Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CMP Products - Wall Chart - Hazardous Area Cable Gland Selection Guide - Australian - 02-09

Caricato da

Gerrard ArchuletaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CMP Products - Wall Chart - Hazardous Area Cable Gland Selection Guide - Australian - 02-09

Caricato da

Gerrard ArchuletaCopyright:

Formati disponibili

CMP PRODUCTS

CABLE GLAND AND CABLE CONNECTION SPECIALISTS

SELECTION GUIDE FOR CMP CABLE GLANDS

IN HAZARDOUS AREAS

In accordance with equipment approvals to AS/NZS 60079.0, AS/NZS 60079.1, AS/NZS 60079.7, AS/NZS 60079.15,

Certified

installed in accordance with IEC 60079-14 and AS/NZS 2381.

Electrical

Equipment

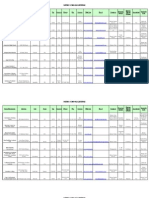

Typical Cable Constructions Equipment Selection Criteria

Triangle

of

Suitably

Carefully Compatibility Certified Equipment Product Certification Standards

Selected

Cable

Cable SWA Cable Protection Withdrawn

Gland Type of Equipment Protection Latest IEC Latest AS / NZS

Do you follow the Compatibility Triangle? Level Australian

For most types of (Gas) Standards Standards

Standards

-

As currently there are no AS/NZS or IEC certification standards for the construction or testing of cables for Hazardous Areas, the evaluation equipment protection

and selection of compatible equipment, cable and cable glands plays a crucial part in ensuring the safety of these installations. effective sealing by the General Requirements IEC 60079-0 AS 2380.1 AS/NZS 60079.0

cable entry device must Ex d Flameproof EPL Gb IEC 60079-1 AS 2380.2 AS/NZS 60079.1

be made on the part of

Ex e Increased Safety EPL Gb IEC 60079-7 AS 2380.6 AS/NZS 60079.7

the cable that enters the

electrical enclosure. This Ex ia EPL Ga

Intrinsically Safe IEC 60079-11 AS 2380.7 AS/NZS 60079.11

is particularly important Ex ib EPL Gb

Sealing Cables in Hazardous Areas for Ex d and Ex nR

enclosure types, but

Ex nA Non-Sparking

Ex nC Enclosed Break

cables should always be EPL Gc IEC 60079-15 AS 2380.9 AS/NZS 60079.15

carefully evaluated before Ex nL Energy Limitation

What is the Main Function of a Cable Gland? the appropriate cable Ex nR Restricted Breathing

glands are selected. Ex o Oil Immersion EPL Gb IEC 60079-6 No Standard AS/NZS 60079.6

Environmental Sealing Ring Earth Continuity by Means Explosion Protection by Ex m Encapsulation EPL Gb IEC 60079-18 AS 2431 AS/NZS 60079.18

Cable Inner Bedding is the

on the Cable Outer Sheath of Armour Clamping means of a Sealing Ring on Ex p Pressurisation EPL Gb IEC 60079-2 AS 2380.4 AS/NZS 60079.2

part of the cable entering

the Cable Inner Bedding the equipment enclosure Ex q Sand / Quartz Filled EPL Gb IEC 60079-5 No Standard AS/NZS 60079.5

Protection Equipment

EPL Group Performance of protection Zone Conditions of operation

Typical (SWA) Braided Cable afforded Protection Level

Two independent means of protection

Single Wire The cable entry device Very High EPL Ga Group II or safe even when two faults occur 0

Equipment remains functioning in

Zones 0, 1 and 2

Armour Cable must provide mechanical independently of each other.

cable retention by gripping Two independent means of protection

Equipment remains functioning in

the outer cable sheath in Very High EPL Da Group III or safe even when two faults occur 20

Zones 20, 21 and 22

the case of braided and independently of each other.

unarmoured cables, as Suitable for normal operation and

Equipment remains functioning in

Provides environmental protection by excluding dust and moisture from the electrical / instrument enclosure. defined in AS/NZS 60079.0 High EPL Gb Group II frequently occurring disturbances or 1

Zones 1 and 2

equipment where faults are normally

Facilitates earth continuity - in the case of armoured cables. Annex A (). The cable will

Suitable for normal operation and

also usually need to be Equipment remains functioning in

Provides a holding force on the cable to ensure cable pull out resistance. High EPL Db Group III frequently occurring disturbances or 21

clamped externally to Zones 21 and 22

equipment where faults are normally

Provides explosion protection at the cable entry point, by maintaining the integrity of the mating equipment via a ensure the safety integrity Equipment remains functioning in

of the installed equipment. Enhanced EPL Gc Group II Suitable for normal operation 2

gas-tight/flameproof seal. Zone 2

Equipment remains functioning in

The cable entry device shall always maintain the integrity of the equipment that it is connected to, including the Enhanced EPL Dc Group III Suitable for normal operation 22

Cable Outer Sheath Zone 22

ingress protection rating. Users should follow the prevailing Installation Standard, e.g. AS/NZS 2381 or IEC 60079-14.

Key to EPL Codes : G = Gas, D = Dust. For further information on cable glands certified for explosive dust hazards please consult CMP Products.

It is evident that some cables do not always resemble their corresponding design data sheets, or their catalogue illustrations when

considering shape, compactness, filler consistency, and uniformity of the inner bedding and overall diameters along the whole of the cable

Cable Glands for IEC protection concepts Ex d, Ex e, Ex n Compatibility of Equipment, Cable and Cable Gland length, or from drum to drum of the same cable. For these reasons relying only on data sheets for evaluation of the cable may lead to issues

of non compatibility and it is therefore recommended that for hazardous area installations, the cable is examined physically before a suitable

cable gland is chosen. The selected combination of cable and cable gland must maintain the integrity of the equipment installed, taking the

Equipment & Cable Gland Compatibility physical cable construction into account. Below are cross sectional illustrations of five cables that could be encountered during electrical

Cable Gland for cables entering Ex e equipment installations, but which would be suited to explosion protected equipment in hazardous area situations ?

In order to ensure the safety of installations and maintain the integrity of equipment in line with the corresponding certification

(Increased Safety Enclosure Type e) documents it is necessary always to consider the compatibility of the cable and the cable gland together with the associated equipment. Cable A Cable B Cable C Cable D Cable E

The Minimum Requirements for Ex e Cable Glands

It should be recognised that whilst there are no IEC hazardous area certification procedures for cables, the careful selection of cable

Impact Strength 7 Nm, plays a vitally important role in the compatibility analysis. For offshore and marine installations, IEC 61892-4 sets out to aid the selection

Outer Seal Entry Thread Sealing Washer process for cables. Graphical illustrations of some of the typical cable gland constructions available for three of the most common forms

Ingress Protection Rating IP54

Single Seal of equipment protection used in hazardous areas are shown opposite. Regardless of which brand of cable gland is to be used it is

important to follow the detailed requirements for selection which are described in the prevailing installation standard applicable to the

Notes

situation, e.g. IEC 60079-14 or AS/NZS 2381. Following only the information referenced in the equipment certification documents,

Trend is to use Double Seal (Inner/Outer). without consulting the installation requirements will usually result in non-conformance. For cables installed in conjunction with

Sealing Washer at cable entry interface is recommended. Flameproof Type d Enclosures, a representation of the AS/NZS 2381.2:2006 requirements is included below. Cable A would not allow a sealing ring to perform around it due to its incorrect non circular shape. Cables B, C & D do not have extruded inner

SWA bedding and, with the white areas representing gaps in the cable, fillers are not present, meaning that a sealing ring would not be effective for

Cable

Note : Whilst the minimum Ingress Protection rating to every type of equipment protection, and there would be a distinct possibility of gas migration along the cable length. Of these five cables Cable

Cables selected for hazardous areas should be evaluated carefully to ensure that they meet criteria laid down in the prevailing installation

achieve Ex e certification under AS/NZS 60079.7 is IP54, E is the only one that appears to have the correct construction properties as it has an extruded inner bedding which is substantially compact

standards. Clause 9.3 of IEC 60079-14 indicates that Cables with low tensile strength sheaths (commonly known as easy tear cables) and without any gaps.

it should be considered that the cable gland is required to shall not be used in hazardous areas unless installed in conduit. Clause 9.3.1 (a) of IEC 60079-14 states that Cables with

maintain the integrity of the equipment enclosure which is thermoplastic, thermosetting, or elastomeric material used for fixed wiring shall be circular, compact, have extruded bedding and fillers, Shielded or Screened Instrument Cables which have figure of eight twisted pairs are very rarely filled effectively along the cable length, so the

CMP CWe invariably higher. use of a cable gland with a sealing ring on the cable inner bedding may not be the correct choice when the cable enters Flameproof Type d,

if any, shall be non hygroscopic. Clause 10.4.2 (b) of IEC 60079-14 states that where a cable, in compliance with 9.3.1 (a) is Pressurised Type p, or Restricted Breathing Type nR enclosures. Special consideration should be given to the construction of optical fibre

substantially compact; a flameproof cable gland, in compliance with IEC 60079-1, may be utilized, providing this incorporates a sealing cables, and the selection of suitable cable glands for them.

It can also be noted that IEC 60079-14, section 11.3 states

ring and is selected in accordance with the flow chart below.

that threaded cable entry devices connected into threaded Please refer to the selection requirements of the prevailing Installation Standards, e.g. AS/NZS 2381.2:2006 as referenced below.

Outer Seal Entry Thread Sealing Washer

cable entry plates or enclosures of 6 mm or greater

thickness need no additional sealing between the cable

entry device and the entry plate or enclosure, providing the

axis of the cable entry device is perpendicular to the

external surface of the cable entry plate or enclosure. This

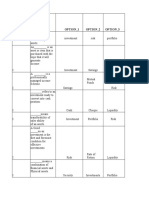

is true only when the cable entry device is correctly Flameproof Type d Compound Barrier Cable Glands Cable Gland selection according to AS/NZS 2381.2:2006 Section 3.6

tightened and the available thread engagement of the cable

Unarmoured

entry device is equal to, or greater than, the depth of

Cable

threads provided in the entry plate or enclosure. Compound Barrier Cable Gland for Armoured Cables Direct cable entries used in conjunction with Flameproof Type d enclosures

CMP Products recommends the use of a CMP Entry Thread Before selecting cable glands for use with hazardous area equipment the cable should be

Sealing Washer, which when installed at the cable entry Flame Path evaluated to ensure that it meets the particular requirements of AS/NZS 2381.2 as stated below

Exhaust Routes

CMP A2e or A2F * interface, between the equipment enclosure and the cable

entry device offers protection in excess of IP66. These

components have been independently 3rd party tested in

Alternative Double Seal Cable Gland Option, Type SS2K, is available for single Ingress Protection tests to IEC 60529. Where a cable that is sheathed with thermoplastic,

or double sheathed unarmoured cables. Direction of thermosetting, or elastomeric material is used and it is

Pressure, Flame

Cable Gland for armoured cables entering Ex d equipment & Hot Gases

circular, substantially compact, with extruded bedding, and

fillers, if any, are non-hygroscopic, a Flameproof Type d

Start

cable gland may be utilised provided that it is selected in

(Flameproof Enclosure Type d) The Minimum Requirements for Ex d Cable Glands

accordance with this flow chart

Screwed entry threads must maintain Flame Path.

Inner & Outer Seals

Barrier

Optional Entry Thread Sealing Washer 5 full threads engaged with mating equipment.

Inner Sealing Ring must be Flameproof & Gas Tight. CMP PX2K Flame Path Compound

Does this

Cables selected must prevent gas migration & Yes enclosure

No

explosion transmission. Compound Barrier Cable Gland for Unarmoured Cables contain an

Notes internal source

SWA

Trend has been to use Dual Certified Ex d / Ex e options Flame Path of ignition?

Cable Exhaust Routes

Conditions of Certification usually exist.

Installation standards, e.g. IEC 60079-14 or

AS/NZS 2381.2 must be carefully followed.

CMP E1FW *

Sealing Washers may be used but are not essential for

Direction of

this type of equipment protection.

Pressure, Flame Yes Does the No

& Hot Gases hazardous

Cable Gland for armoured cables entering Ex nR equipment gas require IIC

apparatus?

(Restricted Breathing Enclosure Type nR) The Minimum Requirements for Ex nR Cable Glands

Sealing Washer at cable entry interface is essential. Barrier

Inner & Outer Seals Entry Thread Sealing Washer

Restricted Breathing enclosure features of Ex nR CMP PXSS2K Flame Path Compound

equipment must be maintained by the cable entry.

Special vacuum test required to prove enclosure integrity The Minimum Requirements for Ex d Compound Barrier Cable Glands

including the cable entries. Yes Is the No Use a suitable

Screwed entry threads must maintain Flame Path. area of

Notes flameproof cable

Braided 5 full threads engaged with mating equipment. Installation

Cable Apply 10.4.2 d) or e) entry device with

Inner Sealing Ring must be air tight in two directions. # Any space in the Compound Tube must be completely filled with compound. zone 1?

In most cases this a sealing ring,

Some certified Flameproof Type d cable entries do not Notes e.g. for

effectively means

meet the test requirements for Ex nR equipment. The installation of compound barrier cable glands should always be carried out by a highly Non- armoured

the use of a flame

Sealing Rings in cable glands for use with braided cables competent person. proof cable entry cables CMP A2F

CMP T3CDS * must provide a holding force preventing the cable from The compound fill should represent not less than 20% of the capacity of the compound tube. or CMP SS2K and

device with a

being pulled out of the equipment The length of the applied compound shall not be less than 20 mm. compound barrier for Armoured

Sealing Washers may be used but are not essential for this form of protection. seal, e.g. for cables CMP

An Increased Safety (Type e) certified cable gland would not type seals. It should be recognised therefore that not all Ex d, or For ease of user equipment maintenance cable disconnection features are usually included Is the T3CDS, or CMP

Non-armoured

usually be suitable if the part of the cable entering the enclosure Ex e, or Dual Certified (Ex d & Ex e) cable glands are suitable for use in barrier type cable gland designs. cables CMP PXSS2K

Yes volume of No E1FW, or CMP

does not have a sealing ring applied to it. Similarly the sealing with the Restricted Breathing type nR equipment protection concept. CMP recommends, and the NEC requires, that any Flameproof or Explosion Proof cable entry with a the enclosure E1FX, or CMP

and for armoured

requirements for Ex nR enclosures are not always achieved with dis-connectable compound barrier seal, should incorporate a flame path between two metallic greater than E1FU, as shown

Please see further explanation on this subject below. cables CMP PX2K,

some Flameproof Type d cable gland types that include diaphragm components in the cable entry device. 2 litres? opposite

as shown opposite

Note: These CMP PX2K & PXSS2K cable glands are Triple Certified Ex d IIC, Ex e II & Ex nR II. Globally certified product

# If standardisation on one cable gland for both Ex d and Ex nR equipment is required. This condition applies to all types of equipment protection

versions are also available marked with Class I, Division 1 & 2, ABCD and Class I, Zone 1 & 2, AEx d IIC & AEx e II forms

* These cable glands are Triple Certified Ex d IIC, Ex e II & Ex nR II of protection in addition to the IEC Ex triple certification detailed above.

Restricted Breathing Ex nR Equipment Typical Installation Configurations Selection of CMP Products Hazardous Area Cable Glands, for Armoured Cables, in accordance with AS/NZS 2381.2.

Protection Method Type nR (Restricted Breathing Enclosure, from the Ex n Family). When the cable selected is substantially compact, circular with extruded bedding and fillers if any are non-hygroscopic, the following products may be used:-

Metallic Enclosure Light Duty Enclosure with

Usually Ex n equipment contains components that are non sparking, however some equipment with with Threaded Entry Through Clearance Hole

type of protection n can generate high temperatures internally. Recommended Cable Gland Type Options (please consult with CMP Products for information on other types of equipment protection and / or unarmoured cable gland requirements)

Optional Earth Tag* Serrated Washer

Optional Earth Tag*

Restricted Breathing equipment Type nR ensures that the flammable gas is kept away from any internal Locknut

Flameproof Type d (Ex d) Enclosure - Direct Cable Entry Flameproof Type d Enclosure -

hot surfaces. Some of the main characteristics of Ex nR Restricted Breathing equipment are as Restricted Breathing

follows: Gas Indirect Cable Entry Increased Safety Intrinsically Safe

Enclosure Type nR

Zone With Internal Ignition Source

Without Internal

Ex d or Ex de (Flameproof Type e Enclosure Type i Enclosure

(Ex nR) - Direct Cable

1. Usually light weight enclosure of metallic or non metallic construction.

Group Ignition Source

Type d with Increased Safety (Ex e) (Ex ia or Ex ib)

Entry

Issue 1 - 02/09 - Document Ref. TPC179 2009

Volume < 2 litres Volume > 2 litres Type e Terminal Chamber)

2. High Ingress Protection levels must be maintained.

3. Not designed to withstand explosion.

4. Enclosure must be tightly sealed and gasketed and not allowed to breathe freely. IIA CMP E1FW/X CMP CW/Xe, CMP CW/Xe,

5. Amount of gas allowed to penetrate the enclosure is insufficient to reach the Lower Explosive Optional Entry Thread Seal

CMP E1FU CMP E1FW/X, CMP E1FW/X, CMP C2K, CMP C2K,

Optional Entry Thread Seal

Limit (LEL), otherwise explosion could occur. Zone 1 IIB CMP T3CDS CMP PX2K/W/X CMP E1FU, CMP E1FU, CMP E1FW/X, CMP E1FW/X, NOT PERMITTED

CMP T3CDS CMP T3CDS CMP E1FU, CMP E1FU,

The principal of Ex nR protection is to ensure that a quantity of the flammable mixture, sufficient to CMP T3CDS CMP T3CDS

reach the Lower Explosive Limit (LEL), does not come in to contact with any internal ignition capable

Parallel threaded cable gland mounted Parallel threaded cable gland mounted in IIC CMP PX2K/W/X

equipment or hot surfaces. The equipment enclosure must be tightly sealed to achieve this and the in conjunction with a metallic enclosure conjunction with a metallic or non-metallic

cable glands selected must also maintain the same level of tight sealing as the equipment itself. This with threaded entry holes. enclosure with through clearance holes. IIA CMP E1FW/X, CMP E1FW/X, CMP CW/Xe, CMP CW/Xe,

involves the use of a two way air tight and gas tight sealing ring (#) around the cable which is intended CMP E1FU, CMP E1FU, CMP E1FW/X, CMP E1FW/X, CMP C2K, CMP C2K, CMP E1FW/X,

to prevent the passage of gas into the enclosure from the outside atmosphere. If the Restricted Zone 2 IIB CMP T3CDS CMP T3CDS CMP E1FU, CMP E1FU, CMP E1FW/X, CMP E1FW/X, CMP E1FU,

Breathing Type nR Enclosure has a facility for routine test following installation and maintenance an Note : The above illustrations are just two of a number of ways in which cable glands may be CMP T3CDS CMP T3CDS CMP E1FU, CMP E1FU, CMP T3CDS

in-situ test should be carried out with the cables and cable entries installed. If there is no facility for configured along with fixing and earthing accessories in industrial and hazardous area situations. CMP T3CDS CMP T3CDS

routine test provided with the equipment then CMP Products would recommend the use of a dedicated IIC CMP PX2K/W/X CMP PX2K/W/X

Ex nR certified cable gland. Users should always follow the prevailing wiring regulations and installation codes of practice.

Note : Where the cable is not effectively filled or a risk of gas migration through the cable exists a Compound Barrier Gland may be required when it would otherwise be unnecessary.

# If standardisation on one cable gland for both Ex d and Ex nR equipment is required.

OFFICES IN: NEWCASTLE DUBAI HOUSTON PERTH PUSAN SINGAPORE SHANGHAI

www.cmp-products.com.au

Printed in Australia

If you need advice on cable gland selection or installation for hazardous areas, contact the experts at CMP Products - Deliverer of Global Cable Connecting Solutions

Potrebbero piacerti anche

- XFBDocumento2 pagineXFBMikeCao1384Nessuna valutazione finora

- 196 Uploaded FileDocumento11 pagine196 Uploaded FileHoangNessuna valutazione finora

- CCH 06-2010 CatalogueDocumento120 pagineCCH 06-2010 CatalogueTudorache IulianNessuna valutazione finora

- Electrical Safety Manual Lockout TestDocumento217 pagineElectrical Safety Manual Lockout TestOscar Leonardo Rincon PulidoNessuna valutazione finora

- CompEx NA Course DescriptionsDocumento2 pagineCompEx NA Course DescriptionsDwi Mulyanti DwimulyantishopNessuna valutazione finora

- Intrinsic Safety MaintenanceDocumento2 pagineIntrinsic Safety MaintenanceRoadieNessuna valutazione finora

- Eex10506 Fund of Hazardous LocationsDocumento52 pagineEex10506 Fund of Hazardous LocationsHonesto BautistaNessuna valutazione finora

- Selection, Installation and Maintenance of Electrical Apparatus for Hazardous LocationsDocumento29 pagineSelection, Installation and Maintenance of Electrical Apparatus for Hazardous Locationskieran43100% (1)

- Calculating Arc Flash Hazards Below 240VDocumento2 pagineCalculating Arc Flash Hazards Below 240VSellappan MuthusamyNessuna valutazione finora

- BICON Prysmian Cable Gland Selection ChartDocumento1 paginaBICON Prysmian Cable Gland Selection ChartMadhavasrinivasan SathiamoorthyNessuna valutazione finora

- 3e-5 Motor Area Classification-Review Compare NEMA and IECDocumento46 pagine3e-5 Motor Area Classification-Review Compare NEMA and IECAlfredo Diaz HernandezNessuna valutazione finora

- Procom Ex certified antennas for hazardous environmentsDocumento8 pagineProcom Ex certified antennas for hazardous environmentsBao Quoc Mai100% (1)

- Australia New-Switchboards-Standards PDFDocumento5 pagineAustralia New-Switchboards-Standards PDFsurag1982Nessuna valutazione finora

- NEC and ATEXDocumento8 pagineNEC and ATEXRobin ZwartNessuna valutazione finora

- Title: Job Description: Ups Technician 8-Skilled ElectricalDocumento4 pagineTitle: Job Description: Ups Technician 8-Skilled ElectricalSundar ThangapandianNessuna valutazione finora

- Selection ChartDocumento2 pagineSelection Chartultrasonic81Nessuna valutazione finora

- Installation Instructions For CMP Cable Gland Types T3Cds & T3CdspbDocumento2 pagineInstallation Instructions For CMP Cable Gland Types T3Cds & T3CdspbLailyMLNessuna valutazione finora

- Factors Affecting StabilityDocumento8 pagineFactors Affecting StabilitySteve MusarurwaNessuna valutazione finora

- Nfpa 70EDocumento27 pagineNfpa 70EAlex Paul Fuentes FloresNessuna valutazione finora

- Electrical Safety ARC FLASH ANALYSISDocumento16 pagineElectrical Safety ARC FLASH ANALYSISOsha InstructorsNessuna valutazione finora

- 2 PDFDocumento10 pagine2 PDFPeter ManNessuna valutazione finora

- Certificate of Calibration and Conformance: OmicronDocumento1 paginaCertificate of Calibration and Conformance: OmicronNadiaNessuna valutazione finora

- CABLE FIL Standards Nema IecDocumento4 pagineCABLE FIL Standards Nema Iecconsultnadeem70Nessuna valutazione finora

- Fundamentals of A Motor Thermal Model and Its Applications in Motor ProtectionDocumento15 pagineFundamentals of A Motor Thermal Model and Its Applications in Motor Protectionnokdiego100% (1)

- Commissioning Switchgear Low Voltage and Circuit Breakers PDFDocumento59 pagineCommissioning Switchgear Low Voltage and Circuit Breakers PDFAhmed AlnagarNessuna valutazione finora

- ABB 615 Series IEC 60870-5-103 Communication Protocol Manual - D PDFDocumento40 pagineABB 615 Series IEC 60870-5-103 Communication Protocol Manual - D PDFSayed Younis SadaatNessuna valutazione finora

- 15 Saip 51Documento5 pagine15 Saip 51malika_00Nessuna valutazione finora

- Cooper - Intrinsic Safety GuideDocumento20 pagineCooper - Intrinsic Safety Guidetkdrt2166100% (2)

- Arc Flash Analysis IEEE Method Versus THDocumento11 pagineArc Flash Analysis IEEE Method Versus THByron CastanedaNessuna valutazione finora

- Iec 60947 2 2016 Amd1 2019Documento15 pagineIec 60947 2 2016 Amd1 2019Ye Min OoNessuna valutazione finora

- Session IV - O'ConnorDocumento18 pagineSession IV - O'ConnorMujeeb Ur Rehman KhalilNessuna valutazione finora

- Srd960 Srd991 Sil enDocumento16 pagineSrd960 Srd991 Sil enryg1360Nessuna valutazione finora

- Pip Elegl02 Arc Flash GuidlinesDocumento25 paginePip Elegl02 Arc Flash Guidlinesger80Nessuna valutazione finora

- ESB Networks Electrical Safety Rules 2006Documento36 pagineESB Networks Electrical Safety Rules 2006bdiaconu20048672Nessuna valutazione finora

- SIP5 ComProt V08.03 Manual C055-7 enDocumento368 pagineSIP5 ComProt V08.03 Manual C055-7 enMauro Lúcio SilvaNessuna valutazione finora

- 8BK88PLUSDocumento8 pagine8BK88PLUSSwapnil PatilNessuna valutazione finora

- Smartplant Instrumentation: Intrinsic Safety EquationsDocumento13 pagineSmartplant Instrumentation: Intrinsic Safety EquationsChristian100% (1)

- CompEx Ex11 CD PDFDocumento1 paginaCompEx Ex11 CD PDFVignesh Madhavan100% (2)

- Arc Flash Risk Assessment Draft Report - VB Engineering India PVT LTD PDFDocumento201 pagineArc Flash Risk Assessment Draft Report - VB Engineering India PVT LTD PDFSudhir SainiNessuna valutazione finora

- IEEE 2014 Paper - Infrared Windows Applied in Switchgear Assemblies - Taking Another LookDocumento6 pagineIEEE 2014 Paper - Infrared Windows Applied in Switchgear Assemblies - Taking Another Lookvenkat chakNessuna valutazione finora

- Communications Backbone CablingDocumento3 pagineCommunications Backbone CablingHumaid ShaikhNessuna valutazione finora

- 16 Samss 503Documento43 pagine16 Samss 503Florante Nobleza100% (2)

- 17 Samss 502Documento25 pagine17 Samss 502umerNessuna valutazione finora

- CompEx Exam1Documento8 pagineCompEx Exam1a.f.nakshaNessuna valutazione finora

- IEEE Standard Requirements For Instrument Transformers: SASO IEEE C 57:2018 IEEE C 57:2013Documento81 pagineIEEE Standard Requirements For Instrument Transformers: SASO IEEE C 57:2018 IEEE C 57:2013ivaneg825Nessuna valutazione finora

- techNOTE - Coding Principles of Beacons and Indicators PDFDocumento1 paginatechNOTE - Coding Principles of Beacons and Indicators PDFŽarko MočnikNessuna valutazione finora

- NETA Setting The Testing StandardsDocumento4 pagineNETA Setting The Testing StandardsJimmy LeeNessuna valutazione finora

- Shivam Compex 01 - 04 PDFDocumento1 paginaShivam Compex 01 - 04 PDFvenkateshNessuna valutazione finora

- As 60204.11-2006 Safety of Machinery - Electrical Equipment of Machines Requirements For HV Equipment For VolDocumento10 pagineAs 60204.11-2006 Safety of Machinery - Electrical Equipment of Machines Requirements For HV Equipment For VolSAI Global - APAC100% (1)

- 1tgc900009b0201 Mns Safety AspectsDocumento24 pagine1tgc900009b0201 Mns Safety AspectsOanh NguyenNessuna valutazione finora

- 1 2 3 4 5 CFC For S7 Continuous Function Chart Simatic: Appendices ManualDocumento126 pagine1 2 3 4 5 CFC For S7 Continuous Function Chart Simatic: Appendices ManualBatchmanNessuna valutazione finora

- CP 5001 Hazardous 5 Days CompEx Competence Based CourseDocumento1 paginaCP 5001 Hazardous 5 Days CompEx Competence Based CourseHan LesyNessuna valutazione finora

- Functional Safety A Complete Guide - 2020 EditionDa EverandFunctional Safety A Complete Guide - 2020 EditionNessuna valutazione finora

- Competency MatrixDocumento2 pagineCompetency MatrixravigurajapuNessuna valutazione finora

- Remote Telemetry For Industrial Gases - DPW900 - ANOVADocumento5 pagineRemote Telemetry For Industrial Gases - DPW900 - ANOVAsunshine dream50% (2)

- AWS D15.2 - 2003 Rec. Practicas Soldadura RielesDocumento50 pagineAWS D15.2 - 2003 Rec. Practicas Soldadura RielesmguilarNessuna valutazione finora

- L5 - Electronic Services Chronogram 2022-2023 - December 2022Documento1 paginaL5 - Electronic Services Chronogram 2022-2023 - December 2022KWITONDA AngeNessuna valutazione finora

- MITEC School List 101215Documento30 pagineMITEC School List 101215mymitecNessuna valutazione finora

- Sandpiper Product Catalog Rev0316Documento37 pagineSandpiper Product Catalog Rev0316Rathish RagooNessuna valutazione finora

- Qatar Mail IdsDocumento3 pagineQatar Mail IdsSINU . S0% (1)

- Topnir Shale OilDocumento32 pagineTopnir Shale OilGerrard ArchuletaNessuna valutazione finora

- Analyzer Technician Competency ModelDocumento31 pagineAnalyzer Technician Competency ModelGerrard ArchuletaNessuna valutazione finora

- Valero Emerson BlendingDocumento3 pagineValero Emerson BlendingGerrard ArchuletaNessuna valutazione finora

- Topnir BlendingDocumento6 pagineTopnir BlendingGerrard ArchuletaNessuna valutazione finora

- IQ Test Interview Questions and Answers Guide.: Global GuidelineDocumento7 pagineIQ Test Interview Questions and Answers Guide.: Global GuidelineGerrard ArchuletaNessuna valutazione finora

- Nuclear Magnetic ResonanceDocumento23 pagineNuclear Magnetic ResonanceGerrard ArchuletaNessuna valutazione finora

- 3 Ways To Check IQ and EQ in Interview - LinkedInDocumento7 pagine3 Ways To Check IQ and EQ in Interview - LinkedInGerrard ArchuletaNessuna valutazione finora

- Moistureiq Datasheet EnglishDocumento4 pagineMoistureiq Datasheet EnglishGerrard ArchuletaNessuna valutazione finora

- Topnir Crude OilDocumento6 pagineTopnir Crude OilGerrard ArchuletaNessuna valutazione finora

- Flyer 2 Sludge Level MeasurementDocumento2 pagineFlyer 2 Sludge Level MeasurementGerrard ArchuletaNessuna valutazione finora

- GE, DF868 User ManualDocumento91 pagineGE, DF868 User ManualGerrard ArchuletaNessuna valutazione finora

- En 305 Magflux Datasheet 1711Documento23 pagineEn 305 Magflux Datasheet 1711Gerrard ArchuletaNessuna valutazione finora

- List To Today For Sales EngineerDocumento1 paginaList To Today For Sales EngineerGerrard ArchuletaNessuna valutazione finora

- Flyer 4 Fdo-700 848-Kb Int PDFDocumento4 pagineFlyer 4 Fdo-700 848-Kb Int PDFGerrard ArchuletaNessuna valutazione finora

- Heated Tubing BrochureDocumento5 pagineHeated Tubing BrochureGerrard ArchuletaNessuna valutazione finora

- Optimized Acrylic Acid Reactor Design Increases Revenue 37Documento10 pagineOptimized Acrylic Acid Reactor Design Increases Revenue 37Gerrard ArchuletaNessuna valutazione finora

- Flyer 2 Sludge Level MeasurementDocumento2 pagineFlyer 2 Sludge Level MeasurementGerrard ArchuletaNessuna valutazione finora

- L29 K ValuecorrelationsDocumento29 pagineL29 K ValuecorrelationsGerrard ArchuletaNessuna valutazione finora

- Pgm-Ir Datasheet Rev2Documento2 paginePgm-Ir Datasheet Rev2Gerrard ArchuletaNessuna valutazione finora

- LICENSEDocumento7 pagineLICENSEkaelinfernoNessuna valutazione finora

- LICENSEDocumento7 pagineLICENSEkaelinfernoNessuna valutazione finora

- IT Company Supervisor Evaluation FormDocumento3 pagineIT Company Supervisor Evaluation FormGerrard ArchuletaNessuna valutazione finora

- Chapter 1Documento28 pagineChapter 1Gerrard Archuleta0% (1)

- Chapter 1Documento28 pagineChapter 1Gerrard Archuleta0% (1)

- Stat Prob Q3 Module 3Documento29 pagineStat Prob Q3 Module 3Reign Evans0% (1)

- Unit 4 Multiple Linear RegressionDocumento3 pagineUnit 4 Multiple Linear RegressionManchilot TilahunNessuna valutazione finora

- Vinyl ChlorideDocumento79 pagineVinyl ChlorideKunal Yadav100% (13)

- 219 Ho SBC (WJB) 9-30-02Documento36 pagine219 Ho SBC (WJB) 9-30-02arkhom1Nessuna valutazione finora

- The Iodine Clock Reaction LabDocumento3 pagineThe Iodine Clock Reaction LabVruti Shah100% (1)

- (WWW Vtuworld Com) Multimedia-Communication-Notes PDFDocumento220 pagine(WWW Vtuworld Com) Multimedia-Communication-Notes PDFAbhinavNessuna valutazione finora

- 01-03 GPON Basic ConceptsDocumento5 pagine01-03 GPON Basic ConceptsFabioAlmeidaNessuna valutazione finora

- Basic Blueprint ReadingDocumento219 pagineBasic Blueprint ReadingJShearer93% (15)

- Watzlawick 1967 Beavin Jackson Pragmatics of Human CommunicationDocumento288 pagineWatzlawick 1967 Beavin Jackson Pragmatics of Human CommunicationPhalangchok Wanphet100% (21)

- Mechanical Engineering Collection List 2017 1Documento33 pagineMechanical Engineering Collection List 2017 1Hanita SlaterNessuna valutazione finora

- MCQ Iapm Double Final 1Documento48 pagineMCQ Iapm Double Final 1moamen BNessuna valutazione finora

- Oscillating Universe TheoryDocumento1 paginaOscillating Universe TheoryArabella BasilioNessuna valutazione finora

- Physics 157 Homework 5 Thermodynamics SkillsDocumento5 paginePhysics 157 Homework 5 Thermodynamics SkillsSherin HamidNessuna valutazione finora

- TLC 549Documento19 pagineTLC 549Farhana ImronNessuna valutazione finora

- Rotational Motion (Practice Questions PDFDocumento46 pagineRotational Motion (Practice Questions PDFSakshamNessuna valutazione finora

- Suffah AcademyDocumento3 pagineSuffah AcademyMian Haroon SahilNessuna valutazione finora

- Soil Stabilization of Road by Using Spent WashDocumento7 pagineSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Natural Convection Heat Transfer Coe Cients in Phase Change Material (PCM) Modules With External Vertical FinsDocumento11 pagineNatural Convection Heat Transfer Coe Cients in Phase Change Material (PCM) Modules With External Vertical FinsResearcherzNessuna valutazione finora

- Igcse Chemistry SolutionsDocumento6 pagineIgcse Chemistry Solutionspreeti.2405Nessuna valutazione finora

- Danfoss RT101Documento7 pagineDanfoss RT101Thomas WilliamNessuna valutazione finora

- C Programming Basics: Structure and Sections of a Simple C ProgramDocumento2 pagineC Programming Basics: Structure and Sections of a Simple C Programshivu_bn5341Nessuna valutazione finora

- Fresh Water Generator On Ships 2Documento16 pagineFresh Water Generator On Ships 2Hamilton RamaNessuna valutazione finora

- IGCSE Physics Revision PlannerDocumento10 pagineIGCSE Physics Revision Plannerivan micoNessuna valutazione finora

- Active Directory Interview Questions and AnswersDocumento4 pagineActive Directory Interview Questions and AnswersUlaga NathanNessuna valutazione finora

- Design and Fluid Structural Interface Analysis of Marine PropellerDocumento67 pagineDesign and Fluid Structural Interface Analysis of Marine PropellerPavaniNessuna valutazione finora

- Polarity and Intermolecular ForcesDocumento59 paginePolarity and Intermolecular ForcesAntonio Louis LlarenaNessuna valutazione finora

- Lesson Plan4Documento3 pagineLesson Plan4api-410721710Nessuna valutazione finora

- Calculus For Engineers: Chapter 16 - Laplace TransformsDocumento41 pagineCalculus For Engineers: Chapter 16 - Laplace TransformsscreamNessuna valutazione finora

- TD InPro8000 Series TurbiditySensor en 52800246 May15Documento8 pagineTD InPro8000 Series TurbiditySensor en 52800246 May15Guy MesikaNessuna valutazione finora

- Ruukki - Panel Modelling With Revit RST 2012Documento33 pagineRuukki - Panel Modelling With Revit RST 2012Peter Poraj GórskiNessuna valutazione finora