Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Interlocked Armor Power Cable, 5000 VOLTS

Caricato da

pedro perez0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

42 visualizzazioni1 paginap-7

Titolo originale

p-7

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentop-7

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

42 visualizzazioni1 paginaInterlocked Armor Power Cable, 5000 VOLTS

Caricato da

pedro perezp-7

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

Little Rock

1-800-945-5542

Baton Rouge

1-888-754-5707

Houston

1-888-388-6280 http://www.prioritywire.com

INTERLOCKED ARMOR POWER CABLE,

5000 VOLTS

3 Conductor, XLP Insulated, Nonshielded,

Aluminum or Steel

Armor, Type MV-90 or Type MC, CT Use,

100% & 133% Insulation Levels

Application: As armored Type MV-90 cable for installation indoors or outdoors, aerially or in rack, tray, trough, cable trays, or direct

buried; for power circuits not exceeding 5000 volts phase to phase at conductor temperatures of 90C for continuous operation, 130C for

emergency overload conditions and 250C for short circuit conditions, in manufacturing and processing plants, substations and generating stations.

May be used in NEC Class I and II, Div. 2 and Class III, Div. 1 and 2 hazardous locations. Specifications: Conductor: 3 conductors of stranded

annealed uncoated copper Class B per Part 2 of ICEA. Conductor Shield: Semiconducting tape covering the conductor firmly bonded to the cable

insulation, meeting requirements of Part 2 of ICEA. Insulation: Cross-linked polyethylene (XLP), the average thickness being 110 mils in sizes

8 - 4/0 AWG, 120 mils in sizes 250 - 500 kcmil, and 130 mils in size 750 kcmil. Minimum thickness at any point shall be not less than 90% of the

specified thickness, physical and electrical properties of the insulation shall be in accordance with Paragraph 3.7 of ICEA.

Phase Identification: The insulated phase conductors shall be printed with numerals 1, 2, and 3 on the surface of the insulation.

Assembly: 3 phase conductors shall be cabled together with a Class B stranded, uncoated copper grounding conductor and suitable fillers to make

round. Length of lay shall not exceed 35 times the phase conductor diameter. The grounding conductor shall comply with the requirements of UL

Standard 1072. Cable Tape: A suitable cable tape shall be applied over the assembly to hold the core together and provide bedding for the armor.

Armor: An aluminum or galvanized steel interlocked armor shall be applied over the cable core and armor shall be in accordance with UL Standard

1072 and Part 4 of ICEA. Covering: an extruded covering of PVC shall be applied over the armor meeting the Sunlight Resistant requirements of UL

with the average thickness and properties of the PVC covering shall be specified in Part 4 of ICEA and minimum thickness at any point shall be not less

than 70% of the required average thickness. Identification: An ink print legend shall be applied to the surface of the PVC covering providing cable and

manufacturer identification. Tests: tested in accordance with UL requirements for Type MV-90 cable and ICEA S-66-524, passing ribbon

burner cable tray flame test requirements of UL and shall be UL listed For CT Use and comply with the IEEE-1202 flame test (2 AWG and larger).

Standards: UL Standard 1072 for Type MV-90, ICEA Pub. No. S-66-524 and NEMA Pub. No. WC7 for Cross-linked thermosetting polyethylene

insulated Wire and Cable

Catalog Size No. of Insulation Nominal PVC Nominal Copper Phase Conductors

No. AWG Strands Thickness Diameter Jacket Diameter Copper Approx. Net Ampicity Ampicity

or (Mils) Over Thick- Over PVC Grounding Weight lb/1000ft. * **

kcmil Armor ness Jacket Conductor AL Steel

(Inches) Mils (Inches) AWG Armor Armor

P01P7 8 7 110 1.02 50 1.12 8 675 810 52 59

P02P7 6 7 110 1.10 50 1.20 6 780 1000 69 79

P03P7 4 7 110 1.19 50 1.30 6 960 1230 91 105

P04P7 2 7 110 1.32 50 1.43 6 1270 1560 125 140

P05P7 1 19 110 1.41 50 1.51 4 1560 1870 140 160

P06P7 1/0 19 110 1.49 50 1.60 4 1820 2200 165 185

P07P7 2/0 19 110 1.59 60 1.71 4 2115 2485 190 215

P08P7 3/0 19 110 1.77 60 1.90 3 2780 3125 220 250

P09P7 4/0 19 110 1.85 60 1.98 3 3105 3750 255 285

P10P7 250 37 120 2.04 60 2.17 3 3700 4200 280 320

P11P7 350 37 120 2.21 60 2.35 2 4740 5365 350 395

P12P7 500 37 120 2.49 75 2.65 1 6515 7200 425 485

P13P7 750 61 130 2.92 75 3.09 1/0 9315 10225 525 615

** Ampacity for cables installed in uncovered cable tray without maintained

* Ampacity for cables installed in uncovered cable tray without maintained

spacing; 90C conductor temperature, 40C ambient.

- spacing of one cable diameter, 90C conductor temperature, 40C ambient.

For other installations refer to the NEC

* Shipping Tolerances +/- 10%

1-800-945-5542

Priority Wire & Cable, Inc. Little Rock, AR, 2003 PWC02/2003

Potrebbero piacerti anche

- HT Cables - Leading China Cable ManufacturerDocumento18 pagineHT Cables - Leading China Cable ManufacturerSIMON S. FLORES G.100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Marine Electrical Practice: Marine Engineering SeriesDa EverandMarine Electrical Practice: Marine Engineering SeriesValutazione: 4 su 5 stelle4/5 (8)

- Starbucks CaseDocumento50 pagineStarbucks CasePhoebe De la RosaNessuna valutazione finora

- HES KABLO POWERCABLE CATALOGUEDocumento292 pagineHES KABLO POWERCABLE CATALOGUEحسن علي جاسمNessuna valutazione finora

- United Wire & Cable: Section 2Documento28 pagineUnited Wire & Cable: Section 2parallax1957Nessuna valutazione finora

- Hoja de Datos Cable Xtu 1C (Xlpe)Documento2 pagineHoja de Datos Cable Xtu 1C (Xlpe)Daniel CordovaNessuna valutazione finora

- Power Cable: CatalogueDocumento49 paginePower Cable: Catalogueirfan nurudinNessuna valutazione finora

- THHN TC FuerzaDocumento2 pagineTHHN TC Fuerzajuan pablo castro gallegoNessuna valutazione finora

- 1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecDocumento2 pagine1-C CU 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105 2x5 Mils Tape Shield - SpecpurushothamnareNessuna valutazione finora

- WELDING CableDocumento2 pagineWELDING CableRezeki SimamoraNessuna valutazione finora

- 15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFDocumento2 pagine15XW 1c, 25kV, 260mil XLP (100%), WS, PVC6871 PDFLuis MartinezNessuna valutazione finora

- 1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specDocumento2 pagine1-C AL 15kV 220 NLEPR 133 Percent SIMpull PVC MV-105.specFrancisco Zanin FernandesNessuna valutazione finora

- 15-16 Inst Lampu Dan Stop Kontak Kabel TR Nya, Nyy, Nym, Nyfgby (KABELINDO)Documento7 pagine15-16 Inst Lampu Dan Stop Kontak Kabel TR Nya, Nyy, Nym, Nyfgby (KABELINDO)hafinNessuna valutazione finora

- Simpull XHHW/CT: SpecificationsDocumento2 pagineSimpull XHHW/CT: SpecificationsrlaureanoNessuna valutazione finora

- Low Voltage Electrical Guide CatalogueDocumento29 pagineLow Voltage Electrical Guide CatalogueAhmed ElsayedNessuna valutazione finora

- XLPE-Insulated Cables: 600/1000V Single-Core XLPE Insulated, Unarmoured & Armoured, PVC Sheathed CableDocumento3 pagineXLPE-Insulated Cables: 600/1000V Single-Core XLPE Insulated, Unarmoured & Armoured, PVC Sheathed CablewkcNessuna valutazione finora

- Instrumentation Cable BSDocumento42 pagineInstrumentation Cable BSShivaniNessuna valutazione finora

- Ficha Técnica CABLE ERP SOUTHWIREDocumento3 pagineFicha Técnica CABLE ERP SOUTHWIREGhislaine SousaNessuna valutazione finora

- Type TC Power Cable-THHN: ApplicationsDocumento2 pagineType TC Power Cable-THHN: ApplicationsHenry MontenegroNessuna valutazione finora

- According To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesDocumento10 pagineAccording To International Standard IEC 60502 - 1: Single Core and Three Core Medium Voltage CablesRaj KiranNessuna valutazione finora

- Standard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Documento7 pagineStandard Power Cables: XLPE Insulated, PVC Sheathed, Single Core Unarmoured Cables To BS7889Bhagoo HatheyNessuna valutazione finora

- PRODUCT CATALOGUE CABLESDocumento78 paginePRODUCT CATALOGUE CABLESBaswara SadewaNessuna valutazione finora

- Enerji Katalog enDocumento406 pagineEnerji Katalog enllruNessuna valutazione finora

- 35kV 1 Core Armored XLPE Power CableDocumento17 pagine35kV 1 Core Armored XLPE Power Cablekser82Nessuna valutazione finora

- Branch Cable Primer TDS - Feb 2018Documento11 pagineBranch Cable Primer TDS - Feb 2018Kerr AgotNessuna valutazione finora

- 1C Cu Epr-Pvc 35KV@133% 2017Documento2 pagine1C Cu Epr-Pvc 35KV@133% 2017CarlosNessuna valutazione finora

- Caledonian: JIS C 3410 Shipboard CablesDocumento54 pagineCaledonian: JIS C 3410 Shipboard Cablestwo travellerNessuna valutazione finora

- Wire Size SpecificationsDocumento2 pagineWire Size Specificationsjaveeed0401Nessuna valutazione finora

- Me1.3.6-Me1.3.10 Cable XHHW SouthwireDocumento2 pagineMe1.3.6-Me1.3.10 Cable XHHW SouthwireHenry MontenegroNessuna valutazione finora

- Data Sheet Southwire 3c#500kcmilDocumento2 pagineData Sheet Southwire 3c#500kcmilNestor-leoNessuna valutazione finora

- 3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecDocumento2 pagine3-c Cu 5kv 115 Nlepr 133 Percent Aia PVC Mv-105.SpecRodrigo Chambilla VernazaNessuna valutazione finora

- N2XSYDocumento5 pagineN2XSYRinda_RaynaNessuna valutazione finora

- Binder - Mvolt - Aluminum Conductor.13 14 1Documento2 pagineBinder - Mvolt - Aluminum Conductor.13 14 1FdWorkNessuna valutazione finora

- Power and Cable GuideDocumento8 paginePower and Cable Guidelam2660% (1)

- B.04. Cable XHHW-2 - General CableDocumento1 paginaB.04. Cable XHHW-2 - General CableBenjamín Benzaquen SalazarNessuna valutazione finora

- N2XYDocumento5 pagineN2XYSamuel SantosNessuna valutazione finora

- RhinoDocumento2 pagineRhinoValeria Rendon NoyolaNessuna valutazione finora

- Spec44140 CablesDocumento2 pagineSpec44140 CablesCarlos LozanoNessuna valutazione finora

- 33Kv Cables MV Cable SpecificationDocumento3 pagine33Kv Cables MV Cable SpecificationelsayedNessuna valutazione finora

- 3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specDocumento2 pagine3-C CU 5kV 115 NLEPR 133 Percent CPE MV-105.specFrancisco Zanin FernandesNessuna valutazione finora

- Technical Specification - Grounding - WP4Documento6 pagineTechnical Specification - Grounding - WP4nnNessuna valutazione finora

- FT Sifer 950iDocumento2 pagineFT Sifer 950iAshik M RasheedNessuna valutazione finora

- NYYDocumento5 pagineNYYrioNessuna valutazione finora

- XHHW-2: 1. DescriptionDocumento2 pagineXHHW-2: 1. DescriptionPreditec PeruNessuna valutazione finora

- 2 KV AL Cable Datasheet - Priority CablesDocumento1 pagina2 KV AL Cable Datasheet - Priority CablesVipin KhandelwalNessuna valutazione finora

- Kabel Metal Nyy, Nym, Nya, NyfgbyDocumento14 pagineKabel Metal Nyy, Nym, Nya, NyfgbyMitha Wahyu PangestiNessuna valutazione finora

- NYY 2 x (1.5-300) mm2 0.6/1 kV Cable SpecDocumento5 pagineNYY 2 x (1.5-300) mm2 0.6/1 kV Cable SpecDen WhNessuna valutazione finora

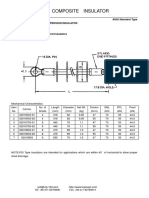

- TCI-ANSI Composite InsulatorsDocumento18 pagineTCI-ANSI Composite InsulatorsDaniel Tapia MarcosNessuna valutazione finora

- 4 MC Armored 5 8 KV Epr 3 ConductorsDocumento1 pagina4 MC Armored 5 8 KV Epr 3 ConductorsJavier MaldonadoNessuna valutazione finora

- Caledonian High Voltage XLPE CablesDocumento2 pagineCaledonian High Voltage XLPE CablesGcNessuna valutazione finora

- PC1 54 PDFDocumento122 paginePC1 54 PDFbharatsehgal00@gmail.comNessuna valutazione finora

- Technical Specification: Single Core Unarmoured Cables Copper Conductors XLPE Insulated 0.6/1KVDocumento4 pagineTechnical Specification: Single Core Unarmoured Cables Copper Conductors XLPE Insulated 0.6/1KVMohammed A. Al NabulsiNessuna valutazione finora

- Origin 350 MCM o Kcmil o MamalonDocumento2 pagineOrigin 350 MCM o Kcmil o MamalonJuan Andres AguileraNessuna valutazione finora

- Kelani Cable - ArmouredDocumento1 paginaKelani Cable - Armouredsukiraj Rasalingam100% (1)

- N2xy PDFDocumento5 pagineN2xy PDFArnold StevenNessuna valutazione finora

- Nyy 1CDocumento1 paginaNyy 1Chenry_gtNessuna valutazione finora

- LT PVC Catalogue PDFDocumento14 pagineLT PVC Catalogue PDFkapilNessuna valutazione finora

- 3 Outdoor Cables - Copper Conductor: 3.7 Single Core Armoured Circular Conductor - XLPE InsulatedDocumento1 pagina3 Outdoor Cables - Copper Conductor: 3.7 Single Core Armoured Circular Conductor - XLPE Insulatedරුසිරු ගුරුගේ (rusig)Nessuna valutazione finora

- 15 KV Cable Data SheetDocumento8 pagine15 KV Cable Data SheetanilNessuna valutazione finora

- British Commercial Computer Digest: Pergamon Computer Data SeriesDa EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNessuna valutazione finora

- CyberProtectionService Userguide en-USDocumento701 pagineCyberProtectionService Userguide en-USpedro perezNessuna valutazione finora

- Operation Standard Features: Fast Response Contact ModulesDocumento1 paginaOperation Standard Features: Fast Response Contact Modulespedro perezNessuna valutazione finora

- HSC Manual Revision 3 4-13-12Documento16 pagineHSC Manual Revision 3 4-13-12pedro perezNessuna valutazione finora

- 7 BCD 1 B 28Documento12 pagine7 BCD 1 B 28pedro perezNessuna valutazione finora

- Howto Reset Unifi AP To Factory Default When Reset Button Is Not WorkingDocumento16 pagineHowto Reset Unifi AP To Factory Default When Reset Button Is Not Workingpedro perezNessuna valutazione finora

- Insulation Testing of Low Voltage CablesDocumento12 pagineInsulation Testing of Low Voltage Cablesmarkigldmm918100% (2)

- 1.IPC D2B20 ZS L - Datasheet - 20190408Documento3 pagine1.IPC D2B20 ZS L - Datasheet - 20190408pedro perezNessuna valutazione finora

- Hussmann Corporation Warranty Performance Parts Warranty CoverageDocumento2 pagineHussmann Corporation Warranty Performance Parts Warranty Coveragepedro perezNessuna valutazione finora

- PDFDocumento56 paginePDFpedro perezNessuna valutazione finora

- Insulation Testing of Low Voltage CablesDocumento12 pagineInsulation Testing of Low Voltage Cablesmarkigldmm918100% (2)

- Brugg Cables User GuideDocumento27 pagineBrugg Cables User GuideMehdi_Mashayekhi_172Nessuna valutazione finora

- Low Voltage and High Voltage CableDocumento4 pagineLow Voltage and High Voltage Cablepedro perezNessuna valutazione finora

- What Is An ArresterDocumento18 pagineWhat Is An Arresterpedro perezNessuna valutazione finora

- Inspect and Test Medium- and High-Voltage CablesDocumento4 pagineInspect and Test Medium- and High-Voltage Cablespedro perezNessuna valutazione finora

- Wonderware Factorysuite: Protocols GuideDocumento36 pagineWonderware Factorysuite: Protocols GuideKhaled AverosNessuna valutazione finora

- Para Que Deje El Gu EvolDocumento19 paginePara Que Deje El Gu Evolpedro perezNessuna valutazione finora

- Pulsar UGDocumento253 paginePulsar UGgusfajNessuna valutazione finora

- TURBIDocumento1 paginaTURBIpedro perezNessuna valutazione finora

- Selection PaP1 1Documento32 pagineSelection PaP1 1RofochoNessuna valutazione finora

- IPv6 Manual Addressing PT LabDocumento3 pagineIPv6 Manual Addressing PT Labpedro perezNessuna valutazione finora

- Auxiliary Function and System Settings: 3.3. PLC and HPP02 Program VerificationsDocumento2 pagineAuxiliary Function and System Settings: 3.3. PLC and HPP02 Program Verificationspedro perezNessuna valutazione finora

- en PDFDocumento2 pagineen PDFpedro perezNessuna valutazione finora

- PCC01-Instruction Sheet-English-20060310 PDFDocumento1 paginaPCC01-Instruction Sheet-English-20060310 PDFpedro perezNessuna valutazione finora

- S731xC TF Examples Manual PDFDocumento92 pagineS731xC TF Examples Manual PDFpedro perezNessuna valutazione finora

- Hpp02 Basic Operation: 2.2. HPP02 Program READ / WRITEDocumento12 pagineHpp02 Basic Operation: 2.2. HPP02 Program READ / WRITEpedro perezNessuna valutazione finora

- Sensorespolvo2 PDFDocumento11 pagineSensorespolvo2 PDFpedro perezNessuna valutazione finora

- Simatic Easy Motion Control - ManualDocumento176 pagineSimatic Easy Motion Control - ManualTomislav CanjugaNessuna valutazione finora

- DVP - Entradas SalidasDocumento1 paginaDVP - Entradas Salidaspedro perezNessuna valutazione finora

- NEMA SB 50 - Guide Emer Comm Audio Intelligibility App - 2014Documento32 pagineNEMA SB 50 - Guide Emer Comm Audio Intelligibility App - 2014virtechNessuna valutazione finora

- Hwange ReportDocumento6 pagineHwange ReportCourage ChigerweNessuna valutazione finora

- Dev ListDocumento8 pagineDev ListPăun MihaiNessuna valutazione finora

- Computer Graphics BCA 33Documento131 pagineComputer Graphics BCA 33Mohiddin SahebNessuna valutazione finora

- PERKINS 2206a-E13tag5 Electropak Pn1882Documento2 paginePERKINS 2206a-E13tag5 Electropak Pn1882Patricia J ÁngelesNessuna valutazione finora

- The Water Supply Regulations 2009Documento22 pagineThe Water Supply Regulations 2009triggs1971Nessuna valutazione finora

- 15890Documento31 pagine15890Arif MohammedNessuna valutazione finora

- ATV Suspension Design Report SummaryDocumento4 pagineATV Suspension Design Report SummaryMohit KumarNessuna valutazione finora

- TC SwitchDocumento5 pagineTC SwitchGolgojan NicusorNessuna valutazione finora

- Crompton Greaves Leading Manufacturer of Power EquipmentDocumento12 pagineCrompton Greaves Leading Manufacturer of Power Equipmentcarlos vidal100% (1)

- Seat Back PetitionDocumento24 pagineSeat Back PetitionCBS Austin WebteamNessuna valutazione finora

- Ficha Motor Gas Natural Jenbacher JMS 612 GSNL PDFDocumento4 pagineFicha Motor Gas Natural Jenbacher JMS 612 GSNL PDFJuan Jose RuedaNessuna valutazione finora

- Performance BudgetingDocumento2 paginePerformance BudgetingPankaj2cNessuna valutazione finora

- Public Review Draft 2404Documento115 paginePublic Review Draft 2404Said100% (1)

- MaxEye DVB Test SolutionDocumento25 pagineMaxEye DVB Test Solutiondan r.Nessuna valutazione finora

- YD Series Three Phase Asynchro Conveyor MotorDocumento18 pagineYD Series Three Phase Asynchro Conveyor MotorAditya SafarudinNessuna valutazione finora

- Substations PDFDocumento16 pagineSubstations PDFsorry2qaz100% (1)

- Em - 1110 2 2610Documento652 pagineEm - 1110 2 2610David LeviNessuna valutazione finora

- Maintenance Coordinator Utilities: Job DescriptionDocumento2 pagineMaintenance Coordinator Utilities: Job DescriptionyagolainNessuna valutazione finora

- H. J. THIM TRUST’S THEEM COLLEGE PUC REPORTDocumento13 pagineH. J. THIM TRUST’S THEEM COLLEGE PUC REPORTPriyanka BhideNessuna valutazione finora

- Tc7200.u User Manual Eng v17 PDFDocumento83 pagineTc7200.u User Manual Eng v17 PDFalbertNessuna valutazione finora

- Soil T-180 Moisture-Density TestDocumento3 pagineSoil T-180 Moisture-Density Testmalika_00Nessuna valutazione finora

- 9IMC - en 1015-11 and en 1015-12 Proposal Updating For Lime ProductsDocumento9 pagine9IMC - en 1015-11 and en 1015-12 Proposal Updating For Lime ProductsHasan Ayouby100% (1)

- MIL std275 PDFDocumento50 pagineMIL std275 PDFAnonymous b6JaSWYNessuna valutazione finora

- TQM in Service SectorDocumento21 pagineTQM in Service SectorPushkar MathureNessuna valutazione finora

- Rittal 7955211 Instrucciones 3 5902Documento68 pagineRittal 7955211 Instrucciones 3 5902Elfy PalmaNessuna valutazione finora

- Lap Splices and DowelsDocumento4 pagineLap Splices and DowelsJaewoo ParkNessuna valutazione finora

- Migration Guide - PV+ 6 Terminals To PV+ 7 Terminals Catalog Number Conversions - 2711P-AP004B-EN-P - January 2017Documento24 pagineMigration Guide - PV+ 6 Terminals To PV+ 7 Terminals Catalog Number Conversions - 2711P-AP004B-EN-P - January 2017Nicolás A. SelvaggioNessuna valutazione finora

- xc8 v1.33 Full Install Release Notes PDFDocumento54 paginexc8 v1.33 Full Install Release Notes PDFG30nyNessuna valutazione finora