Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Outlets and Modules PDF

Caricato da

Venance MasanjaTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Outlets and Modules PDF

Caricato da

Venance MasanjaCopyright:

Formati disponibili

Hydraulics Prof. B.S.

Thandaveswara

15.4 Outlets and Modules

The success of any irrigation enterprise depends on the efficiency of distributing

sufficient supply of water to the irrigator. Each irrigator has to receive certain quantity of

water proportionate to his extent in a canal system at the proper time to ensure him a

good crop. This distribution of water is carried out by means of outlets otherwise called

modules. Hence, proper design of an outlet, is of most importance not only to the canal

engineer but to the irrigator also.

In Punjab and Maharashtra, a number of outlet structures were evolved, designed to

allow into the cultivator's watercourses a constant discharge irrespective of the supply

(level) in the distributing channel (module) or discharges proportional to the supply

(level) in the channel (semi-module). A few of the structures in common use in India are

(i) Standing wave flume.

(ii) Crump's adjustable proportional Semi module.

(iii) Lindley type standing wave flume.

(iv) Orifice type standing wave pipe outlet.

(v) Gibb's module.

There are various types of modules:

a. Rigid Modules

These modules allow constant discharge within reasonable working limits of head

irrespective of water levels in the distributory and the water course of the main canal.

b. Flexible Modules or Semi Modules

This type of module gives discharge in some characteristic manner with surface level in

the supply channel but independent of the variation of the water level in the delivery

channel.

c. Non-Modular Outlets

Non-modular outlets are those whose discharge is a function of the difference in levels

between the water surface in the distributing channel and the water course.

Indian Institute of Technology Madras

Hydraulics Prof. B.S. Thandaveswara

15.4.1 Standing Wave Flume

The standing wave flume is a semi-module measuring discharge with a high degree of

accuracy (viz., 1.5 percent) besides having the advantage that a single gauge reading

upstream is all that required. In the standard standing wave flume evolved at Poona -

the head required can vary from 8 to 15 percent of the upstream depth of water over the

sill without affecting the discharge; the modular ratio (i.e., the ratio of the downstream

water depth to the total upstream depth, measured above the sill level) can be as high

as 85 percent in small flumes and 92 percent in large flumes. It can be best used when

variable discharge needs to be measured accurately and also when facilities for

supervision or for automatic recording for gauges are available. This flume was evolved

by Crump (Punjab) and Inglis (Bombay) after carrying out intensive model

investigations.

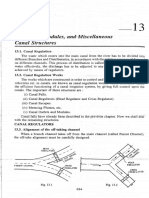

0

60

Glacis

B1 L1 L2 B2 B3

R1=H1.5

0

60

2.5H1.5

Plan

Gauge chamber

hv

H

y H H1 y

1 2:1 y 3 y +25%

3

3

Rhump R = 2H

h = hump height L1 L2 L3

Longitudinal Section

Standard standing wave flume design

The flume comprises of

(1) An approach channel of suitable design,

(2) A bell mouth entrance,

Indian Institute of Technology Madras

Hydraulics Prof. B.S. Thandaveswara

(3) A throat with a horizontal bottom and vertical sides,

(4) A downstream glacis, and

(5) An expansion in which the flow is redistributed before it passes into the downstream

channel and head is recovered.

It is essentially a broad-crested weir and its discharge is given by formula

Q = Co CBH 1.5

in which, B is the width of the throat, H is the total head (depth of water upstream y1 +

head due to velocity of approach hv ) on the upstream side sill level, and C is a

coefficient to allow for losses due to friction, eddies, impact shock, etc.

Values of C and adjusted values of the constant for properly designed flumes without

piers are given in Table.

Discharge in m3/s C C0

0.06 - 0.28 0.97 3.00

0.30 - 1.40 0.98 3.03

1.40 - 14.0 0.99 3.06

over 14.0 1.00 3.09

More abrupt curves than in the standard design will slightly lower the coefficient. The

coefficient C (=0.99) for discharges from (1.4 to 14 m3s-1) was confirmed by actual

observations carried out on the prototype in Sind.

With piers, loss of energy due to shock which lowers the value of C. In Sind, falls and

fall regulators were designed using the values shown in Table above, but observations

showed that C was much lower, the average value of C for discharges 110 to 280 m3s-1

on the Rohri Canal being about 6 percent lower. Based on the experimental

investigations carried out at the Central Water and Power Research Station, Poona, in

1933, the following formula is suggested with the piers:

Q = C ( B k n H ) H 1.5

in which, 'k' is the coefficient of contraction due to piers, (0.82 with standard piers), n is

the number of piers, B is the waterway, C = 3.088, and H = total head (including velocity

head).

Indian Institute of Technology Madras

Hydraulics Prof. B.S. Thandaveswara

15.4.2 Crump's Adjustable Proportional Semi-Module

This semi-module can be either of the orifice type or of the open type and fixed at the

head of the outlet. These have been used extensively in Punjab.

Top of bank 0.76

Roof of block

F.S.L

h

H FSL in water course

y

H 0.14

Brick pitching

19.80 Bed of WC

Bed R.L 22.86

b

Longitudinal Section

Crump's Adjustable Proportional Semimodule

15.4.3 Lindley Type Standing Wave Flume

This is a short throated flume with one side straight and the other curved. This is

normally used as an outlet for water courses taking off at right angles from the

distributary.

GIBB Module:

The main disadvantage of a non-modular outlet is that cultivators can draw more water

by tampering in large numbers on a canal system.

Gibb module was found to be the only module which has no moving parts. As against

modules whose working depends on floats or other moving mechanisms there are a few

devices in which the discharge is automatically regulated by the velocity of the water

itself without the necessity of any moving parts. Gibb an Executive Engineer of the

irrigation Department, Punjab devised a module form of outlet, which was built for the

first time on the Melay distributory of the Lower Thelam Canal. This module is named as

Gibb module after its inventor and it gives an almost constant discharge over a

considerable range, irrespective of the upstream and downstream water levels. It is one

of the rigid modules without any moving parts. It does not need any supervision and

cannot be easily tampered with.

Water is led through an inlet pipe (See Figure) into a spiral rectangular trough (eddy

chamber) in which free vortex flow is developed. The water on the outside of the curve

rises in level and the water surface slopes towards the inner wall. A number of baffles

Indian Institute of Technology Madras

Hydraulics Prof. B.S. Thandaveswara

are inserted in the eddy chamber with their lower edges sloping at the required height

above the bottom. As the head increases, the water banks up at the outer

circumference of the eddy chamber and impinges against the baffles imparting an

upward rotational direction of flow to the water, which spins round in the compartment

between two successive baffles and finally drops on the on-coming stream of water,

thus, dissipating excess energy and keeping the discharge constant. The degree of turn

of the spiral depends on the volume of discharge and the working range required and

generally varies from one semi-circle to one and a half complete circles.

Though this module gives constant discharge, it has the following disadvantages.

1. This module could be easily tampered with by breaking the baffles and eddy

chamber.

2. It is costlier than other types of outlets.

3. Construction of this module is a very difficult process and needs higher technical

skills.

4. It is said to have a lot of trouble regarding silt drawal. The vent is likely to be choked

by the silt and floating materials coming in the channel and periodical cleaning may be

difficult.

Under the circumstances stated above this module can be used in places where small

drawals are required for small plots from main channels. For e.g. in channel having 0.5

m3/s flow a plot of 40 hectares will be requiring 0.03 m3/s and the depth of flow in the

main channel will less than 0.4 m. Under such circumstances this will ensure minimum

losses due to the small branches taking off from main canal.

Indian Institute of Technology Madras

Hydraulics Prof. B.S. Thandaveswara

0.85 m Curved rising pipe

0.41 m 0.34 m

d = 30.48 cm

12.7 cm slab

Outlet channel bed

0.85 m

Longitudinal Section

Baffles

Bell-mouth entrance

Dia 30.48

1 in 10

Spout

Inlet pipe 1 in 10

Plan

Gibb module

Indian Institute of Technology Madras

Hydraulics Prof. B.S. Thandaveswara

Side view of Gibb's Module Eddychamber Gibbs Module (Eddy chamber in action)

Gibb's Module (Side View) Gibb's Module (Downstream View)

Indian Institute of Technology Madras

Potrebbero piacerti anche

- Unit 6 (DESIGN OF REINFORCED CONCRETE CONTINUOUS BEAMS)Documento26 pagineUnit 6 (DESIGN OF REINFORCED CONCRETE CONTINUOUS BEAMS)Zara Nabilah90% (30)

- 6th Central Pay Commission Salary CalculatorDocumento15 pagine6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Site Analysis ChecklistDocumento2 pagineSite Analysis ChecklistBereket K86% (7)

- L 31Documento12 pagineL 31RadhaAnanthalekshmiNessuna valutazione finora

- Pipeline Design for Water EngineersDa EverandPipeline Design for Water EngineersValutazione: 5 su 5 stelle5/5 (1)

- Hydraulic Laboratory Civil Engineering Department Sultan Azlan Shah PolytechnicDocumento12 pagineHydraulic Laboratory Civil Engineering Department Sultan Azlan Shah PolytechnicSyafiq Roslan75% (4)

- Transition DesignDocumento13 pagineTransition DesignlahirujayasiriNessuna valutazione finora

- Broad Crested WeirDocumento7 pagineBroad Crested Weirjccamorim100% (2)

- Broad Crested WeirDocumento9 pagineBroad Crested WeirAli MohsenNessuna valutazione finora

- How To Design BarrageDocumento6 pagineHow To Design BarrageRaja HilalNessuna valutazione finora

- Ned University of Engineering & TechnologyDocumento49 pagineNed University of Engineering & TechnologyFraaz NzarNessuna valutazione finora

- Planning, Design, Installation Operation and Maintenance ofDocumento40 paginePlanning, Design, Installation Operation and Maintenance ofSaiteja PanyamNessuna valutazione finora

- Yall ExperimentDocumento21 pagineYall ExperimentkoteangNessuna valutazione finora

- Lab Weir Exp 3Documento15 pagineLab Weir Exp 3Amy FarhanaNessuna valutazione finora

- Flow Over The Weir Jan20Documento3 pagineFlow Over The Weir Jan20Ammar AzfarNessuna valutazione finora

- Design Principles For Aqueduct and Siphon AqueductDocumento16 pagineDesign Principles For Aqueduct and Siphon AqueductartiNessuna valutazione finora

- Sharp-Crested Weirs For Open Channel Flow Measurement: Course ContentDocumento37 pagineSharp-Crested Weirs For Open Channel Flow Measurement: Course ContentÁrpád VassNessuna valutazione finora

- The Broad Crested WeirDocumento6 pagineThe Broad Crested WeirIshara CoorayNessuna valutazione finora

- Chapter 7 Flow MeasurementDocumento19 pagineChapter 7 Flow MeasurementAce ThunderNessuna valutazione finora

- Hec Ras Training Day 2 PDFDocumento147 pagineHec Ras Training Day 2 PDFHendrickNessuna valutazione finora

- Lecture Notes-Open Channel-1Documento24 pagineLecture Notes-Open Channel-1Leonardo ValentineNessuna valutazione finora

- CHAPTER3 Water Flow MeasurementsDocumento8 pagineCHAPTER3 Water Flow MeasurementsMel CapalunganNessuna valutazione finora

- Final Experiment HydraulicsDocumento12 pagineFinal Experiment HydraulicsKevin OngjuncoNessuna valutazione finora

- Design of Channel Transitions, Open-Channel Hydraulics, Dr. Victor M. Ponce, San Diego State UniversityDocumento19 pagineDesign of Channel Transitions, Open-Channel Hydraulics, Dr. Victor M. Ponce, San Diego State UniversityHip HensNessuna valutazione finora

- Broad Crested WeirDocumento11 pagineBroad Crested WeirKyra Claire Zaharr0% (1)

- 14 - Hydraulic Design of Urban Drainage Systems Part 3Documento38 pagine14 - Hydraulic Design of Urban Drainage Systems Part 3Mai Quang HuyNessuna valutazione finora

- Canal SystemsDocumento69 pagineCanal SystemsAnter TsatseNessuna valutazione finora

- Chapter 6-SpillwaysDocumento27 pagineChapter 6-SpillwaysMohamed Al-Odat100% (1)

- Open Channel FlowDocumento114 pagineOpen Channel FlowTesfaye NegasaNessuna valutazione finora

- Water Flow in Open Channels: The Islamic University of Gaza Faculty of Engineering Civil Engineering DepartmentDocumento74 pagineWater Flow in Open Channels: The Islamic University of Gaza Faculty of Engineering Civil Engineering DepartmentTesfaye NegasaNessuna valutazione finora

- INDIAN - Hydaulic - Design - of - SHP - ProjectDocumento116 pagineINDIAN - Hydaulic - Design - of - SHP - ProjectYasir IqbalNessuna valutazione finora

- Downstream Effect On Submerged Flow in Rectangular Compound Section FlumesDocumento9 pagineDownstream Effect On Submerged Flow in Rectangular Compound Section FlumesLamia BahiNessuna valutazione finora

- Chapter 3. Wells and Well Hydraulics (HWRE 6034)Documento110 pagineChapter 3. Wells and Well Hydraulics (HWRE 6034)Saqalain HaiderNessuna valutazione finora

- Long Crested Weir DesignDocumento9 pagineLong Crested Weir Designbalaji_raochNessuna valutazione finora

- Regulator: Regulator Structures For Controlling The Flow Through A Parent CanalDocumento8 pagineRegulator: Regulator Structures For Controlling The Flow Through A Parent CanalgarusingheNessuna valutazione finora

- Design of Channel Transitions: Victor M. PonceDocumento20 pagineDesign of Channel Transitions: Victor M. PonceKostas LazarakisNessuna valutazione finora

- Flow of Water by Notch and WeirsDocumento15 pagineFlow of Water by Notch and WeirsAngelica Joyce BenitoNessuna valutazione finora

- Lab ManualDocumento15 pagineLab ManualokbhaNessuna valutazione finora

- Spillway DesignDocumento18 pagineSpillway DesignFrancisco Alves100% (2)

- Emprical Equations For Fluid FlowDocumento6 pagineEmprical Equations For Fluid FlowAyub Ali WehelieNessuna valutazione finora

- Flow Ovr WeirDocumento9 pagineFlow Ovr WeirniasandiwaraNessuna valutazione finora

- CIVL4120 Advanced Open Channel Hydraulics and Design - TUTORIALDocumento3 pagineCIVL4120 Advanced Open Channel Hydraulics and Design - TUTORIALWalterHuNessuna valutazione finora

- Chapter 4 FLOW MEASUREMENTDocumento53 pagineChapter 4 FLOW MEASUREMENTCostinel CristescuNessuna valutazione finora

- Low Water Stream CrossingsDocumento8 pagineLow Water Stream CrossingsAnonymous 87xpkIJ6CFNessuna valutazione finora

- Hydraulics Experiment 7Documento9 pagineHydraulics Experiment 7Allen Jesse Alfonso AtanacioNessuna valutazione finora

- Hydraulics: 6.1. Headworks For River Water OfftakeDocumento50 pagineHydraulics: 6.1. Headworks For River Water OfftakesuonsovannakaNessuna valutazione finora

- Fluid Mechanic Lab ManualDocumento15 pagineFluid Mechanic Lab ManualAltamash NadimallaNessuna valutazione finora

- Chapter 4 - 1 Fluid Dynamics (Modifed)Documento21 pagineChapter 4 - 1 Fluid Dynamics (Modifed)KubaNessuna valutazione finora

- Lesson 7. Runoff Measurement Using WeirsDocumento12 pagineLesson 7. Runoff Measurement Using WeirsPasi C4SieleNessuna valutazione finora

- Canal IrrigationDocumento17 pagineCanal IrrigationketemaNessuna valutazione finora

- Chap - 3 - HSI (Part 1)Documento27 pagineChap - 3 - HSI (Part 1)MitikuNessuna valutazione finora

- 13 - Regulators Modules and Miscellaneous Canal StructuresDocumento37 pagine13 - Regulators Modules and Miscellaneous Canal StructuresAbdulbasit Aba BiyaNessuna valutazione finora

- Experimental and Numerical Study of Flow Over A BroadDocumento13 pagineExperimental and Numerical Study of Flow Over A BroadJean Carlos D. VidalNessuna valutazione finora

- Flow Over Spill Ways and Energy Dissipators 08.07.2021Documento7 pagineFlow Over Spill Ways and Energy Dissipators 08.07.2021Chamux skalNessuna valutazione finora

- 4.experiment No 4 - Broad Crested WeirDocumento19 pagine4.experiment No 4 - Broad Crested WeirMd Sajedul Islam SetuNessuna valutazione finora

- Hydrology and Hydraulic Engineering I CEDocumento31 pagineHydrology and Hydraulic Engineering I CEAyodele MastaNessuna valutazione finora

- Spillways: Lecture #2 (Con'd)Documento15 pagineSpillways: Lecture #2 (Con'd)Mūssā Mūhābā ZēĒthiopiāNessuna valutazione finora

- Final EditDocumento21 pagineFinal EditFahmy DiaaNessuna valutazione finora

- Other Canal Structures: Regulation WorksDocumento56 pagineOther Canal Structures: Regulation WorkskkodgeNessuna valutazione finora

- Design of Hydraulic Structure - 3-2018-2019 StudentDocumento6 pagineDesign of Hydraulic Structure - 3-2018-2019 Studentaland pshtiwanNessuna valutazione finora

- Turbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsDa EverandTurbulent Buoyant Jets and Plumes: HMT: The Science & Applications of Heat and Mass Transfer. Reports, Reviews & Computer ProgramsNessuna valutazione finora

- Irrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsDa EverandIrrigation Works: The Principles on Which Their Design and Working Should Be Based, with Special Details Relating to Indian Canals and Some Proposed ImprovementsNessuna valutazione finora

- Hydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedDa EverandHydraulic Tables; The Elements Of Gagings And The Friction Of Water Flowing In Pipes, Aqueducts, Sewers, Etc., As Determined By The Hazen And Williams Formula And The Flow Of Water Over The Sharp-Edged And Irregular Weirs, And The Quantity DischargedNessuna valutazione finora

- Mixture Design Lime Stabilized SoilDocumento6 pagineMixture Design Lime Stabilized SoildandydelabajanNessuna valutazione finora

- Professional Ethics NotesDocumento43 pagineProfessional Ethics NotesVenance MasanjaNessuna valutazione finora

- JBLDocumento1 paginaJBLVenance MasanjaNessuna valutazione finora

- Structural Designing and Detailing of The New Proposed Children Ward Block (Case Study: Kilwa Road, Police Barracks Hospital)Documento1 paginaStructural Designing and Detailing of The New Proposed Children Ward Block (Case Study: Kilwa Road, Police Barracks Hospital)Venance MasanjaNessuna valutazione finora

- JBLDocumento1 paginaJBLVenance MasanjaNessuna valutazione finora

- 1..title. Arctitle. Architechitectural Vs Designing 2..title Itle Construction Materials Vs Geographicaterials Vs Geographic ClimaticDocumento1 pagina1..title. Arctitle. Architechitectural Vs Designing 2..title Itle Construction Materials Vs Geographicaterials Vs Geographic ClimaticVenance MasanjaNessuna valutazione finora

- Ce2301 NolDocumento24 pagineCe2301 NolNatesa IndrasenanNessuna valutazione finora

- Alphonce Magori Updated Resume PESDocumento4 pagineAlphonce Magori Updated Resume PESVenance MasanjaNessuna valutazione finora

- Soil Stabilisation PDFDocumento13 pagineSoil Stabilisation PDFscaldasoleNessuna valutazione finora

- Water ResourcesDocumento1 paginaWater ResourcesVenance MasanjaNessuna valutazione finora

- Chapter 1 - Soils Tex-121-E, Soil-Lime TestingDocumento7 pagineChapter 1 - Soils Tex-121-E, Soil-Lime TestingVenance MasanjaNessuna valutazione finora

- Title Roads Designing Allowing Long Allowing Local Bussiness To Be Acal Bussiness To Be AcccomodetedDocumento1 paginaTitle Roads Designing Allowing Long Allowing Local Bussiness To Be Acal Bussiness To Be AcccomodetedVenance MasanjaNessuna valutazione finora

- Application LatterDocumento1 paginaApplication LatterVenance MasanjaNessuna valutazione finora

- ST Joseph University in Tanzania: S BensinghdhasDocumento25 pagineST Joseph University in Tanzania: S BensinghdhasVenance MasanjaNessuna valutazione finora

- Master 1Documento6 pagineMaster 1Venance MasanjaNessuna valutazione finora

- Training and Working Experience Institute / Organization Task/Duties Group Six International LimitedDocumento1 paginaTraining and Working Experience Institute / Organization Task/Duties Group Six International LimitedVenance MasanjaNessuna valutazione finora

- Mak LetterDocumento1 paginaMak LetterVenance MasanjaNessuna valutazione finora

- Curriculum Vitae-Complete DegreeDocumento5 pagineCurriculum Vitae-Complete DegreeVenance Masanja100% (3)

- PCCB, Urambo Street, Dar Es Salaam To Your Location - Google MapsDocumento1 paginaPCCB, Urambo Street, Dar Es Salaam To Your Location - Google MapsVenance MasanjaNessuna valutazione finora

- Primary CertificateDocumento1 paginaPrimary CertificateVenance MasanjaNessuna valutazione finora

- Resume 1Documento1 paginaResume 1Venance MasanjaNessuna valutazione finora

- Secure Online Banking Transaction by Using One Time Pin: Project ReportDocumento2 pagineSecure Online Banking Transaction by Using One Time Pin: Project ReportVenance MasanjaNessuna valutazione finora

- Environmentall 001Documento1 paginaEnvironmentall 001Venance MasanjaNessuna valutazione finora

- Subject Name: Water Resources Engineering Department: Civil Semester: 7 Group MembersDocumento8 pagineSubject Name: Water Resources Engineering Department: Civil Semester: 7 Group MembersVenance MasanjaNessuna valutazione finora

- Bridge Hydraulic Design (2000)Documento60 pagineBridge Hydraulic Design (2000)ArmandoNessuna valutazione finora

- Semester ExamDocumento4 pagineSemester ExamVenance MasanjaNessuna valutazione finora

- 6300 L11 CalibrationofCanalGates PDFDocumento16 pagine6300 L11 CalibrationofCanalGates PDFVenance MasanjaNessuna valutazione finora

- GJESM Volume 8 Issue 2 Pages 237-250Documento14 pagineGJESM Volume 8 Issue 2 Pages 237-250GJESMNessuna valutazione finora

- Surface WaterDocumento22 pagineSurface WaterLuis MenendezNessuna valutazione finora

- WATER RESOURCE ENGINEERING ReportDocumento10 pagineWATER RESOURCE ENGINEERING ReportIsha Awhale PatilNessuna valutazione finora

- Star San Technical SpecificationsDocumento2 pagineStar San Technical Specificationssamql91GNessuna valutazione finora

- AFIL Eng Capability - RevisedDocumento5 pagineAFIL Eng Capability - RevisedArunprasad MurugesanNessuna valutazione finora

- PDS HEMPATEX ENAMEL 56360 en-GB PDFDocumento2 paginePDS HEMPATEX ENAMEL 56360 en-GB PDFMohamed ChelfatNessuna valutazione finora

- Contact: Product Specification - Tripol™ 9010Documento1 paginaContact: Product Specification - Tripol™ 9010Carlos BenitezNessuna valutazione finora

- Jindal Star Brochure Erw BrandDocumento2 pagineJindal Star Brochure Erw Brandguiness_joe9154Nessuna valutazione finora

- Rain Water HarvestingDocumento19 pagineRain Water HarvestingAbhijit DasNessuna valutazione finora

- Preliminary Documents Design Report PDFDocumento77 paginePreliminary Documents Design Report PDFRamanNessuna valutazione finora

- Essay MuetDocumento1 paginaEssay Muettan yingxuanNessuna valutazione finora

- Bio With Answer KeyDocumento6 pagineBio With Answer KeyMari CrisNessuna valutazione finora

- Haccp Manual: New Foods LimitedDocumento204 pagineHaccp Manual: New Foods LimitedHotna OktariaNessuna valutazione finora

- Catalogo IbtDocumento28 pagineCatalogo IbtGuizza GuizzaaNessuna valutazione finora

- gb5 & fb80: U.S. Installation GuidelineDocumento2 paginegb5 & fb80: U.S. Installation GuidelineAnatoliy RozenbljumNessuna valutazione finora

- Vortex Power GeneratorDocumento22 pagineVortex Power GeneratorMANTECH PublicationsNessuna valutazione finora

- 7.1 Oily Water Treatment JowaDocumento2 pagine7.1 Oily Water Treatment JowaSudath Kularathna0% (1)

- Chapter 2: Biological Molecules: SummaryDocumento9 pagineChapter 2: Biological Molecules: SummaryMerimaNessuna valutazione finora

- Removal of Suspended Fine Particulate Matter From Raw Juice PPT ScribdDocumento45 pagineRemoval of Suspended Fine Particulate Matter From Raw Juice PPT ScribdKunchey JagadeeshNessuna valutazione finora

- The Use of The Normalized Difference Water Index (NDWI) in The Delineation of Open Water FeaturesDocumento9 pagineThe Use of The Normalized Difference Water Index (NDWI) in The Delineation of Open Water FeaturesYasmim MenezesNessuna valutazione finora

- CRX-D Series 2010 Catalogue 1Documento8 pagineCRX-D Series 2010 Catalogue 1Do Ngoc HuuNessuna valutazione finora

- Public Talk On ToiletDocumento1 paginaPublic Talk On ToiletRichard LeongNessuna valutazione finora

- Agricultural MeteorologyDocumento25 pagineAgricultural MeteorologyAman IndwarNessuna valutazione finora

- IELTS Speaking總整理Documento13 pagineIELTS Speaking總整理Sarita Chuang SaraNessuna valutazione finora

- Diesel Storage - Above Ground TankDocumento16 pagineDiesel Storage - Above Ground TankBasil Oguaka100% (1)

- 1.1.8 Explore - The World's Water Problems (Exploration)Documento5 pagine1.1.8 Explore - The World's Water Problems (Exploration)VenniNessuna valutazione finora

- Coastal Processes PDFDocumento33 pagineCoastal Processes PDFنورأنيسزولياناNessuna valutazione finora