Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

en

Caricato da

Raphael LinoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

en

Caricato da

Raphael LinoCopyright:

Formati disponibili

Air oil cooler

62002EN.doc 26.03.2008

AIR OIL COOLER LAC

air

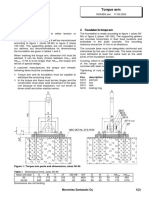

Figure 1

1.2 Cleaning of air fins

The most easy way to clean the air fins is by using

compressed air or rinsing with water. Fouling can be

dealt with using a degreasing agent and a high-

pressure washing system. When using a high-pressure

washing system point the jet carefully parallel to the air

fins.

1.3 Cleaning the inside of oil cooling pipes

1. Operating and maintenance Connect the cooler to a closed circuit and flush the

Air oil cooler LAC is equipped with an electric thermo- inside with perchlorethylene.

switch, which is to be connected to control the fan After cleaning the radiator should be flushed with oil

motor. A relay should be used if the current load is before reconnected to the pressure lubrication system.

superior to:

10 A at 12 V DC 2. Technical data

5A at 24 V DC 2.1 Material

10 A (6 A ind.) 250 V AC

Cooler matrix: Aluminium

Instead of the electric thermo-switch also a spring- Fan blades: Fibre-glass reinforced polypropylene

loaded or thermostatic by-pass valve can be used. Fan house: Steel

2.2 Cooler matrix

Model 50 (C) (standard) dynamic working pressure 14 bar

thermo-switch maximum static pressure 21 bar

maximum oil inlet temperature 120C

Environment: For aggressive atmosphere, check

with Moventas Santasalo Oy for approval.

Model S

2.3 Electric motor

built-in spring-loaded

by-pass valve Insulation: Class F

Temperature rise: Class B

Protection: IP54 (standard)

For the motor power see table 2.

Table 1. The fan diameter

Model T Type [mm] Type [mm]

built-in thermo- LAC 004-2 225 LAC 033-6 650

by-pass valve LAC2 007-4 325 LAC 033-4 650

LAC2 011-4 400 LAC 044-4 650

. LAC2 016-4 456 LAC 056-6 824

LAC2 023-4 538 LAC 0110-6 1066

1.1 Location

Place the cooler so that there is an unrestricted air flow

to and from the cooler. The distance from the nearest

wall should not be less than half the diameter of the fan

(see Figure 1).

Moventas Santasalo Oy 1(2)

Air oil cooler

62002EN.doc 26.03.2008

out

(With bypass

type T)

Bypass

type T

in

Figure 2. Lubrication unit with air oil cooler and MHP pump

Table 2. Lubrication unit with air oil cooler

Cooling Pump Pump Cooler Pump motor Fan motor Noise Dimensions Connections

rating output Module Module 1500 rpm level Weight Oil

Pc Q Power

Power (1m) A B C D E

RC RD

[kW] [dm3/min] [kW] rpm [kW] [dB(A)] [kg] [mm] [mm] [mm] [mm] [mm] male male

0,75 2,5 MHI2 A042 0,75 3000 0,25 70 40 500 730 530 1) 1) R3/4 R3/4

2,5 7,5 MHI5 A042 0,75 3000 0,25 70 40 500 730 530 1) 1) R3/4 R3/4

3,4 11 MHP7 A042 0,75 3000 0,25 70 40 500 730 530 1) 1) R1 R3/4

5,3 18 MHP12 A074 1,1 1500 0,25 64 60 600 800 540 1) 1) R1 R3/4

8,5 18 MHP12 A114 1,1 1500 0,25 71 60 670 870 570 350 400 R1 R3/4

10,5 28 MHP18 A164 1,5 1500 0,37 74 70 730 930 590 350 400 R1 R3/4

15 28 MHP18 A234 1,5 1500 0,75 79 80 850 1020 660 350 400 R1 R3/4

19 44 MHP29 A336 3 1000 0,55 72 100 960 1090 680 350 400 R11/4 R11/4

24 44 MHP29 A334 3 1500 2,2 84 110 960 1090 750 350 400 R11/4 R11/4

25 65 MHP47 A334 4 1500 2,2 84 110 960 1090 750 350 400 R11/4 R11/4

29 65 MHP47 A444 4 1500 2,2 84 130 960 1130 770 350 400 R11/4 R11/4

Moventas Santasalo Oy 2(2)

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Asphalt Quality Control PlanDocumento27 pagineAsphalt Quality Control PlanHassoub Abdul Shafy Hassoub100% (1)

- Calculation of Central Air Conditioning System (Using E20-II Carrier Software) Civil and Architecture Engineering BuildingDocumento88 pagineCalculation of Central Air Conditioning System (Using E20-II Carrier Software) Civil and Architecture Engineering Buildingqshaath87% (15)

- Lessons From Crane RunwaysDocumento5 pagineLessons From Crane Runwaysdicktracy11Nessuna valutazione finora

- Tall Chimney Constrution Old BookDocumento168 pagineTall Chimney Constrution Old BookFrederico Donagemma100% (1)

- Awwa Hdpe PDFDocumento37 pagineAwwa Hdpe PDFRaphael LinoNessuna valutazione finora

- Mil HDBK 697a PDFDocumento122 pagineMil HDBK 697a PDFkulto_kultoNessuna valutazione finora

- Ultrasonic Testing of Austenitic Stainless Steel WeldsDocumento15 pagineUltrasonic Testing of Austenitic Stainless Steel Weldssmartz inspection100% (1)

- A300-600, Ata 36Documento9 pagineA300-600, Ata 36pknight2010Nessuna valutazione finora

- Flare KOD SizingDocumento4 pagineFlare KOD SizingSaid Ahmed Salem100% (1)

- Lubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationDocumento9 pagineLubricants in Industrial Gears: Ath Lubrication Plash Lubrication Rease Lubrication Ressure Feed LubricationRaphael LinoNessuna valutazione finora

- Masonry Support Systems & Lintels: For The Construction IndustryDocumento36 pagineMasonry Support Systems & Lintels: For The Construction IndustryTarun SebastianNessuna valutazione finora

- enDocumento2 pagineenRaphael LinoNessuna valutazione finora

- Mdi 110en PDFDocumento2 pagineMdi 110en PDFRaphael LinoNessuna valutazione finora

- L3206en PDFDocumento2 pagineL3206en PDFRaphael LinoNessuna valutazione finora

- MDI 120EN - Safety GuideDocumento6 pagineMDI 120EN - Safety GuideRaphael LinoNessuna valutazione finora

- 5 - Equivalencia de Normas PERNOSDocumento1 pagina5 - Equivalencia de Normas PERNOSRaphael LinoNessuna valutazione finora

- MDI 165EN - InstallingDocumento5 pagineMDI 165EN - InstallingRaphael LinoNessuna valutazione finora

- Use and Maintenance of Gear UnitDocumento4 pagineUse and Maintenance of Gear UnitRaphael LinoNessuna valutazione finora

- Corrosion Protection and StorageDocumento3 pagineCorrosion Protection and StorageRaphael LinoNessuna valutazione finora

- Assembly Report: Gear Unit: Manuf. Number: DriveDocumento1 paginaAssembly Report: Gear Unit: Manuf. Number: DriveRaphael LinoNessuna valutazione finora

- Use and Maintenance of Gear UnitDocumento4 pagineUse and Maintenance of Gear UnitRaphael LinoNessuna valutazione finora

- Visual Differential Pressure Indicator: Type FPC V 10 VMDocumento1 paginaVisual Differential Pressure Indicator: Type FPC V 10 VMRaphael LinoNessuna valutazione finora

- Pressure Lubrication Unit Connections: 1. GeneralDocumento2 paginePressure Lubrication Unit Connections: 1. GeneralRaphael LinoNessuna valutazione finora

- L3206ENDocumento2 pagineL3206ENRaphael LinoNessuna valutazione finora

- MDI 120EN - Safety GuideDocumento6 pagineMDI 120EN - Safety GuideRaphael LinoNessuna valutazione finora

- Corrosion Protection and StorageDocumento3 pagineCorrosion Protection and StorageRaphael LinoNessuna valutazione finora

- M062210 - Manual Cover SheetDocumento1 paginaM062210 - Manual Cover SheetRaphael LinoNessuna valutazione finora

- M062210 Part ListDocumento4 pagineM062210 Part ListRaphael LinoNessuna valutazione finora

- M062210 Tech SpecDocumento1 paginaM062210 Tech SpecRaphael LinoNessuna valutazione finora

- 2577910.dimensional DrawingDocumento1 pagina2577910.dimensional DrawingRaphael LinoNessuna valutazione finora

- enDocumento1 paginaenRaphael LinoNessuna valutazione finora

- L3206en PDFDocumento2 pagineL3206en PDFRaphael LinoNessuna valutazione finora

- Mdi 110enDocumento2 pagineMdi 110enRaphael LinoNessuna valutazione finora

- Safety Valve Durgo: 2. Ensure The Valve FunctionsDocumento1 paginaSafety Valve Durgo: 2. Ensure The Valve FunctionsRaphael LinoNessuna valutazione finora

- enDocumento2 pagineenRaphael Lino100% (1)

- SHP-Shaft Driven Pump: 1. GeneralDocumento1 paginaSHP-Shaft Driven Pump: 1. GeneralRaphael LinoNessuna valutazione finora

- Astm A105Documento1 paginaAstm A105Raphael LinoNessuna valutazione finora

- enDocumento2 pagineenRaphael LinoNessuna valutazione finora

- Bomba Gorman RuppDocumento15 pagineBomba Gorman RuppdenisNessuna valutazione finora

- Oman-1800x2100-Center Opening Auto Door-b+g+m+5-Sheet No - 01 of 05Documento5 pagineOman-1800x2100-Center Opening Auto Door-b+g+m+5-Sheet No - 01 of 05Lakhwinder SainiNessuna valutazione finora

- 11 Bearing CapacityDocumento14 pagine11 Bearing CapacityVincze RobertNessuna valutazione finora

- Cellecta Sound Proofing Solutions GuideDocumento24 pagineCellecta Sound Proofing Solutions Guidejamiecellecta2012Nessuna valutazione finora

- AlucomatDocumento2 pagineAlucomatJhon WijayaNessuna valutazione finora

- 001 Lca Standard ComponentsDocumento4 pagine001 Lca Standard ComponentsYUCARIE HIGUCHINessuna valutazione finora

- Effect of Various Heat Treatment On The Mechanical Properties of Steel Alloy EN31Documento10 pagineEffect of Various Heat Treatment On The Mechanical Properties of Steel Alloy EN31IJIRSTNessuna valutazione finora

- HIT-HY 200 SupplementDocumento56 pagineHIT-HY 200 SupplementarnoldistunoNessuna valutazione finora

- i.MX 6 Series Thermal Management Guidelines: Document Number: AN4579 Rev. 0, 11/2012Documento90 paginei.MX 6 Series Thermal Management Guidelines: Document Number: AN4579 Rev. 0, 11/2012Daniel MartinsNessuna valutazione finora

- Rr410305 Refrigeration Air ConditioningDocumento8 pagineRr410305 Refrigeration Air ConditioningSrinivasa Rao G100% (5)

- Pitot TubeDocumento8 paginePitot TubeFarhad MalikNessuna valutazione finora

- Application For Fitness Certificate and CertificateDocumento2 pagineApplication For Fitness Certificate and CertificateSreekanth Sreekumar100% (6)

- The Effect of Curing Period and Curing Delay On Concrete in Hot WeatherDocumento8 pagineThe Effect of Curing Period and Curing Delay On Concrete in Hot WeatherSamer al sadikNessuna valutazione finora

- VIC BuildingDocumento80 pagineVIC BuildingSachinNessuna valutazione finora

- Bailey Test Plug PDFDocumento6 pagineBailey Test Plug PDFNissam SidheeqNessuna valutazione finora

- Quiz 1 PrestressDocumento4 pagineQuiz 1 PrestressHeiro KeystrifeNessuna valutazione finora

- Outershield 71E-H: Mild Steel Rutile Cored WireDocumento2 pagineOutershield 71E-H: Mild Steel Rutile Cored WireLuis DuarteNessuna valutazione finora

- PC Enclosure System - PC 5366.350: Date: Jul 21, 2021Documento3 paginePC Enclosure System - PC 5366.350: Date: Jul 21, 2021ashirvad mohantyNessuna valutazione finora

- Aoh Checklist LT and HT MotorDocumento8 pagineAoh Checklist LT and HT MotorElectrical Team100% (1)

- AFBAD2A10971Documento10 pagineAFBAD2A10971Samuel NkereuwemNessuna valutazione finora

- FICARELLI-Loredana Paper-Revised 2 LayoutedDocumento7 pagineFICARELLI-Loredana Paper-Revised 2 LayoutedMarwan ZoueinNessuna valutazione finora