Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

1.13 Inspection & Test Plans

Caricato da

abimanyubawono100%(2)Il 100% ha trovato utile questo documento (2 voti)

184 visualizzazioni1 paginaThis document outlines inspection test plans for pressure vessels. It lists inspection activities to be performed at various stages including raw material receipt, in-process inspections, and final inspections. Specific activities include qualification of welding procedures, non-destructive testing, pressure testing, dimensional checks, nameplate stamping, and final documentation for dispatch. The document provides a legend defining responsibilities of the supplier/vendor, third party inspector, and owner for witnessing or reviewing each inspection activity.

Descrizione originale:

Inspection Test Plan

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThis document outlines inspection test plans for pressure vessels. It lists inspection activities to be performed at various stages including raw material receipt, in-process inspections, and final inspections. Specific activities include qualification of welding procedures, non-destructive testing, pressure testing, dimensional checks, nameplate stamping, and final documentation for dispatch. The document provides a legend defining responsibilities of the supplier/vendor, third party inspector, and owner for witnessing or reviewing each inspection activity.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

100%(2)Il 100% ha trovato utile questo documento (2 voti)

184 visualizzazioni1 pagina1.13 Inspection & Test Plans

Caricato da

abimanyubawonoThis document outlines inspection test plans for pressure vessels. It lists inspection activities to be performed at various stages including raw material receipt, in-process inspections, and final inspections. Specific activities include qualification of welding procedures, non-destructive testing, pressure testing, dimensional checks, nameplate stamping, and final documentation for dispatch. The document provides a legend defining responsibilities of the supplier/vendor, third party inspector, and owner for witnessing or reviewing each inspection activity.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

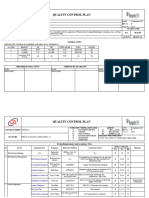

Doc No: PSA-V-ITP

Inspection Test Plans

CCR PSA Vessels Page 1 of 1

Pressure Vessels :

S No Inspection activities Inspect Supplier TPI Owne

ion / vendor r

code

1.0 Raw materials receipt & check / identification

1.1 All pressure parts including plates, forgings, nozzle a,b,c,e H H R

pipes, fasteners, gaskets, etc (Check test, if reqd)

2.0 In Process inspection & Tests

2.1 Qualification of WPS, PQR and WQR a,b,c,d, H H R

e,m

2.2 NDT Procedures, PWHT, leak test, pressure test, c,m H H R

procedures etc

2.3 Joint fit-up ovality, offset, nozzle fit-ups, external / a,b,c H W R

internals, RF pads, etc

2.4 Formed dished ends, inside / outside surface of a,b,c,d H W R

knuckles

2.5 Weld integrity / final weld a,d H R R

2.6 Back chip / root pass weld a,d H W R

2.7 NDT (RT/UT) c,d H W R

2.8 Air test of all reinforcement pads a,c,g H W R

2.9 Heat treatment (if applicable) a,b,c,n H W R

3.0 Final inspection

3.1 Overall workmanship, visual and dimensional checks a,b,c H H R

of completed vessel including internals & externals

3.2 Leak test / pressure test a,g,h,i H H R

3.3 Name plate check, stamping by inspector & rub-off a,b,c H W R

3.4 Cleaning and surface protection / treatment a,j H W R

3.5 Pre-dispatch inspection blanking of nozzle opening, a,b,c H R W

purging, grease filling, spare parts, packing list,

packaging etc

3.6 Final documentation for dispatch clearance c,m H R R

Legend : H HOLD W WITNESS R REVIEW

Inspection codes :

a- Visual check h- Pressure test

b- Dimensional check i- Deformation

c- Review / verification of certificates / j- Cleaning & painting

documents k- Traceability

d- NDT (PT, MT, RT, UT) l- Approval for corrective actions for NCRs

e- Mechanical & Chemical tests m- Approvals

f- Mock-up qualification n- Heat treatment

g- Leak test

Tender no: 12000200-HD-46009/AK

Potrebbero piacerti anche

- Lot Inspection Report For LPG New CylindersDocumento3 pagineLot Inspection Report For LPG New CylindersJagannath MajhiNessuna valutazione finora

- ITP Heat ExchangerDocumento1 paginaITP Heat Exchangersarmad009Nessuna valutazione finora

- Cold Tap Coating Report 2Documento1 paginaCold Tap Coating Report 2Jamal BakhtNessuna valutazione finora

- FInal QAP HDPE WeldingDocumento2 pagineFInal QAP HDPE Weldingkannagi198Nessuna valutazione finora

- HDPE Butt Fusion Weld Inspection and Imaging PDFDocumento19 pagineHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNessuna valutazione finora

- MS For Fabrication of Above-Ground Storage TankDocumento8 pagineMS For Fabrication of Above-Ground Storage Tankdadz mingiNessuna valutazione finora

- Prosedur Penetran TestingDocumento11 pagineProsedur Penetran TestingIkhsan DalimuntheNessuna valutazione finora

- A.9.02 - CPCL Itp For Utility Boiler PackageDocumento3 pagineA.9.02 - CPCL Itp For Utility Boiler PackageGanesh EshwarNessuna valutazione finora

- Working ITPDocumento4 pagineWorking ITPStephen BoodooNessuna valutazione finora

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Documento7 pagine13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- Wps Mig PDF FreeDocumento3 pagineWps Mig PDF Freehanz bermejoNessuna valutazione finora

- Butt JointsDocumento21 pagineButt JointsRaj1-23Nessuna valutazione finora

- (Painting Works) : Inspection and Test PlanDocumento2 pagine(Painting Works) : Inspection and Test Planrize1159Nessuna valutazione finora

- Wps For Smaw06-001 (Pipe 6g CS)Documento10 pagineWps For Smaw06-001 (Pipe 6g CS)walitedisonNessuna valutazione finora

- Inspection, Flushing & Testing of Piping-21Documento6 pagineInspection, Flushing & Testing of Piping-21Saurabh Kumar VermaNessuna valutazione finora

- QAP For Conical StrainerDocumento2 pagineQAP For Conical StrainersatishchidrewarNessuna valutazione finora

- Hydrostatic Test of Pandi WaterDocumento7 pagineHydrostatic Test of Pandi WaterOscar C. GabinayNessuna valutazione finora

- Scaffold ChecklistDocumento5 pagineScaffold ChecklistMohamed GhariebNessuna valutazione finora

- ITP For Hydraulic BarrierDocumento4 pagineITP For Hydraulic Barriermoytabura96Nessuna valutazione finora

- SATR-L-2001 Rev 2 - Flange Joint Tightening Inspection ReportDocumento12 pagineSATR-L-2001 Rev 2 - Flange Joint Tightening Inspection Reportdeepa narayan100% (1)

- Test Pack Clearance FormatDocumento2 pagineTest Pack Clearance FormatKarthikNessuna valutazione finora

- WPS Pipe 08'' SHD 40 SMAW REV02Documento2 pagineWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNessuna valutazione finora

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocumento10 pagineFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- Inspection report-GRVE BlankDocumento2 pagineInspection report-GRVE BlankJoseph Perez100% (1)

- Welder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersDocumento1 paginaWelder Qualification Test - As Run Sheet: Weld Details Filler Shield Welding ParametersGopalakrishnan GovindarajNessuna valutazione finora

- WP 11 Corrosion Protection Tape CoatingDocumento3 pagineWP 11 Corrosion Protection Tape CoatingKarthikNessuna valutazione finora

- Sample WPS 1Documento13 pagineSample WPS 1waqas pirachaNessuna valutazione finora

- Materials System SpecificationDocumento15 pagineMaterials System SpecificationAwais CheemaNessuna valutazione finora

- Itp Electrical SwitchgearDocumento4 pagineItp Electrical SwitchgearpertmasterNessuna valutazione finora

- Chemical Resistance (LLDPE) PDFDocumento24 pagineChemical Resistance (LLDPE) PDFrubyshreeNessuna valutazione finora

- QCP & Report Rev 03Documento30 pagineQCP & Report Rev 03Heri FebriyantoNessuna valutazione finora

- Itp Pipe SupportsDocumento4 pagineItp Pipe SupportskamlNessuna valutazione finora

- 2.FIT-UP & 3. Welding ReportDocumento2 pagine2.FIT-UP & 3. Welding Reportkhurshid alam Khan100% (1)

- Itp Piping PDFDocumento4 pagineItp Piping PDFdashNessuna valutazione finora

- Precision Storage Vessels PVT LTD: Pressure Test ReportDocumento2 paginePrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- Wps Pip Gtaw - ArabianDocumento1 paginaWps Pip Gtaw - ArabianIshack MohammedNessuna valutazione finora

- Itp For Painting - FDocumento5 pagineItp For Painting - FMudabbir HussainNessuna valutazione finora

- Quality Plan and Checklist (HVAC) - Sandvik G BlockDocumento3 pagineQuality Plan and Checklist (HVAC) - Sandvik G BlockParasNessuna valutazione finora

- ITP - (Pressure Testing Piping) PDFDocumento3 pagineITP - (Pressure Testing Piping) PDFSUNNY BOSS100% (1)

- Contractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationDocumento5 pagineContractor Quality Control Plan For Fix or Stationery Equipment Installation Inspection and Test Plan For Fix or Stationery Equipment InstallationSergey KichenkoNessuna valutazione finora

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocumento3 pagineN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNessuna valutazione finora

- Sample Forms WPS PQRDocumento22 pagineSample Forms WPS PQRGMNessuna valutazione finora

- Tech SpecDocumento16 pagineTech SpecKingston RivingtonNessuna valutazione finora

- DD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateDocumento1 paginaDD250 MATERIAL INSPECTION AND RECEIVING REPORT TemplateWaqar SiddiqueNessuna valutazione finora

- Material Inspection Report: Project Name Date InspDocumento22 pagineMaterial Inspection Report: Project Name Date InspRafiqKuNessuna valutazione finora

- PPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFDocumento14 paginePPR Pipe Method Statement For Pipe and Fitting Installation and Testing Commissioning PDFBuraq Aircondition Cont & Gen Maint LLC BuraqNessuna valutazione finora

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocumento2 pagineBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNessuna valutazione finora

- CPVC ChecklistDocumento1 paginaCPVC Checklistchakravarthi kanugulaNessuna valutazione finora

- Pressure Vessel ITP Rev 0Documento10 paginePressure Vessel ITP Rev 0SLC HosurNessuna valutazione finora

- Rotating Itp 1Documento4 pagineRotating Itp 1abdul aziz100% (1)

- 1 Imran Piping QC CVDocumento4 pagine1 Imran Piping QC CVkazim MirzaNessuna valutazione finora

- Hydrotest QI304-sampleDocumento3 pagineHydrotest QI304-sampleHanuman Rao100% (1)

- QAQC Form - ArchitechtureDocumento42 pagineQAQC Form - ArchitechtureMohammad Hadoumi SaldanNessuna valutazione finora

- Nde MapDocumento8 pagineNde MapjorgekarlosprNessuna valutazione finora

- Elding Rocedure Pecification: 7200-HDPE Butt WeldDocumento2 pagineElding Rocedure Pecification: 7200-HDPE Butt Weldsamer8saifNessuna valutazione finora

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Documento4 pagineAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Inspection Test Plan PV Nozzle Modification/AlterationDocumento4 pagineInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNessuna valutazione finora

- QAP FormatsDocumento13 pagineQAP Formatsavvari sureshNessuna valutazione finora

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Documento2 pagineVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- Quality Management - Inspection and Test PlanDocumento1 paginaQuality Management - Inspection and Test PlanVIKASH RAINessuna valutazione finora

- Website JournalDocumento1 paginaWebsite JournalabimanyubawonoNessuna valutazione finora

- 2017 Gap AnalysisDocumento42 pagine2017 Gap Analysisمصطفى محمد100% (8)

- RiskAssessmentGuide PDFDocumento74 pagineRiskAssessmentGuide PDFabimanyubawonoNessuna valutazione finora

- Presentasi Ngelmuning AgesangDocumento1 paginaPresentasi Ngelmuning AgesangabimanyubawonoNessuna valutazione finora

- Aggregate Plan:: The Purpose of Aggregate PlansDocumento14 pagineAggregate Plan:: The Purpose of Aggregate PlansabimanyubawonoNessuna valutazione finora

- Key Features of ISO 45001 PDFDocumento1 paginaKey Features of ISO 45001 PDFTita EricNessuna valutazione finora

- NCR FormDocumento1 paginaNCR FormabimanyubawonoNessuna valutazione finora

- FPA 03-A.01 Permohonan Akreditasi LP LK LI LM PUP PBADocumento595 pagineFPA 03-A.01 Permohonan Akreditasi LP LK LI LM PUP PBAabimanyubawonoNessuna valutazione finora

- Certified Quality Auditor (ASQ Sample Exam Paper)Documento24 pagineCertified Quality Auditor (ASQ Sample Exam Paper)Farhan Shariff86% (7)

- CQI (Wessex Branch) Remote Auditing - April 2012Documento29 pagineCQI (Wessex Branch) Remote Auditing - April 2012abimanyubawonoNessuna valutazione finora

- ERM Application Guide September 2011Documento22 pagineERM Application Guide September 2011abimanyubawonoNessuna valutazione finora

- Integrated Management SystemDocumento1 paginaIntegrated Management SystemabimanyubawonoNessuna valutazione finora

- Communication MatrixDocumento2 pagineCommunication MatrixabimanyubawonoNessuna valutazione finora

- 9004 Self AssessmentDocumento7 pagine9004 Self AssessmentabimanyubawonoNessuna valutazione finora

- Insulation ProcedureDocumento3 pagineInsulation ProcedureabimanyubawonoNessuna valutazione finora

- Maturity Organization Level ISO 9004Documento7 pagineMaturity Organization Level ISO 9004abimanyubawonoNessuna valutazione finora

- Maturity Organization Level ISO 9004Documento2 pagineMaturity Organization Level ISO 9004abimanyubawono100% (2)

- Steel HullDocumento9 pagineSteel HullabimanyubawonoNessuna valutazione finora

- Method Statement For Installation of RO Skids Pressure Vessels and Connecting Pipes R1Documento8 pagineMethod Statement For Installation of RO Skids Pressure Vessels and Connecting Pipes R1abimanyubawonoNessuna valutazione finora

- Insulation ProcedureDocumento3 pagineInsulation ProcedureabimanyubawonoNessuna valutazione finora

- Developing The Team-Based OrganizationDocumento19 pagineDeveloping The Team-Based OrganizationIsmaeldaOricaNessuna valutazione finora

- Green Impact Audit Checklist UoLDocumento6 pagineGreen Impact Audit Checklist UoLMarcos AquinoNessuna valutazione finora

- Maturity Organization Level ISO 9004Documento2 pagineMaturity Organization Level ISO 9004abimanyubawono100% (2)

- 4.53 Change Management ProcedureDocumento4 pagine4.53 Change Management ProcedureAbdel Nasser AdamNessuna valutazione finora

- Correlation Matrices Between ISO 9001 2008 and ISO 9001 2015Documento7 pagineCorrelation Matrices Between ISO 9001 2008 and ISO 9001 2015Wewey NuestroNessuna valutazione finora

- FMEA TemplateDocumento28 pagineFMEA Templatekhawaja Ali100% (1)

- F1109 Management of Change Form 02022011Documento2 pagineF1109 Management of Change Form 02022011abimanyubawonoNessuna valutazione finora

- Iso9001 2015 Process ApprDocumento7 pagineIso9001 2015 Process ApprHaitham NegmNessuna valutazione finora

- Brain GymDocumento1 paginaBrain Gymabimanyubawono100% (3)

- Raised Face Flange Ball ValvesDocumento28 pagineRaised Face Flange Ball Valvesrudy_423522658Nessuna valutazione finora

- Allengers 325 RF - Installation and Service ManualDocumento63 pagineAllengers 325 RF - Installation and Service Manualleopa7880% (20)

- Huawei Agile POL Hotel Solution PDFDocumento31 pagineHuawei Agile POL Hotel Solution PDFMoises TemplinskiNessuna valutazione finora

- Katalog Produk Service Air CompressorDocumento12 pagineKatalog Produk Service Air Compressorirvian_dinataNessuna valutazione finora

- C091 (J) Aisg C091 (K) 3MDocumento2 pagineC091 (J) Aisg C091 (K) 3MАлександрNessuna valutazione finora

- Brochure Scania Irizar I8Documento10 pagineBrochure Scania Irizar I8MioMaulenovoNessuna valutazione finora

- PRINCE2 Quick Reference GuideDocumento2 paginePRINCE2 Quick Reference Guidespm9062100% (5)

- Case Studies in Construction Materials: Richard O. Leramo, Lawson O. Adekoya, Cleophas A. LotoDocumento10 pagineCase Studies in Construction Materials: Richard O. Leramo, Lawson O. Adekoya, Cleophas A. LotoarkpNessuna valutazione finora

- ISO 9001 - HutchinsonDocumento2 pagineISO 9001 - HutchinsonUğurNessuna valutazione finora

- Process Understanding Related To Pharmaceutical Manufacture and ControlDocumento7 pagineProcess Understanding Related To Pharmaceutical Manufacture and ControlDanielle monteiro uchoa alves100% (1)

- New Form For Companies MOIDocumento2 pagineNew Form For Companies MOIM.IMRANNessuna valutazione finora

- Config WCMDocumento22 pagineConfig WCMSUJAYNessuna valutazione finora

- ACME AHX Water-Cooled Condenser - 06.10 PDFDocumento3 pagineACME AHX Water-Cooled Condenser - 06.10 PDFhappale2002Nessuna valutazione finora

- Tools Termux Part 2Documento13 pagineTools Termux Part 2Wanday Rotter State100% (1)

- PCR T465 ManualDocumento92 paginePCR T465 ManualpesotacosNessuna valutazione finora

- CA08100005E Vol04 Ibook PDFDocumento797 pagineCA08100005E Vol04 Ibook PDFFelipe FrancoNessuna valutazione finora

- BEUMER Abfülltechnik Fillpac E PDFDocumento4 pagineBEUMER Abfülltechnik Fillpac E PDFMKPashaPashaNessuna valutazione finora

- SP020 and SP022 Quick User ManualDocumento36 pagineSP020 and SP022 Quick User Manualsekhar rajNessuna valutazione finora

- 03 - Introduction To TrixboxDocumento25 pagine03 - Introduction To TrixboxduyluanNessuna valutazione finora

- IEC 61439-2-2011 - Part01Documento25 pagineIEC 61439-2-2011 - Part01hajjar100% (1)

- Winsock Networking Tutorial (C++)Documento46 pagineWinsock Networking Tutorial (C++)river_11576100% (1)

- p103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesDocumento6 paginep103 Stts Gec Asi Ms Ele 010 - Method Statement For Installation of Wiring AccessoriesAnandu AshokanNessuna valutazione finora

- Huawei OLT MA5608T Power Board H801MPWD Hardware DescriptionDocumento7 pagineHuawei OLT MA5608T Power Board H801MPWD Hardware DescriptionHuawei GPON NetworksNessuna valutazione finora

- CCNA+3+Module+7+Version+4 0+answersDocumento6 pagineCCNA+3+Module+7+Version+4 0+answersMinoli_Silva_7409Nessuna valutazione finora

- A Industral Visit ReportDocumento12 pagineA Industral Visit ReportAnkit SharmaNessuna valutazione finora

- Glossary of Mobile Phone Terms and MeaningDocumento13 pagineGlossary of Mobile Phone Terms and MeaningCarla Brown100% (1)

- Guidance Notes For Applying For UKAS AccreditationDocumento3 pagineGuidance Notes For Applying For UKAS AccreditationJem ChiltonNessuna valutazione finora

- Spain Iban Number - Google SearchDocumento1 paginaSpain Iban Number - Google Search7jfp2yys8fNessuna valutazione finora

- Power System Load Flow Analysis Using Microsoft Excel PDFDocumento21 paginePower System Load Flow Analysis Using Microsoft Excel PDFLanz de la Cruz100% (1)

- 443 840 840C 850 880 Computer Link Descr of Message FramesDocumento140 pagine443 840 840C 850 880 Computer Link Descr of Message FramesООО ЛантисNessuna valutazione finora