tutorialcarrot123456Nessuna valutazione finora

- TranslationDocumento26 pagineTranslationcarrot123456Nessuna valutazione finora

- Examining RCM Vs TPMDocumento16 pagineExamining RCM Vs TPMcarrot123456Nessuna valutazione finora

- 2014 Energized Electrical Work Permit - ByU-IdahoDocumento2 pagine2014 Energized Electrical Work Permit - ByU-Idahocarrot123456Nessuna valutazione finora

- Histret SPDocumento39 pagineHistret SPcarrot123456Nessuna valutazione finora

- OEE Explained PDFDocumento3 pagineOEE Explained PDFcarrot123456Nessuna valutazione finora

- Rating Criteria For Toll Roads, Bridges and Tunnels: Global Infrastructure & Project FinanceDocumento23 pagineRating Criteria For Toll Roads, Bridges and Tunnels: Global Infrastructure & Project Financecarrot123456Nessuna valutazione finora

- MSG3Documento14 pagineMSG3carrot123456Nessuna valutazione finora

- BalancedScorecard Guidance Fall2003Documento2 pagineBalancedScorecard Guidance Fall2003carrot123456Nessuna valutazione finora

- Infor LXDocumento4 pagineInfor LXcarrot123456Nessuna valutazione finora

- Edec Standard: CoretronicDocumento14 pagineEdec Standard: Coretronic彭以和Nessuna valutazione finora

- Fluke 715 Process Calibrator ManualDocumento16 pagineFluke 715 Process Calibrator ManualLuis Angel Quispe AyuqueNessuna valutazione finora

- Please Define Type of Service To Be Performed Here!Documento5 paginePlease Define Type of Service To Be Performed Here!Pedro ViegasNessuna valutazione finora

- Ip RoutingDocumento24 pagineIp RoutingArun SomashekarNessuna valutazione finora

- Jurnal WAHYUDI 2009Documento4 pagineJurnal WAHYUDI 2009Rizka FazanauvaNessuna valutazione finora

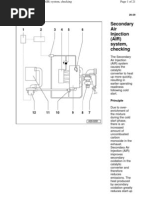

- Audi TT Sec AirDocumento21 pagineAudi TT Sec Airdonghungco080% (1)

- Aws BisDocumento2 pagineAws BisJinesh SanghviNessuna valutazione finora

- DN670 Ductile Iron Manhole Cover D400 EN124Documento11 pagineDN670 Ductile Iron Manhole Cover D400 EN124munisipalcastings100% (1)

- Fiat 500 L User ManualDocumento348 pagineFiat 500 L User ManualtaxydromosNessuna valutazione finora

- Fluke ScopeMeter 120 SeriesDocumento2 pagineFluke ScopeMeter 120 SerieselectricalenginNessuna valutazione finora

- Resource Allocation AuditDocumento37 pagineResource Allocation AuditAnonymous 9sDkJwRJRNessuna valutazione finora

- Enginnering Manual Yale SmartHome Alarm SeriesDocumento38 pagineEnginnering Manual Yale SmartHome Alarm SeriesGuilherme MonteiroNessuna valutazione finora

- Is.3025.14.1984 - ISO 7888 PDFDocumento13 pagineIs.3025.14.1984 - ISO 7888 PDFRoyal BimhahNessuna valutazione finora

- Pages From TEMA20071Documento1 paginaPages From TEMA20071Wade ColemanNessuna valutazione finora

- IS: 2911 (Part I/Sec 1) - 1979 CODE OF PRACTICE FOR DESIGN AND CONSTRUCTION OF PILE FOUNDATIONSDocumento33 pagineIS: 2911 (Part I/Sec 1) - 1979 CODE OF PRACTICE FOR DESIGN AND CONSTRUCTION OF PILE FOUNDATIONSranjith6688100% (2)

- Mesin Bor Explorac R50Documento12 pagineMesin Bor Explorac R50julianusginting00Nessuna valutazione finora

- SQL Server Stored ProceduresDocumento7 pagineSQL Server Stored Procedureshkdashin100% (1)

- Chapter 15 Database Design Using The REA Data ModelDocumento138 pagineChapter 15 Database Design Using The REA Data Modelislamelshahat100% (1)

- Voyager DVD ManualDocumento80 pagineVoyager DVD ManualGianniNessuna valutazione finora

- ISO 9000 WikipediaDocumento11 pagineISO 9000 WikipediaMOHAMEDABBASNessuna valutazione finora

- Outside Coating and Wrapping For Ug PipesDocumento7 pagineOutside Coating and Wrapping For Ug Pipesonur gunesNessuna valutazione finora

- Ba2078 Ept202olct en Rev0Documento24 pagineBa2078 Ept202olct en Rev0enriqueunoNessuna valutazione finora

- TAUS Evaluating Post-Editor Performance Guidelines 2014Documento5 pagineTAUS Evaluating Post-Editor Performance Guidelines 2014TAUSNessuna valutazione finora

- Inox Pipelines Method StatementDocumento11 pagineInox Pipelines Method StatementIlija RunjajicNessuna valutazione finora

- MBDOC48Documento87 pagineMBDOC48Alberto Valero PelaezNessuna valutazione finora

- Eurocargo Tector 6-26t Electronic System PDFDocumento192 pagineEurocargo Tector 6-26t Electronic System PDFRogério Moreno80% (15)

- Aws Csaa NotesDocumento23 pagineAws Csaa NotesShofi MahmudNessuna valutazione finora

- PanelboardsDocumento15 paginePanelboardsMohamed FaragNessuna valutazione finora

- Data Sheet: Multi-Standard SC 2.1Documento1 paginaData Sheet: Multi-Standard SC 2.1kar_ind4u5636Nessuna valutazione finora

- Call Setup Time OptimizationDocumento2 pagineCall Setup Time OptimizationiarnabNessuna valutazione finora