Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

2007 03 173 PDF

Caricato da

Pratap PowerDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

2007 03 173 PDF

Caricato da

Pratap PowerCopyright:

Formati disponibili

Lecture

ALKALI ACTIVATED MATERIALS OR GEOPOLYMERS?

FRANTIEK KVRA

Department of Glass and Ceramics, Institute of Chemical Technology Prague

Technick 5, 166 28 Prague, Czech Republic

E-mail: Frantisek.Skvara@vscht.cz

Submitted January 17, 2007; accepted May, 15 2007

Keywords: Geopolymer, Alkali activated materials, Microstructure, Fly ash

The paper presents an overview of the state-of-the-art on the alkali activated materials since 1973 in Department of Glass

and Ceramics in Prague. Properties of alkali activated materials in comparison with standard Portland cement are dis-

cussed.

INTRODUCTION eventually ended successfully with an industrial viabi-

lity stage [11-13]. Our present day attention focuses on

Alkalis (Na, K) bring about problems in the tech- alkali activation processes of fly ashes occurring during

nology of Portland cement and concrete. These trou- the combustion of brown and bituminous types of coal.

bles can be characterized as problems in the clinker pro-

duction and the formation of undesirable silicate and

aluminous phases of the type KC12S23, NC8A3. However,

the alkali-silica reaction in the concrete that is accom-

panied by expansion represents the major source of

problems. Such problems call for a strict limitation of

the alkali content in the cement to values amounting to

0.6 percent and less (expressed as Na2O). On the other

hand, however, soluble alkali compounds speed up the

hydration process of hydraulic and latently hydraulic

substances thus facilitating the formation of new hy-

dration phases as this was shown by Purdon [1] in his

work from 1940. In 1959 Gluchovskij [2] demonstrated

in his book "Gruntosilikaty" (Figure 1) the possibility of

preparing new materials by means of the reaction of alu-

mino-silicate raw materials (slags, fly ashes, clay mate-

rials) with alkaline compounds (carbonates, hydroxides,

silicates).

The possibilities resulting from the use of the alka-

li activation of alumino-silicate materials were later

investigated by a variety of workers. At present, the data

base in Chemical Abstracts includes more than 1 800

original papers devoted to this topic. Furthermore, a

series of congresses dealing with alkali activated mate-

rials [3-10] took place since 1978.

The Institute of Glass and Ceramics ICT Prague has

been investigating the problems associated with the

alkali activation since 1973. The attention has been

focused on processes of alkali activation of Portland

cements, ground Portland cement clinker, blast-furnace

slags, kaolinite materials and other inorganic wastes.

The investigation into high strength gypsum-free Port-

land cements (alkali-activated) lasted several years and Figure 1. V.D. Gluchovskij: Book Gruntosilikaty, Kijev 1959.

Ceramics Silikty 51 (3) 173-177 (2007) 173

kvra F.

Fly ash wastes represent a considerable environmental In 1976 to 1979 Davidovits [15] coined a new term

problem in the Czech Republic because more than "geopolymer" (almost 20 years after the Gluchovskij's

10 million tons are rejected annually with the majority term "gruntosilikat", "gruntocement-geocement").

of this amount being disposed of on disposal sites. Davidovits defines the material as follows: "The

geopolymer is a material originated by inorganic poly-

condensation, i.e. by so-caled "geopolymerization"" (in

ALKALI ACTIVATION result of the alkali activation of alumino-silicate materi-

als -our note).

Alkali activation of alumino-silicate materials rep- A three-dimensional alumino-silicate network char-

resents a complex process that has not been described to acterized by the empirical formula Na,Kn {-(Si-O)z-Al-

the full yet. The reaction of alumino-silicate materials in O}nwH2O where M is K, Na or Ca atom, n - the degree

a strong alkaline environment re-sults, first of all, in a of poly-condensation, z - 1, 2, 3 or more than 3 is

breakdown of SiOSi bonds; later, new phases arise formed. The network is configurated of SiO4 and AlO4

and the mechanism of their formation seems to be a tetrahedrons united to-gether by oxygen bridges. Chains

process that includes a solution ("synthesis via solu- or rings united by SiOAl bridges are formed. Positive

tion"). The penetration of Al atoms into the original ions (Na+, K+, Ca++) must compensate the negative

SiOSi structure represents a substantial feature of this charge of Al that is present in the coordination 4.

reaction. Alumino-silicate gels (zeolite precursors) are

mostly formed. Their composition can be characterized

by the formula Mn[-(Si-O)z-Al-O]n. wH2O. The CSH CONCEPTION OF GEOPOLYMERS

and CAH phases may also be originated in depen-

dence on the composition of the starting materials and Based on his research work Davidovits [16] elabo-

the conditions of the reaction. Even secondary H2O may rated a structural model of the geopolymer (in this case,

be formed during these (poly-condensation) reactions. the model was designed for a poly-sialate - silox type

Amorphous (gel-like) or partially amorphous or formed by alkali activation of meta-kaolin). In his model

crystalline substances may be originated in dependence he assumed an essentially monolithic polymer similar to

on the character of starting raw materials and on the organic polymers. (Figure 3).

conditions of the reaction. The concentration of the Further progress in the investigation into the

solid matter plays a substantial role in the process of microstructure of the products of alkali activation (geo-

alkali activation. Mostly crystalline zeolite-type prod- polymerization) and, in particular, the results obtained

ucts (analcime, hydro-sodalite and other) are formed in by using the methods of thermal analysis, mercury

extremely diluted suspensions (w > 1 10). Therefore, porosimetry, data obtained by measurement of BET

the above process is used for the synthesis of manmade isothermal curves and MAS NMR spectroscopy (Si, Al

zeolites as this is corroborated by numerous publica- and especially Na) permitted a certain revision of this

tions. Predominantly amorphous products are originated conception. Based on the above results Barbosa [17]

at higher concentrations of the solid phase in the sus- proposed a modified model (Figure 4). Geopolymer

pension (w < 1). materials are similar to vitreous bodies - the NMR spec-

It was for the above amorphous bodies that Davi- tra of alumino-silicate glasses and those of geopolymers

dovits [14] proposed a terminology of poly-sialates by are similar. Both materials exhibit the same three-dimen-

taking into consideration the Si-to-Al ratio (Figure 2). sional arrangement. However, there is no water present

in the glass structure, and the glass is practically without

pores (Figure 5).

Poly(sialate) O O

Si:Al=1 (SiOAlO) O O O

Si Al

SiO4 AlO4

O O

O O O

Poly(sialate-siloxo) O O O O

Si:Al=2 (SiOAlOSiO) Si Al Si

O O O

O O O O

Poly(sialate-disiloxo) O O O O

Si:Al=3 O

(SiOAlOSiOSiO) Si Al Si Si

O O O O

Figure 2. Davidovits terminology. Figure 3. Davidovits model of geopolymer structure [16,18].

174 Ceramics Silikty 51 (3) 173-177 (2007)

Alkali activated materials or geopolymers?

O - the alkali cation (Na, K) is present in the structure in a

OH O solvated form; furthermore, it is bonded more weakly

Al O O O O

O O Al Si Al Si than in the crystalline structure of zeolites (this fact

O O O O O O O

Si O

Al

O represents a potential danger as regards the efflores-

O O Si Si Si

O Al O O O O cence occurrence),

Si O O O O Si

Al H2O +

+ H2O Al + + O H2O H2O - is rather characterized by a random three-dimensional

O H2O H2O H2O OH H2O Na

H2 O

Na

H2OO

H2O H2O

Na

H2O H2O OH

Na Si

H2 O

H2O

H2O arrangement,

H2O H2O O H2O

Si Si H2O

H2O H2O

H2O O

O O O - represents a porous body with pores ranging from

Si Al

O O O O O O O Si O nanometers to micrometers,

Al Al O O O

O O O O

Al

Al Si - contains water in pores and in the gel;

O O O

Si Si O O - the water plays only a role of a carrier of the alkali acti-

O O

O vating agent and that of a "rheological" water;

- crystalline and amorphous hydrates occur only rarely

Figure 4. Barbosa model of geopolymer structure [17].

and only if a slag or Ca-containing material is present.

Silicon Hence, what is a geopolymer?

Oxygen

Davidovits says [16, 18]: " the 27 Al NMR spec-

Sodium

tra of the product must exhibit a peak only at about 55

ppm. Al may be present in the product structure only and

exclusively in the coordination 4 (Figure 6).

If it is not so, the product may not be called a

geopolymer but only an alkali activated material "

This very strictly formulated definition satisfies

essentially only the materials obtained by alkali activa-

tion of pure metakaolin. There is a variety of question

marks coming to mind when the materials originated by

alkali activation (geopolymerization) are analyzed and

classified:

z Do the materials obtained on the basis of other raw

Figure 5. Structure of glass. materials than metakaolin belong to geopolymers too?

z Can also the materials that contain Al in the coordina-

There is also a certain similarity between the tion six, eg unreacted mullite residues (fly ashes) be

geopolymer materials and the Portland cement because regarded as geopolymers?

both materials are resistant to the action of water after

their hardening. Therefore, they behave like a hydraulic

binder. The hardened Portland cement is also a porous AlQ4 (4Si)

55

material with pores ranging from nanometers to microm-

eters. In contrast to the geopolymer, the Portland cement

contains not only amorphous hydrates but also the crys-

talline ones (Ca(OH)2, ettringite, etc.). There is Ca(OH)2

present in the pores of hardened Portland cement and the

surface is coated by a thin layer of CaCO3 (because of

the carbonate formation). The water is used ("con-

sumed") for the hydrate formation during the hardening

of the Portland cement whereas it stays in the structure

during the geopolymer hardening (water serves predom-

inantly as a "carrier" of the alkali activating agent).

The results published up to now (they are in full 27

Al

agreement with our data) give the possibility to declare

that a geopolymer material (on the basis of fly ashes, 200 100 0 -100

metakaolin): ppm

- does not possess any monolithic structure of the poly- Figure 6. NMR MAS 27Al of "true", "genuine" geopolymer

sialate - silox type, [16,18].

Ceramics Silikty 51 (3) 173-177 (2007) 175

kvra F.

z Can the materials that also contain the CSH phase There are visible trends that can be observed in the

(in the case of slags or clinker) be called geopolymers, series starting with clinker, slags, fly ashes and ending

too? with kaolinitic materials:

z Can the materials formed only at a temperature of

z The necessity to increase the Na2O content in the alka-

20C or during a hydrothermal synthesis or at a higher

temperature be called geopolymers? li activating agent is obvious.

z Stronger" activating agents (alkali carbonate, alkali sil-

z Can the materials that also contain B and P atoms in

addition to Si and Al atoms be classified as geopoly- icate, respectively alkali hydroxide) must be used.

z The content in the Mn[-(Si-O)z-Al-O]nwH2O phase

mers (Figure 7)?

increases.

z The Ca content in the product drops and, hence, also

A scientific discussion on the above topics is necessary.

the content of the CSH and CAH phase decreases.

Therefore, two phases co-exist one along another in

What do have alkali-activated aluminosilicate geopolymer materials the Mn [-(Si-O)z-Al-O]nwH2O

materials in common? phase having the character of a zeolite and the CSH

phase, respectively the CAH phase. This coexistence

The presence of the Na,Kn{-(Si-O)z-Al-O}n. wH2O affects the properties of geopolymer materials and we

phase. How should we call this phase? may state that the highest values of strength (up to

An NSAH or KSAH phase (as would be cus- 160 MPa compression strength) could be achieved in

tomary among the cement scientists)? geopolymer materials that exhibited the coexistence of

Or a zeolite-like phase (Gluchovskii)? (analogy to both types of phases.

the tobermorite-like phase, the CSH phase today). The results of system analyses [19] of a wide range

Or shouldn't we rather use a quite different denomi- of aluminosilicate raw materials used for the preparation

nation: polymer silicate, inorganic polymer concrete? of geopolymers show that metakaolin occupies the top

If we forget the strict definition of the geopolymer position as regards the consumption of energy, environ-

formulated by Davidovits (related to pure metakaolin) mental impacts and cost (the cost/benefit factor amoun-

we shall reach a new very large group of inorganic

ting to 7-8); slags and ceramic waste are less demanding

binders with substantial ecological and energetic poten-

and the fly ashes (the cost/benefit factor amounting to

tials as well as the binders with properties that have not

0.5) are the least demanding raw materials. The

been described yet. Then, such materials could be de-

cost/benefit factor of the Portland cement (1.2) was

fined in accordance with the starting raw materials, e.g.:

determined in the same way.

geopolymer on the fly ash basis

geopolymer on the metakaolin basis etc.

Acknowledgement

If the geopolymers are conceptualized as a large

This study was part of the of research project

group of binders, then significant differences in the

CEZ:MSM 6046137302: "Preparation and research of

product character and composition can be found during

functional materials and material technologies using

the alkali activation of various alumino-silicate raw

micro- and nanoscopic methods" and Czech Science

materials (Figure 8).

Foundation Grant 103/05/2314 "Mechanical and engi-

27

Al MAS NMR neering properties of geopolymer materials based on

37.4 alkali activated ashes".

-2.8

Content of Na2O

in activator

Content

of Ca Content of phase

{Na, Kn[-(Si-O)z-Al-O]

nwH2O}

Content CSH

and CAH phase

100 0 -100

ppm from Al(H2O)6 clinker slag fly ash metakaoline raw materials

Figure 7. INMR MAS 27Al of geoolymer containing P [21]. Figure 8. Composition of various alkali activated materials.

176 Ceramics Silikty 51 (3) 173-177 (2007)

Alkali activated materials or geopolymers?

References 15. Davidovits J.: Proc. 1st Euro pean Conf. of Soft Miner-

alurgy "Geopolymer '88", Compiegne (1988).

1. Purdon, A. O..: J. Soc. Chem. Industry, London 59, 16. Davidovits J.: Proc. 2nd Intern. Conf. "Geopolymere

191-202, (1940). '99", St. Quentin (1999).

2. Gluchovskij V.D.:" Gruntosilikaty" Gosstrojizdat Kiev 17. Barbosa V.F.F., Mackenzie K.J.D., Thaumaturgo C.:

1959, Patent USSR 245 627 (1967), Patent USSR Int.J.Inorg.Mater. 2, 309-317 (2000).

449894 (Patent appl. 1958, filled 1974!). 18. Davidovits J.: Proc. World Congress "Geopolymer

3. Proc. 1st, 2nd, 3rd conference "Slag alkaline cements and 2005" St. Quentin (2005).

concrete", Kew (1978, 1985, 1989). 19. Weil M., Dombrowski K., Buchwald A.: Proc.Intern.

4. Proc. 1st Intern. Conf. "Alkaline cements and con- Worshop "Geopolymer Binders" Weimar (2006).

cretes", Kiev (1994). 20. Project Czech Science Foundation Grant No.

5. Proc. 2nd Intern. Conf. "Alkaline cements and con- 103/05/2314 "Me chanical and Engineering Properties

cretes", Kiev (1999). of Geopolymer Materials Based on Alkali-Activated

6. Proc. 1st European Conf. of Soft Mineralurgy "Geo- Ashes" and project MSM No.6046137302 "Preparation

polymer '88", Compiegne (1988). and research of functional materials and material tech-

7. Proc. 2nd Intern. Conf. "Geopolymere '99", St. Quentin nologies using micro- and nanoscopic methods" ICT

(1999). Prague, Czech TU Prague

8. Proc. World Congress "Geopolymer 2005" St. Quentin 21. Cao, Deguang; Su, Dageng; Lu, Bo; Yang, Yunxia.:

(2005). Guisuan yan Xuebao 33(11) 1385-1389 (2005).

9. Proc. GGC 2005 Intern. Workshop on Geopolymers

and Geopolymer Concrete, Perth (2005).

10. Proc. Intern. Workshop "Geopolymer Binders", ALKALICKY AKTIVOVAN MATERILY

Weimar (2006). NEBO GEOPOLYMERY?

11. kvra F.: MRS Symp.Proc. Vol. 370 "Microstructure

of Cement-based systems/Bonding and Interfaces in FRANTIEK KVRA

Cementitious Materials", p. 153-158, editors S.Dia-

mond, S. Mindess, Materials Research Society, Pitts- stav skla a keramiky,

burgh 1994. Vysok kola chemicko-technologick v Praze

12. kvra F. et al.: US Patent 4,168,985 (1979), 5,125,976 Technick 5, 166 28 Praha 6

(1991), 5,076,851 (1991).

13. kvra F., Kol K., Novotn J., Zadk Z., Baantov

V pednce je uveden pehled o vzkumn innosti a

Z.: Proc. 9th Intern. Congr. Chem. Cement Paris 1980,

vsledcch dosaench v oblasti alkalicky aktivovanch mate-

Vol. III, p. V-57. ril od roku 1973. Jsou diskutovny terminologick otzky a

14. Davidovits J.: Proc. Long-term Prop. Polym. Mater. klasifikace alkalicky aktivovanch materil - geopolymer.

Intern. Stockholm (1976). Jsou tak diskutovny mikrostrukturln modely geopolymer.

Ceramics Silikty 51 (3) 173-177 (2007) 177

Potrebbero piacerti anche

- Alkali Activated Materials or GeopolymersDocumento5 pagineAlkali Activated Materials or GeopolymersTran Huynh NamNessuna valutazione finora

- Alkali Activated Material - GeopolymerDocumento16 pagineAlkali Activated Material - GeopolymerDEEKSHA BNessuna valutazione finora

- 2017 - Review - Geopolymers Ceramic-Like Inorganic PolymersDocumento16 pagine2017 - Review - Geopolymers Ceramic-Like Inorganic PolymersJoya Rani MallickNessuna valutazione finora

- Review of Related Literature For Geopolymer CobcreteDocumento6 pagineReview of Related Literature For Geopolymer CobcreteAldrich Francis Ortiz PeñaflorNessuna valutazione finora

- The Role of Active Silica and Alumina in Geopolymerization: AbstractDocumento8 pagineThe Role of Active Silica and Alumina in Geopolymerization: AbstractLê Chí HiệpNessuna valutazione finora

- What Is A GeopolymerDocumento14 pagineWhat Is A GeopolymerGayathri govardhanNessuna valutazione finora

- Ceramics by The Solution-Sol-Gel RouteDocumento6 pagineCeramics by The Solution-Sol-Gel Route王玏Nessuna valutazione finora

- A Study On Strength Behavior ofDocumento9 pagineA Study On Strength Behavior ofOpu DebnathNessuna valutazione finora

- Influence of Si:Al Ratio On The Microstructural and Mechanical Properties of A Fine-Limestone Aggregate Alkali-Activated Slag ConcreteDocumento11 pagineInfluence of Si:Al Ratio On The Microstructural and Mechanical Properties of A Fine-Limestone Aggregate Alkali-Activated Slag ConcreteAndrew PiNessuna valutazione finora

- Kaolin-Based Geopolymers With Various Naoh ConcentrationsDocumento10 pagineKaolin-Based Geopolymers With Various Naoh ConcentrationsAndrew PiNessuna valutazione finora

- The Influence of Parameters in Silica Sol-Gel Process: C.A. Milea A. DuţăDocumento8 pagineThe Influence of Parameters in Silica Sol-Gel Process: C.A. Milea A. DuţăJesha LibreaNessuna valutazione finora

- J ThermalDocumento15 pagineJ ThermalNandia Salsa Restu MulyaniNessuna valutazione finora

- NASTSDocumento25 pagineNASTSManuel AlejandroNessuna valutazione finora

- Advanced GeopolymerizationDocumento11 pagineAdvanced GeopolymerizationsavithaNessuna valutazione finora

- Investigation of Dissolution of Aluminosilicates in Aqueous Alkaline Solution Under Laboratory ConditionsDocumento7 pagineInvestigation of Dissolution of Aluminosilicates in Aqueous Alkaline Solution Under Laboratory ConditionsAli AddieNessuna valutazione finora

- Construction and Building Materials: Aaron R. Sakulich, Edward Anderson, Caroline Schauer, Michel W. BarsoumDocumento7 pagineConstruction and Building Materials: Aaron R. Sakulich, Edward Anderson, Caroline Schauer, Michel W. BarsoumMohammed Rizwan AliNessuna valutazione finora

- 1989 Geopolymers and Geopolymeric MaterialsDocumento13 pagine1989 Geopolymers and Geopolymeric MaterialsAjmal MuhammedNessuna valutazione finora

- 1.1 GeneralDocumento20 pagine1.1 GeneralPriyanshu VarshneyNessuna valutazione finora

- Advanced Powder Technology: Shuangqing Su, Hongwen Ma, Xiuyun ChuanDocumento6 pagineAdvanced Powder Technology: Shuangqing Su, Hongwen Ma, Xiuyun ChuanNELLY KARINA PEREZ GONZALEZNessuna valutazione finora

- STP156620120106 1113241-1Documento10 pagineSTP156620120106 1113241-1N SHYAMANANDA SINGHNessuna valutazione finora

- 2004 Brief Review of DevelopmentsDocumento10 pagine2004 Brief Review of DevelopmentsAvani DedhiaNessuna valutazione finora

- Paper 4. Why Alkaline Activation - ReviewDocumento12 paginePaper 4. Why Alkaline Activation - ReviewHelena LeonNessuna valutazione finora

- Geo Polymer ConcreteDocumento59 pagineGeo Polymer ConcreteJaya Prakash67% (3)

- The Effect of Composition and Temperature On The Properties of Fly Ash-And Kaolinite-Based GeopolymersDocumento11 pagineThe Effect of Composition and Temperature On The Properties of Fly Ash-And Kaolinite-Based GeopolymersYennifer AliocNessuna valutazione finora

- The Coexistence of Geopolymeric Gel and Calcium Silicate Hydrate at The Early Stage of Alkaline ActivationDocumento10 pagineThe Coexistence of Geopolymeric Gel and Calcium Silicate Hydrate at The Early Stage of Alkaline ActivationkailashNessuna valutazione finora

- PDFDocumento21 paginePDFNicolas RozasNessuna valutazione finora

- Yip 2008Documento11 pagineYip 2008Daniela Gonzalez BetancurNessuna valutazione finora

- Gobrecht 2022 A&A 658 167Documento30 pagineGobrecht 2022 A&A 658 167Sergio CristalloNessuna valutazione finora

- The Influence of Parameters in Silica Sol-Gel Process: C.A. Milea A. DuţăDocumento8 pagineThe Influence of Parameters in Silica Sol-Gel Process: C.A. Milea A. DuţădevendrakphyNessuna valutazione finora

- Frankeová-Slížková2016 Article DeterminationOfThePozzolanicAcDocumento9 pagineFrankeová-Slížková2016 Article DeterminationOfThePozzolanicAcShan E Ali MalikNessuna valutazione finora

- Self Assembled Monolayers - A ReviewDocumento8 pagineSelf Assembled Monolayers - A ReviewMeghna SheoranNessuna valutazione finora

- Fu 2020Documento10 pagineFu 2020Alvaro Ruiz AvendañoNessuna valutazione finora

- Preparation and Study Properties of Xerogel Silica Using Sol-Gel MethodDocumento6 paginePreparation and Study Properties of Xerogel Silica Using Sol-Gel MethodInternational Journal of Application or Innovation in Engineering & ManagementNessuna valutazione finora

- Construction and Building Materials: P. Štukovnik, V. Bokan Bosiljkov, M. MarinšekDocumento12 pagineConstruction and Building Materials: P. Štukovnik, V. Bokan Bosiljkov, M. MarinšekManuel AceroNessuna valutazione finora

- Chapter - 1: 1.0 GeneralDocumento19 pagineChapter - 1: 1.0 GeneralKesava KalepuNessuna valutazione finora

- Geopolymer Basics PDFDocumento30 pagineGeopolymer Basics PDFReshmita PallaNessuna valutazione finora

- 2001 Takahashi Silica-Alumina Catalyst With Bimodal Pore StructureDocumento6 pagine2001 Takahashi Silica-Alumina Catalyst With Bimodal Pore Structurelic.escobar2018Nessuna valutazione finora

- Kovářík 2017 IOP Conf. Ser. Mater. Sci. Eng. 175 012044Documento5 pagineKovářík 2017 IOP Conf. Ser. Mater. Sci. Eng. 175 012044Carlos AlarconNessuna valutazione finora

- Blatter 1990Documento3 pagineBlatter 1990Fausto SalazarNessuna valutazione finora

- 05 - Chapter 1Documento8 pagine05 - Chapter 1knight1729Nessuna valutazione finora

- Chemistry: Physics andDocumento30 pagineChemistry: Physics andSamia SharifNessuna valutazione finora

- Tailby, MacKenzie 2010Documento8 pagineTailby, MacKenzie 2010SrToshiNessuna valutazione finora

- Chapter 1 4Documento75 pagineChapter 1 4Gurbir Kaur100% (1)

- Concrete Based On Fly Ash As Geopolymer ReportDocumento15 pagineConcrete Based On Fly Ash As Geopolymer Reportnaveenpnaidu1Nessuna valutazione finora

- Advanced Concrete TechnologyDocumento22 pagineAdvanced Concrete TechnologymustafaNessuna valutazione finora

- International Journal of Mineral ProcessingDocumento6 pagineInternational Journal of Mineral ProcessingBoba AngelNessuna valutazione finora

- Cea 14827748 HDocumento10 pagineCea 14827748 HDemir YurdakulNessuna valutazione finora

- 2012 JPMDocumento8 pagine2012 JPMMaritza UreñaNessuna valutazione finora

- Fly Ash Class C Geopolymer BrickDocumento8 pagineFly Ash Class C Geopolymer BrickSiti AsmahaniNessuna valutazione finora

- Chemistry of Silicates and AluminosilicatesDocumento12 pagineChemistry of Silicates and AluminosilicatesER NurNessuna valutazione finora

- Effects of Si-Al Ratio On The Structure and Properties of MetakaolinDocumento7 pagineEffects of Si-Al Ratio On The Structure and Properties of MetakaolinHoài BãoNessuna valutazione finora

- 1 s2.0 S0950061821012873 MainDocumento11 pagine1 s2.0 S0950061821012873 MainDaniela Gonzalez BetancurNessuna valutazione finora

- Influence of Calcium Addition On Calcined Brick Clay Based GeopolymersDocumento10 pagineInfluence of Calcium Addition On Calcined Brick Clay Based GeopolymersJaouad El FarissiNessuna valutazione finora

- Cimenturi Hibride Alcaline - Modelo Gluvosky PDFDocumento6 pagineCimenturi Hibride Alcaline - Modelo Gluvosky PDFMiguelAngelDelgadoD'AppollonioNessuna valutazione finora

- Effect of Chemical Composition and Network of Fly Ash Glass On The Hydration Process and Properties of Portland-Fly Ash CementDocumento21 pagineEffect of Chemical Composition and Network of Fly Ash Glass On The Hydration Process and Properties of Portland-Fly Ash CementhaiyenngocchulaNessuna valutazione finora

- Organosilicon Reagents Synthesis and ApplicationsDa EverandOrganosilicon Reagents Synthesis and ApplicationsNessuna valutazione finora

- Graphene Oxide: Fundamentals and ApplicationsDa EverandGraphene Oxide: Fundamentals and ApplicationsAyrat M. DimievNessuna valutazione finora

- The Biogeochemical Cycle of Silicon in the OceanDa EverandThe Biogeochemical Cycle of Silicon in the OceanNessuna valutazione finora

- Unit - 3Documento20 pagineUnit - 3yrajesh10Nessuna valutazione finora

- 2Documento2 pagine2Pratap PowerNessuna valutazione finora

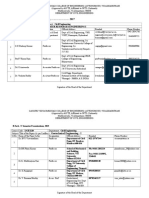

- Pre PHD Exam Subjects 2015Documento1 paginaPre PHD Exam Subjects 2015Pratap PowerNessuna valutazione finora

- Groundwater Measurement in WellsDocumento5 pagineGroundwater Measurement in WellsPratap PowerNessuna valutazione finora

- Groundwater Measurement in WellsDocumento5 pagineGroundwater Measurement in WellsPratap PowerNessuna valutazione finora

- Boundaries Between CountriesDocumento2 pagineBoundaries Between CountriesBasavaraju K RNessuna valutazione finora

- V Sem Paper Setters 2014-15Documento10 pagineV Sem Paper Setters 2014-15Pratap PowerNessuna valutazione finora

- 12Documento34 pagine12yrajesh10Nessuna valutazione finora

- 0000 Field Guide For Use of GPS and GIS OCHADocumento22 pagine0000 Field Guide For Use of GPS and GIS OCHAAnonymous IapvQVNessuna valutazione finora

- Disater Management Unit-1Documento34 pagineDisater Management Unit-1Pratap PowerNessuna valutazione finora

- Road MarkingDocumento29 pagineRoad MarkingSoma Nathan100% (2)

- Faculty Profile: Dr. T.V.PraveenDocumento10 pagineFaculty Profile: Dr. T.V.PraveenPratap PowerNessuna valutazione finora

- UKAYUNIK Chapter 1 To 12Documento31 pagineUKAYUNIK Chapter 1 To 12Chiesa ArellanoNessuna valutazione finora

- Otis C. Mitchell - Hitler-s-Stormtroopers-and-the-Attack-on-the-German-Republic-1919-1933 PDFDocumento201 pagineOtis C. Mitchell - Hitler-s-Stormtroopers-and-the-Attack-on-the-German-Republic-1919-1933 PDFbodyfull100% (2)

- Performace Task 2 Electric Field LinesDocumento31 paginePerformace Task 2 Electric Field LinesStephanie Nichole Ian CasemNessuna valutazione finora

- Epri Guide For Transmission Line Groundingpdf PDF FreeDocumento188 pagineEpri Guide For Transmission Line Groundingpdf PDF FreeHolman Wbeimar Suarez Niño100% (1)

- Graphs in ChemDocumento10 pagineGraphs in Chemzhaney0625Nessuna valutazione finora

- Historic Trial of Ali Brothers and Shankaracharya-1921Documento276 pagineHistoric Trial of Ali Brothers and Shankaracharya-1921Sampath Bulusu100% (3)

- Annex 1: Homeroom Guidance Monitoring Tool (School Level) Homeroom Guidance Monitoring ToolDocumento2 pagineAnnex 1: Homeroom Guidance Monitoring Tool (School Level) Homeroom Guidance Monitoring ToolMariel Gregore0% (1)

- FYP List 2020 21RDocumento3 pagineFYP List 2020 21RSaif UllahNessuna valutazione finora

- Elaborare Modele de Rating in Conformitate Cu IFRS 9Documento8 pagineElaborare Modele de Rating in Conformitate Cu IFRS 9MstefNessuna valutazione finora

- Obat Keras N0vember 2021Documento137 pagineObat Keras N0vember 2021antonNessuna valutazione finora

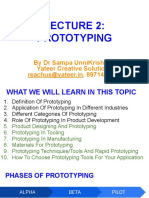

- Prototyping: by DR Sampa Unnikrishnan Yateer Creative Solutions Reachus@Yateer - In, 8971442777Documento70 paginePrototyping: by DR Sampa Unnikrishnan Yateer Creative Solutions Reachus@Yateer - In, 8971442777ShivashankarNessuna valutazione finora

- 4 Qi Imbalances and 5 Elements: A New System For Diagnosis and TreatmentDocumento5 pagine4 Qi Imbalances and 5 Elements: A New System For Diagnosis and Treatmentpixey55100% (1)

- Calculating Periodic Returns and Compound Annual ReturnsDocumento2 pagineCalculating Periodic Returns and Compound Annual ReturnsAlucard77777Nessuna valutazione finora

- Register A Custom Table in Apps SchemaDocumento5 pagineRegister A Custom Table in Apps SchemaIapps ErpSolutionsNessuna valutazione finora

- Kentucky Economic Development Guide 2010Documento130 pagineKentucky Economic Development Guide 2010Journal CommunicationsNessuna valutazione finora

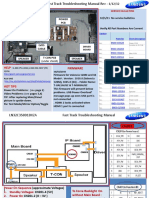

- Samsung LN55C610N1FXZA Fast Track Guide (SM)Documento4 pagineSamsung LN55C610N1FXZA Fast Track Guide (SM)Carlos OdilonNessuna valutazione finora

- Examiners' Report Principal Examiner Feedback January 2018Documento9 pagineExaminers' Report Principal Examiner Feedback January 2018RafaNessuna valutazione finora

- Brochure Delegation Training For LeadersDocumento6 pagineBrochure Delegation Training For LeadersSupport ALProgramsNessuna valutazione finora

- 1422-Article Text-3684-1-10-20211104Documento57 pagine1422-Article Text-3684-1-10-20211104f.kpobi1473Nessuna valutazione finora

- Gynaecology Thesis TopicsDocumento7 pagineGynaecology Thesis TopicsDawn Cook100% (2)

- Russian Sec 2023-24Documento2 pagineRussian Sec 2023-24Shivank PandeyNessuna valutazione finora

- Nail Malformation Grade 8Documento30 pagineNail Malformation Grade 8marbong coytopNessuna valutazione finora

- Mind'S Nest Review Center Inc.,: Criteria of A Good Research Problem: Easibility Nterest EsearchabilityDocumento21 pagineMind'S Nest Review Center Inc.,: Criteria of A Good Research Problem: Easibility Nterest EsearchabilitySherlyn Pedida100% (1)

- A Person On A Position of Air Traffic ControllerDocumento7 pagineA Person On A Position of Air Traffic ControllerMUHAMMAD RAMZANNessuna valutazione finora

- Markov Decision Processes For Path Planning in Unpredictable EnvironmentDocumento8 pagineMarkov Decision Processes For Path Planning in Unpredictable EnvironmentVartolomeiDumitruNessuna valutazione finora

- Jerehy's ReportDocumento65 pagineJerehy's Reportkupetroleum3Nessuna valutazione finora

- Folktales Stories For Kids: Two Brothers StoryDocumento1 paginaFolktales Stories For Kids: Two Brothers StoryljNessuna valutazione finora

- IELTS Materials ReadingDocumento9 pagineIELTS Materials ReadingßläcklìsètèdTȜè0% (1)

- Simon Bolivar PresentationDocumento7 pagineSimon Bolivar Presentationapi-345742212Nessuna valutazione finora

- Progress Test-The 7-Th GradeDocumento2 pagineProgress Test-The 7-Th GradebabystelutaNessuna valutazione finora