Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Asme - 240716

Caricato da

Vinoth KumarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Asme - 240716

Caricato da

Vinoth KumarCopyright:

Formati disponibili

Bio-Pharm Fit tings - ASME BPE

MaxPure BPE

MaxPure is the first world-wide fittings brand to be certified by

ASME BPE.

MaxPure - ASME BPE Certified stainless steel fittings for the bioprocessing industry

By insuring maximum cleanability, full traceability and quality inspection for every fitting, MaxPure has

established itself as a world leading brand in the field of stainless steel fittings for the pharmaceutical

industry.

MaxPures product line production methods insure that no mechanical damage or flaw occurs during the

manufacturing process. The cleaning procedures incorporate multi-process degreasing and washing steps

provided to eliminate any residues of hydrocarbons and stains.

MaxPure procedures and processes capabilities ensure formation of a stabilized passive layer increasing

corrosion resistance.

As the first ASME BPE certified fitting brand, MaxPure establishes itself as a world leader in the stainless steel

Bio-Pharm industry.

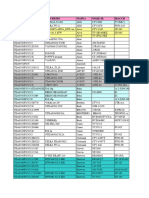

ASME BPE DT Index

2009 DT 2012 DT 2014 DT

Drawing Part Description

ASME-BPE 2009 ASME-BPE 2012 ASME-BPE 2014

TE2S

DT-7 DT-4.1.1-1 DT-4.1.1-1

90 Elbow

TE2C

DT-12 DT-4.1.1-2 DT-4.1.1-2

90 Elbow Clamp One End

TEG2C

DT-16 DT-4.1.1-3 DT-4.1.1-3

90 Elbow

TE2KS

DT-8 DT-4.1.1-4 DT-4.1.1-4

45 Elbow

TE2KC

DT-13 DT-4.1.1-5 DT-4.1.1-5

45 Elbow Clamp One End

TEG2K

DT-17 DT-4.1.1-6 DT-4.1.1-6

45 Elbow

TE2UBWWW

180 Bottom Outlet Weld DT-23 DT-4.1.1-7 DT-4.1.1-7

Use Point

1 EGMONEUMO Ehrenberg Group

Bio-Pharm Fit tings - ASME BPE

ASME BPE DT Index

2009 DT 2012 DT 2014 DT

Drawing Part Description

ASME-BPE 2009 ASME-BPE 2012 ASME-BPE 2014

TE7WWW

DT-9 DT-4.1.2-1 DT-4.1.2-1

Equal Tee

TE9WWWW

DT-9 DT-4.1.2-1 DT-4.1.2-1

Equal Cross

TE7WWCS

DT-15 DT-4.1.2-2 DT-4.1.2-2

Short Outlet Tee

TE7WCSW

DT-25 DT-4.1.2-3 DT-4.1.2-3

Short Outlet Run Tee

TEG7

DT-18 DT-4.1.2-4 DT-4.1.2-4

Equal Tee C

TEG9

DT-18 DT-4.1.2-4 DT-4.1.2-4

Cross

TEG7S

DT-27 DT-4.1.2-5 DT-4.1.2-5

Short Outlet Tee

TE7RWWW

DT-10 DT-4.1.2-6 DT-4.1.2-6

Reducing Tee

TE7RWWCS

DT-14 DT-4.1.2-7 DT-4.1.2-7

Short Outlet Reducing Tee

TEG7R

DT-19 DT-4.1.2-8 DT-4.1.2-8

Reducing Tee

TEG7RS

DT-20 DT-4.1.2-9 DT-4.1.2-9

Short Outlet Reducing Tee

TE7IWWCS

DT-28 DT-4.1.2-10 DT-4.1.2-10

Instrument Tee

2 EGMONEUMO Ehrenberg Group

Bio-Pharm Fit tings - ASME BPE

ASME BPE DT Index

2009 DT 2012 DT 2014 DT

Drawing Part Description

ASME-BPE 2009 ASME-BPE 2012 ASME-BPE 2014

TEG71S

DT-29 DT-4.1.2-11 DT-4.1.2-11

TE31WW - LONG CONCENTRIC REDUCER

Instrument Tee

TE31WW

DT-11 DT-4.1.3-1 (a) N/A

Long Concentric Reducer

TE32WW - LONG ECCENTRIC REDUCER

TE32WW

DT-11 DT-4.1.3-1 (a) N/A

TE31SWW - SHORT CONCENTRIC REDUCER Long Concentric Reducer

TE31SWW

N/A DT-4.1.3-1 (b) DT-4.1.3-1

TE32SWW - SHORT ECCENTRIC REDUCER Short Concentric Reducer

TE32SWW

N/A DT-4.1.3-1 (b) DT-4.1.3-1

TE31CW - LONG CONCENTRIC REDUCER

Short Eccentric Reducer

TE31CW

DT-26 DT-4.1.3-2 (a) N/A

Long Concentric Reducer

TE32CW - LONG ECCENTRIC REDUCER

TE32CW

DT-26 DT-4.1.3-2 (a) N/A

TE31SCW - SHORT CONCENTRIC REDUCER Long Concentric Reducer

TE31SCW

N/A DT-4.1.3-2 (b) DT-4.1.3-2

TE32SCW - SHORT ECCENTRIC REDUCER

Short Concentric Reducer

TE32SCW

A

N/A DT-4.1.3-2 (b) DT-4.1.3-2

Short Eccentric Reducer

TEG31CC - LONG CONCENTRIC REDUCER

TEG31CC

DT-21 DT-4.1.3-3 (a) N/A

TEG32CC - LONG ECCENTRIC REDUCER Long Concentric Reducer

TEG32CC

DT-21 DT-4.1.3-3 (a) N/A

Long Eccentric Reducer

TEG31SCC - SHORT CONCENTRIC REDUCER

TEG31SCC

N/A DT-4.1.3-3 (b) DT-4.1.3-3

Short Concentric Reducer

3 EGMONEUMO Ehrenberg Group

Bio-Pharm Fit tings - ASME BPE

ASME BPE DT Index

2009 DT 2012 DT 2014 DT

Drawing

TEG32SCC - SHORT ECCENTRIC REDCER Part Description

ASME-BPE 2009 ASME-BPE 2012 ASME-BPE 2014

TEG32SCC

N/A DT-4.1.3-3 (b) DT-4.1.3-3

Short Eccentric Reducer

TEG14AM7

DT-22 DT-4.1.4-1 DT-4.1.4-1

Clamp Ferrule Long

TE16W

DT-30 DT-4.1.5-1 DT-4.1.5-1

Weld Cap

TEG16A

DT-31 DT-4.1.5-2 DT-4.1.5-2

Solid End Cap

ABOUT ASME BPE

The ASME Bioprocessing Equipment Standard was developed to aid in the design and construction of new

fluid processing equipment used in industries that require a defined level of purity and bio burden control.

The Standard typically applies to

a. Components that are in contact with the product, raw materials, or product intermediates during

manufacturing, development, or scale-up

b. Systems that are a critical part of product manufacture [e.g., water-for-injection (WFI), clean steam,

filtration, and intermediate product storage]

The General Requirements Part states the scope of the ASME BPE Standard and provides references and

definitions that apply throughout the document.(*)

* American Society of Mechanical Engineers .(2012). ASME BPE 2012 - Bioprocessing Equipment. New-York, NY: United States Author. Retrieved. (1)1. www.asme.org/

products/codes-standards/bpe-2012-bioprocessing-equipment

ASME Certification

The ASME Bioprocessing Equipment Certification program covers

organizations manufacturing or supplying, tubing and fittings -that fall

under the scope of the ASME BPE Standard for Bioprocessing Equipment.

4 EGMONEUMO Ehrenberg Group

Bio-Pharm Fit tings - ASME BPE

Fittings Specifications

Product:

Stainless Steel fittings comply with ASME BPE standards.

Gaskets are made from compounds which are FDA approved and USP 87, 88 Pharmaceutical Class VI certified.

Sizes:

Stainless Steel fittings are available in sizes - 6 O.D. tube size.

Material:

Fittings are fabricated in AISI 316L Stainless Steel with sulfur content of 0.005-0.017% achieving superior

repeatability for automatic orbital welding process.

Dimensions & Tolerances:

Dimensions as specified in ASME BPE Part DT-3-1

Squareness Equivalent Centerline

Nominal Wall Thickness Wall Thickness

O.D. Face to Off Angle, 0 Angle Off Plane, P Radius

Size Mechanical Polish (MP) Electropolish (EP)

Tangent, B (for O) (CLR), R

in. in. mm in. mm in. mm in. mm in. mm deg in. mm in. mm

14 0.005 0.13 +0.003/-0.004 +0.08/-0.10 +0.003/-0.006 +0.08/-0.15 0.005 0.13 0.009 0.23 2.1 0.030 0.76 0.563 14.30

38 0.005 0.13 +0.003/-0.004 +0.08/-0.10 +0.003/-0.006 +0.08/-0.15 0.005 0.13 0.012 0.3 1.8 0.030 0.76 1.125 28.58

1 2 0.005 0.13 +0.005/-0.008 +0.13/-0.20 +0.005/-0.010 +0.13/-0.25 0.005 0.13 0.014 0.36 1.6 0.030 0.76 1.125 28.58

3 4 0.005 0.13 +0.005/-0.008 +0.13/-0.20 +0.005/-0.010 +0.13/-0.25 0.005 0.13 0.018 0.46 1.4 0.030 0.76 1.125 28.58

1 0.005 0.13 +0.005/-0.008 +0.13/-0.20 +0.005/-0.010 +0.13/-0.25 0.008 0.20 0.025 0.64 1.4 0.030 0.76 1.500 38.10

11 2 0.008 0.20 +0.005/-0.008 +0.13/-0.20 +0.005/-0.010 +0.13/-0.25 0.008 0.20 0.034 0.86 1.3 0.050 1.27 2.250 57.15

2 0.008 0.20 +0.005/-0.008 +0.13/-0.20 +0.005/-0.010 +0.13/-0.25 0.008 0.20 0.043 1.09 1.2 0.050 1.27 3.000 76.20

21 2 0.010 0.25 +0.005/-0.008 +0.13/-0.20 +0.005/-0.010 +0.13/-0.25 0.010 0.25 0.054 1.37 1.2 0.050 1.27 3.750 95.25

3 0.010 0.25 +0.005/-0.008 +0.13/-0.20 +0.005/-0.010 +0.13/-0.25 0.016 0.41 0.068 1.73 1.3 0.050 1.27 4.500 114.30

4 0.015 0.38 +0.008/-0.010 +0.20/-0.25 +0.008/-0.012 +0.20/-0.30 0.016 0.41 0.086 2.18 1.2 0.060 1.52 6.000 152.40

6 0.030 0.76 +0.015/-0.015 +0.38/-0.38 +0.015/-0.017 +0.38/-0.43 0.030 0.76 0.135 3.43 1.3 0.060 1.52 9.000 228.60

Roundness Wall Thickness

B O P

C O

T

Squareness Face E

to Tangent Off Angle

General Notes:

Off Plane Height a. Tolerance on E end-to-end and center-to-end: 0.050 in.

(1.27 mm)

b. Tolerance for centerline radius (CLR) is 10% of the

nominal dimension

5 EGMONEUMO Ehrenberg Group

Bio-Pharm Fit tings - ASME BPE

Fittings Specifications

Surface Finish:

Reference: ASME BPE-2014, Part SF, Table SF-2.4-1.

Inside Surface Outside Surface

Surface BPE Surface

Ra Maximum

Finish Code Designation Surface Condition Surface Condition

-in. m

PX SF0 No finish requirement No finish requirement

PC SF1 20 0.51 Mechanically Polished [1] Light Polish

PL SF1 20 0.51 Mechanically Polished [1] Mechanically polished to 32 Ra -in.

PD SF4 15 0.38 Mechanically Polished [1] & Electropolished Light Polish

PM SF4 15 0.38 Mechanically Polished [1] & Electropolished Mechanically polished to 32 Ra -in.

PR - 10 0.25 Mechanically Polished [1] & Electropolished Mechanically polished to 32 Ra -in.

[1] Or any other finishing method that meets the Ra max.

a. MaxPure fittings guarantee the Ra in all internal surfaces, including bent areas where it is difficult to polish and

difficult to measure.

b. All Ra readings are taken across the lay, wherever possible.

c. No single Ra reading shall exceed the Ra max. value in this table.

d. Other Ra readings are available if agreed upon between owner/user and supplier, not to exceed values in this

table.

Cleaning:

A multi step cleaning cycle is conducted to ensure that fittings are cleaned with a perfect passivation layer.

The cleaning process involves degreasing, pickling, electro polishing (as required) and passivation. During the final

stage, the fittings are double-rinsed using D.I. water.

Inspection Procedures:

All fittings produced by EGMO production are 100% visually inspected for any surface finish imperfections, as

mentioned in Table SF-2.2-1, SF-2.2-2, SF-2.4-1 and SF 2.6-1 in the ASME BPE 2014 specification. All dimensional

characteristics are inspected for tolerances listed in parts DT-3-1 to DT-9.3-1 in the ASME BPE 2014 specification.

Fitting Marking Information:

Each fitting and process component is permanently laser Marked to

show the following:

a. Heat number/code traceable to material test report for each product

contact surface component

b. Material type

c. Manufacturers name, logo, & trademark

d. Product contact surface designation for the appropriate BPE specification

e. ASME BPE mark

Packaging & Labeling:

Each fitting is capped, bagged and labeled in full compliance with the ASME BPE standard.

Every label includes a QR Code which directs to the fittings Material Test Report.

Documentation:

Full Material Test Reports are supplied with the finished products and are available On-Line at www.MaxPure.net

6 EGMONEUMO Ehrenberg Group

Potrebbero piacerti anche

- Cross-Reference For Electrical Connectors (7553) : Shutdown SISDocumento132 pagineCross-Reference For Electrical Connectors (7553) : Shutdown SISChris LarsenNessuna valutazione finora

- Yanmar 3TNV88-XMS 4TNV88-XMS Engines: Engine Parts ManualDocumento74 pagineYanmar 3TNV88-XMS 4TNV88-XMS Engines: Engine Parts ManualАлексей100% (1)

- Land Rover LR3 (2006) Owners ManualDocumento358 pagineLand Rover LR3 (2006) Owners Manualt9mek100% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Cleaning Validation Toc MethodDocumento2 pagineCleaning Validation Toc MethodVinoth KumarNessuna valutazione finora

- Materials Data for Cyclic Loading: Low-Alloy SteelsDa EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsValutazione: 5 su 5 stelle5/5 (2)

- Búsqueda Del Medio - REHS0970 - Cross-Reference For Electrical Connectors (7553) 2222Documento93 pagineBúsqueda Del Medio - REHS0970 - Cross-Reference For Electrical Connectors (7553) 2222Juan Perez100% (1)

- Abs - Ship Vibration - 2021Documento87 pagineAbs - Ship Vibration - 2021Jonathan BrasilNessuna valutazione finora

- ECU PinoutDocumento1 paginaECU PinoutAnonymous 4IEjoc79% (14)

- PDA Technical Reports ListDocumento3 paginePDA Technical Reports Listnsk79in@gmail.comNessuna valutazione finora

- Onan Parts Manual DJE Genset 967-0225Documento63 pagineOnan Parts Manual DJE Genset 967-0225GreenMountainGenerators100% (2)

- Fundamentals of Metal Forming - Wagoner ChenotDocumento401 pagineFundamentals of Metal Forming - Wagoner Chenotthacal67% (3)

- 10 1199367786-K Deutz FahrDocumento27 pagine10 1199367786-K Deutz FahrJoe2030us82100% (2)

- ThermodynamicsDocumento28 pagineThermodynamicsJack Lupino100% (2)

- PERMASWAGE System Presentation (NXPowerLite)Documento16 paginePERMASWAGE System Presentation (NXPowerLite)Edwar ZulmiNessuna valutazione finora

- Precision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetDocumento1 paginaPrecision Equipments (Chennai) Pvt. Ltd. Plot No.B-70/1, Sipcot Industrial Park, Irrungattukottai, Chennai - 602105. Mechanical Data SheetAnonymous AyDvqgNessuna valutazione finora

- IRS Seismic Code Nov-2017Documento39 pagineIRS Seismic Code Nov-2017Mohd AftabNessuna valutazione finora

- Referencia Conectores Caterpillar PDFDocumento132 pagineReferencia Conectores Caterpillar PDFRamón José Aponte FrancoNessuna valutazione finora

- IVT Network - Sterility Test Failure Investigations - 2014-05-05Documento8 pagineIVT Network - Sterility Test Failure Investigations - 2014-05-05Vinoth KumarNessuna valutazione finora

- JLG 600a 600aj Illustrated Parts ManualDocumento20 pagineJLG 600a 600aj Illustrated Parts Manualvirgen100% (49)

- 31 Safety Relief Valve HisecDocumento3 pagine31 Safety Relief Valve HisecBheldy Harisafta100% (1)

- TC5013A Manual 101208 PDFDocumento108 pagineTC5013A Manual 101208 PDFThiyagarajan Murugesan100% (1)

- Cleanroom SOP SlidesDocumento34 pagineCleanroom SOP SlidesVinoth KumarNessuna valutazione finora

- Cleanroom SOP SlidesDocumento34 pagineCleanroom SOP SlidesVinoth KumarNessuna valutazione finora

- Double Mechanical Seals, Tandem ArrangementDocumento10 pagineDouble Mechanical Seals, Tandem ArrangementViwek MertiyaNessuna valutazione finora

- Bomba Hidraulica 580NDocumento3 pagineBomba Hidraulica 580NAlvaro MartinezNessuna valutazione finora

- AP Physics C Mechanics Course at A GlanceDocumento3 pagineAP Physics C Mechanics Course at A GlanceTarun AgarwalNessuna valutazione finora

- Datasheet Transmitter Rack 1.0 GeneralDocumento3 pagineDatasheet Transmitter Rack 1.0 Generalmukesh_kht1Nessuna valutazione finora

- Catalog DuctingDocumento9 pagineCatalog DuctingchristiadiargaNessuna valutazione finora

- Technische Dokumentation Technical Documentation: XOMOX Ball Valves Type Kva / KVL / KVKDocumento28 pagineTechnische Dokumentation Technical Documentation: XOMOX Ball Valves Type Kva / KVL / KVKTonyNessuna valutazione finora

- Fisher GX Control Valve and Actuator System: Scope of ManualDocumento44 pagineFisher GX Control Valve and Actuator System: Scope of ManualSaasiNessuna valutazione finora

- Manual de Despiece Remq 16py1Documento35 pagineManual de Despiece Remq 16py1GustavoAguilarNessuna valutazione finora

- 6/7/2018 Item Part No. Description QTY Size Material Notes Parts List Contractor PumpDocumento4 pagine6/7/2018 Item Part No. Description QTY Size Material Notes Parts List Contractor PumpGustavo HuertasNessuna valutazione finora

- Lista RuDocumento94 pagineLista RuasterinserNessuna valutazione finora

- VZBA-4F-L-ASY-PSI-US - 3-Way Ball Valve Assembly VZBA-4F-L and VZBA-4F-TDocumento2 pagineVZBA-4F-L-ASY-PSI-US - 3-Way Ball Valve Assembly VZBA-4F-L and VZBA-4F-TGigin PlusNessuna valutazione finora

- TXD3E PartsDocumento2 pagineTXD3E PartsCarlos Rafael Rondon AbreuNessuna valutazione finora

- DFV112M DFV132SDocumento1 paginaDFV112M DFV132Scarlos aguileraNessuna valutazione finora

- Pulsar DTSi Parts ListDocumento68 paginePulsar DTSi Parts ListSushil Kumar67% (9)

- Ham-Let Metal Seat UCV Valves Catalog 2020Documento6 pagineHam-Let Metal Seat UCV Valves Catalog 2020XavierNessuna valutazione finora

- MP513ENDocumento132 pagineMP513ENAnonymous H3I29yjNessuna valutazione finora

- NP1 5Documento2 pagineNP1 5Elinton De Jesus SarmientoNessuna valutazione finora

- Industrial Gas Generator Illustrated Parts CatalogueDocumento4 pagineIndustrial Gas Generator Illustrated Parts CataloguejuanaNessuna valutazione finora

- GW WS020 1004 E TankcoolDocumento3 pagineGW WS020 1004 E TankcoolNiki PratamaNessuna valutazione finora

- Wave Guide Flange DimensionsDocumento2 pagineWave Guide Flange Dimensionsraymund12345Nessuna valutazione finora

- Ram 624Documento9 pagineRam 624Pedro Schiavi StoiberNessuna valutazione finora

- Grundfosliterature 79607Documento15 pagineGrundfosliterature 79607Carlos BorgesNessuna valutazione finora

- XL2B PumpDocumento2 pagineXL2B PumpJuan NietoNessuna valutazione finora

- Blackmer NP3 Parts ListDocumento2 pagineBlackmer NP3 Parts ListWilson wayerNessuna valutazione finora

- Main Wiring Harness and ConnectionsDocumento4 pagineMain Wiring Harness and ConnectionsJean-Claude GONZALEZNessuna valutazione finora

- Unprotected-006criteria of Parts Replacement of NA TurbochargersDocumento7 pagineUnprotected-006criteria of Parts Replacement of NA Turbochargersstergios meletisNessuna valutazione finora

- DSP300-4 87 10 02Documento44 pagineDSP300-4 87 10 02joeNessuna valutazione finora

- JVC HV-29SL40 - HV-29SL50 Chassis MR2 PDFDocumento63 pagineJVC HV-29SL40 - HV-29SL50 Chassis MR2 PDFBITORSOLONessuna valutazione finora

- 2 Inch Demco Relief Valves Replacement PartsDocumento1 pagina2 Inch Demco Relief Valves Replacement Partsjose villalbaNessuna valutazione finora

- Engine, Compressor and Parts 7.3: Section 7Documento4 pagineEngine, Compressor and Parts 7.3: Section 7rdch78Nessuna valutazione finora

- RIX 2PS2B-.85 Oxygen CompressorDocumento3 pagineRIX 2PS2B-.85 Oxygen CompressorDepartamento TecnicoNessuna valutazione finora

- Sew-Eurodrive, Inc.: MotorDocumento1 paginaSew-Eurodrive, Inc.: MotorcmaradiagaNessuna valutazione finora

- Test and Drain ValveDocumento2 pagineTest and Drain ValveGopinath SekarNessuna valutazione finora

- Quadrant Ball Valve BrochureDocumento2 pagineQuadrant Ball Valve BrochureHecthor Gomez BelloNessuna valutazione finora

- LV195EA 362076D MotorDocumento15 pagineLV195EA 362076D MotorАртур ЛасловNessuna valutazione finora

- Section Two: Outer ShellDocumento65 pagineSection Two: Outer ShellJulian Camilo Moreno CárdenasNessuna valutazione finora

- TDA93XX Service ModeDocumento126 pagineTDA93XX Service Modebiplob akand67% (3)

- Dipod Support CD 8231Documento10 pagineDipod Support CD 8231leonardomarinNessuna valutazione finora

- Argus HK35Documento2 pagineArgus HK35Felipe Gamboa GálvezNessuna valutazione finora

- 10-Frame and BodyDocumento68 pagine10-Frame and BodySidney RodriguesNessuna valutazione finora

- Us Terex pt-100 Forestry Mstr-Parts 1-10Documento37 pagineUs Terex pt-100 Forestry Mstr-Parts 1-10Хелфор УкраинаNessuna valutazione finora

- 3.3 Design Considerations: 3.3.1 Codes, Standards and SpecificationsDocumento7 pagine3.3 Design Considerations: 3.3.1 Codes, Standards and SpecificationsUmar KidaNessuna valutazione finora

- DFV123M BMDocumento2 pagineDFV123M BMcarlos aguileraNessuna valutazione finora

- D9R Case FrameDocumento2 pagineD9R Case FrameJUAN PABLO ACOSTANessuna valutazione finora

- Deutz Fahr Agrotron K110 Profiline Tractor Parts Catalogue ManualDocumento19 pagineDeutz Fahr Agrotron K110 Profiline Tractor Parts Catalogue ManuallaopaodunNessuna valutazione finora

- US US Terex PT-100 Master Parts 2010Documento33 pagineUS US Terex PT-100 Master Parts 2010deniden2013Nessuna valutazione finora

- D-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 06-26 - Oil Pan, 3 CylinderDocumento4 pagineD-155 - 3 Cylinder Diesel Engine (01/75 - 12/85) 00 - Complete Machine 06-26 - Oil Pan, 3 CylinderMANUALESNessuna valutazione finora

- 7 Email Writing TipsDocumento8 pagine7 Email Writing TipsVinoth KumarNessuna valutazione finora

- Capa EffectivenessDocumento4 pagineCapa EffectivenessVinoth KumarNessuna valutazione finora

- Benifts of QualityDocumento5 pagineBenifts of QualityVinoth KumarNessuna valutazione finora

- Sun Pharma 483Documento5 pagineSun Pharma 483Vinoth KumarNessuna valutazione finora

- Body of Quality Knowledge PDFDocumento35 pagineBody of Quality Knowledge PDFVinoth KumarNessuna valutazione finora

- Loq and LodDocumento5 pagineLoq and LodVinoth KumarNessuna valutazione finora

- Diffusion TestDocumento14 pagineDiffusion TestVinoth KumarNessuna valutazione finora

- PF2579EN00EMDocumento2 paginePF2579EN00EMVinoth KumarNessuna valutazione finora

- Yogagowa ManualDocumento76 pagineYogagowa ManualVinoth KumarNessuna valutazione finora

- FDA PPT CPK PDFDocumento29 pagineFDA PPT CPK PDFShafayet HossainNessuna valutazione finora

- 11.4 Formulas For Flat Plates With Straight Boundaries and Constant Thickness (Continued)Documento1 pagina11.4 Formulas For Flat Plates With Straight Boundaries and Constant Thickness (Continued)Anant KumbhejkarNessuna valutazione finora

- Hyundai H380 TrucksDocumento12 pagineHyundai H380 TrucksIrfan SaeedNessuna valutazione finora

- Caterpillar 910 Wheel Loader Operators Manual SN 80u1 and UpDocumento7 pagineCaterpillar 910 Wheel Loader Operators Manual SN 80u1 and Upbambangpadhi7Nessuna valutazione finora

- Hyperco CatalogDocumento28 pagineHyperco CatalogFallo SusiloNessuna valutazione finora

- Primena Application: Belarus DeutzDocumento6 paginePrimena Application: Belarus DeutzDragan LazicNessuna valutazione finora

- Sidewinder 24 30 Manual REV 05 2014Documento6 pagineSidewinder 24 30 Manual REV 05 2014kirk sutherlandNessuna valutazione finora

- DC Motor Modeling and Controller DesignDocumento26 pagineDC Motor Modeling and Controller DesignMauricio bonilla GarageNessuna valutazione finora

- Mechanical Drives PracticalsDocumento2 pagineMechanical Drives PracticalsabyzenNessuna valutazione finora

- Toyota/Lexus: Boost Valve Kit 3 Oversized Lockup Control Valve Kit 1Documento1 paginaToyota/Lexus: Boost Valve Kit 3 Oversized Lockup Control Valve Kit 1Aays thNessuna valutazione finora

- SG6250HV-MV Container InstallationDocumento3 pagineSG6250HV-MV Container InstallationJesica SantibañezNessuna valutazione finora

- Regulador AxialDocumento12 pagineRegulador Axialluis_d_mNessuna valutazione finora

- Low Heating Value Fuel BurningDocumento17 pagineLow Heating Value Fuel BurningalirezaNessuna valutazione finora

- Aspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetDocumento1 paginaAspen Exchanger Design and Rating Shell & Tube V10: File: Printed: 01/07/2019 at 12:08:38 TEMA SheetWael BadriNessuna valutazione finora

- Module 9 - Wave Motion and SoundDocumento27 pagineModule 9 - Wave Motion and SoundHanah ArzNessuna valutazione finora

- 403d 15g EngineDocumento4 pagine403d 15g EngineIqra khanNessuna valutazione finora

- JCTN SampleDocumento8 pagineJCTN Samplepalaniraj pNessuna valutazione finora

- 0.1 Hire Charges of Plants & Machinery: Basic RatesDocumento4 pagine0.1 Hire Charges of Plants & Machinery: Basic RatesSanjan SameerNessuna valutazione finora

- Man l32 44Documento274 pagineMan l32 44Tran Duy NamNessuna valutazione finora

- 9323A270G Parts CatalogDocumento9 pagine9323A270G Parts CatalogOFFICE DANACNessuna valutazione finora