Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tank and Vessel Trace Heating Thermon Temperature Maintenance and Frost Protection HeetSheet Spec Sheet

Caricato da

Carlos SopasCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tank and Vessel Trace Heating Thermon Temperature Maintenance and Frost Protection HeetSheet Spec Sheet

Caricato da

Carlos SopasCopyright:

Formati disponibili

Tel: +44 (0)191 490 1547

Fax: +44 (0)191 477 5371

Email: northernsales@thorneandderrick.co.uk

HeetSheet TM Website: www.heattracing.co.uk

www.thorneanderrick.co.uk

Vessel Heating/Cooling System Product Specifications

Application . . .

HeetSheet tank heating units are comprised of two sheets 1

of 20-gage, type 304 stainless steel, conforming to ASTM

A240. The stainless steel sheets are continuously seam-

welded together along an outer continuous perimeter with

interrupted seam welds arranged inside the perimeter. The

welded unit is hydraulically inflated creating a waffle style 2

pattern of multiple flow paths avoiding internal blockage

possible with single-flow designs.

For temperatures up to 190C, a factory applied non-

hardening heat transfer compound is applied to the surface

of the HeetSheet unit that contacts the tank wall to eliminate

air gaps and provide high thermal contact.

For temperatures above 190C, Thermons BondTrace

425 heat transfer compound may be applied to the

HeetSheet units in the field just prior to the units being

attached to the tank wall.

HeetSheet units are available in multiple sizes and are rolled to

conform to the radius of the tank. Stainless steel tubing inlet Construction . . .

and outlet nozzles are provided for steam or other heating or 1 12 mm Inlet and Outlet Media Connections

cooling media. A simple tubing union compression type fitting 2 Type 304 Stainless Steel Waffle Pattern Panel

is used to attach the inlet and outlet tubes to ThermoTube

3 Factory-Applied Nonhardening Heat

pre-insulated leads (supply tubing) and tails (return tubing).

Transfer Compound (see cross section below)

yyyyyy

;;;;;;

Ratings . . .

Max. operating temperature ........................................ 260C Waffle Pattern

Minimum operating temperature .............................. -200C Heat Transfer Compound Thermal Insulation

;;;;;;

yyyyyy

Max. recommended pressure ............................ 1,720 kPa g

Hydrostatic test pressure ....................................... 2580 kPa

Heat transfer coefficient ............. HeetSheet unit to tank wall

;;;;;;;;;;

yyyyyyyyyy

;;;;;;;;;;

yyyyyyyyyy

115-230 W/m2-C

ASME Inspection/Certification . . .

ASME does not require containers of this internal volume and

pressure rating to be certified. Specifically, the maximum

;;;;;;;;;;

yyyyyyyyyy Tank Wall

Typical Cross Section

stored energy in a HeetSheet unit falls well below the limits set

by the code for certification as defined by the following three Benefits . . .

volume and pressure points: Each installation is based on known and

0.14 m3 and 1720 kPa predictable heat transfer coefficients

0.08 m3 and 2410 kPa Factory applied non-hardening heat transfer

0.04 m3 and 4140 kPa compound provides high heat transfer rates

(See Product Configuration table on reverse side for Requires only 1/2 to 1/3 the heating surface

internal volume of HeetSheet units.) area of plate-type coils for like applications

Light weight, simplified attachment methods

HeetSheet units are designed and fabricated in accordance

with the requirements of ASME Section VIII Div 1 Boiler and and factory applied heat transfer compound

Pressure Vessel Code but are not inspected and stamped. combine to permit quick installation.

However, ASME inspection and stamping is available as an Used for both heating or cooling applications

option for all HeetSheet sizes upon request. No cross contamination of heating media and

process fluid

THERMON . . . The Heat Tracing Specialists

www.thermon.com

Corporate Headquarters Tel: +44 Headquarters

European (0)191 490 1547 Asia Pacific Headquarters

100 Thermon Dr. PO Box 609 Boezemweg

Fax: +44 (0)191

25 477PO5371

Box 205 30 London Dr. PO Box 532

San Marcos, TX 78667-0609

USA Email:

2640

Website:

Pijnacker

AEnorthernsales@thorneandderrick.co.uk

The Netherlands

www.heattracing.co.uk

Bayswater, Victoria 3153 Australia

Phone: 512-396-5801 Phone: 31-15-3615370 Phone: (03) 9762 6900

www.thorneanderrick.co.uk

HeetSheet

TM

Vessel Heating/Cooling System Product Specifications

Typical Steam Tracing System1 . . .

Steam Tracing Materials Scope

Strainer 3*

R

ThermoTube 7*

Roll Style I 1* A

Condensate 5*

HeetSheet B

Steam Header

Header

Trap Station 1*

R 3*

Stainless Steel

Steam Supply Banding FAK-7

Manifold Termination Roll Style II

Seal Kit

To Nearest Condensate

Return Point Condensate B

Return A

Manifold

5*

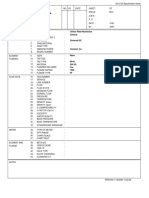

Product Configurations2 . . . 7*

Catalog External Heated Internal Approx.Weight Approx.Weight

Number 3 Dimensions Area Volume Without With

AxB m2 cm3 Compound Compound

Edge of Unit

mm kgs kgs

203 mm

HS-2X 610 x 610 0.37 500 5.2 6.1

.

HS-4X 610 x 1220 0.74 1000 10.5 12.3

HS-8X 610 x 2440 1.49 2000 20.9 24.5

Notes . . .

1. Connections between the steam and condensate headers and the HeetSheet may be accomplished with ThermoTube

preinsulated tubing. ThermoTube is available in a variety of configurations to meet the requirements of the application. 60 mm

For information on ThermoTube preinsulated tubing, refer to Form TSP0009U.

Heat Transfer

Compound

2. For sizes or product configurations other than those listed, contact Thermon.

3. The letter X in the Catalog Number represents standard HeetSheet units. A lighter gage unit is available, contact Thermon. * Denotes inlet/outlet locations. Inlet and outlet

tubes must be located on opposite diagonals only.

(Example: inlet/outlet 1 & 7 or 3 & 5)

Basic Accessories . . .

C204 . . . stainless steel banding ThermoTube . . . preinsulated BondTraceTM 425 . . . high bond

used to secure HeetSheet to tank. tubing used for steam supply and heat transfer compound is used

C001 . . . banding tool for applying condensate return on steam heating where temperatures above 190C

tension to stainless steel banding. circuits. (ThermoTube can also be are prevalent.

1950A . . . crimping tool for C254 utilized to transport other heating or

seals. cooling media.)

FAK-7 . . . contains a roll of self-

C254 . . . crimp seals for fastening vulcanizing silicone rubber tape and

tensioned banding. RTV sealant to complete approxi-

mately six terminations.

Form TSP0014U-0404 Thermon Manufacturing Co.

Potrebbero piacerti anche

- Unlocking The Secrets of Gann PDFDocumento11 pagineUnlocking The Secrets of Gann PDFfsolomon100% (1)

- Post Weld Heat TreatmentDocumento51 paginePost Weld Heat Treatmenttbmari97% (32)

- Wintech ProfileDocumento42 pagineWintech ProfilenurkolipNessuna valutazione finora

- Svsprasad Engineer (Design), Switchgear Products Division, Vijai Electricals LimitedDocumento52 pagineSvsprasad Engineer (Design), Switchgear Products Division, Vijai Electricals Limitedkrmrps0% (1)

- GRP-FT Maintenance ManualDocumento20 pagineGRP-FT Maintenance ManualSaleh EttehadiNessuna valutazione finora

- Aerospace Material SpecificationDocumento9 pagineAerospace Material SpecificationKlaualaNessuna valutazione finora

- Steck Quantum Optics NotesDocumento996 pagineSteck Quantum Optics Notesanon_458994531100% (1)

- Features: DF SeriesDocumento3 pagineFeatures: DF SeriesgeorgenzNessuna valutazione finora

- DF119S PDFDocumento2 pagineDF119S PDFKeiber CamachoNessuna valutazione finora

- EN TankHeating DG H56887 - tcm432 26444 PDFDocumento30 pagineEN TankHeating DG H56887 - tcm432 26444 PDFyassine633Nessuna valutazione finora

- Catalogo Caldera Aceite Termico FT-C FultonDocumento16 pagineCatalogo Caldera Aceite Termico FT-C FultonELTIPAZONessuna valutazione finora

- Traceado KSX 20Documento2 pagineTraceado KSX 20odgp215800Nessuna valutazione finora

- Tank HeatingDocumento28 pagineTank Heatingsnikraftar1406Nessuna valutazione finora

- High Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicsDocumento12 pagineHigh Performance Thermal Solutions Heat-Pipes & Engineering Systems For Power ElectronicscivicbladeNessuna valutazione finora

- C1!34!1604 SpecificationsDocumento2 pagineC1!34!1604 SpecificationsJaime VilaNessuna valutazione finora

- Boiler DesignDocumento26 pagineBoiler Designkmas1612100% (1)

- Gasketed Heat Exchangers Alfa LavalDocumento7 pagineGasketed Heat Exchangers Alfa LavalJunior Montalvo cruzNessuna valutazione finora

- Tep0072u KSX SpecDocumento2 pagineTep0072u KSX SpecYlm PtanaNessuna valutazione finora

- Install Manual RFHM Eng 0904Documento9 pagineInstall Manual RFHM Eng 0904Ernesto MarceloNessuna valutazione finora

- Measuring Instruments For Temperature: Resistance ThermometersDocumento20 pagineMeasuring Instruments For Temperature: Resistance ThermometersAmin Hasan AminNessuna valutazione finora

- PWHT ProcedureDocumento10 paginePWHT ProcedureSang Nguyen QuangNessuna valutazione finora

- TEP0089U Terminator ZT SpecDocumento1 paginaTEP0089U Terminator ZT SpecMuhammad SafeerNessuna valutazione finora

- Product GuideDocumento26 pagineProduct GuideGio gioNessuna valutazione finora

- Air Duct Heater and NTT Custom Made Duct HeaterDocumento2 pagineAir Duct Heater and NTT Custom Made Duct HeaterMaznah MakhtarNessuna valutazione finora

- Engineered Engineered: Thermal Maintenance S Stems For Urea Systems For Urea Applications PPDocumento31 pagineEngineered Engineered: Thermal Maintenance S Stems For Urea Systems For Urea Applications PPdzungNessuna valutazione finora

- 700-908 Adjustable Bimetal ThermostatsDocumento3 pagine700-908 Adjustable Bimetal ThermostatsmasakpNessuna valutazione finora

- Blow in Essar 15.2.10Documento18 pagineBlow in Essar 15.2.10TheleapInoblivionNessuna valutazione finora

- Ultra-Thin Flexible HeatersDocumento12 pagineUltra-Thin Flexible HeatersRon van OudenallenNessuna valutazione finora

- Pipe Freeze Protection Design/Install Guide: Page 1 of 16Documento16 paginePipe Freeze Protection Design/Install Guide: Page 1 of 16Cire Lop CastroNessuna valutazione finora

- TEP0089U Terminator ZT SpecDocumento1 paginaTEP0089U Terminator ZT SpecAV ShrinivasNessuna valutazione finora

- Prevent Tube Leaks: Morris RechillersDocumento2 paginePrevent Tube Leaks: Morris RechillersJhon Lewis100% (1)

- Coil-Type Heat Exchanger PDFDocumento2 pagineCoil-Type Heat Exchanger PDFRuben100% (1)

- RDA Induction Heating 4 PageDocumento4 pagineRDA Induction Heating 4 Pageนภดล สินธุแปงNessuna valutazione finora

- Heat Transfer Compound: Application - .Documento2 pagineHeat Transfer Compound: Application - .susantaNessuna valutazione finora

- CCUG P91 Fabrication Guidelines Dave Buzza-1Documento22 pagineCCUG P91 Fabrication Guidelines Dave Buzza-1Ranjith KumarNessuna valutazione finora

- Boiler MFG PerspectiveDocumento103 pagineBoiler MFG Perspectivetek_surinder100% (2)

- Calentador TIH 030m InstrukcijaDocumento16 pagineCalentador TIH 030m InstrukcijaReynaldo ZeballosNessuna valutazione finora

- Viking SPK StandardDocumento6 pagineViking SPK StandardCostel BalasoiuNessuna valutazione finora

- Johanson 251R15S6R8CV4E DatasheetDocumento3 pagineJohanson 251R15S6R8CV4E DatasheetAnonymous zG9Fj2X76bNessuna valutazione finora

- Mumbai-FOC Bath-1000-19Documento7 pagineMumbai-FOC Bath-1000-19aashishNessuna valutazione finora

- Immersion Heaters Haz Area UK+USADocumento26 pagineImmersion Heaters Haz Area UK+USAAnonymous ffje1rpaNessuna valutazione finora

- PWHTDocumento13 paginePWHTcv100% (2)

- Heat Exchanger CatelogueDocumento4 pagineHeat Exchanger CatelogueAtul GargNessuna valutazione finora

- Post Weld Heat TreatmentDocumento71 paginePost Weld Heat TreatmentaamirapiNessuna valutazione finora

- Schmidt-Bretten Brazed Plate Installation and Maintenance MaDocumento12 pagineSchmidt-Bretten Brazed Plate Installation and Maintenance MacakendriNessuna valutazione finora

- Heat Transfer CompoundDocumento2 pagineHeat Transfer CompoundsusantaNessuna valutazione finora

- Altera Reflow GuideDocumento10 pagineAltera Reflow GuideDUNCAN0420Nessuna valutazione finora

- Technical Data Manual: Vitocell 300-H EHA SeriesDocumento16 pagineTechnical Data Manual: Vitocell 300-H EHA SeriesLaith MahmoudNessuna valutazione finora

- 1211 Vertical EmulsionDocumento2 pagine1211 Vertical Emulsionluislanza_veNessuna valutazione finora

- 1211 Vertical EmulsionDocumento2 pagine1211 Vertical Emulsionhoke-14Nessuna valutazione finora

- MDG 10 TPH Boiler Offer ViessmannDocumento11 pagineMDG 10 TPH Boiler Offer ViessmannSatyam PandeyNessuna valutazione finora

- ReflowDocumento7 pagineReflowAshraf BadriNessuna valutazione finora

- Brazed Plate Heat Exchanger Serie-CSP-CSPIDocumento29 pagineBrazed Plate Heat Exchanger Serie-CSP-CSPIСергей КолесниковNessuna valutazione finora

- Heating Up of KilnsDocumento74 pagineHeating Up of KilnsMehmet C100% (5)

- Tracciatura EledDocumento15 pagineTracciatura Eledmatteo2009Nessuna valutazione finora

- Ti 2 516 UsDocumento2 pagineTi 2 516 Uswill_streetNessuna valutazione finora

- Tech Tip #19: How Do You Keep Steam Coils From Freezing?Documento7 pagineTech Tip #19: How Do You Keep Steam Coils From Freezing?adil_farooq_6Nessuna valutazione finora

- Temp LimitsDocumento8 pagineTemp LimitsVikas VermaNessuna valutazione finora

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDa EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNessuna valutazione finora

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDa EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsValutazione: 5 su 5 stelle5/5 (1)

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsDa EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNessuna valutazione finora

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesDa EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNessuna valutazione finora

- 0901d196807026e8-100-700 SKF Bearings and Mounted Products 2018 TCM 12-314117Documento587 pagine0901d196807026e8-100-700 SKF Bearings and Mounted Products 2018 TCM 12-314117ShiepietNessuna valutazione finora

- Type CraneDocumento9 pagineType CraneNofa Haryanto Mch PrawiroNessuna valutazione finora

- Flexible Pin Bush CouplingsDocumento9 pagineFlexible Pin Bush CouplingsCarlos SopasNessuna valutazione finora

- Crane Selection ChartDocumento4 pagineCrane Selection ChartCarlos SopasNessuna valutazione finora

- Bearing Internal Clearance and Preload PDFDocumento12 pagineBearing Internal Clearance and Preload PDFmaulikgadaraNessuna valutazione finora

- Type CraneDocumento9 pagineType CraneNofa Haryanto Mch PrawiroNessuna valutazione finora

- CeresistDocumento1 paginaCeresistCarlos SopasNessuna valutazione finora

- Crane Selection ChartDocumento4 pagineCrane Selection ChartCarlos SopasNessuna valutazione finora

- Bearings Overview: O O O ODocumento4 pagineBearings Overview: O O O OMohammad Fikri JalaludinNessuna valutazione finora

- Bearings Overview: O O O ODocumento4 pagineBearings Overview: O O O OMohammad Fikri JalaludinNessuna valutazione finora

- Bearing Internal Clearance and Preload PDFDocumento12 pagineBearing Internal Clearance and Preload PDFmaulikgadaraNessuna valutazione finora

- Mod1 PDFDocumento41 pagineMod1 PDFAhmad Budiman100% (2)

- Relay Module - PLC-RSC-24DC/21 - 2966171: Key Commercial DataDocumento16 pagineRelay Module - PLC-RSC-24DC/21 - 2966171: Key Commercial DataCarlos SopasNessuna valutazione finora

- Bearings Overview: O O O ODocumento4 pagineBearings Overview: O O O OMohammad Fikri JalaludinNessuna valutazione finora

- ORIFICE FLOW CALCULATIONS - Refer Crane Flow of Fluids 1983 (Pages 2-14 To 2-15)Documento1 paginaORIFICE FLOW CALCULATIONS - Refer Crane Flow of Fluids 1983 (Pages 2-14 To 2-15)Carlos SopasNessuna valutazione finora

- F400Documento6 pagineF400منير أحمدNessuna valutazione finora

- Restriction Orifice T95500enDocumento2 pagineRestriction Orifice T95500enCarlos SopasNessuna valutazione finora

- EUREKA Orifice Flange AssemblyDocumento6 pagineEUREKA Orifice Flange AssemblyCarlos SopasNessuna valutazione finora

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocumento37 pagineWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsCarlos SopasNessuna valutazione finora

- Orifice Meters Practical Guidelines For Specifying Orifice Fittings Technical White Paper en 55774Documento7 pagineOrifice Meters Practical Guidelines For Specifying Orifice Fittings Technical White Paper en 55774Carlos SopasNessuna valutazione finora

- Restriction Orifice Datasheet PDFDocumento2 pagineRestriction Orifice Datasheet PDFCarlos Sopas0% (1)

- TEMA Type ConfigurationsDocumento7 pagineTEMA Type ConfigurationsCarlos SopasNessuna valutazione finora

- Convection Heat Transfer CoefficientDocumento9 pagineConvection Heat Transfer CoefficientAnonymous sAmJfcVNessuna valutazione finora

- Differential Pressure and Flow Meters Orifice Plate Assemblies Type 90 Orifice Flange Restriction Orifice PlateDocumento4 pagineDifferential Pressure and Flow Meters Orifice Plate Assemblies Type 90 Orifice Flange Restriction Orifice PlateAttyubNessuna valutazione finora

- Bare Plate Heat Exchanger IODocumento33 pagineBare Plate Heat Exchanger IOCarlos SopasNessuna valutazione finora

- API 660 Vs TEMADocumento5 pagineAPI 660 Vs TEMAALONSO GOMEZNessuna valutazione finora

- API 660 Vs TEMADocumento5 pagineAPI 660 Vs TEMAALONSO GOMEZNessuna valutazione finora

- API 660 Vs TEMADocumento5 pagineAPI 660 Vs TEMAALONSO GOMEZNessuna valutazione finora

- Number Patterns and Sequences and Decimals HotsDocumento3 pagineNumber Patterns and Sequences and Decimals Hotszarina binti jusohNessuna valutazione finora

- Mid Term Paper - DynamicsDocumento3 pagineMid Term Paper - DynamicsMălíķ ĂsfęnđýårNessuna valutazione finora

- Applus RTD Seminar - New Developments - Phased ArrayDocumento20 pagineApplus RTD Seminar - New Developments - Phased Arrayjfisher2534Nessuna valutazione finora

- Arnav 1Documento12 pagineArnav 1sales zfNessuna valutazione finora

- Compositional SimulationDocumento35 pagineCompositional SimulationKellen Sanchez100% (1)

- Shaft Model With Mathlook EquationsDocumento112 pagineShaft Model With Mathlook EquationsMoisés MachadoNessuna valutazione finora

- Strength of Materials 2016 by S K Mondal PDFDocumento472 pagineStrength of Materials 2016 by S K Mondal PDFSai Subrahmanyam PvkNessuna valutazione finora

- Millikan Oil Drop ExperimentDocumento6 pagineMillikan Oil Drop ExperimentruleevanNessuna valutazione finora

- Chapter 4Documento20 pagineChapter 4Nasyitah RusliNessuna valutazione finora

- ManualsDocumento34 pagineManualsTreeNessuna valutazione finora

- Aztech LightsDocumento4 pagineAztech Lightskhan4luvNessuna valutazione finora

- Catalogue GX CompressorDocumento6 pagineCatalogue GX CompressorMohit MundraNessuna valutazione finora

- Euroclad Weathertightness RPTDocumento15 pagineEuroclad Weathertightness RPTy2kareinNessuna valutazione finora

- Ducab Flat Cable Catalogue Final HI-ResDocumento8 pagineDucab Flat Cable Catalogue Final HI-Resshaik abdullahNessuna valutazione finora

- EagleBurgmann K-KDE E3 Competence in Compressor Sealing 12.05.2016Documento28 pagineEagleBurgmann K-KDE E3 Competence in Compressor Sealing 12.05.2016MatteoBertoneriNessuna valutazione finora

- SIMS ManuscriptDocumento6 pagineSIMS ManuscriptViraj EdirisingheNessuna valutazione finora

- 7software Development-Final 1st and 2nd Semester-Scheme and Syllabus31.07.2016Documento55 pagine7software Development-Final 1st and 2nd Semester-Scheme and Syllabus31.07.2016Rahul SachdevaNessuna valutazione finora

- UV IR Filter SpectraDocumento12 pagineUV IR Filter SpectrajacekwikloNessuna valutazione finora

- Daftar Pustaka Tugas Akhir Planetarium Dan ObservatoriumDocumento4 pagineDaftar Pustaka Tugas Akhir Planetarium Dan ObservatoriumAzurieMegNessuna valutazione finora

- List of Institutes Engineering (Gujcet)Documento20 pagineList of Institutes Engineering (Gujcet)Kumar ManglamNessuna valutazione finora

- Quantum Information and FoundationsDocumento510 pagineQuantum Information and FoundationsBrent AllieNessuna valutazione finora

- CH 31 Sec 1 - Postwar Uncertainty PDFDocumento5 pagineCH 31 Sec 1 - Postwar Uncertainty PDFMrEHsiehNessuna valutazione finora

- Shreyas Pawale ResumeDocumento1 paginaShreyas Pawale ResumeRahulRajGoldyNessuna valutazione finora

- Physics 2 Current Ohms - Law Resistance Student PDFDocumento26 paginePhysics 2 Current Ohms - Law Resistance Student PDFRaizha GranadoNessuna valutazione finora