Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Frozen Fish BGN Information 1

Caricato da

TinnysumardiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Frozen Fish BGN Information 1

Caricato da

TinnysumardiCopyright:

Formati disponibili

PT Inti Luhur Fuja Abadi, Pasuruan Doc. No.

MH/QA/02

Jl. Raya Cangkringmalang km 6 Beji Rev. No.

Pasuruan Effective Date July 06, 2010

Issued 5 th

BACKGROUND INFORMATION Page Page 1 of 5

MANUAL HACCP

1. BACKGROUND INFORMATION

1.1. COMPANY VISION, MISSION and MOTTO

VISION

PT. Inti Luhur Fuja Abadi is processor and exporter marines products

which should be using sustainable resource of marine.

The Vision is based on the need to harmonize the development

orientation between economic, socio-cultural, terrestrial paradigm and

marine of Indonesia.

MISSION

Increase productivity and make improvement to produce the good

quality products.

Always put customer satisfaction as our top priority.

MOTTO

Quality is our priority

Approved by, Verified by, Prepared by,

Adhie P. Nugraha Budi E. Prasetya Herwanto

PT Inti Luhur Fuja Abadi, Pasuruan Doc. No. MH/QA/02

Jl. Raya Cangkringmalang km 6 Beji Rev. No. 1

Pasuruan Effective Date July 28, 2011

Issued 5 th

BACKGROUND INFORMATION Page Page 2 of 5

MANUAL HACCP

1.2. COMPANY PROFILE

a. Name of Company PT. INTI LUHUR FUJA ABADI

b. Company Address JL.RAYA CANGKRINGMALANG KM 6,

KECAMATAN BEJI- PASURUAN 67154

EAST JAVA INDONESIA

c. Responsibility of Plant Juddy Ang and Adhie P. Nugraha

d. Consumers Complaint Juddy Ang and Adhie P. Nugraha

e. Telephone Number/ Email (62) (343) 656275

intiluhur@yahoo.com

f. Facsimile (62) (343) 656390

g. Name of Processing Plant PT. INTI LUHUR FUJA ABADI

h. Plant Address JL.RAYA CANGKRINGMALANG KM 6,

KECAMATAN BEJI- PASURUAN 67154

EAST JAVA INDONESIA

i. Telephone Number (62) (343) 656275

j. Facsimile (62) (343) 656390

k. Approval Number (UE) 242.13.B.

Korean Register 15.54

China Register CR-056.16

USA Register FDA REG NO. 18705728712

Vietnam Register VR. B-083-16

Approved by, Verified by, Prepared by,

Adhie P. Nugraha Budi E. Prasetya Herwanto

PT Inti Luhur Fuja Abadi, Pasuruan Doc. No. MH/QA/02

Jl. Raya Cangkringmalang km 6 Beji Rev. No.

Pasuruan Effective Date July 06, 2010

Issued 5 th

BACKGROUND INFORMATION Page Page 3 of 5

MANUAL HACCP

1.3 ORGANIZATION PLANT

PRESIDENT DIRECTOR

DIRECTOR

Quality Assurance Plant Manager Marketing Accounting

Manager Manager Manager

Productions Technical Human Purchasing

Department Department Resource Department

Department

QC QC

Sanitation QC Receiving

Production Documentation

Hygiene/ Laboratory

SSOP & Packing

Processing

Freezing

Raw Material In-Process Finished Product

Evaluations Evaluations Evaluation

Packing

Cold Storage &

Export

Approved by, Verified by, Prepared by,

Adhie P. Nugraha Budi E. Prasetya Herwanto

PT Inti Luhur Fuja Abadi, Pasuruan Doc. No. MH/QA/02

Jl. Raya Cangkringmalang km 6 Beji Rev. No. 1

Pasuruan Effective Date January 12, 2012

Issued 5 th

BACKGROUND INFORMATION Page Page 4 of 5

MANUAL HACCP

1.4 FOOD SAFETY TEAM

NO NAME POSITION EDUCATION WORK EXPERIENCE

1. Ir. Adhie P. Nugraha Director S-1 Teknik Kimia, UWM PT. Inti Luhur Fuja Abadi,

Surabaya, 1991 (1999-present)

2. Ir. Budi E. Prasetya Plant Manager S-1 Teknologi Pertanian Tenaga Pengajar MTS & MA

UGM, 1988 Hasyim Ashari, Sukodono,

Sidoarjo (1988-92)

PT. Bumi Mas Indah/ PT. Inti

Luhur Fuja Abadi, (1992-

present)

3. Herwanto, S. Pi. Quality Assurance S-1 Perikanan / THP PT. Inti Luhur Fuja Abadi, -Diklat HAC

Unibraw, 2000 (2000-present) - Semnas ttg

Kasubdit Pen

-Advanced T

Affairs of Fis

4. Muhaimin MS Chief of Production SLTA Sidoarjo PT. Inti Luhur Fuja Abadi,

(2000-present)

5. Mahmud T. QC of Production & SLTA Pasuruan PT. Inti Luhur Fuja Abadi, -

Packing (1992-present)

6. Herlin Q.A, S.Pi. QC of Laboratory S-1 Perikanan / THP PT. Inti Luhur Fuja Abadi, -Diklat HAC

Unibraw, 2011 (2012-present)

7 Atmo Sunoyo QC of Sanitasi & SLTA Pasuruan PT. Inti Luhur Fuja Abadi,

Hygiene / SSOP (1991-present)

8 Samian Chief of Technique STM Pasuruan,1975 PT. Inti Luhur Fuja Abadi, -

(1991-present)

Approved by, Verified by, Prepared by,

Adhie P. Nugraha Budi E. Prasetya Herwanto

PT Inti Luhur Fuja Abadi, Pasuruan Doc. No. MH/QA/02

Jl. Raya Cangkringmalang km 6 Beji Rev. No. 1

Pasuruan Effective Date January 12, 2012

Issued 5 th

BACKGROUND INFORMATION Page Page 5 of 5

MANUAL HACCP

1.5 JOB DESCRIPTION

No Name Position Job Description

1 Adhie P Nugraha Director -To ensure the HACCP system had been implement, maintenance and update.

-Coordinate and manage the activity member of HACCP Team.

-To ensure every member of HACCP Team have skill and knowledge that

needed to implement HACCP system..

2 Budi E Prasetya Plant Manager -Coordinate and manage the activity member of HACCP Team.

-To ensure every member of HACCP Team have skill and knowledge that needed

to implement HACCP system.

3 Herwanto QA Manager -Coordinate and manage the activity member of HACCP Team.

-To ensure every member of HACCP Team have skill and knowledge that needed

to implement HACCP system.

-Understand, comprehend and analyze specification amendment and monitor the

amendment of manual.

-Report the effectiveness and suitability HACCP system to Top Management.

4 Muhaimin MS Chief of - Monitor employee activities in order to meet GMP-HACCP standard.

Production

-- Analyze production process result, discussed it then give suggestion for

improvement.

- Coordinate inters section in production to achieve optimum work of good

production team.

- Motivate and improve ability and skill of employee at each production section.

- Analyze work condition and production process on matters happen mostly or

rarely.

- Monitoring production lay out area.

- Give input to improvement HACCP system according Production Dept.

5 Mahmud T. QC.of Production - Monitoring CCP and motivate employee in implementation company policy in

& Packing

order to achieve product quality based on specification .

- Observation and direction production staff in performing production activities

to produce good quality product.

-Ensuring finished product is suitable with buyers specification.

- Give input to improvement HACCP system according QC Dept.

6 Herlin Qurrotul QC of - Inspection & Analysis sample product (organoleptic, microbiology, kimia &

Aini Laboratory

fisika) from receiving raw material until end product

7 Atmo Sunoyo QC of Sanitation - Control and monitor cleanliness at all section including :

& Hygiene/

SSOP Uniform cleanliness, Equipment cleanliness, Production area cleanliness, Change

cloth room cleanliness, Toilets cleanliness

- Control & monitor in-out of every employee on production area, especially from

toilet based on company rule.

- Control, arrange and monitor chemical usage.

- Monitor and analyze pest activities at each company area.

- Give input to improvement HACCP system according Sanitation Dept.

8 Samian Chief of - Prepare schedule planning both routine & non-routine about operational

Technique

activities of mechanical engineering such as preventive maintenance, daily

maintenance, repair, innovation project and improvement project toward machine

and equipment condition in PT ILUFA.

- Record machine & equipment based on brand, year of purchace, specification,

capacity and function.

- Analyze machine & equipment condition based on machine history, machine

maintenance periodic schedule and broken spare part replacement.

Approved by, Verified by, Prepared by,

Adhie P. Nugraha Budi E. Prasetya Herwanto

Potrebbero piacerti anche

- Biodegradability of SurfactantsDocumento1 paginaBiodegradability of SurfactantsTinnysumardiNessuna valutazione finora

- Federal Register / Vol. 60, No. 183 / Thursday, September 21, 1995 / Proposed RulesDocumento2 pagineFederal Register / Vol. 60, No. 183 / Thursday, September 21, 1995 / Proposed RulesTinnysumardiNessuna valutazione finora

- Calibration, Validation and Verification of Equipment, Instruments and Other DevicesDocumento2 pagineCalibration, Validation and Verification of Equipment, Instruments and Other DevicesTinnysumardiNessuna valutazione finora

- Zoning in Processing Facilities 375003 7Documento2 pagineZoning in Processing Facilities 375003 7TinnysumardiNessuna valutazione finora

- Minireview Escherichia Coli in The Environment: Implications For Water Quality and Human HealthDocumento8 pagineMinireview Escherichia Coli in The Environment: Implications For Water Quality and Human HealthTinnysumardiNessuna valutazione finora

- Rlu PDFDocumento7 pagineRlu PDFTinnysumardiNessuna valutazione finora

- Escherichia Coli O157:H7 Issues and Ramifications: Executive SummaryDocumento12 pagineEscherichia Coli O157:H7 Issues and Ramifications: Executive SummaryTinnysumardiNessuna valutazione finora

- BookDocumento155 pagineBookTinnysumardiNessuna valutazione finora

- Escherichia Coli O157:H7 Strains Isolated From EnvironmentalDocumento7 pagineEscherichia Coli O157:H7 Strains Isolated From EnvironmentalTinnysumardiNessuna valutazione finora

- Monitoring Suhu Dan RH WH Starch 2Documento4 pagineMonitoring Suhu Dan RH WH Starch 2TinnysumardiNessuna valutazione finora

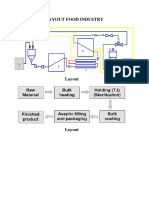

- Layout Food IndustryDocumento2 pagineLayout Food IndustryTinnysumardiNessuna valutazione finora

- Infant Formula RecallDocumento4 pagineInfant Formula RecallTinnysumardiNessuna valutazione finora

- International Formula Council: Formerly The Enteral Nutrition Council and Infant Formula CouncilDocumento6 pagineInternational Formula Council: Formerly The Enteral Nutrition Council and Infant Formula CouncilTinnysumardiNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Reason: God Had Made The Mistake of Sending Only 70 PesosDocumento2 pagineReason: God Had Made The Mistake of Sending Only 70 PesosS Vaibhav81% (21)

- Modeling of Conducted EMI (Model Motor Simulink Bun)Documento8 pagineModeling of Conducted EMI (Model Motor Simulink Bun)Ioan ŢileaNessuna valutazione finora

- Air Cooler With Checking DoorDocumento2 pagineAir Cooler With Checking DoorSuraj KumarNessuna valutazione finora

- Volume 2 Part 1 - Civil & Arch SpecificationsDocumento173 pagineVolume 2 Part 1 - Civil & Arch Specificationsanish100% (1)

- Monitoring:: Steps of Adding New SiteDocumento8 pagineMonitoring:: Steps of Adding New SiteMohammad ZakoutNessuna valutazione finora

- Driver DST-4812 For 7.2 KG CMDocumento5 pagineDriver DST-4812 For 7.2 KG CMWWW.150775.BUGME.PWNessuna valutazione finora

- The Pole and Zeros PDFDocumento24 pagineThe Pole and Zeros PDFKim KeatNessuna valutazione finora

- Vargas, Bartolome Dr. Thornton, Karen 17675251Documento1 paginaVargas, Bartolome Dr. Thornton, Karen 17675251ahmedNessuna valutazione finora

- Rightship Ship Inspection Questionnaire RISQDocumento177 pagineRightship Ship Inspection Questionnaire RISQИгорь100% (3)

- Welrod Silenced PistolDocumento2 pagineWelrod Silenced Pistolblowmeasshole1911Nessuna valutazione finora

- Watercolor SecretsDocumento60 pagineWatercolor Secretsmissdoisneau98% (47)

- BiosintezaDocumento8 pagineBiosintezaLovin BiancaNessuna valutazione finora

- 801 Aeronca PDFDocumento17 pagine801 Aeronca PDFVishveshNessuna valutazione finora

- NHouse SelfBuilder Brochure v2 Jan19 LowresDocumento56 pagineNHouse SelfBuilder Brochure v2 Jan19 LowresAndrew Richard ThompsonNessuna valutazione finora

- Module 1 Hvac Basics Chapter-1Documento5 pagineModule 1 Hvac Basics Chapter-1KHUSHBOONessuna valutazione finora

- Elements, Compounds, MixturesDocumento35 pagineElements, Compounds, MixturesNorvieNessuna valutazione finora

- 31. (NÂNG CAO) Đề soạn theo cấu trúc minh họa 2021 - Tiếng Anh - Đề 31 - DươngDocumento15 pagine31. (NÂNG CAO) Đề soạn theo cấu trúc minh họa 2021 - Tiếng Anh - Đề 31 - DươngNguyễn Quế Anh100% (1)

- Classic Plan: Dog/Cat BedDocumento3 pagineClassic Plan: Dog/Cat BedRobson DiasNessuna valutazione finora

- Nav Bharat Nirman: Indispensable Ideas For Green, Clean and Healthy IndiaDocumento4 pagineNav Bharat Nirman: Indispensable Ideas For Green, Clean and Healthy IndiaRishabh KatiyarNessuna valutazione finora

- B2 - Effects of UV-C Treatment and Cold Storage On Ergosterol and Vitamin D2 Contents in Different Parts of White and Brown Mushroom (Agaricus Bisporus)Documento6 pagineB2 - Effects of UV-C Treatment and Cold Storage On Ergosterol and Vitamin D2 Contents in Different Parts of White and Brown Mushroom (Agaricus Bisporus)Nadya Mei LindaNessuna valutazione finora

- Toolbox Talks Working at Elevations English 1Documento1 paginaToolbox Talks Working at Elevations English 1AshpakNessuna valutazione finora

- Heron's Formula For The Area of A Triangle - Shailesh A ShiraliDocumento9 pagineHeron's Formula For The Area of A Triangle - Shailesh A ShiraliAltananyNessuna valutazione finora

- Modeling The Dynamic and Static Behavior of Chemical ProcessesDocumento4 pagineModeling The Dynamic and Static Behavior of Chemical ProcessesFatma CahyaniNessuna valutazione finora

- Reflection in SystemsDocumento1 paginaReflection in SystemsGeraldine PadillaNessuna valutazione finora

- Learning Guide: Central Texas College Department of NursingDocumento26 pagineLearning Guide: Central Texas College Department of Nursingapi-3697326Nessuna valutazione finora

- Evaluation of Global Research Trends in The Area of Food Waste D - 2020 - Food CDocumento10 pagineEvaluation of Global Research Trends in The Area of Food Waste D - 2020 - Food CAliNessuna valutazione finora

- Bio-Rad D-10 Dual ProgramDocumento15 pagineBio-Rad D-10 Dual ProgramMeesam AliNessuna valutazione finora

- Chapter - 2 - Unit Hydrograph2Documento33 pagineChapter - 2 - Unit Hydrograph2Abhilekh PaudelNessuna valutazione finora

- AD&D - Forgotten Realms - Menzoberranzan - EXTRAS - House Do'Urden RestrospectiveDocumento16 pagineAD&D - Forgotten Realms - Menzoberranzan - EXTRAS - House Do'Urden RestrospectiveThiago RaulinoNessuna valutazione finora

- Medgroup Packet Tracer Skills Integration Challenge: - Design and Prototype The New Medgroup TopologyDocumento4 pagineMedgroup Packet Tracer Skills Integration Challenge: - Design and Prototype The New Medgroup TopologyvilanchNessuna valutazione finora