Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

612 en Sureseal Epdm Tds

Caricato da

Mohamed Ismail ShehabCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

612 en Sureseal Epdm Tds

Caricato da

Mohamed Ismail ShehabCopyright:

Formati disponibili

SCIENCE. SERVICE. SOLUTIONS.

WATERPROOFING

Sure-Seal Standard & FR EPDM Membranes

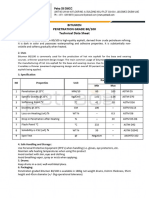

Description Typical Properties

Sure-Seal 45-mil (1.14 mm), 60-mil (1.52 mm) and 90-mil (2.29 mm) Spec.

membranes are Ethylene Propylene Diene Terpolymer (EPDM)-based Property Method Typical

(Pass)

elastomeric homogenous roof coverings that can be used for a variety of Tolerance on Nominal

ASTM D412 10 10

waterproofing applications. Membranes are available in widths up to 10' Thickness, %

(3 m) and lengths up to 100' (30 m). These membranes are available as Weight, 1bm/ft 2 (kg/m2)

Fire Retardant (FR) membranes, which are specially formulated to inhibit 45-mil 0.26 (1.27)

60-mil 0.35 (1.71)

spread of flame and meet or exceed code body testing criteria for fire 90-mil 0.59 (2.88)

retardant roofing membranes.

Tensile Strength, min, psi (Mpa) ASTM D412 1305 (9) 1600 (11.0)

Elongation, Ultimate, min % ASTM D412 300 465

Installation

Tear Strength, min, ASTM D624 200

150 (26.3)

Sure-Seal 45-, 60- and 90-mil membranes are primarily utilized in lbf/in (kN/m) (Die C) (35.0)

Design A, Fully Adhered Roofing System/Waterproofing Systems. The Modified Mebrane Membrane

Factory Seam Strength, min

substrate and membrane are coated with Carlisle Bonding Adhesive. ASTM D816 Rupture Rupture

The membrane is then rolled into place and broomed down. SecurTAPE Resistance to Heat Aging*

and HP-250 Primer are applied to the splice area. As an alternate, Properties after 28 days @ 240F (116C) ASTM D573 1205 1450

Splicing Cement, In-Seam and Lap Sealant may be used for splicing. Tensile Strength, min, psi (MPa) ASTM D412 (8.3) (10.0)

Consult CCW specifications for complete installation information. Elongation, Ultimate, min, % ASTM D412 200 280

Tear Strength, min, lbf/in (kN/m) ASTM D624 125 (21.9) 215 (37.6)

Linear Dimensional Change, max, % ASTM D1204 1.0 -0.5

Warnings and Hazards Ozone Resistance*

Use proper stacking procedures to ensure sufficient stability of

Condition after exposure to 100 pphm ASTM D1149 No Cracks No Cracks

the materials. Ozone in air for 168 hours @ 104F

(40C) Specimen is at 50% strain

Exercise caution when walking on wet membrane. Membranes are

Brittleness Temp., max, F (C)* ASTM D746 -49 (-45) -49 (-45)

slippery when wet.

Resistance to Water Absorption*

After 7 days immersion @ 158F (70C) ASTM D471 +8, -2 +2.0

Limited Warranty Change in mass, max, %

Carlisle Coatings & Waterproofing Incorporated (Carlisle) warrants this product ASTM E96

to be free of defects in workmanship and materials only at the time of shipment Water Vapor Permeance* max, perms (Proc. B 0.10 0.03

from our factory. If any Carlisle materials prove to contain manufacturing defects or BW)

that substantially affect their performance, Carlisle will, at its option, replace the Resistance to Outdoor (Ultraviolet) No Cracks No Cracks

materials or refund its purchase price. This limited warranty is the only warranty Weathering* Xenon-Arc, total radiant No Crazing No Crazing

ASTM G155

extended by Carlisle with respect to its materials. There are no other warranties, exposure at 0.70 W/m irradiance, 80C 7,560 41,580

including the implied warranties of merchantability and fi tness for a particular black panel temp. kJ/m kJ/ m

purpose. Carlisle specifi cally disclaims liability for any incidental, consequential, or

other damages, including but not limited to, loss of profi ts or damages to a structure *Not a Quality Control Test due to the time required for the test or the complexity of

the test. However, all tests are run on a statistical basis to ensure overall long-term

or its contents, arising under any theory of law whatsoever. The dollar value of performance of the sheeting.

Carlisles liability and buyers remedy under this limited warranty shall not exceed

the purchase price of the Carlisle material in question.

Carlisle Coatings & Waterproofing

900 Hensley Lane | Wylie, TX 75098 | 800.527.7092 | www.carlisleccw.com

10.27.16 2016 Carlisle. Carlisle, Sure-Seal and SecurTAPE are trademarks of Carlisle.

REPRINT CODE: 601548 -Sure-Seal Standard & FR EPDM Membranes Technical Data Sheet

Potrebbero piacerti anche

- Self-healing Ceramic Matrix Composites: A MonographDa EverandSelf-healing Ceramic Matrix Composites: A MonographNessuna valutazione finora

- Geotextiles and Geomembranes HandbookDa EverandGeotextiles and Geomembranes HandbookT.S. IngoldValutazione: 5 su 5 stelle5/5 (1)

- PB Elastoseal Tanking ENGDocumento5 paginePB Elastoseal Tanking ENGdan ivan100% (1)

- Polygomma EPDM Roofing Membrane CatalogueDocumento4 paginePolygomma EPDM Roofing Membrane Cataloguepolygomma Industries Pvt. LtdNessuna valutazione finora

- DTM Bonding Primer: Protective & Marine CoatingsDocumento4 pagineDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNessuna valutazione finora

- Basf Masterseal m200 TdsDocumento2 pagineBasf Masterseal m200 Tdsangelito bernalNessuna valutazione finora

- Data Sheet - Polyfelt® Alidrain AD530 (300 604-td-10-18) PDFDocumento1 paginaData Sheet - Polyfelt® Alidrain AD530 (300 604-td-10-18) PDFErnie ErnieNessuna valutazione finora

- Um180821 TDS Tpu 95a RB V11Documento3 pagineUm180821 TDS Tpu 95a RB V11Steven DonosoNessuna valutazione finora

- Basf Masterseal m200 TdsDocumento2 pagineBasf Masterseal m200 Tdsjuli_radNessuna valutazione finora

- Polyken 930: Product Data SheetDocumento2 paginePolyken 930: Product Data SheetEdwin Bustamante Cabrera100% (1)

- Polyken 930: Product Data SheetDocumento2 paginePolyken 930: Product Data SheetAgustina De Winne100% (1)

- Polygomma EPDM Pond Liner BrochureDocumento4 paginePolygomma EPDM Pond Liner Brochurepolygomma Industries Pvt. LtdNessuna valutazione finora

- Nitoproof 600: Constructive SolutionsDocumento22 pagineNitoproof 600: Constructive SolutionsMazen AlRefaaiNessuna valutazione finora

- Techdrain Gtg27.6: Drainage GeocompositeDocumento1 paginaTechdrain Gtg27.6: Drainage GeocompositeJORGE LUIS GAMARRA MIRANDANessuna valutazione finora

- Estane Skythane S190A TPU: TypeDocumento2 pagineEstane Skythane S190A TPU: Typejuliushasan2Nessuna valutazione finora

- Adding A New Dimension To Impact Resistant Glazing and CladdingDocumento1 paginaAdding A New Dimension To Impact Resistant Glazing and CladdingOmer TahaNessuna valutazione finora

- Bitumastic 300 M PDSDocumento2 pagineBitumastic 300 M PDSrekstromNessuna valutazione finora

- JUNE2020 Transparent Noise Barrier Technical Datasheet Final ReducedDocumento2 pagineJUNE2020 Transparent Noise Barrier Technical Datasheet Final Reducedionut cerneaNessuna valutazione finora

- Data Sheet - Polyfelt® Alidrain AD130 (300 603-td-10-18) PDFDocumento1 paginaData Sheet - Polyfelt® Alidrain AD130 (300 603-td-10-18) PDFErnie ErnieNessuna valutazione finora

- Polycarbonate Data SheetDocumento1 paginaPolycarbonate Data SheetJoseph Cloyd Lamberte100% (1)

- Protective & Marine Coatings: DTM Acrylic Primer/FinishDocumento4 pagineProtective & Marine Coatings: DTM Acrylic Primer/FinishAna CabreraNessuna valutazione finora

- PF7000Aliphatic PolyurethaneDocumento2 paginePF7000Aliphatic PolyurethaneLuis ArciaNessuna valutazione finora

- Elastoseal EPDM Tanking SystemDocumento8 pagineElastoseal EPDM Tanking SystemStephen100% (1)

- Heat Shrink Bus Bar Tube: GMB / GHB Series Tubes GSC Series TubesDocumento2 pagineHeat Shrink Bus Bar Tube: GMB / GHB Series Tubes GSC Series TubesCarlos Berrospi ChacaNessuna valutazione finora

- Technical Brief Galal Make SleevesDocumento1 paginaTechnical Brief Galal Make SleevesSELVAGANAPATHINessuna valutazione finora

- Scotch Heavy Duty Mining Tape 31: Data Sheet June 2013Documento2 pagineScotch Heavy Duty Mining Tape 31: Data Sheet June 2013Kishan MohtaNessuna valutazione finora

- DTM Acrylic Coating: Protective & Marine CoatingsDocumento4 pagineDTM Acrylic Coating: Protective & Marine CoatingsAna CabreraNessuna valutazione finora

- DTM Acrylic Pimer Finish B66W1Documento4 pagineDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNessuna valutazione finora

- Imperseal 7000Xl: Salient FeaturesDocumento2 pagineImperseal 7000Xl: Salient FeaturesJeff GajeNessuna valutazione finora

- Global Synthetics Proliner HDPE Smooth DatasheetDocumento1 paginaGlobal Synthetics Proliner HDPE Smooth DatasheetMatt GhanaviNessuna valutazione finora

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsDocumento2 paginePC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D Production SystemsvassaNessuna valutazione finora

- TDS-GEOPROTEC-GS3000S-22-01 Rev.01Documento1 paginaTDS-GEOPROTEC-GS3000S-22-01 Rev.01AMINNessuna valutazione finora

- 2017716154112bitumen 6070Documento1 pagina2017716154112bitumen 6070lab copriNessuna valutazione finora

- HT 800 Medium Cellular SiliconeDocumento2 pagineHT 800 Medium Cellular SiliconeDarwinPowChonLongNessuna valutazione finora

- Tech Data - PF Alidrain AD230 - 250Documento1 paginaTech Data - PF Alidrain AD230 - 250BinSayeed100% (1)

- Klingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingDocumento2 pagineKlingersil: Klingersil C-4400 - Leading Soft Gasket Material For Safe and Reliable SealingSamir ChaudharyNessuna valutazione finora

- Premier Coatings Premtape TropicalDocumento2 paginePremier Coatings Premtape TropicalIm ChinithNessuna valutazione finora

- 9765 Rubber Hydraulic Seals and WaterstopsDocumento20 pagine9765 Rubber Hydraulic Seals and WaterstopsStephenNessuna valutazione finora

- Ninjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrintersDocumento1 paginaNinjaflex 3D Printing Filament: Flexible Polyurethane Material For FDM PrinterssrikanthNessuna valutazione finora

- Wear Plate BrochureDocumento2 pagineWear Plate Brochurec3512Nessuna valutazione finora

- Bitumen 80 100Documento1 paginaBitumen 80 100latexNessuna valutazione finora

- Cx3 9 Film Fact SheetDocumento2 pagineCx3 9 Film Fact SheetCampaign MediaNessuna valutazione finora

- PolyflameDocumento2 paginePolyflameumn_mlkNessuna valutazione finora

- Estane Skythane S185A TPU: TypeDocumento1 paginaEstane Skythane S185A TPU: Typejuliushasan2Nessuna valutazione finora

- Premcote 101 DatasheetDocumento1 paginaPremcote 101 DatasheetHuythuong NguyenNessuna valutazione finora

- Denso TapeDocumento2 pagineDenso TapeagusjuliNessuna valutazione finora

- 3m VHB Tape 5958frDocumento9 pagine3m VHB Tape 5958frDonald A HuntNessuna valutazione finora

- Tikidan TDS - Selfdan Ipe Plus, R3Documento3 pagineTikidan TDS - Selfdan Ipe Plus, R3sandeepNessuna valutazione finora

- FEP & PFA Welding Grade Films: F E F W H SDocumento2 pagineFEP & PFA Welding Grade Films: F E F W H SmansurudinNessuna valutazione finora

- Proofex SMDocumento4 pagineProofex SMSantosh SharmaNessuna valutazione finora

- Polyflame Garden - I & IIDocumento2 paginePolyflame Garden - I & IIAbdul Jaleel MohammedNessuna valutazione finora

- Lldpe - LL7410D PDSDocumento1 paginaLldpe - LL7410D PDSchinchotarngNessuna valutazione finora

- Microstructure Evolution in Metal Forming Processes (2012)Documento2 pagineMicrostructure Evolution in Metal Forming Processes (2012)MedSparkNessuna valutazione finora

- Ajedium Films (Solvay)Documento3 pagineAjedium Films (Solvay)hyper meshNessuna valutazione finora

- Armadillo TDSDocumento1 paginaArmadillo TDSPIETRO DAVID DE LUCANessuna valutazione finora

- Poly FlameDocumento2 paginePoly Flamemk779900mkNessuna valutazione finora

- Lldpe 20100326-165732-Tds-02-Uf1810t-1Documento1 paginaLldpe 20100326-165732-Tds-02-Uf1810t-1Addison FregilNessuna valutazione finora

- PC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrintersDocumento2 paginePC (Polycarbonate) : Production-Grade Thermoplastic For Fortus 3D PrinterskaledioskoppNessuna valutazione finora

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocumento3 pagineControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINessuna valutazione finora

- Rooftex SpecificationDocumento3 pagineRooftex SpecificationTRAG ProjectsNessuna valutazione finora

- Conventional and High-Strength Steel Hooked Bars: Detailing EffectsDocumento61 pagineConventional and High-Strength Steel Hooked Bars: Detailing EffectsMohamed Ismail ShehabNessuna valutazione finora

- Recommendations by The Ultrasonic For Testing Concrete Pulse MethodDocumento10 pagineRecommendations by The Ultrasonic For Testing Concrete Pulse MethodMohamed Ismail ShehabNessuna valutazione finora

- JETIR1904P47Documento6 pagineJETIR1904P47Mohamed Ismail ShehabNessuna valutazione finora

- Use of Rules of ThumbDocumento8 pagineUse of Rules of ThumbMohamed Ismail ShehabNessuna valutazione finora

- ArticleTextPDF 35725 1 10 20180406Documento15 pagineArticleTextPDF 35725 1 10 20180406Mohamed Ismail ShehabNessuna valutazione finora

- Slip Forming: The New Era of Formwork of Unusual Structure: March 2014Documento10 pagineSlip Forming: The New Era of Formwork of Unusual Structure: March 2014Mohamed Ismail ShehabNessuna valutazione finora

- Evaluation of Epoxy Injection Method For Concrete Crack RepairDocumento7 pagineEvaluation of Epoxy Injection Method For Concrete Crack RepairMohamed Ismail ShehabNessuna valutazione finora

- Silo - Tips - Voith Hydro Hydro Power Plants DR Jiri KoutnikDocumento33 pagineSilo - Tips - Voith Hydro Hydro Power Plants DR Jiri KoutnikMohamed Ismail ShehabNessuna valutazione finora

- Ultrasonic Wave Velocity Measurement in Concrete Using The Impact-Echo MethodDocumento6 pagineUltrasonic Wave Velocity Measurement in Concrete Using The Impact-Echo MethodMohamed Ismail ShehabNessuna valutazione finora

- Seismic Design Parameters For Large Dams - Icold Method: August 2010Documento9 pagineSeismic Design Parameters For Large Dams - Icold Method: August 2010Mohamed Ismail ShehabNessuna valutazione finora

- StyrofillGeofoam - EPS12Documento7 pagineStyrofillGeofoam - EPS12Mohamed Ismail ShehabNessuna valutazione finora

- 503.7-07 Specification for Crack Repair by Epoxy Injection-مفتوحDocumento11 pagine503.7-07 Specification for Crack Repair by Epoxy Injection-مفتوحMohamed Ismail ShehabNessuna valutazione finora

- Sikadur®-52 Injection Normal: Product Data SheetDocumento4 pagineSikadur®-52 Injection Normal: Product Data SheetMohamed Ismail ShehabNessuna valutazione finora

- Dispersive Clay Stabilised by Alum and LimeDocumento9 pagineDispersive Clay Stabilised by Alum and LimeMohamed Ismail ShehabNessuna valutazione finora

- AG SL: Installation, Operation and Maintenance Manual Stop Gate Stop LogDocumento15 pagineAG SL: Installation, Operation and Maintenance Manual Stop Gate Stop LogMohamed Ismail ShehabNessuna valutazione finora

- Minimum Steel Reinforcement For Control of Cracking Due To Shrinkage and Temperature Changes in Reinforced Concrete Tension MembersDocumento15 pagineMinimum Steel Reinforcement For Control of Cracking Due To Shrinkage and Temperature Changes in Reinforced Concrete Tension MembersMohamed Ismail ShehabNessuna valutazione finora

- Geofaom Supplier - StyrofillGeofoam - Geofoam Manufacture and SupplierDocumento11 pagineGeofaom Supplier - StyrofillGeofoam - Geofoam Manufacture and SupplierMohamed Ismail ShehabNessuna valutazione finora

- Instrumentation and Structural Monitoring of Dams 2018Documento16 pagineInstrumentation and Structural Monitoring of Dams 2018Mohamed Ismail ShehabNessuna valutazione finora

- Characterization of Dispersive Soils: T. S. Umesh, S. V. Dinesh, Puvvadi V. SivapullaiahDocumento5 pagineCharacterization of Dispersive Soils: T. S. Umesh, S. V. Dinesh, Puvvadi V. SivapullaiahMohamed Ismail ShehabNessuna valutazione finora

- Water 11 01499Documento16 pagineWater 11 01499Mohamed Ismail ShehabNessuna valutazione finora

- Mass Concrete Thermal Control Case Study: I-80 Over The Missouri River Bridge ConstructionDocumento34 pagineMass Concrete Thermal Control Case Study: I-80 Over The Missouri River Bridge ConstructionMohamed Ismail ShehabNessuna valutazione finora

- Cutting Stock Waste Reduction Using Genetic Algorithms: January 2006Documento7 pagineCutting Stock Waste Reduction Using Genetic Algorithms: January 2006Mohamed Ismail ShehabNessuna valutazione finora

- Estimation of The Grout Take Using Empirical Relationships (Case Study: Bakhtiari Dam Site)Documento14 pagineEstimation of The Grout Take Using Empirical Relationships (Case Study: Bakhtiari Dam Site)Mohamed Ismail ShehabNessuna valutazione finora

- Still e 2012Documento22 pagineStill e 2012Mohamed Ismail ShehabNessuna valutazione finora

- Silo - Tips - Kssler Turns Water Into Power A Voith and Siemens Company PPT Anleitung Uwe GobbersDocumento22 pagineSilo - Tips - Kssler Turns Water Into Power A Voith and Siemens Company PPT Anleitung Uwe GobbersMohamed Ismail ShehabNessuna valutazione finora

- L5CoachMentorReflectiveLog TemplateDocumento9 pagineL5CoachMentorReflectiveLog TemplateHadusssNessuna valutazione finora

- Vernacular in Andhra PradeshDocumento1 paginaVernacular in Andhra PradeshNandyala Rajarajeswari DeviNessuna valutazione finora

- Problems 1Documento2 pagineProblems 1Andoy Don M.Nessuna valutazione finora

- Chapter 5 Assessment, Solution Manual, Electrons in Atoms, Glencoe, ChemistryDocumento9 pagineChapter 5 Assessment, Solution Manual, Electrons in Atoms, Glencoe, Chemistrypumeananda100% (3)

- Strain GaugeDocumento7 pagineStrain GaugefahadarizkiNessuna valutazione finora

- Risk LogDocumento1 paginaRisk LogOzu HedwigNessuna valutazione finora

- DOPE Personality TestDocumento8 pagineDOPE Personality TestMohammed Hisham100% (1)

- M 02 0001Documento3 pagineM 02 0001Miguel ruizNessuna valutazione finora

- DPL MDDocumento3 pagineDPL MDCoy IngramNessuna valutazione finora

- Civil & Structural Designer'S Data Pack: Section 7: MasonryDocumento5 pagineCivil & Structural Designer'S Data Pack: Section 7: MasonryMirea Florentin0% (1)

- Assignment ProblemsDocumento22 pagineAssignment ProblemsPooja Yadav100% (1)

- SIP Project ProposalDocumento2 pagineSIP Project ProposalDeep SutariaNessuna valutazione finora

- Project Scheduling: Marinella A. LosaDocumento12 pagineProject Scheduling: Marinella A. LosaMarinella LosaNessuna valutazione finora

- Cutting Aws C5.3 2000 R2011Documento33 pagineCutting Aws C5.3 2000 R2011Serkan AkşanlıNessuna valutazione finora

- Nguyen Ngoc-Phu's ResumeDocumento2 pagineNguyen Ngoc-Phu's ResumeNgoc Phu NguyenNessuna valutazione finora

- Human Resource Development Multiple Choice Question (GuruKpo)Documento4 pagineHuman Resource Development Multiple Choice Question (GuruKpo)GuruKPO90% (20)

- Labnet MultiGene Manual PDFDocumento42 pagineLabnet MultiGene Manual PDFcuma mencobaNessuna valutazione finora

- Briefing Evaluation: Yes / No High / Low Yes / No High / Low Good / Inferior Yes / NoDocumento4 pagineBriefing Evaluation: Yes / No High / Low Yes / No High / Low Good / Inferior Yes / NoAmmarah AzharNessuna valutazione finora

- Project TitleDocumento2 pagineProject TitleVISHAL S. VNessuna valutazione finora

- IUK Routemap - GovernanceDocumento27 pagineIUK Routemap - GovernanceTom RedwayNessuna valutazione finora

- A.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskDocumento28 pagineA.O: Against Order: Desktop Hard Disk Laptop Hard Disk Scsi Hard Disk Adaptec Cards External Hard DiskArul brittoNessuna valutazione finora

- Class 12 Physics Mcqs Chapter: 6 Electromagnetic Induction: AnswerDocumento12 pagineClass 12 Physics Mcqs Chapter: 6 Electromagnetic Induction: AnswerDiksha TNessuna valutazione finora

- Data Structures and Algorithms AssignmentDocumento25 pagineData Structures and Algorithms Assignmentعلی احمد100% (1)

- BUCA IMSEF 2021 Jury Evaluation ScheduleDocumento7 pagineBUCA IMSEF 2021 Jury Evaluation SchedulePaulina Arti WilujengNessuna valutazione finora

- States of Matter LessonDocumento4 pagineStates of Matter Lessonapi-280793165Nessuna valutazione finora

- Guide For H Nmr-60 MHZ Anasazi Analysis: Preparation of SampleDocumento7 pagineGuide For H Nmr-60 MHZ Anasazi Analysis: Preparation of Sampleconker4Nessuna valutazione finora

- Iphone 14 Pro Max Inspired Preset by Rey Dhen - XMPDocumento3 pagineIphone 14 Pro Max Inspired Preset by Rey Dhen - XMPRizkia Raisa SafitriNessuna valutazione finora

- Simulation of Inventory System PDFDocumento18 pagineSimulation of Inventory System PDFhmsohagNessuna valutazione finora

- THDP-3 Worm Gear Manual Interchangeable Single Punch Tablet PressDocumento8 pagineTHDP-3 Worm Gear Manual Interchangeable Single Punch Tablet Pressdibimrane13Nessuna valutazione finora

- DESBLOQUEADO Synesis Erik Hollnagel 2022Documento81 pagineDESBLOQUEADO Synesis Erik Hollnagel 2022Tribu de SSONessuna valutazione finora