Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Bombas 1

Caricato da

Gabriel LopezTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Bombas 1

Caricato da

Gabriel LopezCopyright:

Formati disponibili

2020 INSTALLATION OF STATIONARY PUMPS FOR FIRE PROTECTION

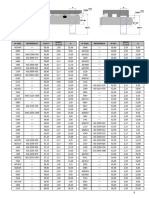

Table 4.26(b) Summary of Centrifugal Fire Pump Data (Metric)

Minimum Pipe Sizes (Nominal) (mm)

Number and

Pump Rating Relief Valve Meter Size of Hose Hose Header

(L/min) Suction* Discharge* Relief Valve Discharge Device Valves Supply

95 25 25 19 25 32 1 38 25

189 38 32 32 38 50 1 38 38

379 50 50 38 50 65 1 65 65

568 65 65 50 65 75 1 65 65

757 75 75 50 65 75 1 65 65

946 85 75 50 65 85 1 65 75

1,136 100 100 65 85 85 1 65 75

1,514 100 100 75 125 100 2 65 100

1,703 125 125 75 125 100 2 65 100

1,892 125 125 100 125 125 2 65 100

2,839 150 150 100 150 125 3 65 150

3,785 200 150 150 200 150 4 65 150

4,731 200 200 150 200 150 6 65 200

5,677 200 200 150 200 200 6 65 200

7,570 250 250 150 250 200 6 65 200

9,462 250 250 200 250 200 8 65 250

11,355 300 300 200 300 200 12 65 250

13,247 300 300 200 300 250 12 65 300

15,140 350 300 200 350 250 16 65 300

17,032 400 350 200 350 250 16 65 300

18,925 400 350 200 350 250 20 65 300

Notes:

(1) The pressure relief valve shall be permitted to be sized in accordance with 4.18.2.1.

(2) The pressure relief valve discharge shall be permitted to be sized in accordance with 4.18.6.2.

(3) The flow meter device shall be permitted to be sized in accordance with 4.19.2.2.

(4) The hose header supply shall be permitted to be sized in accordance with 4.19.3.4.

*Actual diameter of pump flange is permitted to be different from pipe diameter.

Applies only to that portion of suction pipe specified in 4.14.3.4.

4.27.4.2 Where a backflow prevention device is installed, the 4.28.2 The requirements of 4.28.1 shall not apply where the

final arrangement shall provide effective pump performance authority having jurisdiction requires horizontal force factors

with a minimum suction pressure of 0 psi (0 bar) at the gauge other than 0.5; in such cases, NFPA 13, Standard for the Installa-

at 150 percent of rated capacity. tion of Sprinkler Systems, shall apply for seismic design.

4.27.4.3 If available suction supplies do not permit the flow- 4.28.3 Pumps with high centers of gravity, such as vertical

ing of 150 percent of rated pump capacity, the final arrange- in-line pumps, shall be mounted at their base and braced

ment of the backflow prevention device shall provide effective above their center of gravity in accordance with the require-

pump performance with a minimum suction pressure of 0 psi ments of 4.28.1 or 4.28.2, whichever is applicable.

(0 bar) at the gauge at the maximum allowable discharge.

4.27.4.4 The discharge shall exceed the fire protection sys- 4.28.4 Where the system riser is also a part of the fire pump

tem design flow. discharge piping, a flexible pipe coupling shall be installed at

the base of the system riser.

4.27.4.5 Determination of effective pump performance shall

be documented by engineering calculations and tests. 4.29 Packaged Fire Pump Assemblies.

4.28 Earthquake Protection.

4.29.1 A packaged pump house and/or skid unit[s] shall in-

4.28.1* Unless the requirements of 4.28.2 are met and where clude detailed design information acceptable to the authority

local codes require seismic design, the fire pump, driver, die- having jurisdiction.

sel fuel tank (where installed), and fire pump controller shall

be attached to their foundations with materials capable of re- 4.29.2 All electrical components, clearances, and wiring shall

sisting lateral movement of horizontal forces equal to one-half meet the minimum requirements of the applicable NFPA 70,

the weight of the equipment. National Electrical Code, articles.

2010 Edition

Copyright National Fire Protection Association

Provided by IHS under license with NFPA

No reproduction or networking permitted without license from IHS

The Standard is downloaded from www.bzfxw.com Standard Sharing

Potrebbero piacerti anche

- Spherical Roller Bearings - 22318 EJA - VA405-2Documento3 pagineSpherical Roller Bearings - 22318 EJA - VA405-2cumtjerryNessuna valutazione finora

- Ejector A-Type - EllehammerDocumento3 pagineEjector A-Type - EllehammerlucasNessuna valutazione finora

- Torque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsDocumento2 pagineTorque Values For DEFENDER, Isoguard and Isomate Sealing Gaskets/Flange Isolation KitsPranpath NarupantawartNessuna valutazione finora

- A N R S T U V W Y AA AB AC AD AE AF AG SIZE RANGE 150 TO 1500mm Sq. or Dia. (Refer To Both Tables)Documento1 paginaA N R S T U V W Y AA AB AC AD AE AF AG SIZE RANGE 150 TO 1500mm Sq. or Dia. (Refer To Both Tables)rizkboss8312Nessuna valutazione finora

- Flange Torque Recommendations GF PDFDocumento2 pagineFlange Torque Recommendations GF PDFTulioLopezJNessuna valutazione finora

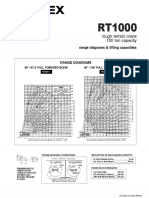

- Terex-Rt 1000 - Rough-Terrain-Cranes-Spec-25ef73Documento8 pagineTerex-Rt 1000 - Rough-Terrain-Cranes-Spec-25ef73Eli DanNessuna valutazione finora

- Flange Torque Recommendations Marcada PDFDocumento2 pagineFlange Torque Recommendations Marcada PDFzerathulNessuna valutazione finora

- Flange Torque Values PDFDocumento2 pagineFlange Torque Values PDFsimsonNessuna valutazione finora

- Protective Conductor Between MV - LV Transformer and The Main Low Voltage Switchboard (MLVS) - Electrical Installation GuideDocumento2 pagineProtective Conductor Between MV - LV Transformer and The Main Low Voltage Switchboard (MLVS) - Electrical Installation GuideENGMNessuna valutazione finora

- Act HC enDocumento4 pagineAct HC enBryan QuirozNessuna valutazione finora

- (Ee) Rab CTPSDocumento190 pagine(Ee) Rab CTPSichsanNessuna valutazione finora

- X028 Current Ratings General For Flexible Cables PDFDocumento1 paginaX028 Current Ratings General For Flexible Cables PDFJorge RojasNessuna valutazione finora

- Polysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Documento1 paginaPolysep... Sized For Every Application: Psg-7 Psg-15 Psg-30 Psg-60 Psg-90Carlos JiménezNessuna valutazione finora

- IEC 60071-1 Page 22Documento1 paginaIEC 60071-1 Page 22omid fathiNessuna valutazione finora

- Model 4WI 100 - 800 HP BoilersDocumento4 pagineModel 4WI 100 - 800 HP BoilerssebaversaNessuna valutazione finora

- Table 1 - Normal Tolerances For Radial Bearings, Except Tapered Roller BearingsDocumento3 pagineTable 1 - Normal Tolerances For Radial Bearings, Except Tapered Roller BearingsGregory Alan Francisco IINessuna valutazione finora

- Epcos Varistor SIOV-GENERALDocumento7 pagineEpcos Varistor SIOV-GENERALsandesh sawateNessuna valutazione finora

- Pumps Centrifugal DBDocumento6 paginePumps Centrifugal DBshariq khanNessuna valutazione finora

- Taha Associates - Step Ejector PinDocumento2 pagineTaha Associates - Step Ejector PinTaha AssociatesNessuna valutazione finora

- Iec 60071-1-2011-25Documento1 paginaIec 60071-1-2011-25Pedro OcantoNessuna valutazione finora

- IMG - 0199 PSME Code 2008 188Documento1 paginaIMG - 0199 PSME Code 2008 188rii amosNessuna valutazione finora

- 30 IlluminationDocumento15 pagine30 Illuminationbinay kumar ParidaNessuna valutazione finora

- FPS-09 - Tee Recta PDFDocumento2 pagineFPS-09 - Tee Recta PDFOscar AmvalNessuna valutazione finora

- Model CB 15-100 HP Boilers: Sound LevelDocumento5 pagineModel CB 15-100 HP Boilers: Sound LevelsebaversaNessuna valutazione finora

- Frame E: Beam ReinforcementDocumento2 pagineFrame E: Beam ReinforcementEdison BoteNessuna valutazione finora

- Gomas AméricasDocumento6 pagineGomas AméricasEurys Manuel AbreuNessuna valutazione finora

- Pump CatalogDocumento10 paginePump Cataloggreatwallshipping.indNessuna valutazione finora

- 3VA Molded Case Circuit Breaker With IEC-and UL-certificationDocumento2 pagine3VA Molded Case Circuit Breaker With IEC-and UL-certificationDinuro DiNessuna valutazione finora

- 5ii. tERASAKIDocumento2 pagine5ii. tERASAKIlimNessuna valutazione finora

- AMERICAN Ductile Iron Mechanical Joint FittingsDocumento1 paginaAMERICAN Ductile Iron Mechanical Joint Fittingssanshinde10Nessuna valutazione finora

- Megaprofil 200-420-840Documento3 pagineMegaprofil 200-420-840ing AFNessuna valutazione finora

- R1 - Compt. of Loads - BocaueDocumento5 pagineR1 - Compt. of Loads - BocaueFrancis Grant ReladoNessuna valutazione finora

- Ampacity Charts: Wire Size and Amp RatingsDocumento1 paginaAmpacity Charts: Wire Size and Amp RatingsEsgurdNessuna valutazione finora

- Circuit Breaker TablesDocumento1 paginaCircuit Breaker TablesJose PirulliNessuna valutazione finora

- Istruzioni Per La Regolazione Del Freno Serie T - EngDocumento2 pagineIstruzioni Per La Regolazione Del Freno Serie T - Engd!egoNessuna valutazione finora

- Jogi Engineering Industries: Candle Machines Since 1972Documento7 pagineJogi Engineering Industries: Candle Machines Since 1972NalliNessuna valutazione finora

- Molded-Case Circuit Breaker Design: Frame Size A Interrupting Capacity A Continuous Current Ratings, ADocumento16 pagineMolded-Case Circuit Breaker Design: Frame Size A Interrupting Capacity A Continuous Current Ratings, AGlenn GregorioNessuna valutazione finora

- Dimensions & Properties of ISI Rolled Steel SectionsDocumento18 pagineDimensions & Properties of ISI Rolled Steel SectionsPRAFULGANATRA89% (18)

- Thermic Fluid Pumps BrochureDocumento8 pagineThermic Fluid Pumps BrochureBala MuruganNessuna valutazione finora

- Bang Gia HPC 05 Bang Gia Fuji Edc Fuji ElectricDocumento17 pagineBang Gia HPC 05 Bang Gia Fuji Edc Fuji ElectricVăn Hùng NguyễnNessuna valutazione finora

- Extracto Norma IEC 60071 T2 y T3Documento3 pagineExtracto Norma IEC 60071 T2 y T3rubenpr17Nessuna valutazione finora

- Motors - Ahmed DawoodDocumento14 pagineMotors - Ahmed DawoodAhmed WagihNessuna valutazione finora

- Retaining Wall3Documento1 paginaRetaining Wall3jparsbNessuna valutazione finora

- Anéis Guia de Nylon: Medidas Nominais MilimétricasDocumento1 paginaAnéis Guia de Nylon: Medidas Nominais MilimétricasGeferson AlvesNessuna valutazione finora

- 170M 6809Documento2 pagine170M 6809bernaNessuna valutazione finora

- TriaxialDocumento7 pagineTriaxialAakash KamthaneNessuna valutazione finora

- OF Effective: Pitch Diameter (MM) Diameter + (2Documento1 paginaOF Effective: Pitch Diameter (MM) Diameter + (2srinivas murthyNessuna valutazione finora

- Panneau Pub LED GeantDocumento6 paginePanneau Pub LED GeantHassen Ben Ali GannouniNessuna valutazione finora

- PPRC EstimateDocumento2 paginePPRC EstimateadnansaghirNessuna valutazione finora

- Cyprus National Annex en 1993-1-1Documento11 pagineCyprus National Annex en 1993-1-1Atalay YordamNessuna valutazione finora

- NullDocumento4 pagineNullnateNessuna valutazione finora

- Positive Displacement Pump SelectionDocumento3 paginePositive Displacement Pump SelectionBimlesh Kumar SinghNessuna valutazione finora

- Phase Clearance - IEC 61936-Part 1Documento5 paginePhase Clearance - IEC 61936-Part 1Sethu Raman75% (4)

- Juntas Fluroflex N3 y N4Documento1 paginaJuntas Fluroflex N3 y N4Alberto Alfaro CerdaNessuna valutazione finora

- Fiberglass Polyester Resin Motor GuardDocumento1 paginaFiberglass Polyester Resin Motor GuardKailash Chandra SutharNessuna valutazione finora

- Anéis Guia de Nylon: Medidas Nominais MilimétricasDocumento1 paginaAnéis Guia de Nylon: Medidas Nominais MilimétricasGeferson AlvesNessuna valutazione finora

- AVK Butterfly Valves Centric 75 - TADocumento1 paginaAVK Butterfly Valves Centric 75 - TANam Nguyễn ĐứcNessuna valutazione finora

- Classification of Conductors According To IEC 60228Documento3 pagineClassification of Conductors According To IEC 60228Jacob de Wilde100% (1)

- Correias Sincronizadoras 5M: em Borracha Neoprene Com Cordonéis em Fibra de VidroDocumento2 pagineCorreias Sincronizadoras 5M: em Borracha Neoprene Com Cordonéis em Fibra de VidroJoãoNessuna valutazione finora

- History of Fire Safety Engineering: Session JT1Documento28 pagineHistory of Fire Safety Engineering: Session JT1Gabriel LopezNessuna valutazione finora

- LONGMAN 2001 Complete - Course.for - The.toefl - Test Preparation - For.the - Computer.and - Paper.testsDocumento5 pagineLONGMAN 2001 Complete - Course.for - The.toefl - Test Preparation - For.the - Computer.and - Paper.testsGabriel Lopez0% (1)

- SPP Pumps - Mod. TD15F - Información TécnicaDocumento7 pagineSPP Pumps - Mod. TD15F - Información TécnicaGabriel LopezNessuna valutazione finora

- Listening and Reading Practice SupplementDocumento224 pagineListening and Reading Practice SupplementGabriel LopezNessuna valutazione finora

- Hydraulic Calculations Fire ProtectionDocumento16 pagineHydraulic Calculations Fire ProtectionGabriel LopezNessuna valutazione finora

- NFPA 99 - Health Care Facilities Code 2000 - 2012Documento56 pagineNFPA 99 - Health Care Facilities Code 2000 - 2012Gabriel LopezNessuna valutazione finora

- MST 1Documento1 paginaMST 1Gabriel LopezNessuna valutazione finora

- A-100 Sprinkler Spray Patterns PDFDocumento22 pagineA-100 Sprinkler Spray Patterns PDFGabriel LopezNessuna valutazione finora

- 7-11 Conveyors: Single Belt Double Tier, Belt With Barrier 4 FT (1.2 M) Belt Enclosed in Dust Control HoodDocumento1 pagina7-11 Conveyors: Single Belt Double Tier, Belt With Barrier 4 FT (1.2 M) Belt Enclosed in Dust Control HoodGabriel LopezNessuna valutazione finora

- FM Global Property Loss Prevention Data Sheets: List of FiguresDocumento17 pagineFM Global Property Loss Prevention Data Sheets: List of FiguresGabriel LopezNessuna valutazione finora

- Spodumene: "Kunzite" Redirects Here. For The Sailor Moon Character, See ShitennouDocumento4 pagineSpodumene: "Kunzite" Redirects Here. For The Sailor Moon Character, See ShitennouGabriel LopezNessuna valutazione finora

- Global Lithium Production: CostsDocumento1 paginaGlobal Lithium Production: CostsGabriel LopezNessuna valutazione finora

- Chart 3Documento1 paginaChart 3Gabriel LopezNessuna valutazione finora

- The Original Dome ValveDocumento4 pagineThe Original Dome ValveTan Nguyen Huu100% (2)

- Air Intake and Exhaust System 13-20-1 (Hino Engine Type J08etm-Ksda)Documento4 pagineAir Intake and Exhaust System 13-20-1 (Hino Engine Type J08etm-Ksda)Oecox Cah DjadoelNessuna valutazione finora

- Weather Head E BRFI MC001 E3Documento159 pagineWeather Head E BRFI MC001 E3jeffls68688100% (1)

- Centrifugal Pump Troubleshooting ChecklistDocumento8 pagineCentrifugal Pump Troubleshooting Checklistab_s5036Nessuna valutazione finora

- Brew House SopDocumento33 pagineBrew House SopRiyanNessuna valutazione finora

- Presentation ConocoPhillips Gas SeparatorDocumento24 paginePresentation ConocoPhillips Gas SeparatorEnyerberht Castañeda BritoNessuna valutazione finora

- Condensate Return Systems 10.11.12 PDFDocumento53 pagineCondensate Return Systems 10.11.12 PDFarunyoga100% (2)

- Thermo Expansion Valves T L 935 ZZ Series Technical Bulletin en GB 4399528Documento8 pagineThermo Expansion Valves T L 935 ZZ Series Technical Bulletin en GB 4399528Ahmed KhalifaNessuna valutazione finora

- CW Pump Intake Forebay Design As Per HIS 9.8.2Documento4 pagineCW Pump Intake Forebay Design As Per HIS 9.8.2Amit SaxenaNessuna valutazione finora

- Auxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Documento81 pagineAuxiliary Boiler Construction Details: BY Mohammed Arif M Mechanical Engineer 41256Arif MechanicalNessuna valutazione finora

- Q116 Hydrostatic Test ProcedureDocumento18 pagineQ116 Hydrostatic Test ProcedureParthiban NCNessuna valutazione finora

- Exhaust System CalculationDocumento2 pagineExhaust System CalculationZa YonNessuna valutazione finora

- Apu Comparison in Igo Fleet PDFDocumento19 pagineApu Comparison in Igo Fleet PDFRahul UnnikrishnanNessuna valutazione finora

- 4 Curvas Das Bombas - R1Documento4 pagine4 Curvas Das Bombas - R1João Paulo Augusto MacedoNessuna valutazione finora

- Manual Compressor de Ar Atlas Copco Ga 55Documento4 pagineManual Compressor de Ar Atlas Copco Ga 55Junior Enrique Yataco Ariza100% (1)

- Thermal Engineering-NozzleDocumento12 pagineThermal Engineering-NozzleJayNessuna valutazione finora

- Manual Partes Diamax Ago2018Documento169 pagineManual Partes Diamax Ago2018Emanoel ResendeNessuna valutazione finora

- Pip Reec001Documento44 paginePip Reec001yoyok susantoNessuna valutazione finora

- Rab HydrantDocumento31 pagineRab HydrantKHANDANessuna valutazione finora

- Liebert Refrigerant SizingDocumento2 pagineLiebert Refrigerant Sizingcoolth2Nessuna valutazione finora

- 1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeDocumento3 pagine1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeNon Etabas GadnatamNessuna valutazione finora

- Aplicaciones Valvulas de ControlDocumento45 pagineAplicaciones Valvulas de ControlLOPEZCRG100% (1)

- Type U' Bops: Shear Bonnet IdentificationDocumento4 pagineType U' Bops: Shear Bonnet IdentificationJeneesh ShanmughanNessuna valutazione finora

- 1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataDocumento24 pagine1000 Hrs Survival Test (ASTM D 1598, ISO 14692-2) : Specimens DataNADEEM AHMEDNessuna valutazione finora

- Grundfos Technical Guide HVACDocumento68 pagineGrundfos Technical Guide HVACJosé Gregorio Rodríguez MedinaNessuna valutazione finora

- Repair ListDocumento36 pagineRepair ListRizky SkrillexNessuna valutazione finora

- MINI BEV Instruction Manual 2019 Eng MGF Rev. 1 A5 - ST-MA-017Documento8 pagineMINI BEV Instruction Manual 2019 Eng MGF Rev. 1 A5 - ST-MA-017Fati ZoraNessuna valutazione finora

- Perkins 1103 Valve InstallDocumento10 paginePerkins 1103 Valve InstallInkanata SacNessuna valutazione finora

- Suyat Experiment-7Documento8 pagineSuyat Experiment-7Lpt Ashley OlbinarNessuna valutazione finora

- Gardner DenverDocumento18 pagineGardner DenverMick V100% (1)