Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pile Cost Analysis

Caricato da

Syed Adnan AqibDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pile Cost Analysis

Caricato da

Syed Adnan AqibCopyright:

Formati disponibili

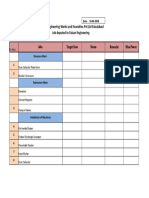

PILE COST ANALYSIS

(Cost in Pak Rupees)

600MM DIA PILE

Length of Pile 13.5 meter

Average length of pile doweled with pile cap 1.00 meter

(This length contains concrete and is

knocked off after casting of pile and

1 meter steel is embedded in pile cap.

Total length of Pile 14.5 meter

Bore Stability:

Using Bentonite Slurry to stabilize the bore walls

Max. Cement Contents:

400 kg/cu.m Ordinary Portland Cement (OPC)

Steel Per Pile:

540 kg/rm, average steel per pile (ASTM A615)

COST OF PILE

Installation of Pile including boring, Rs.4920/-rm

steel placing and concrete as per 4920 x 13.5 Rs.66420/-

specifications.

Avg. Steel in pile including main bars, 40 kg/ rm

reinforcement laps, spiral rings and 40 x 13.5

holding rings etc. = 0.540 ton / pile

0.540 x 120300 Rs.64962/-

TOTAL COST OF A PILE 600MM DIA

Rs.131382/

-

Note: Cost of concrete & steel of 1 meter had been

deducted from M/s Rocky Construction Company Bill.

PILE COST ANALYSIS

(Cost in Pak Rupees)

450MM DIA PILE

Length of Pile 13.5 meter

Average length of pile doweled with pile cap 1.00 meter

(This length contains concrete and is

knocked off after casting of pile and

1 meter steel is embedded in pile cap.

Total length of Pile 14.5 meter

Bore Stability:

Using Bentonite Slurry to stabilize the bore walls

Max. Cement Contents:

400 kg/cu.m Ordinary Portland Cement (OPC)

Steel Per Pile:

390 kg/rm, average steel per pile (ASTM A615)

COST OF PILE

Installation of Pile including boring, Rs.3700/-rm

steel placing and concrete as per 3700 x 13.5 Rs.49950/-

specifications.

Avg. Steel in pile including main bars, 29 kg/ rm

reinforcement laps, spiral rings and 29 x 13.5

holding rings etc. = 0.391 kg / pile

0.391 x 120300 Rs.47037/-

TOTAL COST OF A PILE 450MM DIA Rs.96987/-

Note: Cost of concrete & steel of 1 meter had been

deducted from M/s Rocky Construction Company Bill.

BRIEFING REGARDING WORK

1. ADMINISTRATION BLOCK (G)

1.1 EARTH WORK

The area had been excavated as per drawings, but during excavation it was observed

that surrounding soil was very weak, so immediate precautionary measures taken to

prevent the edges stable to minimize the collapse hazard. Moreover, during

excavation up to 3 meter depth, it was found that the underlying stratum was very

loose and slushy. In view of existing condition and firm strata, further dug and refilled

with the dry material and compaction was carried out to avoid the hazards of collapsing

the superstructure and minimize the risk of human safety aspect.

1.2 BASEMENT

After excavation, it was found that the floor level of Admin Block was about 3 meter

higher from its foundation and huge backfill is required, Mr. Chairman recommended

for the addition of basement in the structure.

1.3 PLASTER WORK

According to BOQ, total quantity of plaster work is 6995SM and according to the Rocky

bills, its 7646SM. According to BOQ, there is difference of plaster thickness in different

areas. Rocky put same plaster all over the structure and this had been done upon

special recommendation of Project Manager keeping in view the climatic conditions

and quality of local water.

1.4 FINISHING ITEMS

Finishing items like marble, tiles, painting, doors, fixtures and plumbing are

recommended by Chairman and so as installed for quality & durability purpose.

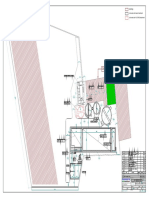

2. MAIN PLANT BUILDING (A)

2.1 EARTH WORK

(a) Originally the land area was water logged and filled up with borrowed

soil to make the place workable.

(b) During the piling works, borings were done in the soft soil with reverse

rotary and mud ponds were established.

(c) Due to large number of piles, most of the main plant building area and

surroundings used for mud ponds up to 2 to 2 meter depth. As the mud

pond contains large quantity of bentonite (clay), silty clay and moisture

which made soil very slushy, so the Project Manager took immediate

action to remove the slush and filled up with the dry soil to make the area

clear from hazards to the human & structures in respect of safety

aspects.

3. CONCRETE PAVEMENT & WALKWAYS (P)

3.1 EARTH WORK

(a) All the Road network was dug up to 1-meter depth because of loose

stratum as per directions of PCL (Consultant).

(b) It was filled and compacted layer wise (150MM) as per AASHTO

standards up to original level of subgrade.

(c) Due to large number of piles, most of the main plant building area and

surroundings used for mud ponds up to 2 to 2 meter depth. As the mud

pond contains large quantity of bentonite (clay), silty clay and moisture

which made soil very slushy, so the Project Manager took immediate

action to remove the slush and filled up with the dry soil to eliminate the

chances of risk for human lives and property.

Potrebbero piacerti anche

- Weekly Progress Pembangunan Jembatan HD 785 SMO Week 31Documento28 pagineWeekly Progress Pembangunan Jembatan HD 785 SMO Week 31kalkulaNessuna valutazione finora

- On Partial Replacement of Sand and AggregateDocumento19 pagineOn Partial Replacement of Sand and Aggregatemohammedzeeshan0% (2)

- 99 StratergyDocumento16 pagine99 StratergyChouhan Akshay SinghNessuna valutazione finora

- Pile Work Presentation at IITK Summer Camp 08Documento82 paginePile Work Presentation at IITK Summer Camp 08praxie0% (1)

- Eecmy Mys Residential Building G+2 BoqDocumento73 pagineEecmy Mys Residential Building G+2 BoqErkiyhu Elias100% (1)

- Eecmy Mys Residential Building BoqDocumento81 pagineEecmy Mys Residential Building BoqErkiyhu EliasNessuna valutazione finora

- Eecmy Mys Residental Building G+4Documento55 pagineEecmy Mys Residental Building G+4Erkiyhu EliasNessuna valutazione finora

- Cost of Sructure WorkDocumento4 pagineCost of Sructure Workzekrab negaNessuna valutazione finora

- Polypropylene Fibre Reinforced ShotcreteDocumento11 paginePolypropylene Fibre Reinforced Shotcreteabhineet srivastava100% (2)

- Boq of Dire Dawa Project Final Price AdjustedDocumento67 pagineBoq of Dire Dawa Project Final Price Adjustedbings1997 BiniamNessuna valutazione finora

- Annexure 1 Yetimoga BOQ - 1 PDFDocumento6 pagineAnnexure 1 Yetimoga BOQ - 1 PDFNour MostafaNessuna valutazione finora

- Second Godavari Bridge The New Link BridDocumento15 pagineSecond Godavari Bridge The New Link Bridprotocol.shivamNessuna valutazione finora

- Suganya 2019 Volume 8Documento4 pagineSuganya 2019 Volume 8dhavamanidossNessuna valutazione finora

- Shotcrete Use in The Southern Link Tunnel, Stockholm: Swedish National Road AdministrationDocumento6 pagineShotcrete Use in The Southern Link Tunnel, Stockholm: Swedish National Road AdministrationHarold TaylorNessuna valutazione finora

- Mousavi 2017Documento21 pagineMousavi 2017PennarasiNessuna valutazione finora

- PartDocumento10 paginePartMohd Zain KangdaNessuna valutazione finora

- Chapter Three: Technical Spec. and Method of Measurements For The Diff. Trade of WorksDocumento67 pagineChapter Three: Technical Spec. and Method of Measurements For The Diff. Trade of Workssamrawit aysheshimNessuna valutazione finora

- The Proposed Dualization of Road Kotangora Auto Saved)Documento6 pagineThe Proposed Dualization of Road Kotangora Auto Saved)Felix IdeboghieNessuna valutazione finora

- Bedele HallDocumento57 pagineBedele Hallfayisamamo126Nessuna valutazione finora

- Design and Constrcution of TSFDocumento7 pagineDesign and Constrcution of TSFvishwaNessuna valutazione finora

- Cho S M Et Al 2008 Geotextile Tube Application As The Cofferdam at The Foreshore With Large Tidal Range For Incheon Bridge Project PDFDocumento6 pagineCho S M Et Al 2008 Geotextile Tube Application As The Cofferdam at The Foreshore With Large Tidal Range For Incheon Bridge Project PDFMuhammad Rizki AnwarNessuna valutazione finora

- Project Repo 1Documento2 pagineProject Repo 1nimish.aquamarineNessuna valutazione finora

- 35-Article Text-165-1-10-20220605Documento20 pagine35-Article Text-165-1-10-20220605S A KaleNessuna valutazione finora

- I-Sand: Replacement of Natural SandDocumento9 pagineI-Sand: Replacement of Natural SandVinay Kumar H SNessuna valutazione finora

- Composite DeckDocumento5 pagineComposite DeckvkagarwaNessuna valutazione finora

- Replacement of Energy Optimizing Furnace Slag (Eof) As A Fine Aggregate in ConcreteDocumento5 pagineReplacement of Energy Optimizing Furnace Slag (Eof) As A Fine Aggregate in ConcretecivilsingamNessuna valutazione finora

- BOQ Lokwii Water Supply Project Turkana EastDocumento6 pagineBOQ Lokwii Water Supply Project Turkana EastMohamed Billow SalatNessuna valutazione finora

- Concrete Silica ReactionDocumento4 pagineConcrete Silica ReactionHusain Masood ChandharNessuna valutazione finora

- Cost Effectiveness of Different Canal Lining Materials: Mr. Amrut Sangale, Dr. S. S. ValunjkarDocumento3 pagineCost Effectiveness of Different Canal Lining Materials: Mr. Amrut Sangale, Dr. S. S. ValunjkarerpublicationNessuna valutazione finora

- 1st Pay. Haddo Kebele Residence IbraDocumento43 pagine1st Pay. Haddo Kebele Residence IbraikramhelenNessuna valutazione finora

- BOQ Guumeys Barkad FinalDocumento2 pagineBOQ Guumeys Barkad FinalDheka 2022Nessuna valutazione finora

- L-10 Pre-Stressed Concrete Part-1Documento21 pagineL-10 Pre-Stressed Concrete Part-1Vinita KumariNessuna valutazione finora

- Steel Slag in ConcreteDocumento4 pagineSteel Slag in ConcreteGreissy Margory Reynaga CalderonNessuna valutazione finora

- Seminartopiconhighdensityconcrete 220907134400 0799e13dDocumento17 pagineSeminartopiconhighdensityconcrete 220907134400 0799e13dArunkumar CHNessuna valutazione finora

- Strength Analysis of Concrete by Using Iron Slag As A Partial Replacement of Normal Aggregate (Coarse) in ConcreteDocumento4 pagineStrength Analysis of Concrete by Using Iron Slag As A Partial Replacement of Normal Aggregate (Coarse) in ConcreteRamya DeepthiNessuna valutazione finora

- TangkiDocumento7 pagineTangkiReza Fadhila0% (1)

- Stabilization of Sub-Graded Soils: by N.Manasa Venkat 1010901015 IV B Tech, Civil EngineeringDocumento27 pagineStabilization of Sub-Graded Soils: by N.Manasa Venkat 1010901015 IV B Tech, Civil EngineeringAnjali chilakalaNessuna valutazione finora

- Bangladesh Ag Uni 0071Documento7 pagineBangladesh Ag Uni 0071Janica GavinoNessuna valutazione finora

- Oman-India Fertilizer Project OIFDocumento24 pagineOman-India Fertilizer Project OIFBassam Dahham83% (6)

- Steel Slag As A Road Construction MaterialDocumento6 pagineSteel Slag As A Road Construction MaterialBinay DhakalNessuna valutazione finora

- Package II Part I.4.1 BOQ SumpDocumento4 paginePackage II Part I.4.1 BOQ Sumpdox4useNessuna valutazione finora

- 06 Chapter 1Documento13 pagine06 Chapter 1Arun GoyalNessuna valutazione finora

- 2 2. BoqDocumento113 pagine2 2. Boqmian NaveedNessuna valutazione finora

- Ethiopian Construction Works Corporation (ECWC) Summary Guard HouseDocumento6 pagineEthiopian Construction Works Corporation (ECWC) Summary Guard Housegetnet100% (3)

- Use of Bamboo in Low Volume Rigid Pavement As Reinforced Material: A ReviewDocumento3 pagineUse of Bamboo in Low Volume Rigid Pavement As Reinforced Material: A ReviewAhad FirdosiNessuna valutazione finora

- Salient Features of Chenab BridgeDocumento2 pagineSalient Features of Chenab BridgeIndra Nath MishraNessuna valutazione finora

- Structural AnalysisnewDocumento6 pagineStructural AnalysisnewJunith Jay CalinawanNessuna valutazione finora

- Driven Steel Piling - BBGEDocumento2 pagineDriven Steel Piling - BBGEmasterumNessuna valutazione finora

- Rock Anchor MethodologyDocumento7 pagineRock Anchor Methodologyzee shanNessuna valutazione finora

- Efficacy of Stone Columns in Flyash AreaDocumento4 pagineEfficacy of Stone Columns in Flyash AreaVetriselvan ArumugamNessuna valutazione finora

- Copper SlagDocumento42 pagineCopper SlagShreedhar KulalNessuna valutazione finora

- "Concrete": Structure, Properties, Processes, Aplication ofDocumento11 pagine"Concrete": Structure, Properties, Processes, Aplication ofMahfud EffendiNessuna valutazione finora

- Bridge Proper SL Item of Work Cl. No. of Unit Qty No. Mort & H'S Specification 1 2 3 4 5Documento16 pagineBridge Proper SL Item of Work Cl. No. of Unit Qty No. Mort & H'S Specification 1 2 3 4 5Hoque joynulNessuna valutazione finora

- (12302945 - Archives of Civil Engineering) Some Durability Aspects of Ambient Cured Bottom Ash Geopolymer ConcreteDocumento16 pagine(12302945 - Archives of Civil Engineering) Some Durability Aspects of Ambient Cured Bottom Ash Geopolymer ConcreteSaravanaKumarNessuna valutazione finora

- Abstract of CostDocumento48 pagineAbstract of CostNikhitha100% (1)

- Effect of Superplasticizer and Silica Fume On Properties of ConcreteDocumento3 pagineEffect of Superplasticizer and Silica Fume On Properties of ConcretemajedsalehNessuna valutazione finora

- An Experimental Investigation of Steel CDocumento4 pagineAn Experimental Investigation of Steel CnomadiczapatoNessuna valutazione finora

- Solutions Manual to accompany Engineering Materials ScienceDa EverandSolutions Manual to accompany Engineering Materials ScienceValutazione: 4 su 5 stelle4/5 (1)

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionDa EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionNessuna valutazione finora

- Bill Receiving Date Work Done AmountDocumento1 paginaBill Receiving Date Work Done AmountSyed Adnan AqibNessuna valutazione finora

- Rate Analysis (KAPCO Kot Addu) : EarthworkDocumento13 pagineRate Analysis (KAPCO Kot Addu) : EarthworkSyed Adnan AqibNessuna valutazione finora

- New Microsoft Word DocumentDocumento10 pagineNew Microsoft Word DocumentSyed Adnan AqibNessuna valutazione finora

- General Notes: Creative Agro ChemicalsDocumento1 paginaGeneral Notes: Creative Agro ChemicalsSyed Adnan AqibNessuna valutazione finora

- Boundary Wall ConstrctDocumento6 pagineBoundary Wall ConstrctSyed Adnan AqibNessuna valutazione finora

- Construction of Sand Plant: (Chenab Engineering & Foundries PVT LTD) (Project Lead)Documento4 pagineConstruction of Sand Plant: (Chenab Engineering & Foundries PVT LTD) (Project Lead)Syed Adnan AqibNessuna valutazione finora

- TT & PSTDocumento26 pagineTT & PSTSyed Adnan AqibNessuna valutazione finora

- Boq - 162-Cca (Vi)Documento11 pagineBoq - 162-Cca (Vi)Syed Adnan AqibNessuna valutazione finora

- Book1 PDFDocumento1 paginaBook1 PDFSyed Adnan AqibNessuna valutazione finora

- Incredible HRS: Modular High-Bay FixturesDocumento2 pagineIncredible HRS: Modular High-Bay FixturesSyed Adnan AqibNessuna valutazione finora

- Time Table-20171101-07Documento4 pagineTime Table-20171101-07Syed Adnan AqibNessuna valutazione finora

- Translation 2Documento1 paginaTranslation 2Syed Adnan AqibNessuna valutazione finora

- Faizan Engineering Report ManuallDocumento1 paginaFaizan Engineering Report ManuallSyed Adnan AqibNessuna valutazione finora

- Medi Build EOIDocumento48 pagineMedi Build EOIdan_COLLINS2787100% (1)

- Section 7 and 8Documento59 pagineSection 7 and 8Marvin SironNessuna valutazione finora

- Architecture Is The Art of Building Structures of EnclosedDocumento3 pagineArchitecture Is The Art of Building Structures of EnclosedNirbhay SinghNessuna valutazione finora

- Major Parks of GHMCDocumento1 paginaMajor Parks of GHMCShailuSreeNessuna valutazione finora

- s0!00!10 - Foundation Typical Details and SchedulesDocumento1 paginas0!00!10 - Foundation Typical Details and Scheduleshuyxpkiss100% (1)

- Labour ContractDocumento2 pagineLabour ContractMuthukumarNessuna valutazione finora

- General Requirements For Occupant Loads and ExitsDocumento2 pagineGeneral Requirements For Occupant Loads and Exitsjeckson magboo100% (1)

- Brosur Jembatan (Terbaru) OKkkDocumento24 pagineBrosur Jembatan (Terbaru) OKkkdede_anfieldNessuna valutazione finora

- Cip 42 Fissuras TérmicasDocumento2 pagineCip 42 Fissuras Térmicasandré felipe da silvaNessuna valutazione finora

- Proposed Sports ComplexDocumento16 pagineProposed Sports ComplexJuliusNessuna valutazione finora

- Ground Floor Plan First Floor Plan: Elevation Section Aa' Section BB'Documento1 paginaGround Floor Plan First Floor Plan: Elevation Section Aa' Section BB'saqib ullahNessuna valutazione finora

- Void TubesDocumento6 pagineVoid TubesAistė VaitkuvienėNessuna valutazione finora

- The Los Angeles Guide To World CitiesDocumento118 pagineThe Los Angeles Guide To World CitiesMarco MilazzoNessuna valutazione finora

- CCPU-Monthly Progress Report No.013Documento42 pagineCCPU-Monthly Progress Report No.013Nhoek RenNessuna valutazione finora

- Pipe Culvert Bridge RamdurgDocumento20 paginePipe Culvert Bridge RamdurgHemant SonawadekarNessuna valutazione finora

- CV - Alberto Marroquin - PeruDocumento9 pagineCV - Alberto Marroquin - PeruLUIS ALBERTO MARROQUIN RIVERANessuna valutazione finora

- Building ConstructionDocumento12 pagineBuilding ConstructionpriyankaoswalNessuna valutazione finora

- PL 01Documento1 paginaPL 01Reyjel PanaliganNessuna valutazione finora

- Ludwig Mies Van Der RoheDocumento18 pagineLudwig Mies Van Der RoheDhwani AntalaNessuna valutazione finora

- Material Take-Off List: Saudi Aramco 6228-ENG (11/2010)Documento1 paginaMaterial Take-Off List: Saudi Aramco 6228-ENG (11/2010)FahadNessuna valutazione finora

- Effect of Expansive Agent and Shrinkage Reducing Admixture On ECC With Polyvinyl Alcohol and PolypropyleneDocumento7 pagineEffect of Expansive Agent and Shrinkage Reducing Admixture On ECC With Polyvinyl Alcohol and Polypropyleneci_balaNessuna valutazione finora

- Besser Block and Brick Guide: VictoriaDocumento8 pagineBesser Block and Brick Guide: VictoriaKim Hien LeeNessuna valutazione finora

- CASE STUDY Taj MahalDocumento7 pagineCASE STUDY Taj MahalSajna SalasNessuna valutazione finora

- 048 Vernacular Architecture - Seeking An ApproachDocumento27 pagine048 Vernacular Architecture - Seeking An ApproachYoka PrimaNessuna valutazione finora

- Iluna Brochure PDFDocumento11 pagineIluna Brochure PDFIzzuanNessuna valutazione finora

- Reinforcing BarsDocumento3 pagineReinforcing BarsSabre D. ButitoNessuna valutazione finora

- Spec-ACI 506.2-95Documento8 pagineSpec-ACI 506.2-95jeff3201100% (2)

- LadakhDocumento25 pagineLadakhBereket ArayaNessuna valutazione finora

- Great Places PlanDocumento152 pagineGreat Places PlanGeoff RiceNessuna valutazione finora

- Sarhad University, Peshawar: (Distance Education)Documento1 paginaSarhad University, Peshawar: (Distance Education)Faisal HayatNessuna valutazione finora