Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

LH307 PDF

Caricato da

Rigo McFly Casanova ArmijoTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

LH307 PDF

Caricato da

Rigo McFly Casanova ArmijoCopyright:

Formati disponibili

Technical Specification

LH307-15 Sandvik LH307

Technical Specification

2013-11-18

APPLICATIONS

Sandvik LH307 is a 6,7 tonnes Load-Haul-Dump (LHD) developed specially for underground use for the most diverse

application, including development work, mining and tunnelling construction.

Capacities Bucket Motion Times

Tramming capacity 6 700 kg 14 800 lb Raising time 6,5 sec

Break out force, lift 13 700 kg 30 200 lb Lowering time 3,8 sec

Break out force, tilt 11 400 kg 25 100 lb Dumping time 2,0 sec

Tipping load 16 070 kg 35 430 lb

Standard bucket 3,0 m3 3,9 yd3

Main dimensions Speeds Forward & Reverse (Level / Loaded)

Total length 8 631 mm 340 1st gear 4,8 km/h 3,0 mph

Maximum width 2 136 mm 84 2nd gear 9,5 km/h 5,9 mph

Height without safety 1 720 mm 68 3rd gear 15,9 km/h 9,9 mph

canopy 4th gear 26,4 km/h 16,4 mph

Height with safety canopy 2 212 mm 87

Sandvik Mining and Construction Reserves the right to change

this specification without further notice.

Sandvik Mining and Construction

PO. Box 434 20101 Turku Finland

Tel. +358 205 44 131Fax +358 205 44 130

www.sandvik.com 1/6

Technical Specification

LH307-15

Sandvik LH307

2013-11-18

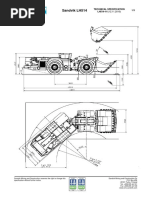

DIMENSIONS (SIDE VIEW)

4908 (193)

2324 (91)

3210 (126)

40

2212 (87)

1830 (72)

1647 (65)

557 (22)

45

13,3

(17)

440

640 312 274

(25) (12) (11)

972 (38)

2700 (106) 1760 (69) 1400 (55) 2771 (109)

8631 (340)

DIMENSIONS (TOP VIEW)

3660 (144)

2100 (83)

21 4)

36

(8

42,5

19

00

(7

5)

R3043 (1

R5812 (229) 2 0)

3660 (144)

Sandvik Mining and Construction Reserves the right to change this specification without further notice.

Sandvik Mining and Construction

PO. Box 434 20101 Turku Finland

Tel. +358 205 44 131Fax +358 205 44 130

www.sandvik.com 2/ 6

Technical Specification

LH307-15

Sandvik LH307

2013-11-18

POWER TRAIN

Engine STANDARD OPERATORS COMPARTMENT

Diesel engine Mercedes-Benz OM 906 LA ROPS/FOPS certified safety canopy

Output 150 kW (201 hp) @ 2 200 rpm Height 2 212 mm 87

Torque 750 Nm @ 1 400 rpm Width 2 136 mm 84

Number of cylinders In-line 6

Displacement 6 400 cm (409,6 in3)

Cooling system Water cooled

Combustion principle Direct injection, four stroke FRAME

Air filtration Dry type Rear and front Welded steel construction

Electric system 24 V frame

Emissions Tier III, Euro Stage 3 Central hinge Fully sealed, adjustable upper

Exhaust system Double wall exhaust pipe with bearing

catalytic purifier / muffler

Rear tanks, hydraulic tank and cabin base are welded to

Average Fuel 19,0 l/h (at 50% load)

frame

Consumption

Fuel Tank Capacity 210 l (55 gal) STEERING HYDRAULICS

Centre-point articulation, power steering with two double

Converter

acting cylinders. Steering system is equipped with electric

Dana C273,1 Single controlled joystick. Emergency steering is optional.

stage

Turning Radius

Transmission

Turning angle 42,5

Dana RT32421 Power shift transmission with Inner 3 043 mm 119

modulation, four gears forward Outer 5 812 mm 228

and reverse, automatic gear

control Main Components

Axles Main valve

Pilot control valve

Front axle Kessler D91, Spring applied

Steering cylinders 100 mm (3,9 )

hydraulic operated brakes, limited

Steering and pilot hydraulic Gear type

slip differential, fixed

pumps

Rear axle Kessler D91, Spring applied

hydraulic operated brakes, limited BUCKET HYDRAULICS

slip differential, oscillating 8

(with roller bearings) Monostick bucket and boom control (electric), equipped

with gear pump that delivers oil to the bucket hydraulic

Tires main valve. The oil flow from steering hydraulic pump is

Tire size 17.5x25 L5S, 20 ply directed to bucket hydraulics when steering is not used.

Brand and type subject to availability

Main Components

VEHICLE WEIGHTS Boom system Z-link

Lift cylinders 140 mm (5,5 )

Operating weights Dump cylinder 200 mm (7,9 )

Total operating weight 18 020 kg 39 730 lb Pilot control valve

Front axle 7 950 kg 17 500 lb Main valve

Rear axle 10 070 kg 22 200 lb Pump for bucket Gear type

hydraulics

Loaded weights Fittings ORFS

Total loaded weight 24 720 kg 54 500 lb Hydraulic oil tank 230 l (61,8 gal)

Front axle 18 050 kg 39 800 lb

Rear axle 6 670 kg 14 700 lb Oil cooler for hydraulic and transmission oil. Capability up

to 52C ambient temperature.

Sandvik Mining and Construction Reserves the right to change this specification without further notice.

Sandvik Mining and Construction

PO. Box 434 20101 Turku Finland

Tel. +358 205 44 131Fax +358 205 44 130

www.sandvik.com 3/ 6

Technical Specification

LH307-15

Sandvik LH307

2013-11-18

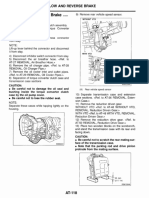

BRAKES

Service brakes are spring applied, hydraulically operated OTHER STANDARD EQUIPMENT

multidisc wet brakes on all wheels. Automatic central lubrication

Fire extinguisher, 12 kg (CEN)

Two independent circuits: one for the front and one for the Flashing beacon

rear axle. Neutral brake

Service brakes also function as an emergency and parking Wheel chocks and brackets

brake.

Electrically driven brake release pump Additional options

Automatic brake activation, ABA Emergency steering (CEN)

Fire suppression system ANSUL, 6 nozzles (CEN),

Main Components incl. auto engine shutdown

Pressure Piston type Fire suppression system ANSUL, 6 nozzles (CEN),

accumulator CHECKFIRE, incl. auto engine shutdown

Brake pedal valve Fire suppression system Sandvik FS1000 with auto

Charging valve engine shutdown

Cover grills for lamps

Gear limit (specify max gear to factory)

ELECTRICAL EQUIPMENT OPTIONAL

Spare rimEQUIPMENT

(17.5-25)

Alternator 24V 100A, Bosch Replaces standard (ride

Boom suspension equipment

control)

Batteries 2x 12V, 145Ah Driving bucket

Ejector direction lights

size 3,0 (red/green)

m (4,0yd), width 2100 mm

Starter 24V Bosch Wiggins

(83), fill set (hydraulic, transmission, engine oil)

HB500/400

Driving and working lights 2 pcs in front 65 W Wiggins

Side fuelbucket

tipping fill set 3.0m3

2 pcs in rear 65 W Jump start

Safety cabin, ROPS/FOPS, inc. A/C and radio/MP3-

2 pcs in canopy 65 W Accordance

player, with CE-norms

el. Steering & Bucket(CEN)

Control, height 2 250 mm

Parking lights 2 pcs in front, LED Pressure accumulator certificates

lights RRC HBC CAN complete

Brake lights RRC interface for HBC, analogue, not with automation

Blinkers RRC recovery kit (brake release by radio signal),

Electronic control system with 5,7 hook included

display and inbuild system Integrated scale

diagnostics Monitoring camera system

Tyre Pressure Monitoring System

SAFETY AND ERGONOMICS LinkOne electric spare part manual

Seat belt CatBase spare part manual

Lockable main switch Cabin heater

Reverse alarm (CEN)

External shutdown, 2 pcs in rear

Low frequency seat Alternative buckets

Material density 2,5 2,0 1,8

STANDARD MANUALS (t/m)

Instructions Manual Volume, heaped 2,7 3,3 3,7

- Operators Manual Hard copy, EU-languages (m)

- Maintenance Manual Hard copy, EU-languages Width(mm) 1 953 2 153 2 153

Parts Manual Hard copy, English

Service and Repair Hard copy, English

Manual

ToolMan CD (2pcs) Electronic, in pdf. format,

includes all the above

manuals

Sandvik Mining and Construction Reserves the right to change this specification without further notice.

Sandvik Mining and Construction

PO. Box 434 20101 Turku Finland

Tel. +358 205 44 131Fax +358 205 44 130

www.sandvik.com 4/ 6

Technical Specification

LH307-15

Sandvik LH307

2013-11-18

GRADE PERFORMANCE

Mercedes-Benz OM 906 LA, 150

kW

Calculated with 2% rolling

resistance

Without lock-up

Empty

Percent grade 0 2.0 4.0 6.0 8.0 10.0 12.5 14.3 17

Ratio 1:12 1:10 1:8 1:7

1st gear (km/h) 4,8 4,7 4,6 4,5 4,4 4,4 4,3 4,3 4,2

2nd gear (km(h) 9,7 9,3 9,1 8,9 8,7 8,5 8,3 8,1 7,5

3rd gear (km/h) 16,2 15,5 15,0 14,5 13,5 11,9 9,8 8,3

4th gear (km/h) 27,1 25,5 22,9 17,8 13,0

Loaded

Percent grade 0 2.0 4.0 6.0 8.0 10.0 12.5 14.3 17

Ratio 1:12 1:10 1:8 1:7

1st gear (km/h) 4,8 4,6 4,5 4,4 4,3 4,3 4,2 4,2 4,1

2nd gear (km(h) 9,5 9,1 8,8 8,6 8,4 8,0 7,2 6,5 5,4

3rd gear (km/h) 15,9 15,1 14,4 12,8 10,4 8,2

4th gear (km/h) 26,4 24,0 17,2 10,9

PRODUCTIVITY CURVE

Sandvik Mining and Construction Reserves the right to change this specification without further notice.

Sandvik Mining and Construction

PO. Box 434 20101 Turku Finland

Tel. +358 205 44 131Fax +358 205 44 130

www.sandvik.com 5/ 6

Technical Specification

LH307-15

Sandvik LH307

2013-11-18

TRACTIVE EFFORT CURVE

Sandvik Mining and Construction Reserves the right to change this specification without further notice.

Sandvik Mining and Construction

PO. Box 434 20101 Turku Finland

Tel. +358 205 44 131Fax +358 205 44 130

www.sandvik.com 6/ 6

Potrebbero piacerti anche

- TransmisioDocumento34 pagineTransmisioWilliams ArayaNessuna valutazione finora

- Epiroc Boomer s2Documento164 pagineEpiroc Boomer s2Jerson MieresNessuna valutazione finora

- Single Accumulator Charging Valve: Description and OperationDocumento6 pagineSingle Accumulator Charging Valve: Description and OperationWladimir Franz Rodríguez SaloméNessuna valutazione finora

- Preforadoras DS311Documento1 paginaPreforadoras DS311Gerardo RiosNessuna valutazione finora

- 81460229single Accumulator Charging ValveDocumento8 pagine81460229single Accumulator Charging ValveCésar Cusi LazoNessuna valutazione finora

- JCB Loadall 533: High Performance by DesignDocumento4 pagineJCB Loadall 533: High Performance by DesignFrancisco gajardoNessuna valutazione finora

- Operators Guide ST7 and ST7LPDocumento86 pagineOperators Guide ST7 and ST7LPRichard J. Castañeda Estrella100% (1)

- Datos Tecnicos LH202Documento8 pagineDatos Tecnicos LH202Roel Aroni CuaresmaNessuna valutazione finora

- Spare Parts List: Hydraulic BreakersDocumento40 pagineSpare Parts List: Hydraulic BreakersomertiryakimakineNessuna valutazione finora

- Atlas Copco Boomer L2C Hydraulic Diagrams & DrawingsDocumento43 pagineAtlas Copco Boomer L2C Hydraulic Diagrams & Drawingshaimay118Nessuna valutazione finora

- Sandvik Rd525 Rock Drill: Technical SpecificationDocumento2 pagineSandvik Rd525 Rock Drill: Technical SpecificationWaltherEnriqueAlcocerNessuna valutazione finora

- Bean Pump W11-Data SheetDocumento2 pagineBean Pump W11-Data SheetDamNessuna valutazione finora

- DS410 83100fDocumento4 pagineDS410 83100fzliang100% (1)

- Presiones Transmision R1300GDocumento12 paginePresiones Transmision R1300GgeniusnetxxxxNessuna valutazione finora

- Ficha Tecnica Alpha 30Documento7 pagineFicha Tecnica Alpha 30jonathan francisco allende escobarNessuna valutazione finora

- GHHDocumento20 pagineGHHdiegoNessuna valutazione finora

- Technical Specification Sandvik LH514-14Documento3 pagineTechnical Specification Sandvik LH514-14enriquerojoperez_539100% (2)

- Especificaciones DT820Documento5 pagineEspecificaciones DT820Jorge Cid BlancoNessuna valutazione finora

- LH410 18Documento3 pagineLH410 18JavierNessuna valutazione finora

- LH 514 Technical Specification Sandvik LH514-10Documento3 pagineLH 514 Technical Specification Sandvik LH514-10Emanuel Nicolas Villarruel100% (1)

- 13.atlas Copco ROCKET BOOMER E1-E2 SerijaDocumento8 pagine13.atlas Copco ROCKET BOOMER E1-E2 Serijaadamajaks1985Nessuna valutazione finora

- Sandvik Lh204 Underground Loader: Technical SpecificationDocumento7 pagineSandvik Lh204 Underground Loader: Technical SpecificationRigo McFly Casanova ArmijoNessuna valutazione finora

- 8999 3592 00 Diagrams and Drawings (3) - 1Documento98 pagine8999 3592 00 Diagrams and Drawings (3) - 1Ami Nicolas Concha ArnesNessuna valutazione finora

- 02-02 Boomer 282 - Valves Location On Hydraulic SchematicsDocumento11 pagine02-02 Boomer 282 - Valves Location On Hydraulic SchematicsRonald Perez OspinoNessuna valutazione finora

- Valvulas Joystic Parquer # Atlas CopcoDocumento52 pagineValvulas Joystic Parquer # Atlas CopcoRicardo Ramirez Estrello0% (1)

- Diamec Brochure PDFDocumento12 pagineDiamec Brochure PDFDangol RupeshNessuna valutazione finora

- CS 3001 Marketing PresentationDocumento15 pagineCS 3001 Marketing PresentationJailson Dantas100% (1)

- Sandvik Dd311 Development Drill: Technical SpecificationDocumento4 pagineSandvik Dd311 Development Drill: Technical SpecificationJuan David Rondinel BulejeNessuna valutazione finora

- Atlas Copco Scooptram: St2G Diagrams & DrawingsDocumento50 pagineAtlas Copco Scooptram: St2G Diagrams & Drawingsferdy ramosNessuna valutazione finora

- DD311 Planos HidráulicosDocumento8 pagineDD311 Planos HidráulicosBrayan vidal López GuzmánNessuna valutazione finora

- Sandvik LH203-11 PDFDocumento3 pagineSandvik LH203-11 PDFEstyNessuna valutazione finora

- Sistema Hco EJC 145 (Colores)Documento92 pagineSistema Hco EJC 145 (Colores)JorgeNessuna valutazione finora

- Manuel Partes ElectricoDocumento28 pagineManuel Partes ElectricoAndersonNessuna valutazione finora

- Scoop EJC145Documento8 pagineScoop EJC145kelvisbaNessuna valutazione finora

- 08 ST1030 Dump and Hoist - enDocumento25 pagine08 ST1030 Dump and Hoist - enGerardo HuertaNessuna valutazione finora

- Rotary HeadsDocumento1 paginaRotary HeadsmhasansharifiNessuna valutazione finora

- Electric Control Modulation ValveDocumento28 pagineElectric Control Modulation Valveahmad nur100% (1)

- EJC430Documento6 pagineEJC430Jose Luyo SanchezNessuna valutazione finora

- Operating ST1000-SN 281Documento102 pagineOperating ST1000-SN 281Rene Ramos MenesesNessuna valutazione finora

- Guide To Ejc 417 Hydraulic SystemDocumento50 pagineGuide To Ejc 417 Hydraulic SystemAnonymous VCvIxKNessuna valutazione finora

- Operation Manual Wj-3 LHDDocumento64 pagineOperation Manual Wj-3 LHDJopeth YoussefNessuna valutazione finora

- MT 5020/6020 TRAINING: Brake SystemDocumento48 pagineMT 5020/6020 TRAINING: Brake SystemFrancisco RojasNessuna valutazione finora

- T685WS11 05Documento2 pagineT685WS11 05govindsr0% (1)

- Atlas Copco Blasthole Drills Dm45-SeriesDocumento4 pagineAtlas Copco Blasthole Drills Dm45-SeriesfelipeNessuna valutazione finora

- Spraymec 6050 WPCDocumento3 pagineSpraymec 6050 WPCPatop CofréNessuna valutazione finora

- Cap.5 547705 High Pressure Cleaner HPW Manual ENGDocumento20 pagineCap.5 547705 High Pressure Cleaner HPW Manual ENGJoaquin CardenasNessuna valutazione finora

- Transmicion R1600Documento31 pagineTransmicion R1600Anonymous SxvgPDoEpNessuna valutazione finora

- GHH Fahrzeuge LF 3 Ac EN V1 16 2016 01 21Documento4 pagineGHH Fahrzeuge LF 3 Ac EN V1 16 2016 01 21Enrique CalquínNessuna valutazione finora

- Brochure Valvula Alivio 83948Documento4 pagineBrochure Valvula Alivio 83948Robert Karlo RodriguezNessuna valutazione finora

- Normet Concrete Transportation Offering-Product Presentation-2017Documento33 pagineNormet Concrete Transportation Offering-Product Presentation-2017pedroNessuna valutazione finora

- Alpha 20 Training Material Small FileDocumento68 pagineAlpha 20 Training Material Small Filemiguel100% (3)

- Operation ManualDocumento116 pagineOperation ManualEnrique MurgiaNessuna valutazione finora

- 90 400 - Funk X SpecDocumento3 pagine90 400 - Funk X SpecMATTHEWS HENRIQUE COTA ARAUJONessuna valutazione finora

- BrakeDocumento12 pagineBrakeJuan Guzmán100% (1)

- R1600H Sistema ImplementosDocumento31 pagineR1600H Sistema ImplementosLuis Angel Pablo Juan de Dios100% (1)

- Sandvik LH307: Technical SpecificationDocumento6 pagineSandvik LH307: Technical SpecificationRigo McFly Casanova ArmijoNessuna valutazione finora

- Sandvik LH203 15Documento6 pagineSandvik LH203 15seidualimatu8364Nessuna valutazione finora

- Sandvik LH203: Technical SpecificationDocumento6 pagineSandvik LH203: Technical SpecificationRigo McFly Casanova ArmijoNessuna valutazione finora

- Grove RT500D SpecDocumento14 pagineGrove RT500D SpecHoward HoacNessuna valutazione finora

- (LHD) Datasheet LH517Documento7 pagine(LHD) Datasheet LH517fik29100% (1)

- Yamana Mir - Final 1Documento44 pagineYamana Mir - Final 1Rigo McFly Casanova ArmijoNessuna valutazione finora

- nr22 EnglishDocumento34 paginenr22 EnglishRigo McFly Casanova ArmijoNessuna valutazione finora

- Cómo Llegar / How To Get: Free MapDocumento1 paginaCómo Llegar / How To Get: Free MapValenzuela WaleNessuna valutazione finora

- FotosDocumento1 paginaFotosRigo McFly Casanova ArmijoNessuna valutazione finora

- Sandvik TH315: Technical SpecificationDocumento6 pagineSandvik TH315: Technical SpecificationRigo McFly Casanova ArmijoNessuna valutazione finora

- Sandvik TH430: Technical SpecificationDocumento6 pagineSandvik TH430: Technical SpecificationRigo McFly Casanova Armijo0% (1)

- Sandvik Lh204 Underground Loader: Technical SpecificationDocumento7 pagineSandvik Lh204 Underground Loader: Technical SpecificationRigo McFly Casanova ArmijoNessuna valutazione finora

- PaginaDocumento1 paginaPaginaRigo McFly Casanova ArmijoNessuna valutazione finora

- Licencia TemporarDocumento1 paginaLicencia TemporarRigo McFly Casanova ArmijoNessuna valutazione finora

- Sandvik LH203: Technical SpecificationDocumento6 pagineSandvik LH203: Technical SpecificationRigo McFly Casanova ArmijoNessuna valutazione finora

- Sandvik LH307: Technical SpecificationDocumento6 pagineSandvik LH307: Technical SpecificationRigo McFly Casanova ArmijoNessuna valutazione finora

- Sandvik Lh201 Narrow Vein Loader: Technical SpecificationDocumento4 pagineSandvik Lh201 Narrow Vein Loader: Technical SpecificationRigo McFly Casanova Armijo50% (2)

- Opportunity CostDocumento14 pagineOpportunity CostAnonymous UmRfguyBhkNessuna valutazione finora

- Dec 12-12 Stall Concerns PDFDocumento2 pagineDec 12-12 Stall Concerns PDFRigo McFly Casanova ArmijoNessuna valutazione finora

- WHO TRS 684 SpaDocumento92 pagineWHO TRS 684 SpaRigo McFly Casanova ArmijoNessuna valutazione finora

- 3.0 Data Vent. 148 PG 900 HP 680 CFMDocumento1 pagina3.0 Data Vent. 148 PG 900 HP 680 CFMRigo McFly Casanova ArmijoNessuna valutazione finora

- Getting Started - DropboxDocumento6 pagineGetting Started - DropboxAnonymous Aeh0aDhF2Nessuna valutazione finora

- 100 Redox EquilibriaDocumento4 pagine100 Redox EquilibriaRigo McFly Casanova ArmijoNessuna valutazione finora

- Drawworks Operation Manual S0100707-OPM-200 - Rev. 0Documento46 pagineDrawworks Operation Manual S0100707-OPM-200 - Rev. 0Mohammad Usman100% (2)

- Baja SAE Tech Inspection Sheet 2014-2015Documento12 pagineBaja SAE Tech Inspection Sheet 2014-2015FoureyeddjNessuna valutazione finora

- LHD Sandvik 10 Ton LH400TDocumento8 pagineLHD Sandvik 10 Ton LH400THéctor Morales100% (2)

- PIAGGIO X10 500 Service Station ManualDocumento226 paginePIAGGIO X10 500 Service Station ManualMichaeluiMichaeluiNessuna valutazione finora

- 2012 Spec Shts-Hauler 800-E 8-4-11,0Documento6 pagine2012 Spec Shts-Hauler 800-E 8-4-11,0Forklift Systems IncorporatedNessuna valutazione finora

- EPL152 Operation ManualDocumento56 pagineEPL152 Operation ManualXULFATONessuna valutazione finora

- DFL1160 999系列 (KD5K) 使用手册 ENDocumento115 pagineDFL1160 999系列 (KD5K) 使用手册 ENlocario1Nessuna valutazione finora

- 2009 Polaris Ranger 500 4X4 EFI Service Manual PDFDocumento284 pagine2009 Polaris Ranger 500 4X4 EFI Service Manual PDFRogelio RuizNessuna valutazione finora

- Simulation of Energy Efficiency Improvements On Commuter Railways PDFDocumento9 pagineSimulation of Energy Efficiency Improvements On Commuter Railways PDF曾乙申Nessuna valutazione finora

- CASE WX145 165 185 ManualDocumento375 pagineCASE WX145 165 185 ManualКонстантин ГетьманNessuna valutazione finora

- All Lubrico Products - SEP2017Documento2 pagineAll Lubrico Products - SEP2017Mario CoronadoNessuna valutazione finora

- iAutoConnect Sellers 2022Documento135 pagineiAutoConnect Sellers 2022Arun KumarNessuna valutazione finora

- Van Ambulance Specification: Engine & TransmissionDocumento1 paginaVan Ambulance Specification: Engine & TransmissionWilfredo Gabata SinoyNessuna valutazione finora

- JDN Monocrane - Manufacturers of Overhead Lifting EquipmentDocumento19 pagineJDN Monocrane - Manufacturers of Overhead Lifting EquipmentJDN MonocraneNessuna valutazione finora

- OMLVU10940Documento140 pagineOMLVU10940drwskatefilmsNessuna valutazione finora

- Citaro K (Tech Info)Documento12 pagineCitaro K (Tech Info)Philippine Bus Enthusiasts SocietyNessuna valutazione finora

- CT3000 DynapacDocumento4 pagineCT3000 Dynapacyanwu shangNessuna valutazione finora

- Lift Schedule of Tender SpecificationDocumento33 pagineLift Schedule of Tender Specificationchia yeewahNessuna valutazione finora

- Parts Catalog: 1270D Wheel Harvester (0001-0997)Documento772 pagineParts Catalog: 1270D Wheel Harvester (0001-0997)NunesSergioNessuna valutazione finora

- Liebherr 794 Litronic BrochureDocumento20 pagineLiebherr 794 Litronic BrochureLiebherrNessuna valutazione finora

- Great Plains Parts Manual NTA607HD & NTA2007HDDocumento176 pagineGreat Plains Parts Manual NTA607HD & NTA2007HDa04205Nessuna valutazione finora

- Low and Reverse Brake: Automatic TransmissionDocumento7 pagineLow and Reverse Brake: Automatic TransmissionAnton FortovNessuna valutazione finora

- Ryme Veh Testing EqptDocumento103 pagineRyme Veh Testing EqptAnonymous I9qfl1agqBNessuna valutazione finora

- MODEL 1500: Manual No. TI065Documento154 pagineMODEL 1500: Manual No. TI065anon_947584266Nessuna valutazione finora

- Working Model of Manual Hand Stacker (Forklift)Documento43 pagineWorking Model of Manual Hand Stacker (Forklift)Ronak Gajjar100% (2)

- Elephant Catalog V13 PDFDocumento96 pagineElephant Catalog V13 PDFsamuelNessuna valutazione finora

- 2006 2008 Cbf1000 A 15 Rear Wheel SuspensionDocumento28 pagine2006 2008 Cbf1000 A 15 Rear Wheel SuspensionMurariu IonutNessuna valutazione finora

- GREAT WALL HOVER - Service - Manual PDFDocumento878 pagineGREAT WALL HOVER - Service - Manual PDFTeofilo Roman Reco MarinNessuna valutazione finora

- Karunakar Uk Rum 2015Documento7 pagineKarunakar Uk Rum 2015tsegayNessuna valutazione finora

- Multiple Disc Brake: Service InstructionsDocumento4 pagineMultiple Disc Brake: Service InstructionsMarcelo ArayaNessuna valutazione finora

- Strong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerDa EverandStrong Is the New Beautiful: Embrace Your Natural Beauty, Eat Clean, and Harness Your PowerValutazione: 4 su 5 stelle4/5 (5)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDa EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestValutazione: 4 su 5 stelle4/5 (28)

- ANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionDa EverandANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionNessuna valutazione finora

- The RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVDa EverandThe RVer's Bible (Revised and Updated): Everything You Need to Know About Choosing, Using, and Enjoying Your RVValutazione: 5 su 5 stelle5/5 (2)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDa EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerValutazione: 4.5 su 5 stelle4.5/5 (54)

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDa EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyValutazione: 5 su 5 stelle5/5 (1)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceDa EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceNessuna valutazione finora

- Automotive Electronic Diagnostics (Course 1)Da EverandAutomotive Electronic Diagnostics (Course 1)Valutazione: 5 su 5 stelle5/5 (6)

- CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Da EverandCDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]Valutazione: 5 su 5 stelle5/5 (2)

- Training for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersDa EverandTraining for the Uphill Athlete: A Manual for Mountain Runners and Ski MountaineersValutazione: 5 su 5 stelle5/5 (13)

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)Da EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)Nessuna valutazione finora

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisDa EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisValutazione: 5 su 5 stelle5/5 (1)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WDa EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WValutazione: 4.5 su 5 stelle4.5/5 (6)

- A Complete Guide to Safety Officer Interview Questions and AnswersDa EverandA Complete Guide to Safety Officer Interview Questions and AnswersValutazione: 4 su 5 stelle4/5 (1)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideDa EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideValutazione: 4.5 su 5 stelle4.5/5 (8)

- The Official Highway Code: DVSA Safe Driving for Life SeriesDa EverandThe Official Highway Code: DVSA Safe Driving for Life SeriesValutazione: 3.5 su 5 stelle3.5/5 (25)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsDa EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNessuna valutazione finora

![CDL Study Guide 2024-2025: Exam Prep Book With 425+ Questions and Explained Answers to Pass the Commercial Driver’s License Exam on Your First Try, With the Most Complete and Up-To-Date Practice Tests [Complete Version]](https://imgv2-1-f.scribdassets.com/img/audiobook_square_badge/710834945/198x198/00b81cbbd3/1714482720?v=1)