Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ISO 9001 13485 and FDA QSR Compare

Caricato da

Noorm MECopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

ISO 9001 13485 and FDA QSR Compare

Caricato da

Noorm MECopyright:

Formati disponibili

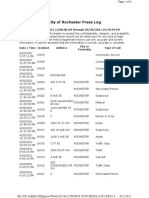

Correspondence between ISO 9001:2000 and ISO 13485:2003

and the US Quality System Regulation

Prepared by: Ed Kimmelman, Consultant

E:mail --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 1

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

1 Scope 1 Scope 820.1 Scope The scope sections of each document

1.1 General 1.1 General (a) Applicability. set out their objectives. For the

This International Standard specifies This International Standard specifies (1) Current good manufacturing practice ISO/DIS, the objective is to harmonize

requirements for a quality management requirements for a quality management (CGMP) requirements are set forth in this regulation around the world. As a result

system where an organization system where an organization needs to quality system regulation. The an attempt was made by FDA during

needs to demonstrate its ability to demonstrate its ability to provide medical requirements in this part govern the the revision of the GMPs, while the

consistently provide product that meets devices and related services that methods used in, and the facilities and 1996 version of ISO 13485 was being

customer and applicable regulatory consistently meet customer requirements controls used for, the design, developed, to incorporate the

requirements, and aims to enhance and regulatory requirements applicable to manufacture, packaging,labeling, storage, requirements that were included in that

customer satisfaction through the effective medical devices and related services. installation, and servicing of all finished version of the Standard. While the

application of the system, including devices intended for human use. The agency could not revise the format of

processes for continual improvement of the The primary objective of this International requirements in this part are intended to the regulation to follow that of the

system and the assurance of conformity to Standard is to facilitate harmonized ensure that finished devices will be safe Standard, the requirements were

customer and applicable regulatory medical device regulatory requirements for and effective and otherwise in compliance included.

requirements. quality management systems. As a result, with the Federal Food, Drug, and

it includes some particular requirements Cosmetic Act (the act). This part This section of the regulation contains

NOTE In this International Standard, the for medical devices and excludes some of establishes basic requirements applicable some additional regulatory isssues that

term product applies only to the the requirements of ISO 9001 that are not to manufacturers of finished medical are not appropriate for the Standard.

product intended for, or required by, a appropriate as regulatory requirements. devices.

customer. Because of these exclusions,

organizations whose quality management (c) Authority. Part 820 is established

systems conform to this International and issued under authority of sections

Standard cannot claim conformity to ISO 501, 502, 510, 513, 514, 515, 518, 519,

9001 unless their quality management 520, 522, 701, 704, 801, 803 of the act

systems conform to all the requirements of (21 U.S.C. 351, 352, 360, 360c, 360d,

ISO 9001 (see Annex B) 360e, 360h, 360i, 360j, 360l, 371, 374,

381, 383). The failure to comply with any

applicable provision in this part renders a

device adulterated under section 501(h) of

the act. Such a device, as well as any

person responsible for the failure to

comply, is subject to regulatory action.

(d) Foreign manufacturers. If a

manufacturer who offers devices for

import into the United States refuses to

permit or allow the completion of a Food

and Drug Administration (FDA) inspection

of the foreign facility for the purpose of

determining compliance with this part, it

Prepared by: Ed Kimmelman, Consultant

E:mail --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 2

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

shall appear for purposes of section

801(a) of the act, that the methods used

in, and the facilities and controls used for,

the design, manufacture, packaging,

labeling, storage, installation, or servicing

of any devices produced at such facility

that are offered for import into the United

States do not conform to the requirements

of section 520(f) of the act and this part

and that the devices manufactured at that

facility are adulterated under section

501(h) of the act.

(e) Exemptions or variances.

(1) Any person who wishes to petition

for an exemption or variance from any

device quality system requirement is

subject to the requirements of section

520(f)(2) of the act.

Petitions for an exemption or variance

shall be submitted according to the

procedures set forth in Sec. 10.30 of this

chapter, the FDA's administrative

procedures. Guidance is available from

the Center for Devices and Radiological

Health, Division of Small Manufacturers

Assistance, (HFZ-220), 1350 Piccard Dr.,

Rockville, MD 20850, U.S.A., telephone 1-

800-638-2041 or 1-301-443-6597, FAX

301-443-8818.

(2) FDA may initiate and grant a variance

from any device quality system

requirement when the agency determines

that such variance is in

the best interest of the public health. Such

variance will remain in effect only so long

as there remains a public health need for

the

device and the device would not likely be

made sufficiently available without the

variance.

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 3

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

1.2 Application 1.2 Application 820.1 Scope Basically, the applicability guidance for

All requirements of this International All requirements of this International (a) Applicability. the two documents is the same in both

Standard are generic and are intended to Standard are specific to organizations (1) Current good manufacturing practice documents. In essence, they allow for

be applicable to all organizations, providing medical devices, regardless of (CGMP) requirements are set forth in this the exclusion from the QMS

regardless of type, size and product the type or size of the organization. quality system regulation. The requirements associated with activities

provided. requirements in this part govern the not performed by the organization. The

Where any requirement(s) of this If regulatory requirements permit methods used in, and the facilities and standard explicitly limits those

International Standard cannot be applied exclusions of design and development controls used for, the design, exclusions to those associated with

due to the nature of an organization and its controls (see 7.3), this can be used as a manufacture, packaging,labeling, storage, product realization.

product, this can be considered for justification for their exclusion from the installation, and servicing of all finished

exclusion. quality management system. These devices intended for human use. The Because of this approach, it will be

Where exclusions are made, claims of regulations can provide alternative requirements in this part are intended to necessary for registrars to explain in

conformity to this International Standard are arrangements that are to be addressed in ensure that finished devices will be safe detail the scope of any certificates of

not acceptable unless these exclusions are the quality management system. It is the and effective and otherwise in compliance compliance with ISO 13485:2003. They

limited to requirements within clause 7, and responsibility of the organization to ensure with the Federal Food, Drug, and will have to spelled out clearly any

such exclusions do not affect the that claims of conformity with this Cosmetic Act (the act). This part exclusions.

organizations ability, or responsibility, to International Standard reflect exclusion of establishes basic requirements applicable

provide product that meets customer and design and development controls [see to manufacturers of finished medical

applicable regulatory requirements. 4.2.2 a) and 7.3]. devices.

If any requirement(s) in Clause 7 of this If a manufacturer engages in only some

International Standard is(are) not operations subject to the requirements in

applicable due to the nature of the medical this part, and not in others, that

device(s) for which the quality manufacturer need only comply with those

management system is applied, the requirements applicable to the operations

organization does not need to include in which it is engaged. With respect to

such a requirement(s) in its quality class I devices, design controls apply only

management system [see 4.2.2 a)]. to those devices listed in Sec.

820.30(a)(2). This regulation does not

The processes required by this apply to manufacturers of components or

International Standard, which are parts of finished devices, but such

applicable to the medical device(s), but manufacturers are encouraged to use

which are not performed by the appropriate provisions of this regulation as

organization, are the responsibility of the guidance. Manufacturers of human blood

organization and are accounted for in the and blood components are not subject to

organizations quality management system this part, but are subject to part 606 of this

[see 4.1 a)]. chapter.

In this International Standard the terms if

appropriate and where appropriate are (2) The provisions of this part shall be

used several times. When a requirement applicable to any finished device as

is qualified by either of these phrases, it is defined in this part, intended for human

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 4

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

deemed to be appropriate unless the use, that is manufactured, imported, or

organization can document a justification offered for import in any State or Territory

otherwise. A requirement is considered of the United States, the District of

appropriate if it is necessary in order for Columbia, or the Commonwealth of Puerto

. the product to meet specified Rico.

requirements, and/or

. the organization to carry out corrective (3) In this regulation the term ``where

action. appropriate'' is used several times. When

a requirement is qualified by ``where

appropriate,'' it is deemed to be

``appropriate'' unless the manufacturer

can document justification otherwise. A

requirement is ``appropriate'' if

nonimplementation could reasonably be

expected to result in the product not

meeting its specified requirements or the

manufacturer not being able to carry out

any necessary corrective action.

(b) Limitations. The quality system

regulation in this part supplements

regulations in other parts of this chapter

except where explicitly s tated otherwise.

In the event that it is impossible to comply

with all applicable regulations, both in this

part and in other parts of this chapter, the

regulations specifically applicable to the

device in question shall supersede any

other generally applicable requirements.

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 5

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

2 Normative reference 2 Normative reference

The following normative document contains The following referenced documents are

provisions which, through reference in this indispensable for the application of this

text, constitute provisions of this document. For dated references, only the

International Standard. For dated edition cited applies. For undated

references, subsequent amendments to, or references, the latest edition of the

revisions of, any of these publications do referenced document (including any

not apply. However, parties to agreements amendments) applies .

based on this International Standard are

encouraged to investigate the possibility of ISO 9000:2000, Quality management

applying the most recent edition of the systems Fundamentals and vocabulary

normative document indicated below. For

undated references, the latest edition of the

normative document referred to applies.

Members of ISO and IEC maintain registers

of currently valid International Standards.

ISO 9000:2000, Quality management

systems Fundamentals and vocabulary.

3 Terms and definitions 3 Terms and definitions 820.3 Definitions. The Standard spells out clearly the new

For the purposes of this International For the purposes of this document, the (a) Act means the Federal Food, Drug, meanings of the words supplier and

Standard, the terms and definitions given in terms and definitions given in ISO 9000 and Cosmetic Act, as amended (secs. organization

ISO 9000:2000 apply. apply, together with the following. 201-903, 52 Stat. 1040 et seq., as

The following terms, used in this edition of amended (21 U.S.C. 321-394)). All

ISO 9001 to describe the supply chain, The following terms, used in this edition of definitions in section 201 of the act shall

have been changed to reflect the ISO 13485 to describe the supply chain, apply to the regulations in this part.

vocabulary currently used: have been changed to reflect the

supplier---->organization-------> customer vocabulary currently used:

supplier ---> organization ---> customer

The term "organization" replaces the term

supplier used in ISO 9001:1994, and The term organization replaces the term

refers to the unit to which this International supplier used in ISO 13485:1996, and

Standard applies. Also, the term "supplier" refers to the unit to which this International

now replaces the term "subcontractor". Standard applies. Also, the term supplier

Throughout the text of this International now replaces the term subcontractor.

Standard, wherever the term product

occurs, it can also mean service. Throughout the text of this International

Standard, wherever the term product

occurs, it can also meanservice.

Wherever requirements are specified as

applying to medical devices, the

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 6

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

requirements apply equally to related

services as supplied by the organization.

The following definitions should be

regarded as generic, as definitions

provided in national regulations can differ

slightly and take precedence.

3.1 I was not able to find the regulatory

active implantable medical device definitions of these items, even though

active medical device which is intended to

Im sure the definitions in the Standard

be totally or partially introduced, surgically

or medically, into the human body or by were taken from a regulatory source.

medical intervention into a natural orifice,

and which is intended to remain after the

procedure

3.2

active medical device

medical device relying for its functioning

on a source of electrical energy or any

source of power other than that directly

generated by the human body or gravity

3.3

advisory notice

notice issued by the organization,

subsequent to delivery of the medical

device, to provide supplementary

information and/or to advise what action

should be taken in

. the use of a medical device,

. the modification of a medical device,

. the return of the medical device to the

organization that supplied it, or

. the destruction of a medical device

NOTE Issue of an advisory notice might

be required to comply with national or

regional regulations.

3.4 (b) Complaint means any written, The regulatory definition is a bit

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 7

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

customer complaint electronic, or oral communication that broader, as it covers products that have

written, electronic or oral communication alleges deficiencies related to the identity, not, as yet, been placed on the market,

that alleges deficiencies related to the quality, durability,

but have been released for distribution.

identity, quality, durability, reliability, safety reliability, safety, effectiveness, or

or performance of a medical device that performance of a device after it is released This would mean that a lot of product

has been placed on the market for distribution. that has been released for distribution

could be included in the activities

associated with a customer complaint,

even though no part of the lot has not

reached the cus tomer.

3.5 [21CFR 812.3(d) Implant means a device The definition in the Standard includes

implantable medical device that is placed into a surgically or naturally explicitly eye implants. I am not sure

medical device intended formed cavity of the human body if it is

how FDA treats these products.

. to be totally or partially introduced into intended to remain there for a period of 30

the human body or a natural orifice, or days or more. FDA man, in order to protect

. to replace an epithelial surface or the public health, determine that devices placed in

surface of the eye, subjects for shorter periods are also implants

by surgical intervention, and which is for purposes of this part.]

intended to remain after the procedure for

at least 30 days, and which can only be

removed by medical or surgical

intervention

NOTE This definition applies to

implantable medical devices other than

active implantable medical devices.

(c) Component means any raw material,

substance, piece, part, software, firmware,

labeling, or assembly which is intended to

be

included as part of the finished, packaged,

and labeled device.

(d) Control number means any distinctive

symbols, such as a distinctive combination

of letters or numbers, or both, from which

the

history of the manufacturing, packaging,

labeling, and distribution of a unit, lot, or

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 8

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

batch of finished devices can be

determined.

(e) Design history file (DHF) means a

compilation of records which describes the

design history of a finished device.

3.6 [Federal Food, Drug, and Cosmetics Act, The definition in the regulation is a bit

labelling Section 201: more detailed, but the definition in the

written, printed or graphic matter (m) The term labeling means all labels and

Standard should cover all that is

. affixed to a medical device or any of its other written, printed, or graphic matter (1)

containers or wrappers, or upon any article or any of its containers or covered in the definitions of label and

. accompanying a medical device, wrappers or (2) accompanying such article. labeling in the regulation.

related to identification, technical

description, and use of the medical device, (k) The label means a display of written,

but excluding shipping documents printed, or graphic matter upon the immediate

container of any article; and a requirement

NOTE Some regional and national made by or under authority of this Act that any

regulations refer to labelling as word, statement, or other information appear

information supplied by the on the label shall not be considered to be

manufacturer. complied with unless such word, statement, or

other information also appears on the outside

container or wrapper, if any there be, of the

retail package or such article, or is easity

legible through the outside container or

wrapper.]

[ISO 13485:2003, 7.3.2 Design and (f) Design input means the physical and The definition of design and

development inputs performance requirements of a device that development inputs in the Standard is

Inputs relating to product requirements are used as a basis for device design.

shall be determined and records actually incorporated into the

maintained (see 4.2.4). These inputs shall requirements section. It is also a bit

include more explicit.

a) functional, performance and safety

requirements, according to the intended

use,

b) applicable statutory and regulatory

requirements,

c) where applicable, information derived

from previous similar designs,

d) other requirements essential for design

and development, and

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 9

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

e) output(s) of risk management (see 7.1).

These inputs shall be reviewed for

adequacy and approved.

Requirements shall be complete,

unambiguous and not in conflict with each

other.

[ISO 13485:2003, 7.3.3 Design and (g) Design output means the results of a The definition of design and

development outputs design effort at each design phase and at development outputs in the Standard is

The outputs of design and development the end of the total design effort. The

actually incorporated into the

shall be provided in a form that enables finished design output is the basis for the

verification against the design and device master record. The total finished requirements section. It is also a bit

development input and shall be approved design output consists of the device, its more explicit.

prior to release. packaging and labeling, and the device

master record. While the regulation doesnt explicitly

Design and development outputs shall

include examples of design output, it is

a) meet the input requirements for design

and development, clear that FDA considers items like the

b) provide appropriate information for product and component specifications,

purchasing, production and for service manufacturing procedures, engineering

provision, drawings, and logbooks are part of the

c) contain or reference product

design output.

acceptance criteria, and

d) specify the characteristics of the

product that are essential for its safe and

proper use.

Records of the design and development

outputs shall be maintained (see 4.2.4).

NOTE Records of design and

development outputs can include

specifications, manufacturing procedures,

engineering drawings, and engineering or

research logbooks.

3.7 [Federal Food, Drug, and Cosmetics Act, No significant difference.

medical device Section 201:

any instrument, apparatus, implement, (h) The term device () means an

machine, appliance, implant, in vitro instrument, apparatus, implement, machine,

reagent or calibrator, software, material or contrivance, implant, in vitro reagent, or other

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 10

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

other similar or related article, intended by similar or related article, including any

the manufacturer to be used, alone or in component, part, or accessory, which is

combination, for human beings for one or (1) recognized in the official National

more of the specific purpose(s) of Formulary, or the United States

. diagnosis, prevention, monitoring, Pharmacopeia, or any supplement to

treatment or alleviation of disease, them,

. diagnosis, monitoring, treatment, (2) intended for use in the diagnosis of

alleviation of or compensation for an disease or other conditions, or in the

injury, cure, mitigation, treatment, or prevention

. investigation, replacement, modification, of disease, in man or other animals, or

or support of the anatomy or of a (3) intended to affect the structure or any

physiological process, function of thte body of man or other

. supporting or sustaining life, animals, and which does not achieve its

. control of conception, primary intended purposes through

. disinfection of medical devices, chemical action within or on the body of

man or other animals and which is not

. providing information for medical

dependent upon being metabolized for

purposes by means of in vitro examination

the achievement of its primary intended

of specimens derived fromthe human

body, purposes.]

and which does not achieve its primary

intended action in or on the human body

by pharmacological, immunological or

metabolic means, but which may be

assisted in its function by such means.

NOTE This definition has been developed

by the Global Harmonization Task Force

(GHTF). See bibliographicreference [15].

[ISO 13485:2003, 7.3.4 Design and (h) Design review means a documented, The definition of design and

development review comprehensive, systematic examination of development review in the Standard is

At suitable stages, systematic reviews of a design to evaluate the adequacy of the

actually incorporated into the

design and development shall be design requirements, to evaluate the

performed in accordance with planned capability of the design to meet these requirements section. Otherwise there

arrangements (see 7.3.1) requirements, and to identify problems. is no significant difference.

a) to evaluate the ability of the results of

design and development to meet

requirements, and

b) to identify any problems and propose

necessary actions.

Participants in such reviews shall include

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 11

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

representatives of functions concerned

with the design and development stage(s)

being reviewed, as well as other specialist

personnel (see 5.5.1 and 6.2.1).

Records of the results of the reviews and

any necessary actions shall be maintained

(see 4.2.4).

3.8

sterile medical device

category of medical device intended to

meet the requirements for sterility

NOTE The requirements for sterility of a

medical device might be subject to

national or regional regulations or

standards

(i) Device history record (DHR) means a

compilation of records containing the

production history of a finished device.

(j) Device master record (DMR) means a

compilation of records containing the

procedures and specifications f or a

finished device.

(k) Establish means define, document (in

writing or electronically), and implement.

(l) Finished device means any device or

accessory to any device that is suitable for

use or capable of functioning, whether or

not it is packaged, labeled, or sterilized.

(m) Lot or batch means one or more

components or finished devices that

consist of a single type, model, class, size,

composition, or software version that are

manufactured under essentially the same

conditions and that are intended to have

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 12

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

uniform characteristics and quality within

specified limits.

[ISO 9000:2000, 3.2.7 top management (n) Management with executive The intent of both definitions is the

person or group of people who directs responsibility means those senior same.

and controls an organization (3.3.1) at the employees of a manufacturer who have

highest level.] the authority to establish or make changes

to the manufacturer's quality policy and

quality system.

(o) Manufacturer means any person who

designs, manufactures, fabricates,

assembles, or processes a finished

device. Manufacturer

includes but is not limited to those who

perform the functions of contract

sterilization, installation, relabeling,

remanufacturing, repacking, or

specification development, and initial

distributors of foreign entities performing

these functions.

(p) Manufacturing material means any

material or substance used in or used to

facilitate the manufacturing process, a

concomitant

constituent, or a byproduct constituent

produced during the manufacturing

process, which is present in or on the

finished device as a residue or impurity

not by design or intent of the

manufacturer.

[ISO 9000:2000, 3.6.2 nonconformity (q) Nonconformity means the Identical

non-fulfillment of a requirement (3.1.2)] nonfulfillment of a specified requirement.

[ISO 9000:2000, 3.4.2 product the (r) Product means components, The definition in the Standard more

result of a process (3.4.1) manufacturing materials, in- process clearly reflects the process approach of

NOTE 1 There are four generic product devices, finished devices, and returned

categories, as follows: devices. this document.

Services (e.g., transport);

Software (e.g., computer program, The definition in the Standard is a bit

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 13

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

dictionary); more detailed.

Hardware (e.g., engine mechanical

part);

Processed materials (e.g., lubicant).

Many products comprise elements

belonging to different generic product

categories. Whether the aproduct is then

called service, software, hardware or

processed material depends on the

dominant element. For example, the

offered product automobile consists of

hardware (e.g., tires), processed material

(e.g., fuel, cooling system liquid), software

(e.g., engine control software, drivers

manual), and service (e.g., operating

explanations given by the salesman). ]

[ISO 9000:2000, 3.1.1 quality degree to (s) Quality means the totality of features No significant difference. The definition

which a set of inherent characteristics and characteristics that bear on the ability in the regulation reflects the objective of

(3.5.1) fulfills requirements (3.1.2)] of a device to satisfy fitness-for-use,

including safety and performance. the regulation, that is the assurance of

product safety and effectiveness.

[ISO 90002000, 3.9.1 audit systematic, (t) Quality audit means a systematic, The definition in the regulation imposes

independent and documented process independent examination of a the requirement related to defined

(3.4.1) for obtaining audit evidence (3.9.4) manufacturer's quality system that is

and evaluating it objectively to determine performed at defined intervals and at intervals, and includes activities that

the extent to which audit criteria (3.9.3) sufficient frequency to determine whether occur after the audit is actually

are fulfilled both quality system activities and the performed.

] results of such activities comply with

quality system procedures, that these

procedures are implemented effectively,

and that these procedures are suitable to

achieve quality system objectives.

[ISO 9000:2000, 3.2.4 quality policy (u) Quality policy means the overall No significant difference.

overall intentions and direction of an intentions and direction of an organization

organization (3.3.1) related to quality with respect to quality, as established by

(3.1.1) as formally expressed by top management with executive responsibility.

management ((3.2.7)]

[ISO 9000:2000, 3.2.2 system set of (v) Quality system means the The definition in the regulation is more

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 14

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

interrelated or interactring elements] organizational structure, responsibilities, instructive, but is consistent with the

procedures, processes, and resources for intent of the Standard.

implementing quality management.

(w) Remanufacturer means any person

who processes, conditions, renovates,

repackages, restores, or does any other

act to a finished

device that significantly changes the

finished device's performance or safety

specifications, or intended use.

[ISO 9000:2000, 3.6.7 rework action (x) Rework means action taken on a No significant difference.

on a nonconforming product (3.4.2) to nonconforming product so that it will fulfill

make it conform to the requirements the specified DMR requirements before it

(3.1.2) is released for distribution.

NOTE Unlike rework, repair (3.6.9) can

affect or change parts of the

nonconforming product.]

[ISO 9000:2000, 3.7.3 specification (y) Specification means any requirement The regulation requires documentation

document (3.7.2) stating requirements with which a product, process, service, or of specifications.

(3.1.2) other activ ity must conform.

NOTE A specification can be related to

activities (e.g., procedure document,

process specification and test

specification), or products (3.4.2) (e.g.,

product specification, performance

specification and drawing)]

[ISO 9000:2000, 3.8.5 validation (z) Validation means confirmation by No significant difference, but neither

confirmation, through the provision of examination and provision of objective definition is very informative.

objective evidence (3.8.1), that the evidence that the particular requirements

requirements (3.1.2) for a specific for a specific intended use can be

intended use or application have been consistently fulfilled. The regulatory definition is more

fulfilled. detailed in that it breaks out and defines

(1) Process validation means establishing process validation and design

NOTE 1 The term validated is used to by objective evidence that a process validation.

designate the corresponding status consistently produces a result or product

meeting its

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 15

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

NOTE 2 The use conditions for validation predetermined specifications. Normally, validation is performed on the

can be real or simulated] final product or process for

(2) Design validation means establishing

manufacturing, monitoring, testing, and

by objective evidence that device

specifications conform with user needs supporting the product.

and intended use(s).

[ISO 9000:2000, 3.8.4 verification (aa) Verification means confirmation by No significant difference.

confirmation, through the provision of examination and provision of objective

objective evidence (3.8.1) that specified evidence that specified requirements have

requirements (3.1.2) have been fulfilled been fulfilled. The Standard is more detailed.

NOTE 1 The term verified is used to

designate the corrresponding status.

NOTE 2 Confirmation can comprise

activities such as

Performing alternative calculations

Comparing a new design

specification (3.7.3) with a similar

proven design specification,

Undertaking tests (3.8.3) and

demonstrations, and

Reviewing documents prior to issue.]

4 Quality management system 4 Quality management system 820.5 Quality system. No significant differences

4.1 General requirements 4.1 General requirements Each manufacturer shall establish and

The organization shall establish, document, The organization shall establish, maintain a quality system that is

implement and maintain a quality document, implement and maintain a appropriate for the specific medical

management system and continually quality management system and maintain device(s) designed or manufactured, and

improve its effectiveness in accordance with its effectiveness in accordance with the that meets the requirements of this part.

the requirements of this International requirements of this International

Standard. Standard.

The organization shall The organization shall

a) identify the processes needed for the

a) identify the processes needed for the quality management system and their

quality management system and their application throughout the organization

application thoughout the organization (see 1.2),

(see 1.2) b) determine the sequence and interaction

of these processes,

b) determine the sequence and c) determine criteria and methods needed

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 16

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

interaction of these processes to ensure that both the operation and

control of these processes are effective,

c) determine criteria and methods d) ensure the availability of resources and

needed to ensure that both the information necessary to support the

operation and control of these operation and monitoring of these

processes are effective, processes,

e) monitor, measure and analyse these

d) ensure the availability of resources processes, and

and information necessary to support f) implement actions necessary to achieve

the operation and monitoring of these planned results and maintain the

processes, effectiveness of theseprocesses.

e) monitor, measure and analyze these These processes shall be managed by the

processes, and organization in accordance with the

requirements of this International

f) implement actions necessary to Standard.

achieve planned results and continual

improvement of these processes. Where an organization chooses to

outsource any process that affects product

These processes shall be managed by the conformity with requirements, the

organization in accordance with the organization shall ensure control over

requirements of this International Standard. such processes. Control of such

Where an organization chooses to outsourced processes shall be identified

outsource any process that affects product within the quality management system

conformity with requirements, the (see 8.5.1).

organization shall ensure control over such

processes. Control of such outsourced NOTE Processes needed for the quality

processes shall be identified within the management system referred to above

quality management system. should include processes for management

activities, provision of resources, product

NOTE: Processes needed for the quality realization and measurement.

management system referred to above

should include processes for management

activities, provision of resources, product

realization and measurement.

4.2 Documentation requirements 4.2 Documentation requirements The ISO13485 standard lists the

4.2.1 General 4.2.1 General required quality management system

The quality management system The quality management system documentation in this clause, while the

documentation shall include documentation shall include QS Reg indicates the documentation

a) documented statements of a quality requirements in the various sections

a) documented statements of a quality policy and quality objectives, throughout the regulation. There is no

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 17

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

policy and quality objectives, b) a quality manual, significant difference in the

c) documented procedures required by documentation requirements for the two

b) a quality manual, this International Standard, documents, except as indicated below.

d) documents needed by the organization

c) documented procedures required by to ensure the effective planning, operation

this International Standard, and control of its processes,

e) records required by this International

d) documents needed by the organization Standard (see 4.2.4), and

to ensure the effective planning, f) any other documentation specified by

operation and control of its processes, national or regional regulations.

and

Where this International Standard

e) records required by this International specifies that a requirement, procedure,

Standard (see 4.2.4). activity or special arrangement be

documented, it shall, in addition, be

NOTE 1 Where the term documented implemented and maintained.

procedure appears within this International

Standard, this means that the procedure is For each type or model of medical device,

established, documented, implemented and the organization shall establish and

maintained. maintain a file either containing or

identifying documents defining product

NOTE 2 The extent of the quality specifications and quality management The QS Reg implicitly recognizes that

management system documentation can system requirements (see 4.2.3). These the extent of quality management

differ from one organization to another due documents shall define the complete system documentation will reflect the

to manufacturing process and, if applicable, size and complexity of the organization.

a) the size of organization and type of installation and servicing. It also implicitly recognizes that some

activities, documentation may not be needed due

b) the complexity of processes and their NOTE 1 The extent of the quality to the expertise (either through training,

interactions, and management system documentation can education, or experience) of the

c) the competence of personnel. differ from one organization to another personnel.

due to

NOTE 3 The documentation can be in any a) the size of the organization and type of

form or type of medium. activities,

b) the complexity of processes and their

interactions, and

c) the competence of personnel. This text is included in ISO 13485:2003

in order to accommodate the definition

NOTE 2 The documentation can be in any of establish in the QS Reg.

form or type of medium.

4.2.2 Quality manual 4.2.2 Quality manual The QS Reg has no requirement for a

The organization shall establish and The organization shall establish and Quality Manual. Such a manual would

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 18

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

maintain a quality manual that includes maintain a quality manual that includes still be helpful in explaining the nature

a) the scope of the quality management and extent of the quality management

a) the scope of the quality management system, including details of and system to an FDA investigator during

system, including details of and justification for any exclusion and/or non- an inspection. It would also be useful in

justification for any exclusion (see 1.2) application (see 1.2), the training of personnel with regard to

b) the documented procedures the quality management system of the

b) the documented procedures established for the quality management organization and their place within that

established for the quality system, or reference to them, and system.

management system, or reference to c) a description of the interaction between

them, and the processes of the quality management The Quality Manual could be used as

system. the repository of some of the individual

c) a description of the interaction quality management system

between the processes of the quality The quality manual shall outline the documentation required by the QS Reg

management system. structure of the documentation used in the (e.g., the organizational structure and

quality management system. interrelationships, the highest level

procedures in a small organization

dealing with items like document

control, recordskeeping, training)

4.2.3 Control of documents 4.2.3 Control of documents 820.40 Document controls. The requirements are essentially the

Documents required by the quality Documents required by the quality Each manufacturer shall establish and same, except that the QS Reg has the

management system shall be controlled. management system shall be controlled. maintain procedures to control all specific requirement to communicate

Records are a special type of document and Records are a special type of document documents that are required by this part. changes to documents to the affected

shall be controlled according to the and shall be controlled according to the The procedures personnel.

requirements given in 4.2.4. requirements given in 4.2.4. shall provide for the following:

ISO/DIS 13485:2003 requires the

A documented procedure shall be A documented procedure shall be (a) Document approval and distribution. organization to define a retention period

established to define the controls needed established to define the controls needed Each manufacturer shall designate an for obsoleted documents.

a) to review and approve documents for individual(s) to review for adequacy and

a) to approve documents for adequacy prior to issue, approve prior to issuance all documents

adequacy prior to issue, b) to review and update as necessary and established to meet the requirements of

re-approve documents, this part. The approval, including the date

b) to review and update as c) to ensure that changes and the current and signature of the individual(s)

necessary and re-approve revision status of documents are approving the document, shall be

documents, identified, documented. Documents established to

d) to ensure that relevant versions of meet the requirements of this part shall be

c) to ensure that changes and the applicable documents are available at available at all locations for which they are

current revision status of points of use, designated, used, or otherwise necessary,

documents are identified, e) to ensure that documents remain and all obsolete documents shall be

legible and readily identifiable, promptly removed from all points of use or

d) to ensure that relevant versions of f) to ensure that documents of external otherwise prevented from unintended use.

applicable documents are origin are identified and their distribution

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 19

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

available at points of use, controlled, and (b) Document changes. Changes to

g) to prevent the unintended use of documents shall be reviewed and

e) to ensure that documents remain obsolete documents, and to apply suitable approved by an individual(s) in the same

legible and readily identifiable, identification to them if they are retained function or organization that performed the

for any purpose. original review and approval, unless

f) to ensure that documents of specifically designated otherwise.

external origin are identified and The organization shall ensure that Approved changes shall be communicated

their distribution controlled, and changes to documents are reviewed and to the appropriate personnel in a timely

approved either by the original approving manner. Each manufacturer shall maintain

g) to prevent the unintended use of function or another designated function records of changes to documents. Change

obsolete documents, and to apply which has access to pertinent background records shall include a description of the

suitable identification to them if information upon which to base i ts change, identification of the affected

they are retained for any purpose. decisions. documents, the signature of the approving

individual(s), the approval date, and when

The organization shall define the period the change becomes effective.

for which at least one copy of obsolete

controlled documents shall be retained.

This period shall ensure that documents to

which medical devices have been

manufactured and tested are available for

at least the lifetime of the medical device

as defined by the organization, but not

less than the retention period of any

resulting record (see 4.2.4), or as

specified by relevant regulatory

requirements.

4.2.4 Control of records 4.2.4 Control of records 820.180 General requirements. No significant differences in the general

Records shall be established and Records shall be established and All records required by this part shall be requirements associated with control of

maintained to provide evidence of maintained to provide evidence of maintained at the manufacturing records, except that the QS Reg

conformity to requirements and of the conformity to requirements and of the establishment or other location that is contains requirements for

effective operation of the quality effective operation of the quality reasonably communications with FDA.

management system. Records shall remain management system. Records shall accessible to responsible officials of the

legible, readily identifiable and retrievable. A remain legible, readily identifiable and manufacturer and to employees of FDA

documented procedure shall be established retrievable. A documented procedure shall designated to perform inspections. Such

to define the controls needed for the be established to define the controls records,

identification, storage, protection, retrieval, needed for the identification, storage, including those not stored at the inspected

retention time and disposition of records. protection, retrieval, retention time and establishment, shall be made readily

disposition of records. available for review and copying by FDA

employee(s). Such

The organization shall retain the records records shall be legible and shall be

for a period of time at least equivalent to stored to minimize deterioration and to

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 20

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

the lifetime of the medical device as prevent loss. Those records stored in

defined by the organization, but not less automated data processing systems shall

than two years from the date of product be backed up.

release by the organization or as specified

by relevant regulatory requirements. (a) Confidentiality. Records deemed

confidential by the manufacturer may be

marked to aid FDA in determining whether

information may be disclosed under the

public information regulation in part 20 of

this chapter.

(b) Record retention period. All records

required by this part shall be retained for a

period of time equivalent to the design and

expected life of the device, but in no case

less than 2 years from the

date of release for commercial distribution

by the manufacturer.

(c) Exceptions. This section does not

apply to the reports required by Sec.

820.20(c) Management review, Sec.

820.22 Quality audits, and

supplier audit reports used to meet the

requirements of Sec. 820.50(a) Evaluation

of suppliers, contractors, and consultants,

but does apply to procedures established

under these provisions. Upon request of a

designated employee of FDA, an

employee in management with executive

responsibility shall certify in writing that the

management reviews and quality audits

required under this part, and supplier

audits where applicable, have been

performed and documented, the dates on

which they were performed, and that any

required corrective action has been

undertaken.

820.181 Device master record. The QS Reg requires the establishment

Each manufacturer shall maintain device of a Device Master Record (DMR). The

master records (DMR's). Each DMR may be a separate file of

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 21

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

manufacturer shall ensure that each DMR documents and records, or it may be

is prepared and approved document containing references to the

in accordance with Sec. 820.40. The DMR various elements of the DMR. ISO/DIS

for each type of device shall include, or 13485:2003 has no requirement for

refer to the location of, the following such a file even though it requires the

information: individual documents and records that

would be contained within that file.

(a) Device specifications including

appropriate drawings, composition,

formulation, component specifications,

and software specifications;

(b) Production process specifications

including the appropriate equipment

specifications, production methods,

production procedures, and production

environment specifications;

(c) Quality assurance procedures and

specifications including acceptance criteria

and the quality assurance equipment to be

used;

(d) Packaging and labeling specifications,

including methods and processes used;

and

(e) Installation, maintenance, and

servicing procedures and methods.

820.184 Device history record. The QS Reg requires the establishment

Each manufacturer shall maintain device of a Device History Record (DHR) for

history records (DHR's). Each each lot of devices or unit

manufacturer shall establish and maintain manufactured. The DHR may be a

procedures to ensure separate file containing the records, or

that DHR's for eac h batch, lot, or unit are may be document that references the

maintained to demonstrate that the device location of these records. ISO/DIS

is manufactured in accordance with the 13485:2003 does not require the

DMR and the requirements of this part. establishment of such a file, even

The DHR shall include, or refer to the though it requires the individual records

location of, the following information: that would be contained with that file.

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 22

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

(a) The dates of manufacture;

(b) The quantity manufactured;

(c) The quantity released for distribution;

(d) The acceptance records which

demonstrate the device is manufactured in

accordance with the DMR;

(e) The primary identification label and

labeling used for each production unit; and

(f) Any device identification(s) and control

number(s) used.

820.186 Quality system record. The QS Reg requires the establishment

Each manufacturer shall maintain a quality of a Quality System Record, which may

system record (QSR). The QSR shall be a separate file containing the

include, or refer to the location of, required documents or a document

procedures and the referencing the required contents.

documentation of activities required by this ISO/DIS 13485:2003 does not require

part that are not specific to a particular the establishment of suc h a file, even

type of device(s), including, but not limited though it does requirement the

to, the establishment of the various documents

records required by Sec. 820.20. Each that would be included in that file.

manufacturer shall ensure that the QSR is

prepared and approved in accordance

with Sec. 820.40.

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 23

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

5 Management responsibility 5 Management responsibility 820.20 Management responsibility. No significant differences in

5.1 Management commitment 5.1 Management commitment (a) Quality policy. Management with management responsibilities; the QS

Top management shall provide evidence of Top management shall provide evidence executive responsibility shall establish its Reg spells some of them out in

its commitment to the development and of its commitment to the development and policy and objectives for, and commitment subsequent sections of the regulation.

implementation of the quality management implementation of the quality management to, quality.

system and continually improving its system and maintaining its effectiveness Management with executive responsibility

effectiveness by by shall ensure that the quality policy is

a) communicating to the organization the understood, implemented, and maintained

a) communicating to the organization the importance of meeting customer as well at all levels of the organization.

importance of meeting customer as as statutory and regulatory requirements,

well as statutory and regulatory b) establishing the quality policy,

requirements, c) ensuring that quality objectives are

established,

b) establishing the quality policy, d) conducting management reviews, and

e) ensuring the availability of resources.

c) ensuring that quality objectives are

established, NOTE For the purposes of this

International Standard, statutory

d) conducting management reviews, and requirements are limited to the safety and

performance of the medical device only.

e) ensuring the availability of resources.

5.2 Customer focus 5.2 Customer focus ISO/DIS 13485:2003 has a distinct

Top management shall ensure that Top management shall ensure that focus on meeting customer

customer requirements are determined and customer requirements are determined requirements in addition to meeting

are met with the aim of enhancing customer and are met (see 7.2.1 and 8.2.1). regulatory requirements. The QS Reg

satisfaction (see 7.2.1 and 8.2.1). is entirely focused on meeting those

requirements that have as their

objective the design, manufacture,

distribution, and support of safe and

effective medical devices.

ISO/DIS 13485:2003 will include

requirements for determining customer

requirements during the entire product

realization process, while the QS Reg

will include requirements that identify

product and process requirements that

are focused on ensuring safe and

effective medical devices.

5.3 Quality policy 5.3 Quality policy 820.20 Management responsibility. No significant differences

Top management shall ensure that the Top management shall ensure that the (a) Quality policy. Management with

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 24

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

quality policy quality policy executive responsibility shall establish its

a) is appropriate to the purpose of the policy and objectives for, and commitment

a) is appropriate to the purpose of the organization, to, quality.

organization, b) includes a commitment to comply with Management with executive responsibility

requirements and to maintain the shall ensure that the quality policy is

b) includes a commitment to comply with effectiveness of the quality understood, implemented, and maintained

requirements and continually improve management system, at all levels of the organization.

the effectiveness of the quality c) provides a framework for establishing

management system, and reviewing quality objectives,

d) is communicated and understood within

c) provides a framework for establishing the organization, and

and reviewing quality objectives, e) is reviewed for continuing suitability.

d) is communicated and understood

within the organization, and

e) is reviewed for continuing suitability.

5.4 Planning 5.4 Planning 820.20 Management responsibility. No significant differences

5.4.1 Quality objectives 5.4.1 Quality objectives (a) Quality policy. Management with

Top management shall ensure that quality Top management shall ensure that quality executive responsibility shall establish its

objectives, including those needed to meet objectives, including those needed to policy and objectives for, and commitment

requirements for product [see 7.1 a)], are meet requirements for product [see 7.1 to, quality.

established at relevant functions and levels a)], are established at relevant functions Management with executive responsibility

within the organization. The quality and levels within the organization. The shall ensure that the quality policy is

objectives shall be measurable and quality objectives shall be measurable and understood, implemented, and maintained

consistent with the quality policy. consistent with the quality policy. at all levels of the organization.

5.4.2 Quality management system 5.4.2 Quality management system 820.5 Quality system. The QS Reg contains the proscriptive

planning planning Each manufacturer shall establish and requirements for a quality plan and

Top management shall ensure that Top management shall ensure that maintain a quality system that is quality system procedures.

a) the planning of the quality management appropriate for the specific medical

system is carried out in order to meet the device(s) designed or manufactured, and

a) the planning of the quality requirements given in 4.1, as well as the that meets the requirements of this part.

management system is carried out in quality objectives, and

order to meet the requirements given b) the integrity of the quality management (d) Quality planning. Each manufacturer It is not clear what the FDA is looking

in 4.1, as well as the quality objectives, system is maintained when changes to the shall establish a quality plan which defines for when they ask for a quality plan. It

quality management system are planned the quality practices, resources, and seems to be combination of a high level

and and implemented. activities relevant to devices that are quality planning document, containing

designed and manufactured. The policy and key objectives, with a

b) the integrity of the quality management manufacturer shall establish how the mandate to drive those objectives down

requirements for quality will be met. into the organization, and a set of high

system is maintained when changes to

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 25

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

the quality management level procedures that illustrate how that

plan will be met.

(e) Quality system procedures. Each Both the QS Reg and ISO/DIS

manufacturer shall establish quality 13485:2003 require the establishment

system procedures and instructions. An of these kinds of procedures; only the

outline of the structure of the QS Reg gives them special standing as

documentation used in the quality system quality system procedures.

shall be established where appropriate.

5.5 Responsibility, authority and 5.5 Responsibility, authority and 820.20 Management responsibility No significant differences

communication communication (b) Organization. Each manufacturer

5.5.1 Responsibility and authority 5.5.1 Responsibility and authority shall establish and maintain an adequate

Top management shall ensure that Top management shall ensure that organizational structure to ensure that

responsibilities and authorities are defined, responsibilities and authorities are devices are designed and produced in

documented and communicated within the defined, documented and accordance with the requirements of this

organization. communicated within the organization. part.

Top management shall establish the (1) Responsibility and authority. Each

interrelation of all personnel who manage, manufacturer shall establish the

perform and verify work affecting quality, appropriate responsibility, authority, and

and shall ensure the independence and interrelation of all

authority necessary to perform these personnel who manage, perform, and

tasks. assess work affecting quality, and provide

the independence and authority necessary

NOTE National or regional regulations to perform these tasks.

might require the nomination of specific

persons as responsible for activities

related to monitoring experience from the

post-production stage and reporting

adverse events (see 8.2.1 and 8.5.1).

5.5.2 Management representative 5.5.2 Management representative 820.20 Management responsibility No significant differences, except the

Top management shall appoint a member Top management shall appoint a member (b) Organization requirements in ISO/DIS 13485:2003

of management who, irrespective of other of management who, irrespective of other (3) Management representative. reflect the focus on meeting customer

responsibilities, shall have responsibility responsibilities, shall have responsibility Management with executive responsibility requirements.

and authority that includes: and authority that includes shall appoint, and document such

a) ensuring that processes needed for the appointment of, a

a) ensuring that processes needed for quality management system are member of management who, irrespective

the quality management system are established, implemented and maintained, of other responsibilities, shall have

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 26

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

established, implemented and b) reporting to top management on the established authority over and

maintained; performance of the quality management responsibility for:

system and any need for improvement

b) reporting to top management on the (see 8.5), and (i) Ensuring that quality system

performance of the quality c) ensuring the promotion of awareness of requirements are effectively established

management system and any need for regulatory and customer requirements and effectively maintained in accordance

improvement; and throughout the with this part; and

organization.

c) ensuring the promotion of awareness (ii) Reporting on the performance of the

of customer requirements throughout NOTE The responsibility of a management quality system to management with

the organization. representative can include liaison with executive responsibility for review.

external parties on matters relating to the

NOTE The responsibility of a management quality management system.

representative can include liaison with

external parties on matters relating to the

quality management system.

5.5.3 Internal communication 5.5.3 Internal communication 820.20 Management responsibility No significant differences; the QS Reg

Top management shall ensure that Top management shall ensure that (b) Organization. Each manufacturer implicitly requires the necessary

appropriate communication processes are appropriate communication processes are shall establish and maintain an adequate communication processes that make for

established within the organization and that established within the organization and organizational structure to ensure that successful interrelationships

communication takes place regarding the that communication takes place regarding devices are designed and produced in

effectiveness of the quality management the effectiveness of the quality accordance with the requirements of this

system. management system. part.

(1) Responsibility and authority. Each

manufacturer shall establish the

appropriate responsibility, authority, and

interrelation of all

personnel who manage, perform, and

assess work affecting quality, and provide

the independence and authority necessary

to perform these tasks.

5.6 Management review 5.6 Management review 820.20 Management responsibility No significant differences.

5.6.1 General 5.6.1 General (c) Management review.

Top management shall review the Top management shall review the Management with executive responsibility

organizations quality management system, organizations quality management shall review the suitability and

at planned intervals, to ensure its continuing system, at planned intervals, to ensure its effectiveness of the quality system at

suitability, adequacy and effectiveness. This continuing suitability, adequacy and defined intervals and with sufficient

review shall include assessing opportunities effectiveness. This review shall include frequency according to established

for improvement and the need for changes assessing opportunities for improvement procedures to ensure that the quality

Prepared by: Ed Kimmelman, Consultant

E:ma il --- GPA_ED@msn.com Rev: 5 Aug. 2003

PH: 1-302-762-0947 Page 27

FAX: 1-302-765-3947

Correspondence between ISO 9001:2000 and ISO 13485:2003 and the US Quality System Regulation

ISO/DIS 9001:2000 U.S. Quality System Regulation (21 Comments

ISO 13485:2003 CFR 820)

to the quality management system, and the need for changes to the quality system satisfies the requirements of this

including the quality policy and quality management system, including the quality part and the manufacturer's established

objectives. policy and quality objectives. quality policy and objectives. The dates

and results of quality system reviews shall

Records from management reviews shall be Records from management reviews shall be documented.

maintained (see 4.2.4). be maintained (see 4.2.4).

5.6.2 Review input 5.6.2 Review input The requirements for review input that

The input to management review shall The input to management review shall are spelled out in ISO/DIS 13485:2003

include information on include information on are logical and would be expected by

a) results of audits, an FDA investigator during an

a) results of audits,

b) customer feedback, inspection that focused on management

c) process performance and product responsibilities.

b) customer feedback, conformity,

d) status of preventive and corrective

actions,

c) process performance and product

e) follow -up actions from previous

conformity, management reviews,

f) changes that could affect the quality

d) status of preventive and corrective management system,

g) recommendations for improvement, and

actions, h) new or revised regulatory requirements

e) follow -up actions from previous

management reviews,

f) changes that could affect the quality

management system, and

g) recommendations for improvement.

5.6.3 Review output 5.6.3 Review output The requirements for review output that

The output from the management review The output from the management review are spelled out in ISO/DIS 13485:2003

shall include any decisions and actions shall include any decisions and actions are logical and would be expected by

related to related to an FDA investigator during an