Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CTPAT 7-Point Container Seal Inspection Checklist

Caricato da

Kartika WulandariCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CTPAT 7-Point Container Seal Inspection Checklist

Caricato da

Kartika WulandariCopyright:

Formati disponibili

7-Point Container Inspection Checklist

Date:

Container Number:

Seal Number:

1 Outside/Undercarriage 2 Inside/Outside Doors

Check for structural damage (dents, Ensure locks and locking

holes, repairs) mechanisms are secure and reliable

Support beams are visible Check for loose bolts

Ensure no foreign objects are Ensure hinges are secure and

mounted on container reliable

3 Right Side 4 Left Side

Look for unusual repairs to Look for unusual repairs to

structural beams structural beams

Repairs to inside wall must also be Repairs to inside wall must also be

visible on the outside & vice versa visible on the outside & vice versa

5 Front Wall 6 Ceiling/Roof

Front wall should be made of Ensure support beams are visible

corrugated material

Interior blocks in top left and right Ensure ventilation holes are visible.

corners should be visible. Missing They should not be covered or

or false blocks are abnormal. absent.

Ensure Vents are visible. Ensure no foreign objects are

mounted to the container

7 Floor 8 Seal Verification

Ensure floor of container is flat. Seal properly affixed

Ensure floor is of uniform height. Seal meets or exceeds

PAS ISO 17712

Look for unusual repairs to the Ensure seal is not broken or

floor damaged.

Remarks:

I have visually inspected and verified the condition of the container noted above. I confirm that the container

is structurally sound, weather tight, has no false compartments, and the locking mechanisms are in good

order and show no visible signs of being tampered with.

Inspected by: Date:

Seal affixed and verified by: Date:

The following list is an overview of the

7 point inspection process.

1. Undercarriage

The undercarriage should be visibly inspected prior to the trailers entry into our facility.

All the support beams should be visible. Wheels and tires should look normal.

If anything seems unusual about the trailers undercarriage, report this problem to your supervisor.

2. Outside/Inside Doors

Inspect both the inside and outside of the trailers doors (or the containers doors if working with a

shipping container).

The doors should have secure and reliable locking mechanisms, and they should not have loose

bolts.

Be suspicious of different color bonding materials and unusual plates or repairs.

Plates should not cover door cavities.

3. Right Side

Investigate the right side wall.

Look for any unusual repairs to structural beams.

Use a tool to tap the side walls. Listen and feel for a hollow sound.

Any major repairs to the walls on the inside of the trailer should be visible on the outside, too.

4. Left Side

Investigate the left side wall.

Look for any unusual repairs to structural beams.

Use a tool to tap the side walls. Listen and feel for a hollow sound.

Any major repairs to the walls on the inside of the trailer should be visible on the outside, too.

5. Front Wall

Use a range finder, measuring tape, or string to determine the length of the trailer.

Blocks and vents must be visible and several inches apart. All the vent holes should be visible.

Use a tool to tap the front wall. Listen and feel for a hollow sound.

6. Ceiling/Roof

The ceiling is a certain standard distance from the floor. Blocks and vents must be visible.

Repairs to the ceiling on the inside of the trailer should be visible on the outside.

Use a tool to tap the ceiling. Listen for a hollow sound.

7. Floor

The floor should be flat and uniform with no raised platforms.

Be suspicious of any unusual repairs, bad repairs, and bad welding.

Potrebbero piacerti anche

- Updated 7 Point Container Inspection SheetDocumento2 pagineUpdated 7 Point Container Inspection SheetMohd Shahrul Irwan Mohd Zin0% (1)

- Container Loading InstructionsDocumento2 pagineContainer Loading InstructionsGabyObreque100% (2)

- CTPAT 7 - Point Container Seal Inspection ChecklistDocumento3 pagineCTPAT 7 - Point Container Seal Inspection ChecklistFriska Devi Mella Nurita67% (3)

- 8 Point Container Inspection Checklist: Location of Container SecureDocumento3 pagine8 Point Container Inspection Checklist: Location of Container SecureCarlos Moreno100% (2)

- Beall's Imports, Inc.: Beall's Import Vendor Container 7-Point Inspection FormDocumento1 paginaBeall's Imports, Inc.: Beall's Import Vendor Container 7-Point Inspection FormbgaldamezNessuna valutazione finora

- Container Inspection Checklist: Caterpillar: Confidential Green Updated: October 14, 2015Documento3 pagineContainer Inspection Checklist: Caterpillar: Confidential Green Updated: October 14, 2015Leandro Sampaio100% (1)

- C-TPAT: Container, Trailer & Seal CheckingDocumento20 pagineC-TPAT: Container, Trailer & Seal CheckingMartin Joe Kolondam100% (1)

- Container Inspection 3 PDFDocumento63 pagineContainer Inspection 3 PDFIs Ra Ro100% (1)

- 7-Point Security Inspection Guide PDFDocumento1 pagina7-Point Security Inspection Guide PDFLoan HuynhNessuna valutazione finora

- 7-Point Ocean Container Security Inspection GuideDocumento2 pagine7-Point Ocean Container Security Inspection GuideEngr Malik100% (1)

- Cargo Verification ChecklistDocumento3 pagineCargo Verification ChecklistMANOLOTEDIAZMURILLONessuna valutazione finora

- Gate in ProcedureDocumento4 pagineGate in ProcedurebayuanakNessuna valutazione finora

- Panalpina 7-Point Container Inspection ChecklistDocumento1 paginaPanalpina 7-Point Container Inspection ChecklistNisma NilamNessuna valutazione finora

- 7-Point Ctpat Container Inspection Checklist: Container Number: Shippers Name: Seal Number: Inspected By: (Print Clearly)Documento1 pagina7-Point Ctpat Container Inspection Checklist: Container Number: Shippers Name: Seal Number: Inspected By: (Print Clearly)MOHAMED100% (2)

- C TpatDocumento4 pagineC TpatTrivesh SNessuna valutazione finora

- Document Checklist For C TPAT Audit PDFDocumento2 pagineDocument Checklist For C TPAT Audit PDFJaker Saurav88% (24)

- Ctpat PresentationDocumento29 pagineCtpat Presentationrubber jayaNessuna valutazione finora

- C-TPAT Check ListDocumento4 pagineC-TPAT Check ListFaruque UddinNessuna valutazione finora

- C-TPAT Security Policies and ProceduresDocumento35 pagineC-TPAT Security Policies and Proceduresferesza81% (16)

- C-TPAT Container Inspection Check ListDocumento2 pagineC-TPAT Container Inspection Check Listkarachiguy27100% (9)

- WRAP Manual EnglishDocumento30 pagineWRAP Manual EnglishYogesh Sharma50% (6)

- Documents Review For CtpatDocumento1 paginaDocuments Review For CtpatBenny Adityaning BntoroNessuna valutazione finora

- Ctpat Documentation RequirementsDocumento6 pagineCtpat Documentation RequirementsAkhil Sharma100% (1)

- 7 Point Container Inspecation ChecklistDocumento1 pagina7 Point Container Inspecation ChecklistFirman RamadanNessuna valutazione finora

- 7 Point Container InspectionDocumento1 pagina7 Point Container InspectionAkash PandyaNessuna valutazione finora

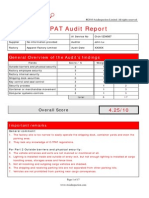

- C-TPAT Audit Report: General Overview of The Audit's FindingsDocumento17 pagineC-TPAT Audit Report: General Overview of The Audit's FindingsArsalan Ahmed Sheikh100% (1)

- SOP 18 Foreign Material Control - WM PDFDocumento5 pagineSOP 18 Foreign Material Control - WM PDFkhairul alamNessuna valutazione finora

- CTPAT Best PracticeDocumento19 pagineCTPAT Best PracticeLoan Huynh100% (1)

- Loading and Unloading Checklist May 2021Documento2 pagineLoading and Unloading Checklist May 2021Beatrix Uy50% (2)

- CTPAT Requirements: C-TPAT Means Customs Trade Partnership Against Terrorism Which Is The Result of September 11Documento7 pagineCTPAT Requirements: C-TPAT Means Customs Trade Partnership Against Terrorism Which Is The Result of September 11honey zmeuyNessuna valutazione finora

- WRAP ChecklistDocumento1 paginaWRAP ChecklistHasan100% (4)

- Container InspectionDocumento8 pagineContainer InspectionDr-Eng Nabawy Mostafa100% (2)

- SASDOC-22 - General Documents Checklist For CTPAT or Security or SCAN Audit PDFDocumento1 paginaSASDOC-22 - General Documents Checklist For CTPAT or Security or SCAN Audit PDFFaruque Uddin0% (1)

- C-TPAT Questionnaire For Manufacturer 2020Documento5 pagineC-TPAT Questionnaire For Manufacturer 2020r0yalgirlNessuna valutazione finora

- CTPAT Questionnaire BlankDocumento6 pagineCTPAT Questionnaire BlankDeka FabNessuna valutazione finora

- C-TPAT SlidesDocumento10 pagineC-TPAT SlidesDonna AcupanNessuna valutazione finora

- C TPAT InspectionDocumento65 pagineC TPAT Inspectiondidsh100% (2)

- Best Security PracticesDocumento38 pagineBest Security Practicesneil926100% (1)

- Container ChecklistDocumento1 paginaContainer Checklistzahid_497100% (1)

- Section/Control Description Security Management System: C-TPAT Self-Assessment - Manufacturing & WarehousingDocumento5 pagineSection/Control Description Security Management System: C-TPAT Self-Assessment - Manufacturing & Warehousingaprilia retno0% (1)

- Factory Capability & Capacity Audit (FCCA)Documento10 pagineFactory Capability & Capacity Audit (FCCA)Lia Erizka100% (1)

- Customs Trade Partnership Against Terrorism (C-Tpat) Vendor Security Questionnaire Effective: January 29, 2019Documento3 pagineCustoms Trade Partnership Against Terrorism (C-Tpat) Vendor Security Questionnaire Effective: January 29, 2019Carlos MorenoNessuna valutazione finora

- 7 Point Container Inspection June2016Documento1 pagina7 Point Container Inspection June2016Nisma Nilam100% (2)

- Monthly Fire Hose Reel InspectionDocumento1 paginaMonthly Fire Hose Reel InspectionJun Wang100% (7)

- IICL 6 Measurement TechniqueDocumento16 pagineIICL 6 Measurement Techniqueacere1871% (7)

- Document Checklist For C-TPAT Audit PDFDocumento2 pagineDocument Checklist For C-TPAT Audit PDFboypardede75% (4)

- Warehouse Audit ChecklistDocumento2 pagineWarehouse Audit ChecklistWalid Sonji82% (11)

- SCAN Security Audit-Pre Audit QuestionnaireDocumento8 pagineSCAN Security Audit-Pre Audit Questionnairejuan50% (4)

- Factory Security Policy PDFDocumento2 pagineFactory Security Policy PDFTrần Tiến Đạt100% (2)

- Audit C-TPAT (Checklist)Documento15 pagineAudit C-TPAT (Checklist)Dhiya Muhammad Dzaki100% (1)

- CTPAT Security ProgramDocumento4 pagineCTPAT Security ProgramAdishree Solusi MandiriNessuna valutazione finora

- C-TPAT Minimum RequirementDocumento5 pagineC-TPAT Minimum RequirementdedysuyetnoNessuna valutazione finora

- CT Pat Human ResourceDocumento23 pagineCT Pat Human Resourcedinesh_haiNessuna valutazione finora

- Ctpat Best PracticesDocumento56 pagineCtpat Best Practicesaristian27100% (2)

- CTPAT 7-Point Container Inspection ChecklistDocumento14 pagineCTPAT 7-Point Container Inspection ChecklistAshley100% (1)

- 7-Point Ocean Container Security Inspection GuideDocumento2 pagine7-Point Ocean Container Security Inspection GuideGeroldo 'Rollie' L. QuerijeroNessuna valutazione finora

- C-TPAT 7 Point Inspection ChecklistDocumento2 pagineC-TPAT 7 Point Inspection ChecklistJohan Dewa SiraitNessuna valutazione finora

- DBL Group Jinnat Complex: 9-Point Container Inspection ProcessDocumento1 paginaDBL Group Jinnat Complex: 9-Point Container Inspection ProcessFaruque UddinNessuna valutazione finora

- Fort Doors Side Hinged Framed Fitting Instructions V4.1 FinalDocumento8 pagineFort Doors Side Hinged Framed Fitting Instructions V4.1 FinalbarryNessuna valutazione finora

- Container Inspection Checklist: Caterpillar: Confidential Green Updated: October 14, 2015Documento3 pagineContainer Inspection Checklist: Caterpillar: Confidential Green Updated: October 14, 2015achmad chusnu riswantoNessuna valutazione finora

- Performance of Mentik Wangi Rice Generation M1 From The Results of Gamma Ray IrradiationDocumento9 paginePerformance of Mentik Wangi Rice Generation M1 From The Results of Gamma Ray IrradiationKartika WulandariNessuna valutazione finora

- Sabun Cuci Tangan Sabun Cuci Tangan Sabun Cuci TanganDocumento1 paginaSabun Cuci Tangan Sabun Cuci Tangan Sabun Cuci TanganKartika WulandariNessuna valutazione finora

- Form Permit To WorkPermit To WorkDocumento1 paginaForm Permit To WorkPermit To WorkFaisel Raheem100% (1)

- Prosedur PembersihanDocumento2 pagineProsedur PembersihanKartika WulandariNessuna valutazione finora

- RockStarCV-com - Askella Resume TemplateDocumento1 paginaRockStarCV-com - Askella Resume TemplateKartika WulandariNessuna valutazione finora

- Prosedur Nelson SomogyDocumento2 pagineProsedur Nelson SomogyKartika WulandariNessuna valutazione finora

- Kadar Protein Ampas SaguDocumento1 paginaKadar Protein Ampas SaguKartika WulandariNessuna valutazione finora

- Business Plan RealDocumento17 pagineBusiness Plan RealKartika WulandariNessuna valutazione finora

- Statistics and Probability Course Syllabus (2023) - SignedDocumento3 pagineStatistics and Probability Course Syllabus (2023) - SignedDarence Fujihoshi De AngelNessuna valutazione finora

- Sailpoint Topic Wise SyllabusDocumento2 pagineSailpoint Topic Wise SyllabusKishore KodaliNessuna valutazione finora

- 525 2383 2 PBDocumento5 pagine525 2383 2 PBiwang saudjiNessuna valutazione finora

- Summer Internship Project Report ANALYSIDocumento60 pagineSummer Internship Project Report ANALYSIKshitija KudacheNessuna valutazione finora

- Character Paragraph Analysis RubricDocumento2 pagineCharacter Paragraph Analysis RubricDiana PerrottaNessuna valutazione finora

- LG) Pc-Ii Formulation of Waste Management PlansDocumento25 pagineLG) Pc-Ii Formulation of Waste Management PlansAhmed ButtNessuna valutazione finora

- Homelite 18V Hedge Trimmer - UT31840 - Users ManualDocumento18 pagineHomelite 18V Hedge Trimmer - UT31840 - Users ManualgunterivNessuna valutazione finora

- Tablet Time - Student GuideDocumento5 pagineTablet Time - Student GuideAyesha BaigNessuna valutazione finora

- Applications PDFDocumento90 pagineApplications PDFahmedNessuna valutazione finora

- Hasan Bin Ekram: Career ObjectiveDocumento3 pagineHasan Bin Ekram: Career ObjectiveHasan SarikNessuna valutazione finora

- Objective-C Succinctly PDFDocumento110 pagineObjective-C Succinctly PDFTKKNessuna valutazione finora

- The 100 Best Books For 1 Year Olds: Board Book HardcoverDocumento17 pagineThe 100 Best Books For 1 Year Olds: Board Book Hardcovernellie_74023951Nessuna valutazione finora

- LANY Lyrics: "Thru These Tears" LyricsDocumento2 pagineLANY Lyrics: "Thru These Tears" LyricsAnneNessuna valutazione finora

- ELS 15 Maret 2022 REVDocumento14 pagineELS 15 Maret 2022 REVhelto perdanaNessuna valutazione finora

- Encephalopathies: Zerlyn T. Leonardo, M.D., FPCP, FPNADocumento50 pagineEncephalopathies: Zerlyn T. Leonardo, M.D., FPCP, FPNAJanellee DarucaNessuna valutazione finora

- Cooperative LinuxDocumento39 pagineCooperative Linuxrajesh_124Nessuna valutazione finora

- Solving Systems of Linear Equations in Three Variables: You Should LearnDocumento8 pagineSolving Systems of Linear Equations in Three Variables: You Should LearnTheodore JoaquinnNessuna valutazione finora

- Burj Khalifa: Engineer Abdul MananDocumento29 pagineBurj Khalifa: Engineer Abdul MananabdulmananNessuna valutazione finora

- Microcontrollers DSPs S10Documento16 pagineMicrocontrollers DSPs S10Suom YnonaNessuna valutazione finora

- Oxygenation - NCPDocumento5 pagineOxygenation - NCPCazze SunioNessuna valutazione finora

- CD4 12-P374493Documento30 pagineCD4 12-P374493suraj_savant1Nessuna valutazione finora

- Open Book Online: Syllabus & Pattern Class - XiDocumento1 paginaOpen Book Online: Syllabus & Pattern Class - XiaadityaNessuna valutazione finora

- Exchange 2010 UnderstandDocumento493 pagineExchange 2010 UnderstandSeKoFieNessuna valutazione finora

- MGN815: Business Models: Ajay ChandelDocumento38 pagineMGN815: Business Models: Ajay ChandelSam RehmanNessuna valutazione finora

- Instruction Manual Il-Obct-R1: Slip-Over Current Transformer ObctDocumento2 pagineInstruction Manual Il-Obct-R1: Slip-Over Current Transformer Obctبوحميدة كمالNessuna valutazione finora

- Chapter 5: Current and Resistance: 5.1 The Motion of Electric ChargeDocumento11 pagineChapter 5: Current and Resistance: 5.1 The Motion of Electric Chargeayunna ayunniNessuna valutazione finora

- Aloe Vera An Ancient Herb For Modern Dentistry-A LDocumento7 pagineAloe Vera An Ancient Herb For Modern Dentistry-A LRuth Ransel Yadao ValentinNessuna valutazione finora

- Benefits and Drawbacks of Thermal Pre-Hydrolysis For Operational Performance of Wastewater Treatment PlantsDocumento7 pagineBenefits and Drawbacks of Thermal Pre-Hydrolysis For Operational Performance of Wastewater Treatment PlantsmartafhNessuna valutazione finora

- MarimbaDocumento5 pagineMarimbaLeonardo D'AngeloNessuna valutazione finora

- Reaffirmed 1998Documento13 pagineReaffirmed 1998builconsNessuna valutazione finora