Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

What I Wish I Knew

Caricato da

Benard OmondiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

What I Wish I Knew

Caricato da

Benard OmondiCopyright:

Formati disponibili

September 2005

Quality Corner

What I Wish I Knew Then

What every structural engineer should know about AISC Certification.

By Brian Raff

W

hen I was a practicing These questions seem so trivial, but it Skidmore test (which I didnt know any-

engineer, I didnt know makes sense that every company should thing about), and demonstrate bolt test-

much about AISC Certifi- be able to answer them for every single ing procedures on site that conform to

cation or how it affected one of their operational activities. These RCSC (Research Council on Structural

my projects. I would use four questions are the heart of what AISC Connections) standards. In case youre

the firms typical standard specification Certification is all about. wondering, too, according to the Bolt Sci-

for each project and omit the material sec- As engineers, we want to make sure ence glossary, a Skidmore-Wilhelm bolt

tions that didnt apply. At the time, I was that what gets built in the field is exactly tension calibrator is a hydraulic load cell

uneducated as to what AISC Certification what we show in our details and plans. used to determine the tension in a bolt

meant, and I certainly didnt realize what By looking at those four simple questions, or other threaded fastener. The tension in

impact it had on our Quality Assurance one can begin to understand the types of the bolt compresses fluid in a hydraulic

section of the project specification (1.6 in things QMCs auditors look for in the cylinder; a pressure gauge connected to

section 5120Structural Steel). Looking shop or on a construction site. the cylinder is then calibrated to read in

back, there are a number of things that I terms of force rather than pressure.

wish I had known, and the most impor- The auditor asks these and many

tant is that structural engineers play one other questions to ensure that all of the

of the most significant roles in overall

Specifying required information for a particular pro-

project quality.

AISC Certification cedure is on site, available, and that the

procedural information has been docu-

Whats in an audit? is one of the only mented and conveyed appropriately to

If you have been following Quality the staff.

Corner in Modern Steel Construction these ways to really know

last few months, then you probably have Welding looks so easy...

a fair understanding of what AISC Certi- that your structural Another important audit topic was

fication is all about. It involves a rigorous welding. QMC auditors not only spoke

audit to evaluate a companys quality design will be to the individual welders about how they

management system. But, what exactly perform their workand how they check

does being audited mean, and why realized in the field. their workbut also asked the manage-

would that be important for a structural ment to show that they have their weld-

engineer to know? ing procedures documented, and that

Recently, I had the opportunity to ob- they have all the appropriate paperwork

serve audits for both steel fabricators and Its just a bolt, right? that proves their employees are qualified

steel erectors. I realized afterward that I As a simple example, lets look at the by the American Welding Society (AWS)

had learned more about steel fabrication auditing process for bolt installation. On to perform the work. Auditors wanted

and erection on those two trips than I did a fabricator audit, an auditor might ask, to know if their welding electrodes were

working for years as a practicing engi- What type of bolts are being used on this kept in an oven, and at what temperature.

neer. project, and how do you know? Is this This ensured that excess moisture was

What I found amazing was the sim- information written down somewhere? not being held in by the electrodes, since

plicity in the questions pertaining to such Where are these bolts stored? How do coatings on welding electrodes rapidly

an important audit: you know which material and what size absorb atmospheric moisture once they

How does something get done? bolts are required for this particular proj- are removed from factory tins.

Who is responsible for checking that it ect? Can you describe and show me an When a moisture-contaminated elec-

gets done correctly? example of what your bolt tightening trode is used in the welding process, hy-

How does one go about checking it? procedures are? drogen is released into the metal when

How is a situation dealt with if a mis- Many times the auditor will actually heat is applied. When the weld cools it

take is made? require the shop employee to set up a can become brittle, crack, and/or develop

September 2005 Modern Steel Construction

pinholes. Auditors also wanted to know are being asked to lower the quality on is the only way to communicate to you

the amperage settings on their welding their project and take a chance. that they have the knowledge, training,

machines, how the welders knew which Because I wasnt aware of the intrica- and skills to provide you the professional

settings to use, and if those settings con- cies of AISC Certification when I was a service that you expect.

formed to the procedures written down practicing engineer, I was unprepared to Certification is the root of communi-

in the companys quality manual. defend my projects against the pressures cation for almost every known profes-

The auditors asked questions that, of waiving these certification require- sion. How does an owner know that you,

as an engineer, I just took for granted ments. Ultimately, it is the owners deci- as a structural engineer, are qualified?

or never even thought to ask. I would sion to keep these requirements, and it is Your state issued license, right? Why

specify a specific grade of material, cer- up to the specifier, as well as other mem- would you allow a non-certified fabri-

tain weld sizes, or perhaps even a certain bers of the project team, to educate the cator to work on your project without a

bolt type. But I never thought about how owner on the potential pitfalls of waiving license stating that they are qualified to

I could be sure all of these requirements the certification requirement. One other do the work? As a profession, structural

were met, and what documented steps thing I was not aware of was that there engineers are responsible for the safety

were being taken to avoid mistakes. are people at AISC who are there to help of many lives, and this same responsibil-

To me, specifying certification is really when it comes to defending your certifi- ity can only be realized by the participa-

one of the only ways to really know that cation requirements. Visit www.aisc.org/ tion of every member of a project team.

your structural design will be realized in NoMoreWaivers for more information. Without quality certification, how does

the field without any deviation from the one know that a fabricator or erector is

drawings and specifications you have How do you know? capable of meeting the demands of this

provided. When you visit your physician, you important responsibility?

expect to receive professional health care

Its your responsibility! services. But how do you know when Brian Raff is AISCs Manager of Certification

One misconception about the certifi- you walk into your doctors office that Marketing. Contact Brian at raff@aisc.org.

cation specification requirement is that it the person wielding the stethoscope is

can just be removed from the specifica- a qualified professional? You probably

tion without any consequences. When never really gave it much thought, but

one is asked to waive the certification re- that license issued by the American Med-

quirements for a project, essentially, they ical Association on the wall in their office

September 2005 Modern Steel Construction

Potrebbero piacerti anche

- The Answer Is: and Pressure Vessel Code and The AWS Steel, Are Separate, Stand-Alone CodesDocumento2 pagineThe Answer Is: and Pressure Vessel Code and The AWS Steel, Are Separate, Stand-Alone CodesJuan Gutier CcNessuna valutazione finora

- 09 Welding Procedures and Qualifcations As Per ASME SEC IXDocumento7 pagine09 Welding Procedures and Qualifcations As Per ASME SEC IXvilukNessuna valutazione finora

- Pre-Functional Testing: Technical vs. Process CommissioningDocumento6 paginePre-Functional Testing: Technical vs. Process Commissioningsenthilarasu5Nessuna valutazione finora

- Answered by Kenneth Erickson & Kip Mankenberg: 30 - Inspection TrendsDocumento2 pagineAnswered by Kenneth Erickson & Kip Mankenberg: 30 - Inspection TrendsJuan Gutier CcNessuna valutazione finora

- Wit T 2008PVDocumento6 pagineWit T 2008PVCharles JacobNessuna valutazione finora

- Steelwise: Says Who?Documento2 pagineSteelwise: Says Who?alberto rosadoNessuna valutazione finora

- AISC Shop InspectionDocumento19 pagineAISC Shop InspectionkblaxtonNessuna valutazione finora

- Part A - CWI - Fundamental Orignal 2017 PDFDocumento588 paginePart A - CWI - Fundamental Orignal 2017 PDFLopez Beto88% (8)

- Motivation:-: WWW - Parhladsharma.inDocumento7 pagineMotivation:-: WWW - Parhladsharma.insurajit biswasNessuna valutazione finora

- Auditoria de Calidad Vs InspeccionDocumento3 pagineAuditoria de Calidad Vs Inspecciondavid perezNessuna valutazione finora

- Itp Itr QCPDocumento6 pagineItp Itr QCPtarik moumeneNessuna valutazione finora

- Quality Manual Guideline QC010Documento66 pagineQuality Manual Guideline QC010Hegazy91% (11)

- NATE Preparation Certification Exam Volume 1Documento129 pagineNATE Preparation Certification Exam Volume 1ambuenaflor100% (2)

- Validation Commissioning DocumentsDocumento4 pagineValidation Commissioning DocumentsPrashansa ShresthaNessuna valutazione finora

- Scope and Application: Be TheDocumento3 pagineScope and Application: Be TheAli KNessuna valutazione finora

- Motivation:-: Subject:-Welding Codes and Standards. Reading of Assembly Drawing. Welding ProcedureDocumento6 pagineMotivation:-: Subject:-Welding Codes and Standards. Reading of Assembly Drawing. Welding ProcedureDeekshith DileepNessuna valutazione finora

- Wi 2015 PVDocumento14 pagineWi 2015 PVSidheshwar Kumar100% (1)

- WeldingDocumento3 pagineWeldingABDELKADER SULTANE OFFICIELNessuna valutazione finora

- Cwi 1Documento65 pagineCwi 1Deepak Negi100% (1)

- Importance of Welding SoftwareDocumento3 pagineImportance of Welding SoftwareAshfaq AnwerNessuna valutazione finora

- Basic Quality Assurance of Structural SteelDocumento82 pagineBasic Quality Assurance of Structural SteelMarlon Delos ReyesNessuna valutazione finora

- Part A - CWI - Fundamental Orignal 2017Documento588 paginePart A - CWI - Fundamental Orignal 2017Husseinallawi banderNessuna valutazione finora

- Interview QuestionDocumento27 pagineInterview Questionsivacwi75% (4)

- Piping & Welding PDFDocumento27 paginePiping & Welding PDFTanveer Memon50% (2)

- Module Two Documents Governing Welding Inspection and Quality of MaterialsDocumento11 pagineModule Two Documents Governing Welding Inspection and Quality of MaterialsZaheed ManooNessuna valutazione finora

- An Introduction To Welding InspectionDocumento3 pagineAn Introduction To Welding InspectionMUHAMMAD SHARIFNessuna valutazione finora

- QC .ResponsibilitiesDocumento8 pagineQC .ResponsibilitiesMuhammed ThanzeelNessuna valutazione finora

- Contoh WpsDocumento30 pagineContoh WpsxernozaqilNessuna valutazione finora

- QuestionspanelistDocumento14 pagineQuestionspanelistAr Srinivas PullogiNessuna valutazione finora

- HappyDocumento93 pagineHappyWillie Tanyu100% (1)

- UntitledDocumento22 pagineUntitledTrecita BacoNessuna valutazione finora

- AWS - Practical Reference Guide For Visual Inspection of Pressure Vessel and Pressure PipingDocumento32 pagineAWS - Practical Reference Guide For Visual Inspection of Pressure Vessel and Pressure PipingAndres Gerena Cortes100% (1)

- WPSPQRWQTWPQDocumento44 pagineWPSPQRWQTWPQmasmunirNessuna valutazione finora

- Non Destructive Testing Report WritingDocumento5 pagineNon Destructive Testing Report WritingHyujeii Mce100% (1)

- ASME Training and Development-Spring-Catalog PDFDocumento100 pagineASME Training and Development-Spring-Catalog PDFJiménez Chávez JaimeNessuna valutazione finora

- Heat Exchanger Inspection Checklist - QC, Inspection & Testing Engineering - Eng-TipsDocumento2 pagineHeat Exchanger Inspection Checklist - QC, Inspection & Testing Engineering - Eng-TipsdileepNessuna valutazione finora

- Increasing Need For Weld QualityDocumento4 pagineIncreasing Need For Weld Qualityabdullaziz.albazNessuna valutazione finora

- Visual Inspection Workshop2Documento42 pagineVisual Inspection Workshop2saeedsaeed31100% (2)

- Calificacion de Procedimeintos y Soldadores Segun AwsDocumento22 pagineCalificacion de Procedimeintos y Soldadores Segun AwsULISES HERNANDEZNessuna valutazione finora

- AWS Qualification Program: Dr. Eng. Hamed A. NagyDocumento65 pagineAWS Qualification Program: Dr. Eng. Hamed A. Nagyislamaktham100% (3)

- An Overview Ot He ASME Guide For Verification and Validation in Computational Solid MechanicsDocumento12 pagineAn Overview Ot He ASME Guide For Verification and Validation in Computational Solid MechanicsBib GmzNessuna valutazione finora

- AWS Catalog 2019 PDFDocumento104 pagineAWS Catalog 2019 PDFTANVEER AHMED100% (1)

- ASSESS Theme Positioning Paper Credibility 1 - 4Documento8 pagineASSESS Theme Positioning Paper Credibility 1 - 4A LettristeNessuna valutazione finora

- Wps Guides 2006Documento25 pagineWps Guides 2006BE GNessuna valutazione finora

- WJ 2012 12 PDFDocumento148 pagineWJ 2012 12 PDFMarcelo AlbeNessuna valutazione finora

- CWI ResponsibilitiesDocumento9 pagineCWI ResponsibilitiesahmedNessuna valutazione finora

- Answer: Answered by Kenneth Erickson and Kip MankenbergDocumento2 pagineAnswer: Answered by Kenneth Erickson and Kip MankenbergJuan Gutier CcNessuna valutazione finora

- Self Inspection Handbook Oct 2006Documento31 pagineSelf Inspection Handbook Oct 2006iikh3ansNessuna valutazione finora

- IBC Steel Special InspectionsDocumento3 pagineIBC Steel Special InspectionsEng MessiNessuna valutazione finora

- WI & CERT Kelas EDocumento22 pagineWI & CERT Kelas EKevin ArmandoNessuna valutazione finora

- What Is A WPS?: Presented by AWSDocumento7 pagineWhat Is A WPS?: Presented by AWSdavidNessuna valutazione finora

- To Stamp Not StampDocumento4 pagineTo Stamp Not Stampkinjalpatel12345Nessuna valutazione finora

- Visual Inspection of WeldsDocumento137 pagineVisual Inspection of Weldssjois_hs100% (1)

- Metal Stamping Sheet Metal: Safety Handbook ForDocumento78 pagineMetal Stamping Sheet Metal: Safety Handbook ForherikNessuna valutazione finora

- SOP Equipment Validation Issue-6Documento15 pagineSOP Equipment Validation Issue-6Saravana kumar NagarajanNessuna valutazione finora

- Certification Option 2009 PDFDocumento9 pagineCertification Option 2009 PDFQueens QueensNessuna valutazione finora

- A Quick Guide to Welding and Weld InspectionDa EverandA Quick Guide to Welding and Weld InspectionValutazione: 4.5 su 5 stelle4.5/5 (16)

- Terzaghi FactorsDocumento1 paginaTerzaghi FactorsBenard OmondiNessuna valutazione finora

- Strut and Tie ModelDocumento3 pagineStrut and Tie ModelBenard OmondiNessuna valutazione finora

- Review - Shear Strength of SoilDocumento6 pagineReview - Shear Strength of SoilBenard OmondiNessuna valutazione finora

- СSE 827E Plates and Shell StructuresDocumento1 paginaСSE 827E Plates and Shell StructuresBenard OmondiNessuna valutazione finora

- Detailing Symbols (Previous & Current) : Buildings and StructuresDocumento1 paginaDetailing Symbols (Previous & Current) : Buildings and StructuresBenard OmondiNessuna valutazione finora

- Detailing Symbols HistoryDocumento1 paginaDetailing Symbols HistoryBenard OmondiNessuna valutazione finora

- CVS 517 E Possible QuestionsDocumento1 paginaCVS 517 E Possible QuestionsBenard OmondiNessuna valutazione finora

- Moi University Department of Civil and Structural EngineeringDocumento1 paginaMoi University Department of Civil and Structural EngineeringBenard OmondiNessuna valutazione finora

- Strong Medicine: Renovation and RetrofitDocumento3 pagineStrong Medicine: Renovation and RetrofitBenard OmondiNessuna valutazione finora

- Continuous Assessment Test - StructuresDocumento1 paginaContinuous Assessment Test - StructuresBenard OmondiNessuna valutazione finora

- CVS 215 - Course OutlineDocumento2 pagineCVS 215 - Course OutlineBenard Omondi100% (1)

- Technology TriumphDocumento3 pagineTechnology TriumphBenard OmondiNessuna valutazione finora

- CVS 217 - Course OutlineDocumento2 pagineCVS 217 - Course OutlineBenard OmondiNessuna valutazione finora

- CVS 315 Course OutlineDocumento2 pagineCVS 315 Course OutlineBenard Omondi100% (1)

- Bridge BearingsDocumento13 pagineBridge BearingsBenard OmondiNessuna valutazione finora

- Design of Composite Steel Beams For Bridges To AASHTODocumento36 pagineDesign of Composite Steel Beams For Bridges To AASHTOBenard Omondi100% (1)

- ToplinelistDocumento9 pagineToplinelistRS DulayNessuna valutazione finora

- CH 05 PDFDocumento11 pagineCH 05 PDF朱亦詳Nessuna valutazione finora

- Cycloid Instructions WebDocumento16 pagineCycloid Instructions Webanil100% (4)

- Information and Communication Technology: Module ForDocumento6 pagineInformation and Communication Technology: Module ForRemy GutierrezNessuna valutazione finora

- Valve Lash 777 DialDocumento6 pagineValve Lash 777 DialBroCactusNessuna valutazione finora

- 56000FH05 RF-PR025J230277 - Materiales en PropuestaDocumento2 pagine56000FH05 RF-PR025J230277 - Materiales en PropuestaErick CrespoNessuna valutazione finora

- Schedule C PRICEDocumento163 pagineSchedule C PRICESUDDHA CHAKRABARTYNessuna valutazione finora

- Screws, Fasteners, and The Design of Nonpermanent JointsDocumento118 pagineScrews, Fasteners, and The Design of Nonpermanent JointsSOUBHIK ROYNessuna valutazione finora

- Fastener ListDocumento9 pagineFastener ListMani Rathinam RajamaniNessuna valutazione finora

- Chinese Centrifuge LW450x1000 Centrifuge ManualDocumento34 pagineChinese Centrifuge LW450x1000 Centrifuge ManualNurlan Valiyev100% (1)

- LEXION After Sales PartsDocumento48 pagineLEXION After Sales Parts孙维华100% (1)

- Caimbang 4thqtrFINALDocumento131 pagineCaimbang 4thqtrFINALChesella Kaye Lungay100% (1)

- SNOW BLADE (Standard) (60'' 6107) (72'' 2231) (84'' 6836) (96'' 6838)Documento4 pagineSNOW BLADE (Standard) (60'' 6107) (72'' 2231) (84'' 6836) (96'' 6838)PetarbrateNessuna valutazione finora

- ESP Engineering B1 Glossary PDFDocumento6 pagineESP Engineering B1 Glossary PDFbadgalzuzixNessuna valutazione finora

- Makita Ls1020 Users Manual 405647Documento20 pagineMakita Ls1020 Users Manual 405647Martin HaryadiNessuna valutazione finora

- Details of 14B 11BDocumento8 pagineDetails of 14B 11BPrashant PunjabiNessuna valutazione finora

- Fanatec GT3 RS V2Documento27 pagineFanatec GT3 RS V2Tiago ParroNessuna valutazione finora

- Microfichas LC180 Yamaha 50 CCDocumento36 pagineMicrofichas LC180 Yamaha 50 CCHernan Pablo AlvarezNessuna valutazione finora

- Miter Saw Dust HoodDocumento9 pagineMiter Saw Dust HoodLonebeavNessuna valutazione finora

- Catalogo Dr200sel5 (2014-5 E24)Documento72 pagineCatalogo Dr200sel5 (2014-5 E24)Javier Llumpo100% (1)

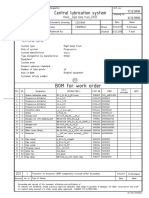

- Central Lubrication System: BOM For Work Order BOM For Work OrderDocumento2 pagineCentral Lubrication System: BOM For Work Order BOM For Work OrderMartinezNessuna valutazione finora

- Installation Instructions: Fittings and PortsDocumento5 pagineInstallation Instructions: Fittings and PortsVictor Lo Dastek UnichipNessuna valutazione finora

- User Manual Portable Mixer MachineDocumento32 pagineUser Manual Portable Mixer MachineFadhli HashimNessuna valutazione finora

- Joist Installation-GuideDocumento4 pagineJoist Installation-GuideDoble EmeNessuna valutazione finora

- Standard Groove Specifications PDFDocumento5 pagineStandard Groove Specifications PDFDavid Salguero OlveaNessuna valutazione finora

- k1200rs 02-04 PDFDocumento416 paginek1200rs 02-04 PDFsteveNessuna valutazione finora

- Technical Specification:: A3-SIZE 121023Documento4 pagineTechnical Specification:: A3-SIZE 121023MIHAINessuna valutazione finora

- Hume Doors Frontier Barn Door SystemsDocumento16 pagineHume Doors Frontier Barn Door SystemsedmondschanNessuna valutazione finora

- Student's Project InventorDocumento10 pagineStudent's Project InventorSatish BollamNessuna valutazione finora

- Catalogo Peças Mhindra Scorpions Pik-Up - 2011 PDFDocumento194 pagineCatalogo Peças Mhindra Scorpions Pik-Up - 2011 PDFEuclides Melo JúniorNessuna valutazione finora