Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

47

Caricato da

Yola BertilsyaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

47

Caricato da

Yola BertilsyaCopyright:

Formati disponibili

TECHNICAL PAGES

Basics of deionization

To design an effective system, dealers should know the

application, desired purity and the existing impurities in the water.

By Mario C. Uy and Domingo A. Mesa

eionization (DI), also referred to

D as demineralization, is an ion-

exchange process wherein virtu-

ally all of the dissolved ions in the water

can be removed, producing pure water.

Depending on the type and combina-

tion of equipment, DI can produce a

purity from 100,000 ohms/cm to 18 mil-

lion ohms/cm (or mega-ohms/cm).

Types of resin

A deionizer uses two opposing charged

resins (cationic and anionic). While the

cationic resin removes the cations, the

anionic resin removes the anions.

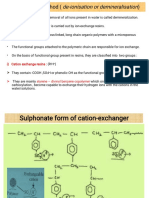

The cationic resin is typically made

from styrene containing sulfonic acid

groups, which are negatively charged. Figure 1 Typical dual-bed deionizer

Although the resin is actually negatively

charged, it is called a cationic resin, precharged with hydrogen ions on its or Type 2. Type 1 can remove silica and

referring to the cations that it will exchange sites. CO2 better than Type 2 but at a reduced

exchange. Anionic resin is typically made from capacity.

This resin typically comes in the styrene containing quaternary ammoni- There are other variations of resins to

hydrogen ion (H+) form, meaning it is um groups, which are positively consider, with each providing its own

charged. Despite its positive charge, it is advantages and disadvantages such as

called an anionic resin, referring to the thermal, physical and chemical stability,

Sizing the deionizer anions that it will exchange.

oxidation and organic fouling resist-

Cationic resin is rated at about 20,000 ance, kinetics and costs. One must

This resin typically comes in the

choose the proper type of resin to fit the

grains per ft3 at 2-gallons HCl regenerant hydroxide ion (OH-) form, meaning it is

application.

per ft3 of resin. Anionic resin is rated at precharged with hydroxide ions on its

about 12,000 grains per ft3 at 1-gallon exchange sites. Dual and mixed-beds

NaOH regenerant per ft3 of resin

Resin variations Deionizers come in dual-beds or

Despite the higher capacity of the mixed-beds. In a dual-bed system, the

cationic resin, dual-beds typically come

Cationic resin is referred to as

strong acid or weak acid. cationic resin and the anionic resin are in

with equal amount of cationic and anionic separate vessels, where as in a mixed-

Anionic resin is referred to as strong

resin. In essence, the cationic vessels are bed the cationic and the anionic resins

base or weak base.

oversized because they also supply the are mixed in a single vessel. This is also

The basic difference is the weakly ion-

regenerant water for the anionic vessels. called a single-bed DI.

ized resin will exchange only the weak

Mixed-beds come with a 40/60 blend In a dual-bed DI (see Figure 1) water is

ions, where as a strongly ionized resin

of cationic and anionic resin. passed through the cationic vessel where

will exchange both weak and strong ions

M.C.U. and D.A.M. but at the expense of a reduced capacity. the cations in the water are exchanged

The strong base anion comes in Type 1 (Continued on page 40)

January 2004 www.watertechonline.com Water Technology 39

TECHNICAL PAGES

with the hydrogen ions from the resin.

The cationic resin, having a greater

affinity for the cations, releases the hydro-

gen ions while grabbing the cations. The

released hydrogen ions form acid with

the remaining anions in the water.

Figure 2 A fraction of the DI water is recirculated to

This water is then passed through the

the front of the deionizer to maintain the waters purity.

anionic vessel where the anions are now

exchanged with the hydroxide ions from ions are removed and exchanged, pro- Recycling DI water

the resin. Similarly, the anionic resin, ducing an even purer water. In a mixed- If the flow through the deionizer is

having a greater affinity for the anions, bed, the water passes through the temporarily halted, the water in the ves-

releases the hydroxide ions while grab- cationic resin and the anionic resin sels will begin to take back the impure

bing the anions. repeatedly, virtually for an infinite time. ions from the resin. When the flow is

The released hydrogen ions (H+) from The resulting water is usually ultrapure. resumed, the first few gallons will usu-

the cationic vessel and hydroxide ions A mixed-bed can produce over 10M- ally be below specs.

(OH-) from the anionic vessel now com- ohm water, whereas a dual-bed typical- To prevent this, the DI water can be

bine to form HOH or H2O. ly produces only 50K-ohms to 100K- recycled back at a fraction of the service

Some of the ions will slip by and ohms water. flow rate to the front of the deionizer to

wont be exchanged. If the DI water can Another variation is a combination of keep the water moving and the purity

be passed through the dual-bed again, dual-bed and mixed-bed, where the up (See Figure 2).

the deionizer will have another chance mixed-bed is used as a polisher. Such a This method is also used when DI

to remove the ions that slipped by. set-up can produce ultrapure water up water is stored after the deionizer. If the

Each time this pass is repeated, more to 18 mega-ohm/cm. water is not used immediately, it will

The #1 Industry Trade Publication

A tradition of being first:

First to have its circulation audited by BPA International,

a third-party auditing bureau.

First to offer overnight delivery of reader inquiry sales

leads to advertisers via faxes.

Water

The Information Source for Water Treatment Professionals

First to publish an exhibitor guide for the WQA Show.

Weve maintained this tradition of innovative

services to the POU/POE marketplace

First to publish a Spanish edition.

because like thousands of our readers

First to have a website. and advertisers we are entrepreneurial,

and we believe that creative change and

First to offer a daily e-news service. aggressive competition develops a stronger

and more vibrant industry.

Building a better industry through innovation and competition

Humphrey S. Tyler 13 Century Hill Drive

Latham, NY 12110

President 518-783-1281

www.watertechonline.com

40 Water Technology www.watertechonline.com January 2004

Non-ionic treatment

AquaVantage

Deionizers do not remove non-ionic solids such as

THE INTELLIGENT CHOICE FOR

hydrophobic organic and some biological matters. Since

these particles may be present in water, it would be pru-

HARD WATER TREATMENT!

dent to add other equipment such as multi-media filters,

activated carbon filters, RO and/or UV light to remove the Be the first to offer your customers the

non-ionic solids and to keep microbiological growth and best solution to their hard water prob-

fouling under control. lems, and the problems associated with

If the water contains significant amount of dissolved salt water.

gasses like CO2, removing them mechanically via

degasifiers may be more cost efficient. AquaVantage offers dramatic savings,

M.C.U. and D.A.M. great convenience, proven technology

absorb gasses like CO2 and other air-borne particles,

and a host of health benefits. You can

reducing the waters resistivity. now offer a system that saves hundreds

To prevent the water from falling below specs, it of dollars on water softening salts. An

can also be recycled back to front of the deionizer for environmentally sound alternative to

similar benefits. obsolete systems in millions of homes

Expiration across the country.

Eventually the resins will expire, as all the hydro-

gen and/or hydroxide ions are expelled and all the AquaVantage is now available in the U.S.

exchange sites are filled with impure ions. Thereafter, exclusively from ENPROTEC, a leader in

the deionizer will no longer remove any subsequent water sciences, and it costs less than a

impure ions, allowing them to leak through, reducing penny a day to operate.

water purity.

The most common indicator of a deionizer expira-

All the benefits of soft water

tion is a sudden and significant drop in the resistivity

No salt or backwash

of the DI water.

There are other indicators. When the cationic resin

Meets all state discharge regulations

expires, the first ion to leak through will be sodium Environmentally friendly

(Na+). When the anionic resin expires, the first ions to Saves up to 70% on hot water costs

leak through will be silica (SiO2) and/or carbonate Retains beneficial minerals

alkalinity (CO3-2). Removes and eliminates scale buildup

Regeneration Uses $3 of electricity per year

5-Year Warranty

To bring the water purity back to spec, the deioniz-

er must be regenerated. Most deionizers are regener-

ated based on resistivity, while others are based on the

ion leakage.

The cationic resin is regenerated with acid to

replace the hydrogen ions. The preferred acid is

hydrochloric acid (HCl), typically 20oBe (32 percent)

at about 2-gallons per ft3 of resin. Pipe scale Three months

The anionic resin is regenerated with caustic to before later

replace the hydroxide ions. The preferred caustic is

a rayon or mercury grade sodium hydroxide Phone: 1- 800-864-0830

(NaOH), typically 50oBe (50 percent) at about 1-gal-

lon per ft3 of resin. WEB SITE: www.enprotec.net

A dual-bed can be regenerated in series or parallel:

Circle fast action no. 204

(Concluded on page 42)

January 2004 www.watertechonline.com Water Technology 41

TECHNICAL PAGES

Series regeneration means the cation- Parallel regeneration means both the be returned to service faster.

ic vessel is regenerated first and then cationic and anionic vessels are regener- With a parallel regeneration, an alter-

supplies the water to regenerate the ated simultaneously, reducing regenera- nate softwater or equivalent must be

anionic vessel. tion time and enabling the deionizer to used to regenerate the anionic vessel to

prevent fouling the anionic resin. An

Types of solids alternate softwater or equivalent must

also be used to regenerate mixed-beds

Water dissolves minerals by dissociating the minerals to cations (+) and anions (-). For

for the same reason.

example, sodium chloride (NaCl), a table salt, will dissolve in water by dissociating to

In dual-beds the regenerants are typ-

sodium (Na+) cation and chloride (Cl-) anion.

ically introduced downflow through

Dissociated ions, having ionic charges, are easily removed by DI.

Some gasses like carbon dioxide (CO2 ) react with water to form carbonic acid (HCO3), the resin beds and discharged through

which dissociates to 2H+ and CO3-2 . Likewise, these ions are easily removed by DI. the risers. In a mixed-bed, the cation

Other solids, when dissolved in water, do not dissociate to ions but they have enough and anion resins are first stratified via

density of charges that allow them to bridge with the water molecule. Examples are backwash.

organic compounds like sugar, alcohol and solvents. The cation resin being heavier than

Although these compounds do not dissociate to ions, they impart some ionic charges the anion resin will settle at the bot-

and thus can be removed by DI. tom half. The acid is introduced at the

Still other compounds like hydrophobic organics and some biological matters, when bottom, while the caustic is introduced

mixed in water, are non-ionic and thus cannot be removed by DI. These non-ionic com- at the top.

pounds can be removed by equipment such as multi-media filters, activated carbon fil- The regenerants meet at the interface

ters and reverse osmosis (RO). collector at the middle of the tank where

M.C.U. and D.A.M. they are discharged. After regeneration,

compressed air is introduced to re-mix

the resins.

Regenerant discharge

218,569 Hours The resins have greater affinity

toward the impure ions than the hydro-

gen and hydroxide ions. As such, the

Spent by Visitors on WaterTechOnline resins will release the hydrogen and

During 1.8 Million Visits in 2003* hydroxide ions during the service cycle,

to grab the impure ions.

In order to reverse this preference

during regeneration, the deionizer is

regenerated with excess regenerants

(hydrogen and hydoxide ions) to force

the impure ions off the resins.

Advertise on the Website with the Only a fraction of the regenerants is

used. Most of the regenerants, along with

Highest Traffic Documented the released impure ions, are discharged.

To prevent the discharge of spent acid

in the Water Treatment and and caustic to the sewer, they are typical-

Wastewater Industry ly routed to a neutralization tank where

they neutralize each other. Further

adjustment of the pH may be necessary

For More Information, Contact

to comply with the final discharge

Account Executive: Leah Sysman

Phone: 518-783-1281, ext. 3184 requirements of the local water district.

Fax: 518-783-1386

lsysman@ntpinc.com Mario C. Uy and Domingo A. Mesa are

*Publishers own data, Web Trends statistics with WET, Inc. (World Environmental

Technologies, Inc.), Carol Stream, IL.

42 Water Technology www.watertechonline.com January 2004

Potrebbero piacerti anche

- ScannDocumento1 paginaScannYola BertilsyaNessuna valutazione finora

- Azas Teknik Kimia I PDFDocumento1 paginaAzas Teknik Kimia I PDFYola BertilsyaNessuna valutazione finora

- GrafikkkkkkDocumento4 pagineGrafikkkkkkYola BertilsyaNessuna valutazione finora

- VVVDocumento1 paginaVVVYola BertilsyaNessuna valutazione finora

- Biodiesel production from high FFA rubber seed oilDocumento6 pagineBiodiesel production from high FFA rubber seed oilRizky AndreNessuna valutazione finora

- Azas Teknik Kimia I PDFDocumento1 paginaAzas Teknik Kimia I PDFYola BertilsyaNessuna valutazione finora

- Atk I-2Documento18 pagineAtk I-2pebrian sahputraNessuna valutazione finora

- Bab07 Pembacaan P&IDDocumento13 pagineBab07 Pembacaan P&IDYola BertilsyaNessuna valutazione finora

- STUDENT-ACHIEVEMENTSDocumento25 pagineSTUDENT-ACHIEVEMENTSYola BertilsyaNessuna valutazione finora

- F&EI IntroductionDocumento5 pagineF&EI IntroductionAbhinav AjmaniNessuna valutazione finora

- How Structure Fires Spread and Cause Additional Home Exposure FiresDocumento7 pagineHow Structure Fires Spread and Cause Additional Home Exposure FiresYola BertilsyaNessuna valutazione finora

- 471 5178 1 PBsDocumento12 pagine471 5178 1 PBsJohnNessuna valutazione finora

- Daftar Pustaka: Mineralugy. Compeigne, FranceDocumento5 pagineDaftar Pustaka: Mineralugy. Compeigne, FranceYola BertilsyaNessuna valutazione finora

- Raw Mill Oktober 2017Documento27 pagineRaw Mill Oktober 2017Yola BertilsyaNessuna valutazione finora

- Deionizer MaintenaceDocumento3 pagineDeionizer MaintenaceKaizerNessuna valutazione finora

- YyyyyDocumento62 pagineYyyyyYola BertilsyaNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Ion Exchange ProcessDocumento10 pagineIon Exchange Process056 Jatin GavelNessuna valutazione finora

- Asignment - Chapter 1 PDFDocumento3 pagineAsignment - Chapter 1 PDFDo Cong Minh100% (1)

- Ias 4 4 275 284 PDFDocumento10 pagineIas 4 4 275 284 PDFHarjinder SinghNessuna valutazione finora

- Lateral-Torsional Buckling of Orthotropic Rectangular Section BeamsDocumento8 pagineLateral-Torsional Buckling of Orthotropic Rectangular Section BeamsMina AdlyNessuna valutazione finora

- Fibre Rope - Terminology and Good PracticesDocumento19 pagineFibre Rope - Terminology and Good PracticesLe Quyen NguyenNessuna valutazione finora

- Hydro-Flo Technologies, Inc.: Chemical Name Acid - Typical Project Name XX-XXXXDocumento4 pagineHydro-Flo Technologies, Inc.: Chemical Name Acid - Typical Project Name XX-XXXXPutra TatorNessuna valutazione finora

- 1singly-Reinforced Beams1Documento29 pagine1singly-Reinforced Beams1Jayson MariNessuna valutazione finora

- Plastic FormingDocumento11 paginePlastic FormingAngeloLorenzoSalvadorTamayoNessuna valutazione finora

- Pozzolith 575: Chloride Accelerating AdmixtureDocumento2 paginePozzolith 575: Chloride Accelerating AdmixtureFrancois-Nessuna valutazione finora

- Nitofill EPLV : Constructive SolutionsDocumento4 pagineNitofill EPLV : Constructive SolutionsmilanbrasinaNessuna valutazione finora

- Rubber Insulating Matting: Standard Specification ForDocumento9 pagineRubber Insulating Matting: Standard Specification ForPaula DiasNessuna valutazione finora

- 2 - (Biochem) Oxidizing and ReducingDocumento3 pagine2 - (Biochem) Oxidizing and ReducingKaireen OzNessuna valutazione finora

- Purification of Wastewater by Metal Oxide NanoparticlesDocumento12 paginePurification of Wastewater by Metal Oxide NanoparticlesEditor IJTSRDNessuna valutazione finora

- Module 8 Welding Metallurgy For The WIDocumento39 pagineModule 8 Welding Metallurgy For The WIRamesh R100% (1)

- Zheng Et Al., 2006Documento10 pagineZheng Et Al., 2006vaniserNessuna valutazione finora

- Specification - Road Repairs (Ade)Documento11 pagineSpecification - Road Repairs (Ade)Sathish KumarNessuna valutazione finora

- ManualDocumento2 pagineManualJose Arthur AbellaNessuna valutazione finora

- Namma Kalvi 12th Chemistry Volume 1 One Mark Study Material 215342Documento25 pagineNamma Kalvi 12th Chemistry Volume 1 One Mark Study Material 215342Aakaash C.K.Nessuna valutazione finora

- Hari Ke-2 - KimiaDocumento5 pagineHari Ke-2 - KimiaYose RizalNessuna valutazione finora

- EBSD OxfordDocumento13 pagineEBSD OxfordBruna CallegariNessuna valutazione finora

- Verification of Debye-Hückel-Onsager EquationDocumento3 pagineVerification of Debye-Hückel-Onsager EquationJOSEPH HERBERT MABEL50% (6)

- Evaluating the Structural Strength of Shipping Containers for Building ApplicationsDocumento10 pagineEvaluating the Structural Strength of Shipping Containers for Building ApplicationsSergio OrozcoNessuna valutazione finora

- NA-5 Automatic Welding Systems: SVM131-ADocumento152 pagineNA-5 Automatic Welding Systems: SVM131-AmaxNessuna valutazione finora

- Conductor and SuperconductorDocumento12 pagineConductor and Superconductorankesh_ghoghariNessuna valutazione finora

- Falcon C Concentrators Recover Down to 10 MicronsDocumento2 pagineFalcon C Concentrators Recover Down to 10 MicronsevalenciaNessuna valutazione finora

- PT MineralDocumento2 paginePT MineralFajar Premana PutraNessuna valutazione finora

- The Effect of Strain Rate On Mechanical PropertiesDocumento11 pagineThe Effect of Strain Rate On Mechanical Propertiesmechanicaltestinglab.acmsNessuna valutazione finora

- Article - Waste Glass in The Production of Cement and Concrete - A ReviewDocumento35 pagineArticle - Waste Glass in The Production of Cement and Concrete - A ReviewAnonymous OG8ApT4go100% (1)

- Leaching Unit OpsDocumento60 pagineLeaching Unit OpsCamille LeiNessuna valutazione finora

- Fermacell Orange BookDocumento138 pagineFermacell Orange BookabudabeejajaNessuna valutazione finora