Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Factors Affecting Electrical Conductivity of Cu - 2011

Caricato da

ak_onweb0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

27 visualizzazioni1 paginaFactors Affecting Electrical Conductivity of Cu - 2011

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoFactors Affecting Electrical Conductivity of Cu - 2011

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

27 visualizzazioni1 paginaFactors Affecting Electrical Conductivity of Cu - 2011

Caricato da

ak_onwebFactors Affecting Electrical Conductivity of Cu - 2011

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

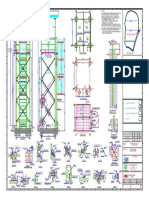

General Inuence of Impurities on Copper Conductivity Effect of Each Possible Impurity on Copper Resistivity Technology 11

Factors Affecting Electrical

Conductivity of Copper

Electrical conductivity is the reciprocal of resistivity. IACS is In accordance with ASTM specifications B 49 and

a calculated number that is obtained by dividing the Interna- B 193, Test Method for Resistivity of Electrical Conductor

tional Annealed Copper Standard (IACS) value for resistivity Materials, resistance measurements may be performed on

at 20 C by the measured resistivity of the wire at the same finished copper rod. However, in case of dispute, the rod is

temperature. Multiplication of this ratio by 100 produces to be cleaned and processed to a diameter of ~ 2 mm, and

percent IACS values. Electrical resistance is measured then annealed for 30 minutes at 500 C. Other equivalent

experimentally and it is dependent upon the dimensions annealing methods may be used. When performing conduc-

(diameter and length). In contrast to resistance, electrical tivity calculations, the copper resistivity standard value that

resistivity is an intrinsic property of the conductor and is is currently in use and was established by the International

associated with the ease with which conduction electrons Electrochemical Commission (IEC) in 1913, corresponds to

can move through the material under influence of an electric 100 % IACS. Since copper purity has improved significant-

field. There are three major influencers of resistivity, and ly since that time, commercial coppers have conductivities

impurities in the copper are one of the most important since approaching 102 % IACS. Only silver has higher conductivity,

every solute element increases resistivity linearly with increas- namely, 106 % IACS. by H. Pops

ing concentration. Impurities have their most potent effect

when they are dissolved in the copper solid solution, and are

less effective when they are present as oxides or intermetallic

compounds. The second influencer of (residual) resistivity

is attributed to structural imperfections such as dislocations,

which are produced in great numbers during work harden-

ing. Consequently, electrons can travel more easily through

the conductor when it is in the annealed condition. Electrical

conductivity of cold worked copper can be 3 % lower com-

pared with the same material in its annealed state. Tempera-

ture is the third major influencer of resistivity. Since atoms

vibrate at all temperatures above 0K, they increase resistivity

by scattering electrons. Because resistivity is strongly influ-

enced by temperature, corrections for temperature must be

made if resistance measurements are not conducted at 20 C.

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Jis D0202 - Udc 629 PDFDocumento17 pagineJis D0202 - Udc 629 PDFaditya bansalNessuna valutazione finora

- Material Selection Guide PDFDocumento86 pagineMaterial Selection Guide PDFpbsrivinay100% (1)

- SCDPL - C - DWG - 087 - Detailed Drawing For Watchtower - R00 20200615Documento1 paginaSCDPL - C - DWG - 087 - Detailed Drawing For Watchtower - R00 20200615Raviraj Thorat100% (1)

- Cambridge IGCSE: Combined Science 0653/42Documento21 pagineCambridge IGCSE: Combined Science 0653/42ردينه فايزNessuna valutazione finora

- PDF JoinerDocumento109 paginePDF JoinerOsama GamilNessuna valutazione finora

- Seydel Complete Chemistry For Denim2Documento4 pagineSeydel Complete Chemistry For Denim2İbrahim GüneşNessuna valutazione finora

- Comparative Life Cycle Environmental Assessment of CCS TechnologiesDocumento11 pagineComparative Life Cycle Environmental Assessment of CCS Technologiesmiguel_jose123Nessuna valutazione finora

- Science PortfolioDocumento12 pagineScience Portfolioapi-210690979Nessuna valutazione finora

- Study of Holding Time, Fade Effect and Microstructure in Ductile IronDocumento14 pagineStudy of Holding Time, Fade Effect and Microstructure in Ductile Irondemiancito06Nessuna valutazione finora

- Manufacturing Ammonia Using The Haber Process: BSC IllDocumento8 pagineManufacturing Ammonia Using The Haber Process: BSC Illdigukharade9848Nessuna valutazione finora

- Bonny Light Crude AssayDocumento2 pagineBonny Light Crude AssaySmitha MohanNessuna valutazione finora

- Hardener H1Documento7 pagineHardener H1Kate HdezNessuna valutazione finora

- MSDS - 3 Produced Water - TypicalDocumento5 pagineMSDS - 3 Produced Water - TypicalAnonymous LfeGI2hMNessuna valutazione finora

- 2011 - 08 - 17 Controlling Activated Sludge Bulking and Foaming - From Theory - To Practice by Marten - LynneDocumento25 pagine2011 - 08 - 17 Controlling Activated Sludge Bulking and Foaming - From Theory - To Practice by Marten - LynnePablo Santander AcevedoNessuna valutazione finora

- Calcium and Magnesium AAS ISO-7980-1986Documento8 pagineCalcium and Magnesium AAS ISO-7980-1986maría joséNessuna valutazione finora

- Development of Bioplastic From Lignocellulosic Biomass: Guided By: Dr. Heena Sood Presented By: Aakshat and Jyoti RaniDocumento26 pagineDevelopment of Bioplastic From Lignocellulosic Biomass: Guided By: Dr. Heena Sood Presented By: Aakshat and Jyoti RaniSandhya SharmaNessuna valutazione finora

- SART For Copper Control in Cyanide Heap Leaching: by M. Stewart, and D. KappesDocumento7 pagineSART For Copper Control in Cyanide Heap Leaching: by M. Stewart, and D. KappesVasily ShapovalenkoNessuna valutazione finora

- Material GTCDocumento47 pagineMaterial GTCremaNessuna valutazione finora

- Process Validation Final ReportDocumento9 pagineProcess Validation Final ReportShagorShagor75% (4)

- Tensile Strength of FibersDocumento15 pagineTensile Strength of FibersBharat PatelNessuna valutazione finora

- Johnson.C. Scientia.EDocumento9 pagineJohnson.C. Scientia.ETomas FloresNessuna valutazione finora

- Copper Alloy: Leaded Gun Metal Cusn5Zn5Pb5-CDocumento1 paginaCopper Alloy: Leaded Gun Metal Cusn5Zn5Pb5-CPankaj KumbhareNessuna valutazione finora

- Epoxy Paint Coal Tar (Black), Lead Paints, Chrome Free Paints, Polyurethane Coatings, Manufacturer, IndiaDocumento4 pagineEpoxy Paint Coal Tar (Black), Lead Paints, Chrome Free Paints, Polyurethane Coatings, Manufacturer, IndiaPritha DasNessuna valutazione finora

- Lecture 9 - The Amino Acids II - Acid-Base CharacteristicsDocumento33 pagineLecture 9 - The Amino Acids II - Acid-Base CharacteristicsThomas JonesNessuna valutazione finora

- Cor Cote HTDocumento4 pagineCor Cote HTlovaldes62Nessuna valutazione finora

- Melc Bow Grade 7 Q1W1 7Documento7 pagineMelc Bow Grade 7 Q1W1 7Barbs Castillo Paglinawan-PrincipeNessuna valutazione finora

- Aircraft Construction Mock Exam - Answer SheetDocumento5 pagineAircraft Construction Mock Exam - Answer SheetVandane ReyesNessuna valutazione finora

- Material Safety Data Sheet: Poly Aluminium ChlorideDocumento4 pagineMaterial Safety Data Sheet: Poly Aluminium ChlorideKusmianti DeoraNessuna valutazione finora

- Chemical For ConsumerDocumento13 pagineChemical For ConsumerNorsuriani AwangNessuna valutazione finora

- Exercise 10 - Amines, Amino Acids and ProteinsDocumento2 pagineExercise 10 - Amines, Amino Acids and Proteinskatealyssa_2028100% (1)