Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

A512 06

Caricato da

Sasi KumarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

A512 06

Caricato da

Sasi KumarCopyright:

Formati disponibili

Designation: A512 06

Standard Specification for

Cold-Drawn Buttweld Carbon Steel Mechanical Tubing1

This standard is issued under the fixed designation A512; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon () indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 3. Ordering Information

1.1 This specification covers cold-drawn buttweld carbon 3.1 Orders for material under this specification should

steel tubes for use as mechanical tubing. include the following, as required, to describe the required

1.2 This specification covers round, square, rectangular, and material adequately:

special shape mechanical tubing. 3.1.1 Quantity (feet, weight (Note 1), or number of lengths),

1.3 Round tube size ranges covered are outside diameters up NOTE 1The term weight is temporarily used in this specification

to 3 12 in. (88.9 mm) and wall thickness from 0.035 to 0.500 because of established trade usage. The word is used to mean both force

in. (0.89 to 12.70 mm). and mass, and care must be taken to determine which is meant in each

1.4 Optional supplementary requirements are provided and, case (SI unit for force = newton and for mass = kilogram).

when desired, shall be so stated in the order. 3.1.2 Name of material (buttweld carbon steel mechanical

1.5 The values stated in inch-pound units are to be regarded tubing),

as standard. The values given in parentheses are mathematical 3.1.3 Form (round, square, rectangular, special shape),

conversions to SI units that are provided for information only 3.1.4 Condition, description and code letters (Section 5),

and are not considered standard. 3.1.5 Grade, if required (Section 6),

2. Referenced Documents 3.1.6 Dimensions (round, Section 9 or square and rectangu-

lar, Section 10),

2.1 ASTM Standards:2 3.1.7 Length (round length, 9.2; square and rectangular

A370 Test Methods and Definitions for Mechanical Testing length, 10.5),

of Steel Products 3.1.8 Burr removal (Section 11),

A1040 Guide for Specifying Harmonized Standard Grade 3.1.9 Report of chemical analysis and products analysis, if

Compositions for Wrought Carbon, Low-Alloy, and Alloy required,

Steels 3.1.10 Individual supplementary requirements if required

E59 Practice for Sampling Steel and Iron for Determination (S1 through S5),

of Chemical Composition3 3.1.11 Special requirements,

2.2 Military Standards:4 3.1.12 End use,

MIL-STD-129 Marking for Shipment and Storage 3.1.13 Specification designation,

MIL-STD-163 Steel Mill Products Preparation for Ship- 3.1.14 Special marking (Section 15), and

ment and Storage 3.1.15 Special packaging (Section 16).

2.3 Federal Standard:

Fed. Std. No. 123 Marking for Shipments (Civil Agencies)4 4. Materials and Manufacture

4.1 The steel shall be made by any process.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, 4.2 If a specific type of melting is required by the purchaser,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee it shall be as stated on the purchase order.

A01.09 on Carbon Steel Tubular Products. 4.3 The primary melting may incorporate separate degas-

Current edition approved Oct. 1, 2006. Published October 2006. Originally

approved in 1964. Last previous edition approved in 2005 as A512 96 (2005). sing or refining, and may be followed by secondary melting,

DOI: 10.1520/A0512-06. such as electroslag or vacuum-arc remelting. If secondary

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or melting is employed, the heat shall be defined as all of the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standards Document Summary page on

ingots remelted from a single primary heat.

the ASTM website. 4.4 Steel may be cast in ingots or may be strand cast. When

3

Withdrawn. steel of different grades is sequentially strand cast, identifica-

4

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700 tion of the resultant transition material is required. The

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright (C) ASTM International, 100 Barr Harbor Drive P.O. box C700, West Conshohocken, Pennsylvania USA

Copyright by ASTM Int'l (all rights reserved); 1

A512 06

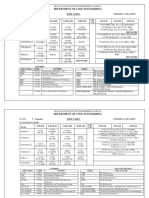

producer shall remove the transition material by an established TABLE 2 Chemical Requirements for Other Carbon GradesA

procedure that positively separates the grades. Grade Chemical Composition Limits, %

4.5 Tubes shall be made by the furnace buttweld process. Desig-

Phospho-

nationB Carbon Manganese Sulfur, max

4.6 Tubes shall be cold finished, either externally only rus, max

(sunk) or externally and internally (mandrel drawn). 1008 0.10 max 0.300.50 0.040 0.045

1010 0.080.13 0.300.60 0.040 0.045

1012 0.100.15 0.300.60 0.040 0.045

5. Condition 1015 0.130.18 0.300.60 0.040 0.045

5.1 The purchaser shall specify in the order one of the 1016 0.130.18 0.600.90 0.040 0.045

1018 0.150.20 0.600.90 0.040 0.045

following conditions: 1019 0.150.20 0.701.00 0.040 0.045

MD (Mandrel Drawn)No final thermal treatment 1020 0.180.23 0.300.60 0.040 0.045

SD (Sink Drawn)No final thermal treatment 1021 0.180.23 0.600.90 0.040 0.045

1025 0.220.28 0.300.60 0.040 0.045

MDSRMandrel Drawn and Stress Relieved 1026 0.220.28 0.600.90 0.040 0.045

SDSRSink Drawn and Stress Relieved 1030 0.280.34 0.600.90 0.040 0.045

MDSAMandrel Drawn and Soft Annealed or normalized 1035 0.320.38 0.600.90 0.040 0.045

1110 0.080.13 0.300.60 0.040 0.130C

SDSASink Drawn and Soft Annealed or normalized 1115 0.130.20 0.600.90 0.040 0.130C

NORM-MD-SRNormalized, Mandrel Drawn, and Stress 1117 0.140.20 1.001.30 0.040 0.130C

Relieved A

Rimmed or capped steels which may be used for the above grades are

NORM-SD-SRNormalized, Sink Drawn, and Stress Re- characterized by a lack of uniformity in their chemical composition, and for this

reason product analysis is not technologically appropriate unless misapplication is

lieved clearly indicated.

B

Other analyses are available.

C

6. Chemical Composition Grades 1110, 1115, and 1117 shall contain 0.08 min % sulfur.

6.1 The steel shall conform to the requirements as to

TABLE 3 Tolerances for Product Analysis for Steels Shown in

chemical composition prescribed in Table 1 or Table 2 (see

Table 1

Specification A1040) and Table 3.

Limit, or Maximum Variation, Over Maximum Limit or

6.2 When a grade is ordered under this specification, sup- Element

of Specified Under Minimum Limit

plying an alloy grade that specifically requires the addition of Range, %

Under min, % Over max, %

any element other than those listed for the ordered grade in

Carbon To 0.15, incl 0.02 0.03

Table 1 or Table 2 is not permitted. Over 01.5 0.03 0.04

Manganeses To 0.60, incl 0.03 0.03

7. Heat Analysis Over 0.60 0.04 0.04

Phosphorus ... ... 0.01

7.1 An analysis of each heat of steel shall be made by the Sulfur ... ... 0.01

steel manufacturer to determine the percentages of the ele-

ments specified; if secondary melting processes are used, the

heat analysis shall be obtained from one remelted ingot or the 8. Product Analysis

product of one remelted ingot of each primary melt. The heat 8.1 When requested on the purchase order, a product analy-

analysis shall conform to the requirements specified, except sis shall be made by the manufacturer. The chemical compo-

that where the heat identity has not been maintained or where sition thus determined shall conform to the requirements

the analysis is not sufficiently complete to permit conformance prescribed in Table 1 or Table 2 as modified by Table 3.

to be determined, the chemical composition determined from a 8.2 The product analysis limits shown for carbon are not

product analysis made by the tubular manufacturer shall normally applicable to the MT grades.

conform to the requirements specified for heat analysis. When 8.3 The number and source of samples for such product

requested in the order or contract, a report of such analyses analysis shall be based on the individual heat or lot identity of

shall be furnished to the purchaser. one of the following forms of material.

7.2 A report of this analysis shall be furnished only when 8.3.1 Heat Identity MaintainedOne product analysis per

requested on the order. heat on either a billet, a length of flat rolled stock, or a tube.

8.3.2 Heat Identity Not MaintainedOne product analysis

from one tube per 2000 ft (610 m) or less for sizes over 3 in.

TABLE 1 Chemical RequirementsA

(76.2 mm), or one product analysis from one tube per 5000 ft

Chemical Composition Limits, %

Grade (1524 m) or less for sizes under 3 in. (76.2 mm).

Designation Phospho- 8.4 If the original test for product analysis fails, retests of 2

Carbon Manganese Sulfur, max

rus, max

additional billets, 2 lengths of flat rolled stock, or 2 tubes shall

MT 1010 0.050.15 0.300.60 0.04 0.045

MT 1015 0.100.20 0.300.60 0.04 0.045

be made. Both retests for the elements in question shall meet

MT X 1015 0.100.20 0.600.90 0.04 0.045 the requirements of this specification; otherwise all remaining

MT 1020 0.150.25 0.300.60 0.04 0.045 material in the heat or lot shall be rejected, or at the option of

MT X 1020 0.150.25 0.701.00 0.04 0.045

the producer, each billet, length, flat rolled stock, or tube may

A

Rimmed or capped steels which may be used for the above grades are be individually tested for acceptance.

characterized by a lack of uniformity in their chemical composition, and for this

reason product analysis is not technologically appropriate unless misapplication is 8.5 Samples for product analysis, except for spectrochemi-

clearly indicated. cal analysis, shall be taken in accordance with Practice E59,

Copyright by ASTM Int'l (all rights reserved); 2

A512 06

and the composition thus determined shall correspond to the TABLE 5 Permissible Variations in LengthRound Tubing

requirements in applicable section or table. Lengths 4 ft (1.2 m) and underup to 2 in. (50.8 6 132 in. (0.8 mm)

mm) diameter

Lengths 4 ft (1.2 m) and underover 2 in. (50.8 6364 in. (1.2 mm)

9. Permissible Variations in Dimensions of Round Tubing mm) diameter

9.1 Diameter and Wall Thickness: Lengths 4 ft to 10 ft (1.2 to 3.0 m), inclup to 2 6364 in. (1.2 mm)

in. (50.8 mm) diameter

9.1.1 Variations in outside diameter, inside diameter, and Lengths 4 ft to 10 ft (1.2 to 3.0 m), inclover 2 6116 in. (1.6 mm)

wall thickness shall not exceed the amounts prescribed in Table in. (50.8 mm) diameter

4. Lengths 10 ft to 24 ft (3.0 to 7.3 m), inclall 618 in. (3.2 mm)

diameters

9.1.2 These variations apply to round, unannealed, and Lengths over 24 ft (7.3 m)all diameters 618 in. (3.2 mm)A

stress-relieved tubing. A

Plus an additional tolerance of 6116 (1.6 mm) for each 10 ft (3.0 m) or fraction

9.1.3 Diameter tolerance includes ovality. over 24 ft (7.3 m).

9.1.4 Sink tubing is normally ordered by outside diameter

and nominal wall. Mandrel-drawn tubing is normally ordered

by outside diameter and inside diameter and may be ordered by 10. Permissible Variations in Dimensions of Square and

outside diameter or inside diameter and wall thickness but not Rectangular Tubing

by all three dimensions.

9.2 LengthRandom lengths between acceptable limits 10.1 Outside Dimensions and Wall ThicknessVariations

will be furnished, utilizing the full mill length. Tubing will be in largest outside dimensions across flats and wall thickness

cut in half if specified. Full length random tubing will have a shall not exceed the amounts prescribed in Table 6.

spread not exceeding 7 ft (2.1 m). Half-length random tubing 10.2 Corner RadiiThe corners of square and rectangular

will have a spread not exceeding 4 ft (1.2 m). Not more than tubes shall be slightly rounded inside and slightly rounded

10 % of the total footage of a shipment may be furnished in outside consistent with wall thickness. The outside corners

lengths shorter than the minimum specified but not less than may be slightly flattened. The radii of corners for square and

6 ft (1.8 m). rectangular cold-finished buttweld tubes shall be in accordance

9.2.1 When specified, multiple lengths will be furnished and with Table 7. Special radii may be obtained.

should include allowances made for the customers cutting tool 10.3 Squareness TolerancePermissible variations for the

width and grippage. Maximum and minimum lengths may be side of square and rectangular tube shall be determined by the

specified with the understanding that not more than 10 % of the following equation:

total footage in a shipment may be furnished in individual 6 b 5 c 3 0.006, in. ~mm!

multiples cut to the customers specifications.

9.2.2 Variations from the specified length shall not exceed where:

the amounts prescribed in Table 5. b = tolerance for out-of-square, and

9.3 Straightness: c = largest external dimensions across flats, in. (mm).

9.3.1 A round tube shall be considered straight provided that

no 3-ft (0.9-m) section departs from a straight line by more The squareness of sides is commonly determined by one of

than 0.030 in. (0.76 mm). the following methods:

9.3.2 The straightness of round tubes shorter than 3 ft (0.9 10.3.1 A square, with two adjustable contact points on each

m) shall be proportionate to 0.010 in./ft (0.8 mm/m). arm, is placed on two sides. A fixed feeler gage is then used to

9.3.3 These straightness tolerances do not apply to soft- measure the maximum distance between the free contact point

annealed tubing nor to long lengths of small diameter tubing. and the surface of the tubing.

TABLE 4 Diameter and Wall Thickness Tolerances for Round Tubing

Outside Diameter, in. (mm) Inside Diameter, in. (mm) Wall Thickness, %

Outside Diameter Range, in. (mm)

Over Under Over Under Over Under

Sunk

Up to 12 (12.7), excl 0.004 (0.10) 0 ... ... 15A 15

12 to 112 (12.7 to 38.1), excl 0.005 (0.13) 0 ... ... 10A 10

112 to 3 (38.1 to 76.2), incl 0.010 (0.25) 0 ... ... 10A 10

Mandrel Drawn

Less than 0.156 (3.96) wall:

Up to 12 (12.7), excl 0.004 (0.10) 0 0 0.010 (0.25) 1212 1212

12 to 112 (12.7 to 38.1), excl 0.005 (0.13) 0 0 0.005 (0.13)B 10 10

0.156 (3.96) wall and over:

12 to 112 (12.7 to 38.1), excl 0.005 (0.13) 0 0 0.005 (0.13)B 7 7

Under 0.156 (3.96) wall:

112 (38.1) and over 0.010 (0.25) 0 ... 0.010 (0.25) 10 10

0.156 (3.96) wall and over:

112 (38.1) and over 0.010 (0.25) 0 0 0.010 (0.25) 7 7

A

Except at the weld line, where the weld pad may exceed this figure.

B

Tubes with an inside diameter under 12 in. (12.7 mm) may require more than 0.005 in. (0.13 mm) inside diameter tolerance and the producer should be consulted.

Copyright by ASTM Int'l (all rights reserved); 3

A512 06

TABLE 6 Outside Dimension and Wall Thickness Tolerances for Square and Rectangular Tubing

Largest Outside Dimension Across Outside Dimension, Including Convexity or

Wall Thickness Tolerance, 6, %

Flats Wall Thickness Concavity

Over Under SinkA Mandrel

Inch-Pound Units

in. in. in. in.

To 34 over 0.065 0.010 0.010 15 1212

Over 34 to 114 under 0.156 0.015 0.015 10 10

Over 34 to 114 0.156 and over 0.015 0.015 10 7

Over 114 to 212 under 0.156 0.020 0.020 10 10

Over 114 to 212 0.156 and over 0.020 0.020 10 7

SI Units

mm mm mm mm

To 19.0 over 1.65 0.25 0.25 15 1212

Over 19.0 to 31.8 under 3.96 0.38 0.38 10 10

Over 19.0 to 31.8 3.96 and over 0.38 0.38 10 7

Over 31.8 to 63.5 under 3.96 0.51 0.51 10 10

Over 31.8 to 63.5 3.96 and over 0.51 0.51 10 7

A

Except at the weld line where the weld pad may exceed this figure.

TABLE 7 Radii of Corners of Butt-Weld Square and Rectangular spread not exceeding 7 ft (2.1 m). Half-length random tubing

Tubing will have a spread not exceeding 4 ft (1.2 m). Not more than

Maximum Radii of 10 % of the total footage of a shipment may be furnished in

Wall Thickness, in. (mm)

Corners, in. (mm)A

lengths shorter than the minimum specified, but not less than 6

0.065 to 0.083 (1.65 to 2.11), incl

9 64 (3.6) ft (1.8 m).

Over 0.083 to 0.095 (2.11 to 2.41), incl

3 16 (4.8)

Over 0.095 to 0.109 (2.41 to 2.76), incl (5.2)

13 64 10.5.1 When specified, multiple lengths will be furnished

Over 0.109 to 0.134 (2.76 to 3.40), incl 732 (5.6)

and should include allowances made for the customers cutting

Over 0.134 to 0.156 (3.40 to 3.96), incl 14 (6.4)

Over 0.156 to 0.188 (3.96 to 4.78), incl 932 (7.1)

tool width and grippage. Maximum and minimum lengths may

Over 0.188 to 0.250 (4.78 to 6.35), incl 1132 (8.7) be specified with the understanding that not more than 10 % of

Over 0.250 to 0.313 (6.35 to 7.95), incl 716 (11.1)

the total footage in a shipment may be furnished in individual

Over 0.313 to 0.375 (7.95 to 9.52), incl 12 (12.7)

Over 0.375 to 0.500 (9.52 to 12.70), incl 1116 (17.5)

multiples cut to the customers specifications.

A

10.5.2 Variations from the specified length shall not exceed

These tolerances apply to grades MT 1010 and MT 1015 steel only. Toler-

ances on other grades shall be established between the manufacturer and the the amounts prescribed in Table 9.

purchaser. 10.6 StraightnessThe straightness tolerance for square

and rectangular tubing shall be 116 in. in 3 ft (1:576).

10.3.2 A square, equipped with direct-reading vernier, may 11. Workmanship, Finish, and Appearance

be used to determine the angular deviation which, in turn, may

be related to distance to inches. 11.1 Tubes shall have a surface finish compatible with the

10.4 Twist ToleranceVariation in twist for square and conditions (Section 5) to which the tubes are ordered.

rectangular tubing shall not exceed the amounts prescribed in 11.2 Special surface preparations as may be required for

Table 8. The twist in square and rectangular tubing may be specific applications are not within the scope of this section.

measured by holding one end of the tubing on a surface plate Such requirements shall be considered under the supplemen-

and noting the height of either corner of the opposite end of tary or basis of purchase provisions of this specification, and

same side above the surface plate. Twist may also be measured details shall be provided in the purchase order.

by means of a beveled protractor equipped with a level. The 11.3 The tubing shall be free of injurious defects and shall

angular deviation is measured on opposite ends or at any point have a workmanlike finish. Surface imperfections such as

throughout the length. handling marks, straightening marks, light die marks, or

10.5 LengthRandom lengths between acceptable limits shallow pits are not considered injurious.

will be furnished, utilizing the full mill length. Tubing will be 11.4 The tubing shall be free of scale. In the case of

cut in half if specified. Full length random tubing will have a thermally treated tubing, a slight amount of color will not be

considered cause for rejection.

TABLE 8 Twist Tolerance, Square and Rectangular Mechanical

Tubing TABLE 9 Permissible Variation in LengthSquare and

Twist Tolerance in 3 ft, Rectangular Tubing

Largest Dimension, in. (mm)

in. (in 1 m, mm)

Lengths 3 ft (0.9 m) and under 6116 in. (1.,6 mm)

Under 12 (12.7) 0.050 (0.014) Lengths over 3 to 12 ft (0.9 to 3.7 m), incl 6132 in. (2.4 mm)

12 to 112 (12.7 to 38.1), incl 0.075 (0.020) Lengths over 12 to 20 ft (3.7 to 6.1 m), incl 618 in. (3.2 mm)

Over 112 to 212 (38.1 to 63.5), incl 0.095 (0.026) Lengths over 20 to 30 ft (6.1 to 9.1 m), incl 6316 in. (4.8 mm)

Over 212 (63.5) 0.125 (0.035) Lengths over 30 to 40 ft (9.1 to 12.2 m), incl 638 in. (9.5 mm)

Copyright by ASTM Int'l (all rights reserved); 4

A512 06

11.5 Saw cut tubes will be furnished without removing identified by a tag or stencil with the manufacturers name or

outside diameter and inside diameter burrs. brand, grade or material, purchasers order number, and this

11.6 Lathe cut tubes will be furnished with outside diameter specification number (ASTM designation).

burr only removed. 15.2 Bar CodingIn addition to the requirements in 15.1

11.7 Burr removal may be obtained by so specifying in the and 15.3 bar coding is acceptable as a supplemental identifi-

purchase order. cation method. The purchaser may specify in the order a

12. Machining AllowanceRound Tubing specific bar coding system to be used.

12.1 For the method of calculating the tube size required to 15.3 Government ProcurementWhen specified in the con-

clean up machining to a particular finished part, see Appendix tract or order, and for direct procurement by or direct shipment

X1. to the government, marking for shipment, in addition to

requirements specified in the contract or order, shall be in

13. Coating accordance with MIL-STD-129 for Military agencies and in

13.1 Unless otherwise specified, the outside surface of the accordance with Fed. Std. No. 123 for civil agencies.

tubing shall be coated, before shipping, with a film of rust-

retarding oil. Unless otherwise specified, the inside surface of 16. Packaging

the tubing may also be coated with a film of rust-retarding oil

at the option of the manufacturer. When the order specifies that 16.1 Civilian ProcurementThe manufacturer, at his op-

the tubing be shipped without rust-retarding oil, the film of oils tion, will box, crate, carton, package in secured lifts, or bundle

incidental to manufacturing will remain on the surfaces. If the to ensure safe delivery. Special packaging requiring extra

order specifies no oil, the purchaser assumes responsibility for operations other than those normally used by the manufacturer

rust in transit. must be specified on the order.

16.2 Government ProcurementWhen specified in the con-

14. Rejection

tract or order, and for direct procurement by or direct shipment

14.1 Tubes that fail to meet the requirements of the speci- to the government when Level A is specified, preservation,

fication shall be set aside, and the manufacturer shall be packaging, and packing shall be in accordance with the Level

notified. A requirements of MIL-STD-163.

15. Product Marking

17. Keywords

15.1 Civilian ProcurementEach box, bundle, lift, or,

when individual pieces are shipped, each piece shall be 17.1 carbon steel tube; mechanical tubing; steel tube

SUPPLEMENTARY REQUIREMENTS

These requirements shall not be considered unless specified in the order, and the necessary tests

shall be made at the mill. Mechanical property tests shall be performed in accordance with applicable

portions of Test Methods and Definitions A370.

S1. Hardness and Tension TestsRound Tubing the purchase order. When Tensile Properties Required is

S1.1 When hardness is specified in the order, the tubing specified in the purchase order, the tubing shall conform to the

shall conform to the hardness limits specified in Table S1.1 or tension test requirements and not necessarily the hardness

Table S1.2, unless Tensile Properties Required is specified in limits shown in Table S1.1 or Table S1.2.

TABLE S1.1 Tensile and Hardness Requirements for Stress Relief Annealed Round Tubes

Tensile Strength, ksi (MPa) (0.2 % Offset) Elongation in Rockwell Hardness

Grade Yield Strength, 2 in. or 50 mm,

min max min, ksi (MPa) min, % min max

MT1010 63 (434) 100 (689) 58 (400) 15 B 70 B 90

1011 65 (448) 100 (689) 59 (407) 13 B70 B 100

MT1015 66 (555) 100 (689) 60 (414) 14 B 70 B 100

1016 67 (462) 100 (689) 61 (421) 13 B 70 B 100

MT1017 67 (462) 100 (689) 62 (427) 13 B 72 B 100

1018 68 (469) 100 (689) 62 (427) 13 B 73 B 100

MT1020 71 (490) 130 (896) 65 (448) 11 B 75 C 20

1025 72 (496) 130 (896) 67 (462) 11 B 78 C 20

1030 80 (552) 130 (896) 70 (483) 10 B 80 C 20

1110 63 (434) 100 (689) 58 (400) 15 B 70 B 100

1115 68 (469) 100 (689) 62 (427) 13 B 70 B 100

Copyright by ASTM Int'l (all rights reserved); 5

A512 06

TABLE S1.2 Tensile and Hardness Requirements for Soft outside diameter of the tube. Likewise, no cracks, other than

Annealed Round Tubes superficial surface ruptures, shall appear in the metal of the

Tensile Yield Strength, Elongation tube other than the weld metal until the distance between the

Strength, min, ksi in 2 in. Rockwell

Grade

min, ksi (MPa) or 50 mm, Hardness

flattening plates is less than three fifths of the outside diameter

(MPa) min, % of the tube.

MT1010 40 (276) 20 (138) 35 B 40 to B 65 S2.2 Number of Tests and Retests:

MT1015 43 (296) 25 (172) 34 B 40 min S2.2.1 One test per lot (Note S1.1).

MT1020 50 (345) 30 (207) 32 B 50 min

MT1025 55 (379) 35 (241) 32 B 55 min

S2.2.2 Two retests per lot (Note S1.1).

MT1030 65 (448) 40 (276) 30 B 60 min

S3. Flaring TestRound Tubing

S3.1 A tapered mandrel having a slope of 1 in 10 shall be

S1.2 Number of Tests and Retests: driven into one end of a soft-annealed section cut to a suitable

S1.2.1 HardnessOne percent of all tubes per lot (Note length and thus expanding the specimen until the outside

S1.1), diameter has been increased 5 %.

S1.2.2 Tension: S3.2 Number of Tests and Retests:

S1.2.2.1 One test per lot (Note S1.1). S3.2.1 One test per lot (Note S1.1).

S1.2.2.2 The yield strength corresponding to a permanent S3.2.2 Two retests per lot (Note S1.1).

offset of 0.2 % of the gauge length of the specimen or to a total

S4. Nondestructive Electrical TestRound Tubing

extension of 0.5 % of the gauge length under load shall be

determined. S4.1 The manufacturer shall test the tubing by an electrical

S1.2.3 If the results of the mechanical tests do not conform method of nondestructive test for detection of harmful faults

to the requirements shown in Table S1.1 and Table S1.2, retests and soundness of weld. The equipment used shall be capable of

shall be made on additional tubes double the original number, indicating and rejecting all defects on the outside diameter or

each of which shall conform to the specified requirements. inside diameter greater than 116 in. (1.6 mm) in length and to

a depth greater than approximately one fourth the wall thick-

NOTE S1.1A lot shall consist of all tubes, before cutting to length, of ness.

the same size and wall thickness which are produced from the same heat

of steel and, when heat treated, subjected to the same finishing treatment S5. Certification for Government Orders

in a continuous furnace. When final heat treatment is in a batch-type

furnace, the lot shall include only those tubes which are heat treated in the S5.1 A producers or suppliers certification shall be fur-

same furnace charge. nished to the Government that the material was manufactured,

sampled, tested, and inspected in accordance with this speci-

S2. Flattening TestSoft-Annealed Round Tubing fication and has been found to meet the requirements. This

S2.1 The weld shall be located 45 from the line of the certificate shall include a report of heat analysis (product

direction of applied force. No cracks other than superficial analysis when requested in the purchase order), and, when

surface ruptures shall appear in the weld until the distance specified in the purchase order or contract, a report of test

between the flattening plates is less than three fourths of the results shall be furnished.

APPENDIX

(Nonmandatory Information)

X1. MACHINING ALLOWANCES

X1.1 The minimum diameter stock allowance for removal TABLE X1.1 Machining AllowancesA

of imperfections by machining from the outside of the tube NOTE1 in. = 25.4 mm.

when chucked concentrically on the tube outside diameter is Wall Thickness, in.

given in Table X1.1. Diameter, in.

Up to 0.200 0.200 and Over

X1.2 Boring Mandrel Drawn TubingWhen chucked con- Sink Drawn:

centrically with the outside diameter, mandrel drawn tubing Up to 112 0.025 0.030

112 and over 0.030 0.035

will clean up concentrically with the outside diameter on a Mandrel Drawn:

boring operation at a size derived from the following equation: Up to 112 0.020 0.025

112 and over 0.025 0.030

Ordered inside diameter = finished inside diameter

A

(0.075 in. (1.90 mm) 3 original outside If a specific size is desired, these allowances plus normal size tolerances must

diameter amount shown in Table X1.1). be considered in calculating the size to be ordered.

Copyright by ASTM Int'l (all rights reserved); 6

A512 06

X1.2.1 To this equation, add 0.005 in. (0.13 mm) when the over 1 12 in. These equations apply to tubes chucked within 2

original outside diameter does not exceed 1 12 in. (38.1 mm); in. (50.8 mm) of the end being bored.

add 0.010 in. (0.25 mm) when the original outside diameter is

SUMMARY OF CHANGES

Committee A01 has identified the location of selected changes to this specification since the last issue,

A512 96(2005), that may impact the use of this specification. (Approved October 1, 2006)

(1) Revised Table 2 to agree with composition requirements

contained in Specification A1040.

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright by ASTM Int'l (all rights reserved); 7

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Astm A 501-07Documento8 pagineAstm A 501-07Sasi KumarNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Is 6913Documento11 pagineIs 6913Sasi KumarNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- 16041143Documento23 pagine16041143Sasi KumarNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- En13445-2 V35Documento90 pagineEn13445-2 V35Kostas Menagias100% (2)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- EVRAZ Catalog ENG 2013 PDFDocumento114 pagineEVRAZ Catalog ENG 2013 PDFSasi KumarNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Plane Strain Fracture Toughness (Kic) Data Handbook For MetalsDocumento92 paginePlane Strain Fracture Toughness (Kic) Data Handbook For MetalssurawutwijarnNessuna valutazione finora

- LR Tata Steel Plates BrochureDocumento8 pagineLR Tata Steel Plates BrochureAGNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- HSS Dimensions Section Properties PDFDocumento28 pagineHSS Dimensions Section Properties PDFErland Ramírez SalazarNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- AIL Structures PDFDocumento12 pagineAIL Structures PDFSuresh DevarajanNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- JRC72702 - Choice of Material For Hollow Section Structures - 2016edDocumento202 pagineJRC72702 - Choice of Material For Hollow Section Structures - 2016edSasi KumarNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Bars, Rods & Rebars PDFDocumento10 pagineBars, Rods & Rebars PDFSasi KumarNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- A512 06Documento7 pagineA512 06Sasi KumarNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- A 304 - 04Documento50 pagineA 304 - 04Sasi KumarNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- ASTM-A108-07 Standard Specification For Steel Bar Carbon and Alloy Cold-Finished1 PDFDocumento7 pagineASTM-A108-07 Standard Specification For Steel Bar Carbon and Alloy Cold-Finished1 PDFCarlos Sanchez MarinNessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- A600Documento2 pagineA600Sasi KumarNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Man 009 139Documento1 paginaMan 009 139Sasi KumarNessuna valutazione finora

- General 04 Fixed Flow Pump To Three TanksDocumento13 pagineGeneral 04 Fixed Flow Pump To Three TanksjpalauguillemNessuna valutazione finora

- Excel Dynamic Arrays: Department Item Quantity Price Total $Documento5 pagineExcel Dynamic Arrays: Department Item Quantity Price Total $Bilal Hussein SousNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- VSD Operacion ControlDocumento138 pagineVSD Operacion ControlLeon PerezNessuna valutazione finora

- Bill of Material: The Hanover CompanyDocumento17 pagineBill of Material: The Hanover CompanyLIVIANessuna valutazione finora

- 000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Documento22 pagine000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Raul Bautista100% (1)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 3RP15 05-1aDocumento3 pagine3RP15 05-1atycristinaNessuna valutazione finora

- M.E. Comm. SystemsDocumento105 pagineM.E. Comm. SystemsShobana SNessuna valutazione finora

- Reliability EngineeringDocumento9 pagineReliability Engineeringnvaradharajan1971Nessuna valutazione finora

- Stereochemistry Practce PDFDocumento6 pagineStereochemistry Practce PDFFerminNessuna valutazione finora

- SIEMENS-7SA522 Setting CalculationDocumento20 pagineSIEMENS-7SA522 Setting Calculationnaran19794735Nessuna valutazione finora

- Velocity profiles and incompressible flow field equationsDocumento2 pagineVelocity profiles and incompressible flow field equationsAbdul ArifNessuna valutazione finora

- Analisis Pengaruh Profitabilitas, Strategi Diversifikasi, Dan Good Corporate Governance Terhadap Nilai PerusahaanDocumento16 pagineAnalisis Pengaruh Profitabilitas, Strategi Diversifikasi, Dan Good Corporate Governance Terhadap Nilai PerusahaanEra ZsannabelaNessuna valutazione finora

- Rodi TestSystem EZSDI1 Iom D603Documento25 pagineRodi TestSystem EZSDI1 Iom D603Ricardo AndradeNessuna valutazione finora

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- BetaDocumento16 pagineBetaAkshita Saxena100% (2)

- A Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingDocumento10 pagineA Design and Analysis of A Morphing Hyper-Elliptic Cambered Span (HECS) WingJEORJENessuna valutazione finora

- Superalloy Brochure PDFDocumento16 pagineSuperalloy Brochure PDFDaren NeradNessuna valutazione finora

- MleplustutorialDocumento13 pagineMleplustutorialvorge daoNessuna valutazione finora

- Training Matrix For TM IDocumento14 pagineTraining Matrix For TM IApril NavaretteNessuna valutazione finora

- Measurements/ Specifications: Torque Wrench Selection GuideDocumento5 pagineMeasurements/ Specifications: Torque Wrench Selection GuideSylvester RakgateNessuna valutazione finora

- Records of Intervention On The Findings of Test Results and Other Forms of AssessmentDocumento10 pagineRecords of Intervention On The Findings of Test Results and Other Forms of AssessmentLea May MagnoNessuna valutazione finora

- PDS OperatorStationDocumento7 paginePDS OperatorStationMisael Castillo CamachoNessuna valutazione finora

- EET422 EMC Intro-Banana Skins 2011-2012 MSWDocumento6 pagineEET422 EMC Intro-Banana Skins 2011-2012 MSWVeeradasan PerumalNessuna valutazione finora

- Valve Actuator Data SheetDocumento1 paginaValve Actuator Data SheetRob StorrowNessuna valutazione finora

- HowTo Work With CR 90Documento87 pagineHowTo Work With CR 90WagBezerraNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 04.protection of 33KV Feeder.Documento16 pagine04.protection of 33KV Feeder.gnpr_10106080Nessuna valutazione finora

- Time TableDocumento7 pagineTime TableChethan .H.GNessuna valutazione finora

- Proper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFDocumento12 pagineProper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFAnonymous bHh1L1Nessuna valutazione finora

- Eltek PSR 327Documento2 pagineEltek PSR 327fan liuNessuna valutazione finora

- Tutorial CorelDRAW-X8Documento10 pagineTutorial CorelDRAW-X8Ajay BhargavaNessuna valutazione finora

- Lecture 1: Encoding Language: LING 1330/2330: Introduction To Computational Linguistics Na-Rae HanDocumento18 pagineLecture 1: Encoding Language: LING 1330/2330: Introduction To Computational Linguistics Na-Rae HanLaura AmwayiNessuna valutazione finora