Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Process Validation Protocol For Ketofast 10 Tablet

Caricato da

ShagorShagorTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Process Validation Protocol For Ketofast 10 Tablet

Caricato da

ShagorShagorCopyright:

Formati disponibili

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

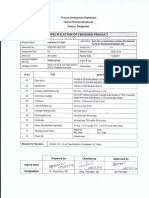

VERITAS PHARMACEUTICALS LTD

Muradpur, Vannara, Mouchak, Kaliakoir, Gazipur

Document Title: Process Validation Protocol of Ketofast 10

Tablet

Document Number : VPL-PVP-007, Revision - 00

Document Type : Concurrent Validation

Prepared by Checked by Agreed by Approved by Date

Signature

Name Md. Shafayat Hossain Md. Tarikul Islam Bossunia H. M. Jahid Murad Md. Moniruzzaman

Sr. Executive, Product Quality Assurance

Designation Asst. Manager, QC Manager, Production

Development Manager

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 1 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

TABLE OF CONTENT

01 Introduction 3

02 Purpose 3

03 Scope 3

04 Validation team 3

05 Qualification and training of personnel 3

06 Calibration and qualification status of equipment 4

07 Batch details of validation batches 4

08 Qualification of starting materials 4

09 Details of reference / working standards 5

10 Validation methodology 5

11 Manufacturing procedure details 5

A Unit formula 5

B (i) Manufacturing formula 5

B (ii) List of Coating material 6

B (iii) List of packaging materials 6

C Process Description 6-7

D Manufacturing flow chart 8

12 Special precaution 8

13 Process parameters for IPC test 8

14 Analytical Test Methods 8

15 Sampling plan 9

16 Acceptance criteria & finish product specification 10

17 Critical process parameters and justification 11-13

18 Analysis of sample 14-18

19 Summary of test result of individual batch 19-20

20 Summary format of three validation batches 20-22

21 Reference documents 23

22 Yield Summary 23

23 Deviation reporting 23

24 Revalidation 23

25 Review of results and reporting 23

26 Final summary report 23

27 Compilation of control data and records 23

28 Batch Analysis report 23

29 Final Approval 24

30 Appendices 24

31 Revision History 24

1.0 Introduction

This protocol includes the process validation activities for the manufacture of Ketofast 10mg

Tablet (Batch size: 41.250 Kg, 2, 75,000 pcs). These validation activities will be carried out on

three successive batches. The process is validated when three successful batches of this

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 2 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

product will made by same procedure and can meet the acceptance criteria stated in this

protocol.

0.0 Purpose

The objective of the Performance Qualification for concurrent Validation is to verify that the

manufacturing equipment, raw material and the manufacturing & coating process for Ketofast

10 mg tablet specified in SPEC/PK 001/GR/00, SPEC/PK 001/IP/01, SPEC/PK 001/CT/01 &

SPEC/PK 001/FP/01 produces a tablet product of the consistent strength, friability, weight,

hardness, dissolution, thickness, disintegration and LOD/moisture content.

1.0 Scope

This protocol is valid for Performance Qualification of Concurrent Validation for Ketofast 10mg

tablet manufacturing facility of VPL, Gazipur.

2.0 Validation Team

The exercise will be carried out by participation of the members from QA, QC, Production,

Engineering and Product Development. The team is not exclusive and others may become

part of the validation if it is considered necessary. During validation exercise any changes will

be controlled by the change control.

Validation team & responsibilities

Department Designation Responsibilities

To coordinate the entire validation process by scheduling

meetings and discussions with production, quality control and

Product Executive/Sr. quality assurance. Preparation of preliminary validation

Development Executive protocol, master formula record, monitoring the process,

compiling and analyzing data and test results and preparing

the final report. To review the preliminary validation documents.

Executive/Asst. To participate in performing the validation steps during

Production

Manager manufacturing processes. To assist in collection of data.

To coordinate the entire validation process by scheduling

meetings and discussions with the team.

Quality Preparation of validation protocol, monitoring the process,

Executive

Assurance compiling and analyzing data and test results and preparing the

final report. To review of validation documents. Collect sample at

different stages.

Quality Executive/Sr.

To test and report the test results at different stages.

Control Executive

Quality Will ensure that all tests are performed at different stages. To

Head

Control check results.

To ensure product is manufactured following protocol and overall

Production Manager

co-operation in validation activities

To approve the process validation protocol and report.

Quality

Manager To review of validation documents.

Assurance

To approve the process.

5.0 Qualification and training of personnel

Personnel engaged in the Validation project must have adequate qualification and should be

trained in the basic principles of validation and should be thoroughly briefed about the

manufacturing process Ketofast 10mg tablet and the detailed methodology to be adopted for

the Performance Qualification of the process.

A list of the personnel with the qualification and training details should be prepared as per the

following format:

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 3 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

Name Designation Department Signature of Trainee Signature of Trainer

6.0 Calibration and qualification status of equipment and utility system

The calibration and qualification status of the following equipments used in the Performance

Qualification of process Ketofast 10 mg Tablet shall be checked and listed in the following

format.

Batch No. Batch Size:

Identification Last qualification

Equipment Name Ref. Doc. Remarks

No. /Calibration date

7.0 Batch details of validation batches

A minimum three consecutive batches shall be planned for the validation project. The batch

details of validation batches shall be planned well in advance. If three batches are not

available, concurrent validation will be carried out.

The batch size of these batches shall be maintained uniform and no recovery from previous

batches shall be added in these batches

8.0 Qualification of starting materials

All the raw materials proposed to be used for the manufacture of validation batches shall have

the following qualification.

Name of the materials QC Ref. No. Release status Remarks

9.0 Details of reference / working standards

Sl. Exp. Date/

Name Source Ref. No. Strength

No. Retest test

01

02

03

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 4 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

04

05

10.0 VALIDATION METHODOLOGY

10.1 The validation will be performed on three consecutive production scale batches of the same

batch size following the established manufacturing process described in this validation

protocol as well as Batch Manufacturing Record (BMR). If three batches are not available,

concurrent validation will be carried out.

10.2 It shall be carried out at optimum values within the acceptable ranges of critical process control

parameter. All critical process parameter will be monitored and documented for review.

10.3 Sampling shall be done following sampling plan given in this protocol as per PQ.

10.4 Finished product sampling and testing shall be carried out as per the established sampling

procedure and testing procedure respectively.

10.5 During execution of the validation protocol batch record will be completed. Results of all critical

process control parameter and batch information will be recorded in Critical Process Parameter

Manufacturing Ranges.

10.6 Process validation shall be considered successfully when three (3) successful batches of

Ketofast 10 mg tablet have been manufactured using the critical parameter in section 16 and

finished products meets its specification for three batches.

11.0 Manufacturing procedure details

A) Unit formula:

Ingredients Code No. mg/Tab

Ketorolac Tromethamine 1111001 10.000

Microcrystalline Cellulose (Avicel PH 102) 1113005 130.392

Sodium Starch Glycolate 1119001 7.502

Colloidal Silicon Dioxide (Aerosil 200) 1103001 1.124

Magnesium Stearate 1113002 0.750

Green Lake 1103001 0.233

B) (i) Manufacturing formula

Batch

Batch size 41.25 Kg 275000 Standard Qty B/N.:

Qty

(Kg/Batch)

Ingredients Code No. Actual Qty.

Ketorolac Tromethamine 1111001 2.750*

Microcrystalline Cellulose (Avicel PH 102) 1113005 35.858*

Sodium Starch Glycolate 1119001 2.063

Colloidal Silicon Dioxide (Aerosil 200) 1103001 0.309

Magnesium Stearate 1113002 0.206

Green Lake 1103001 0.064

*The quantity will be calculated based on potency.

B) (ii) List of Coating materials

Code No. Description of Materials Standard Qty (Kg) Actual Qty

1108001 Hydroxy propyl Methyl Cellulose (15cps) 2.550

1113006 Methylene Chloride 25.500

1113007 Methanol 25.500

1116003 Polyethylene Glycol (PEG-6000) 0.284

1120001 Titanium Dioxide 0.070

1120002 Purified Talc 0.378

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 5 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

1117003 Green Lake 0.005

B) (iii) List of packaging materials

Code No. Description of Materials Standard Qty (Kg) Actual Qty

120002 Printed Alu Foil for Ketofast 10 Tablet

120010 Alu Bottom foil 228 mm

030005 Leaflet for Ketofast 10 Tablet

040005 Inner Carton for Ketofast 10 Tablet (2X10s)

110001 Hollogram Sticker

060005 Master Carton Size # 1

070026 Master Carton Label for Ketofast 10 Tablet

100001 Gum Tape 2"

100002 Glue

C) PROCESS DESCRIPTION

1. Dispensing order

a. Ketorolac Tromethamine

b. Microcrystalline Cellulose (Avicel PH 102)

c. Sodium Starch Glycolate

d. Colloidal Silicon Dioxide (Aerosil 200)

e. Magnesium Stearate

f. Green lake

2. Granulation

i) Sieving: Sieve the following materials through mesh # 20/60

Ketorolac Tromethamine

Microcrystalline Cellulose ( Avicel PH 102)

Sodium starch Glycolate

Green Lake (use mesh #60)

ii) Dry Mixing: Take the sieved materials of step I the Pillar Bin Blender & mix for 30

minutes

iii) Lubrication & Blending: Sieve & take the following materials along with the dried granules

of step II & Mix for 10 minutes in the Pillar bin Blender. Measure LOD/Moisture content, which

will be within (2.5 3.5) %. If necessary, dry further.

Colloidal Silicon Dioxide ( Aerosil-200)

Magnesium Stearate

iv) Discharge: Discharge the materials into double polythene bags with silica gel

between the bags placed in a plastic drum. Close it tightly & mark the drum with

Product Name, Batch No, Date, Gross weight, Tare along with signature of the

operator.

v) Sampling and Testing: Carryout sampling and testing as per sampling plan 15.0 &

18.0.

3. Compression

Granules are compressed in Cadmac 45 Punch machine by maintaining following specification

mentioned:

SPECIFICATIONS

Machine : B-type Press: Cadmac 45 Punch

Punch set : Round

Upper punch : Engraved with V

Lower punch : With break line

Average weight : 142.50.0mg 157.50 mg (150.0 mg 5 %)

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 6 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

(mg/tablet

: Not more than two of the individual weight of 20 tablets deviate from

Weight variation average weight by more than 7.5% and none deviate by more than

15%

Thickness : 3.45mm 3.81 mm (3.63mm 5%)

Hardness : Not less than 5 Kg

Disintegration time : Not more than 15 minutes

Friability : Not more than 1.0 %

Description of : A green colored, round shaped, one side engraved with V and other

tablet side break line tablet

4. Coating

Compressed tablets are coated in PAM GLATT Coating machine by maintaining following Procedure:

Inlet Temperature Pan speed Duration Spray RPM Test parameter Remarks

400c 3 rpm 60 minutes 20 rpm

Appear uniform

430c 4 rpm 30 minutes 25 rpm

color

450c 5 rpm 30 minutes 30 rpm

Appearance,

500c 6 rpm 60 minutes 35 rpm

weight gain

weight gain &

550c 1 rpm 15 minutes Off other parameter

as specification

5. Packaging Description

1. Cartons shall be overprinted with relevant information as follows

Name Batch Coding information

Inner carton for Ketofast 10 mg Tablet Batch No.

Mfg. Date

Exp. Date

IP/MRP Tk. (if not printed on Carton)

2. Blister strips of Ketofast 10 mg tablet shall be overprinted with relevant information as follows

Name Batch Coding information

Batch No.

Blister strip of Ketofast 10 mg Tablet

Exp

3. Primary and secondary packaging area will be free from previous packing

materials.

4. Coated tablets are packed in Blister Packing Machine (HOONGA) by maintaining

following specification. Sealing temperature : 1400C 1700C

Blister Forming Temperature: 1250c 1350c

5. After giving start up by Production and QA subsequently, Products will be packed

with relevant packing materials.

D) Manufacturing flow chart

PROCESS FLOW DIAGRAM

PROCESS STEPS EQUIPMENT

MATERIALS

Weighing balance All active and Excipients

DISPENSING

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 7 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

SIEVING Ketorolac Tromethamine,

20 mesh screen Sodium Starch Glycolate,

Vibratory shifter Avicel PH 102)

DRY MIXING

Pillar Bin Blender Colloidal Silicon Dioxide,

Magnesium Stearate

LUBRICATION &

BLENDING

45 Station Cadmach Blended materials

Compression Machine

COMPRESSION HPMC (15 cps)

Methylene Clhloride

Methanol

Pam Glatt Polyethylene Glycole

Titanium dioxide

Purified Talc

COATING Green Lake

Coated Tablet, Packaging

Hoonga material

PACKING

QC TEST SAMPLE

12.0 SPECIAL PRECAUTION:

The product will manufacturing and filling with special precautions

13.0 PROCESS PARAMETERS FOR IPC TEST

All manufacturing process, record & specifications are given in Batch Manufacturing Record

(BMR)

14.0 ANALYTICAL TEST METHODS

The test method used for the analytical data evaluation of Ketofast 10 mg tablet is TP/PK 001/01

The parameters are evaluated according to the specification:

Item Ref. No.

Specification of Granules SPEC/PK 001/GR/00

Specification of Core Tablet SPEC/PK 001/IP/01

Specification of Coated Tablet SPEC/PK 001/CT/01

Specification of Finish Product SPEC/PK 001/FP/01

15.0 SAMPLING PLAN

15.1 Granulation Stage (Dry Mixing and Blending) & Follow the diagram below for sampling

Sampling Quantity of samples to

Sampling frequency

Point collect

Top 20 gm 2 set of sample from each point

Middle 20 gm 2 set of sample from each point

Bottom 20 gm 2 set of sample from each point

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 8 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

1 & 2 = Top

3 & 4 = Middle

5 & 6 = Bottom

1 2

4 3

5 6

15.2 Compression Stage

Sampling Point Quantity of samples to collect Sampling frequency

Channel-1 ( Left) 100 tablets at each stage Start, middle and end of operation

Channel-2 ( right) 100 tablets at each stage Start, middle and end of operation

15.3 Coating

Sampling Point (After Quantity of samples to collect Sampling frequency

coating)

Top 100 tablets Three different places

Middle 100 tablets Three different places

Bottom 100 tablets Three different places

15.4 Blistering

Sampling Quantity of samples

Sampling frequency

Point to collect

Start of After start of operation, at 5 minutes interval (at

30 strips

operation least three times)

Middle of At middle of operation, at 5 minutes interval (at

30 strips

operation least three times)

End of 15 minutes before end of operation, at 5

30 strips

operation minutes interval (at least three times)

15.5 Finish Product

Sampling Point Quantity of samples to collect Sampling frequency

Start of operation 100 tablets Three different places

Middle of operation 100 tablets Three different places

End of operation 100 tablets Three different places

Deviation (if any):

16.1 Acceptance Criteria

Stage Test Parameter Acceptance criteria

Loss on drying

Not more than 3.5%

/Water content

Granulation 9.50mg 10.50mg (95.0% to 105.0% of the label claim)

Assay

RSD: NMT 3%

Identification Must be positive for Ketorolac Tromethamine

Compression Physical A green colored, round shaped, one side engraved with V

appearance and other side break line tablet

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 9 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

Hardness NLT 5 kg

Thickness 3.45mm 3.81 mm (3.63mm 5%)

Average Weight 142.50mg 157.50 mg (150.0mg 5%)

Not more than two of the individual weight of 20 tablets

Weight variation deviate from average weight by more than 7.5% and none

deviate by more than 15%

Disintegration test Not more than 15 minutes

Assay 9.0mg 11.0mg (90.0% to 110.0% of the label claim)

Individual: 85% - 115% (10 dosage units)

If one unit is outside the limit but within 75% -125% then

test another 20 units individually.

Content uniformity

30 units: None should be outside of 75% - 125% of

average content (30 units) and maximum one can be

outside 85% -115% of average content (30 units).

Physical A green colored round shaped film coated tablet with one

appearance sides engraved V and other side break line

Average weight 152.0 mg 168.0 mg (160.0 mg 5 %)

Hardness Not less than 6 kg

Thickness 3.55 mm 3.93 mm (3.74 mm 5%)

Coating Not more than two of the individual weight of 20 tablets

Weight variation deviate from average weight by more than 7.5% and none

deviate by more than 15%

Disintegration test Not more than 30 minutes

Assay 9.0mg 11.0mg (90.0% to 110.0% of the label claim)

Dissolution Not less than 75% within 45 minutes

Pocket Formation Must be OK.

Blistering

Leak test Must be leak proof.

16.2 Finish Product Specification

Physical A green colored round shaped film coated tablet with one sides engraved V

appearance and other side break line

Average weight 152.0 mg 168.0 mg (160.0 mg 5 %)

Hardness Not less than 6 kg

Thickness 3.55 mm 3.93 mm (3.74 mm 5%)

Not more than two of the individual weight of 20 tablets deviate from average

Weight variation

weight by more than 7.5% and none deviate by more than 15%

Disintegration test Not more than 30 minutes

Assay 9.0mg 11.0mg (90.0% to 110.0% of the label claim)

Individual: 85% - 115% (10 dosage units)

If one unit is outside the limit but within 75% -125% then test another 20 units

Content uniformity individually.

30 units: None should be outside of 75% - 125% of average content (30 units)

and maximum one can be outside 85% -115% of average content (30 units).

Dissolution Not less than 75% within 45 minutes

Primary packaging Alu-Pvdc

Pack size 2X10s

17.1 Set critical parameters at different conditions, justify the suitable one at which meets

specification and then run the machine at justified condition.

Sl. Control Variable Critical parameters to be checked

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 10 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

No.

01 Dry mixing Time Mixing time

Lubrication &

02 Time Mixing time and speed (fixed)

blending

Machine speed and compression

03 Compression Pressure and turrent speed

pressure

Pan speed, inlet & Outlet temperature

04 Coating Pan speed and spay rate

and spray rate

Forming temperature,

Forming temperature, pressure &

05 Blistering pressure & sealing

sealing temperature

temperature

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 11 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

17.2 CRITICAL PROCESS PARAMETERS AND JUSTIFICATION

The following process parameters shall be considered as "critical" because the uniform results meeting the acceptance criteria will depend upon

these parameters. Collect sample as per sampling plan (15.0) and carryout test (18.0) as per specification.

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 12 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

Sl. Control Critical

Steps Desired set value Justification Acceptance criteria Result

No. Variable parameters

Check the moisture content, LOD/Moisture content: NMT 3.5%

Mix for 30 minutes, uniformity of granules by assay Assay: 9.50mg 10.50mg (95.0%

QC/QA will collect analysis. If does not meet

Dry to 105.0% of the label claim)

01 Time Mixing time sample as per sampling specification then mix for 5

mixing minutes & carryout test. From

RSD value is within 3%

plan and analyze as per

next batches, it will be mixing Identification: must be positive for

specification

time. Ketorolac Tromethamine

Check the moisture content,

Carryout blending for 10 uniformity of granules. Moisture LOD/Moisture content: NMT 3.5%

content & assay is within 5% of

Lubrication &

minutes, QC/QA will Assay: 9.50mg 10.50mg (95.0%

Mixing time theoretical values & RSD value is

blending

collect sample as per to 105.0% of the label claim)

02 Time and speed within 3%. If the result does not

sampling plan and meet specification then mix for

RSD value is within 3%

(fixed)

analyze as per another 5 minutes and carryout Identification: must be positive for

specification tests. From next batches, it will Ketorolac Tromethamine

be blending time.

Description: A green colored,

round shaped, one side engraved

with V and other side break line

Check all physical parameters

tablet

Run the like Description, Average

Hardness: NLT 5 kg

compression machine weight, Hardness, Thickness,

Compression

Thickness: 3.45mm 3.81 mm

Pressure Machine at 12, 16 & 20 RPM Friability, Disintegration time

(3.63mm 5%)

and speed and and pressure at 3 tons, and uniformity of weight at

03 Average weight: 142.50 mg

turrent compression QC/QA will collect each speed and pressure.

157.50 mg (150.0 mg 5%)

speed pressure sample as per sampling Define the speed & pressure

Weight variation: Not more than

plan and analyze as at which the results meet

two of the individual weight of 20

per specification specification. Then run the

tablets deviate from average weight

machine at defined conditions.

by more than 7.5% and none

deviate by more than 15%

Disintegration Time: NMT 15 min.

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 13 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 14 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

Content Uniformity-

Run the compression machine Individual: 85% - 115% (10 dosage units)

Compression

Machine at 12, 16 & 20 RPM and If one unit is outside the limit but within 75%

Pressure

speed and pressure at 4 tons, QC/QA will -125% then test another 20 units individually.

03 and turret

compression collect sample as per sampling 30 units: None should be outside of 75% -

speed

pressure plan and analyze as per 125% of average content (30 units) and

specification maximum one can be outside 85% -115% of

average content (30 units).

Set Inlet temperature at 400c, pan

speed 3 rpm, spray rate 20 rpm for

60 minutes and QC/QA will collect

sample as per sampling plan and

carryout test as per specification

Set Inlet temperature at 430c, pan Description: A green colored, round shaped,

Check

speed 4 rpm, spray rate 25 rpm for one side engraved with V and other side

appearance

30 minutes and QC/QA will collect break line tablet

(Color

sample as per sampling plan and Hardness: NLT 5 kg

uniformity)

carryout test as per specification Thickness: 3.55mm 3.93 mm (3.74mm

at each

Pan speed, Set Inlet temperature at 450c, pan 5%)

Pan stage up to Average weight: 152.0 mg 168.0 mg

Coating

inlet & Outlet speed 5 rpm, spray rate 30 rpm for

speed completion

04 temperature 30 minutes and QC/QA will collect (160.0 mg 5%)

and spay of process.

and spray sample as per sampling plan and Weight variation: Not more than two of the

rate After that

rate carryout test as per specification individual weight of 20 tablets deviate from

carryout test

Set Inlet temperature at 500c, pan average weight by more than 7.5% and

as per

speed 6 rpm, spray rate 35 rpm for none deviate by more than 15%

sampling

60 minutes and QC/QA will collect Disintegration Time: NMT 15 min.

plan &

sample as per sampling plan and Dissolution: Not less than 75% within 45

specification

carryout test as per specification. min

Set Inlet temperature at 550c, pan

speed 1 rpm, sprays off for 15

minutes and QC/QA will collect

sample as per sampling plan and

carryout test as per specification

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 15 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

18.0 Analysis of samples

18.1 Granulation Stage Analytical method Ref. No.:

Testing

Test

plan/sample Sample ID No. Result Range Acceptance criteria Pass/fail Remarks

parameters

preparation plan

Top-1 Not more than 3.5%

Top

Top-2

Loss on Carry out tests on

Middle-1

drying/Wate each sample ( 6 Middle

Middle-2

r content samples)

Bottom-1

Bottom

Bottom-2

Top-1 9.50mg 10.50mg

Top

Top-2 (95.0% to 105.0% of

Carry out tests on the label claim)

Middle-1

Assay each sample ( 6 Middle

Middle-2

samples) RSD: NMT 3%

Bottom-1

Bottom

Bottom-2

Must be positive for

Identificatio

Ketorolac

n

Tromethamine

18.2 Compression stage Batch No.:

Test Testing plan/sample Sample ID

Result Average Range Acceptance criteria Pass/fail Remarks

parameters preparation plan No.

Ch.-1 A green colored, round

Start

Ch.-2 shaped, one side

Physical Check at each sampling Middl Ch.-1 engraved with V and

appearance stage & each channel e Ch.-2 other side break line

Ch.-1 tablet

End

Ch.-2

Ch.-1 NLT 5 kg

Start

Ch.-2

Check at each sampling

Hardness Middl Ch.-1

stage & each channel

e Ch.-2

End Ch.-1

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 14 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

Test Testing plan/sample Sample ID Pass

Result Average Range Acceptance criteria Remarks

parameters preparation plan No. /fail

Ch.-1 3.45mm 3.81 mm

Start

Ch.-2 (3.63mm 5%)

Check at each sampling Middl Ch.-1

Thickness

stage & each channel e Ch.-2

Ch.-1

End

Ch.-2

Average Weight 10 tabs at each Channel-1 142.50 mg 157.50 mg

weight stage from each channel Channel-2 (150.0 mg 5%)

Channel-1 Not more than two of the

individual weight of 20

Weight Sample from each stage at tablets deviate from average

variation each channel with 20 tabs. Channel-2 weight by more than 7.5%

and none deviate by more

than 15%

Ch.-1 Not more than 15 minutes

Start

Ch.-2

Disintegratio 6 samples from each stage Middl Ch.-1

n test at each channel e Ch.-2

Ch.-1

End

Ch.-2

Channel-1 9.50mg 10.50mg (95.0%

Composite of 20 tablets

to 105.0% of the label claim

Assay from each stage and

Channel-2 RSD: NMT 3%

channel

Individual: 85% - 115% (10

dosage units)

If one unit is outside the limit

but within 75% -125% then

Select 10 tablets from test another 20 units

Content composite sample collected individually.

Uniformity from different steps & 30 units: None should be

carryout assay of each unit. outside of 75% - 125% of

average content (30 units)

and maximum one can be

outside 85% -115% of

average content (30 units).

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 15 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

18.3 Coating stage Batch No.:

Test Testing plan/sample Acceptance

Sample ID No. Result Average Range Pass/fail Remarks

parameters preparation plan criteria

Top A green colored

Middle round shaped film

coated tablet with

Physical Check at each sampling

one sides

appearance stage

End engraved V and

other side break

line

Top 152.0 mg 168.0

Average Weight 20 tabs at each

Middle mg (160.0 mg 5

weight stage

End %)

Top Not less than 6 kg

Sample from each stage

Hardness Middle

with 10 tablets

End

Top 3.55 mm 3.93

Sample from each stage

Thickness Middle mm (3.74 mm

with 10 tablets

End 5%)

Not more than two

Top of the individual

weight of 20

tablets deviate

Weight Sample from each stage

from average

variation with 20 tablets Middle

weight by more

than 7.5% and

End none deviate by

more than 15%

Top Not more than 30

Disintegratio

6 samples from each stage Middle minutes

n test

End

9.50mg

10.50mg (95.0%

Composite of 20 tablets

Assay Composite to 105.0% of the

from each stage

label claim)

RSD: NMT 3%

Composite of sample from Top Not less than 75%

Dissolution each stage (at 5, 10, 15, Middle within 45 minutes

30, 45 & 60 minutes) End

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 16 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

18.4 Blistering

Test parameters Testing plan/sample preparation plan Result Acceptance criteria Pass/fail Remarks

Start of operation

Pocket Formation Middle of operation Must be OK.

End of operation

Start of operation

Leak test Must be leak proof.

Middle of operation

End of operation

18.5 Finish Product

Test Testing plan/sample Sample ID Acceptance

Result Average Range Pass/fail Remarks

parameters preparation plan No. criteria

Top A green colored

round shaped film

Middle coated tablet with

Physical Check at each sampling

one sides

appearance stage

engraved V and

End other side break

line

Top 152.0 mg 168.0

Average Weight 20 tabs at each

Middle mg (160.0 mg 5

weight stage

End %)

Top

Sample from each stage

Hardness Middle Not less than 6 kg

with 10 tablets

End

Top 3.55 mm 3.93

Sample from each stage

Thickness Middle mm (3.74 mm

with 10 tablets

End 5%)

Not more than two

Top of the individual

weight of 20 tablets

Weight Sample from each stage Middle deviate from

variation with 20 tablets average weight by

more than 7.5%

End and none deviate

by more than 15%

Top

Disintegratio Not more than 30

6 samples from each stage Middle

n test minutes

End

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 17 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

Testing

Test Sample ID

plan/sample Result Average Range Acceptance criteria Pass/fail Remarks

parameters No.

preparation plan

Composite of 20 9.50mg 10.50mg (95.0% to

Assay tablets from each Composite 105.0% of the label claim)

stage RSD: NMT 3%

Composite of Top

sample from each Middle

Not less than 75% within 45

Dissolution stage (at 5, 10, 15,

minutes

30, 45 & 60 End

minutes)

Individual: 85% - 115% (10

dosage units)

If one unit is outside the limit

Select 10 tablets but within 75% -125% then

from composite test another 20 units

Content sample collected individually.

Uniformity from different steps 30 units: None should be

& carryout assay of outside of 75% - 125% of

each unit. average content (30 units) and

maximum one can be outside

85% -115% of average

content (30 units).

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 18 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

19.0 Summary of test result of individual batch Batch No.:

Resul Pass/Fai

Stage Test Parameter Acceptance criteria Remarks Deviation (if any)

t l

Loss on

drying/Water Not more than 3.5%

Granulation content

9.50mg 10.50mg (95.0% to 105.0% of the

Assay

label claim) RSD: NMT 3%

A green colored, round shaped, one side

Physical

engraved with V and other side break line

appearance

tablet

Hardness NLT 5 kg

Thickness 3.45mm 3.81 mm (3.63mm 5%)

Average Weight 142.50mg 157.50 mg (150.0mg 5%)

Not more than two of the individual weight of 20

tablets deviate from average weight by more

Weight variation

than 7.5% and none deviate by more than

Compression 15%

Disintegration test Not more than 15 minutes

9.50mg 10.50mg (95.0% to 105.0% of the

Assay

label claim) RSD: NMT 3%

Individual: 85% - 115% (10 dosage units)

If one unit is outside the limit but within 75%

-125% then test another 20 units individually.

Content uniformity 30 units: None should be outside of 75% -

125% of average content (30 units) and

maximum one can be outside 85% -115% of

average content (30 units).

Coating A green colored round shaped film coated tablet

Physical

with one sides engraved V and other side

appearance

break line

Average weight 152.0 mg 168.0 mg (160.0 mg 5 %)

Hardness Not less than 6 kg

Thickness 3.55 mm 3.93 mm (3.74 mm 5%)

Not more than two of the individual weight of 20

tablets deviate from average weight by more

Weight variation

than 7.5% and none deviate by more than

15%

Disintegration test Not more than 30 minutes

Assay 9.50mg 10.50mg (95.0% to 105.0% of the

label claim) RSD: NMT 3%

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 19 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

Dissolution Not less than 75% within 45 minutes

Resul Pass/Fai

Stage Test Parameter Acceptance criteria Remarks Deviation (if any)

t l

Pocket Formation Must be OK.

Blistering

Leak test Must be leak proof.

A green colored round shaped film coated tablet

Physical

with one sides engraved V and other side

appearance

break line

Average weight 152.0 mg 168.0 mg (160.0 mg 5 %)

Hardness Not less than 6 kg

Thickness 3.55 mm 3.93 mm (3.74 mm 5%)

Not more than two of the individual weight of 20

tablets deviate from average weight by more

Weight variation

than 7.5% and none deviate by more than

15%

Finish

Product Disintegration test Not more than 30 minutes

9.50mg 10.50mg (95.0% to 105.0% of the

Assay

label claim) RSD: NMT 3%

Dissolution Not less than 75% within 45 minutes

Individual: 85% - 115% (10 dosage units)

If one unit is outside the limit but within 75%

-125% then test another 20 units individually.

Content Uniformity 30 units: None should be outside of 75% -

125% of average content (30 units) and

maximum one can be outside 85% -115% of

average content (30 units).

20. Summary format of three validation batches

Result Deviation

Stage Test Parameter Acceptance criteria Pass/Fail Remarks

(if any)

Loss on

drying/Water Not more than 3.5%

Granulation content

9.50mg 10.50mg (95.0% to 105.0%

Assay

of the label claim) RSD: NMT 3%

Compression A green colored, round shaped, one

Physical

side engraved with V and other side

appearance

break line tablet

Hardness NLT 5 kg

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 20 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

Thickness 3.45mm 3.81 mm (3.63mm 5%)

Average Weight 142.50mg 157.50 mg (150.0mg 5%)

Not more than two of the individual

weight of 20 tablets deviate from

Weight variation

average weight by more than 7.5%

and none deviate by more than 15%

Result Deviation

Stage Test Parameter Acceptance criteria Pass/Fail Remarks

(if any)

Disintegration test Not more than 15 minutes

9.50mg 10.50mg (95.0% to 105.0%

Assay

of the label claim) RSD: NMT 3%

Individual: 85% - 115% (10 dosage

units). If one unit is outside the limit

Compression but within 75% -125% then test

another 20 units individually.

Content uniformity 30 units: None should be outside of

75% - 125% of average content (30

units) and maximum one can be

outside 85% -115% of average content

(30 units).

A green colored round shaped film

Physical

coated tablet with one sides engraved

appearance

V and other side break line

152.0 mg 168.0 mg (160.0 mg 5

Average weight

%)

Hardness Not less than 6 kg

Thickness 3.55 mm 3.93 mm (3.74 mm 5%)

Coating Not more than two of the individual

weight of 20 tablets deviate from

Weight variation

average weight by more than 7.5%

and none deviate by more than 15%

Disintegration test Not more than 30 minutes

9.50mg 10.50mg (95.0% to 105.0%

Assay

of the label claim) RSD: NMT 3%

Dissolution Not less than 75% within 45 minutes

Pocket Formation Must be OK.

Blistering

Leak test Must be leak proof.

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 21 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

Result Deviation

Stage Test Parameter Acceptance criteria Pass/Fail Remarks

(if any)

A green colored round shaped film

Physical

coated tablet with one sides engraved

appearance

V and other side break line

152.0 mg 168.0 mg (160.0 mg 5

Average weight

%)

Hardness Not less than 6 kg

Thickness 3.55 mm 3.93 mm (3.74 mm 5%)

Not more than two of the individual

weight of 20 tablets deviate from

Weight variation

average weight by more than 7.5%

and none deviate by more than 15%

Finish Disintegration test Not more than 30 minutes

Product 9.50mg 10.50mg (95.0% to 105.0%

Assay

of the label claim) RSD: NMT 3%

Dissolution Not less than 75% within 45 minutes

Individual: 85% - 115% (10 dosage

units)

If one unit is outside the limit but within

75% -125% then test another 20 units

individually.

Content Uniformity

30 units: None should be outside of

75% - 125% of average content (30

units) and maximum one can be

outside 85% -115% of average content

(30 units).

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 22 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

21. Reference documents

1) Raw data

2) Certificate of analysis for Granules, Core, Coated & Finish Product

3) Attachments

4) Analytical note book reference No.

5) Analytical note book No.

22.0 YIELD SUMMARY Batch No.:

Sl. No. Stage Specification Actual yield Pass/Fail Remarks

01 Granulation

02 Compression

03 Coating

Finish

04

Product

23.0 DEVIATION REPORTING

After careful study of all results a deviation report shall be prepared and documented in the following format

Deviation Type Problem Investigation Conclusion

Analytical

Process

24.0 Revalidation

The manufacturing process of Ketofast 10 Tablet shall be revalidated in one or more of following cases:

24.1 Change in formulation, procedure or quality of pharmaceutical ingredients

24.2 Change of equipment, addition of new equipment which affect the performance of equipment.

24.3 Major change of process parameter.

24.4 Change in site.

24.5 On appearance of negative quality trends.

24.6 On appearance of new findings based on current knowledge.

24.7 Batch size change implementation of these changes shall be carried out as per change control system.

24.8 Major changes in utility system (HVAC, purified water etc.)

24.9 Each change should be as per change control procedure.

25.0 REVIEW OF RESULTS AND REPORTING

Results collected from the three batches shall be reviewed and a validation report will be prepared,

Compliance to specification in all three batches shall validate the manufacturing process concurrently. The

validation report shall include the final conclusion and recommendation. Conclusion shall clearly state the

status of compliance to the validation protocol and its acceptance criteria.

26.0 FINAL SUMMARY REPORT

Final Summary report with conclusion and recommendation to be included in Validation report.

27.0 COMPILATION OF CONTROL DATA AND RECORDS

Control data and records of three batches to be compiled and compliance to be checked as per validation

protocol and its acceptance criteria.

28.0 BATCH ANALYSIS REPORT

Finished batch analysis report of three batches to be compiled and uniformity and RSD to be checked for

each parameter for compliance.

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 23 of 26

Veritas Pharmaceuticals limited Process Validation

Muradpur,Vannara,Mouchak,Gazipur VPL-PVP-007

Rev No.: 00

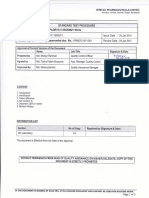

29.0 FINAL APPROVAL

CERTIFICATE OF APPROVAL

Product : Ketofast 10 Tablet

Process : Granulation, Compression, Coating & Packing of Ketofast 10 mg Tablet

Reference : VPL-PVP-007

Prepared by:

Signature:________________

Sr. Executive, Product Development Date :________________

Checked by:

Assistant Manager, Quality Control Signature:________________

Date :________________

Agreed by:

Manager, Production Signature:________________

Date :________________

Approved by:

Quality Assurance Manager Signature:________________

Date :________________

cc: Head, Production

cc: Product Development

cc: Head, QA

30.0 APPENDICES

APPENDIX-1: Finished Batch Analysis Documents

APPENDIX-2: Control Data and Records

APPENDIX-3: Copies of Batch Documents

31.0 REVISION HISTORY

Version & Issue

Sl. No. Revision/Change in brief Reason for change

details

Version : 00, Date of

1 New N/A

issue: April 2014

Ketofast 10 Tablet COMPANY PROPRIETARY AND CONFIDENTIAL Page 24 of 26

Potrebbero piacerti anche

- Juvia Protocol 50-1000Documento16 pagineJuvia Protocol 50-1000ziauddin bukhariNessuna valutazione finora

- PVPRDocumento47 paginePVPRBRIJENDRA KUMAR SINGH100% (2)

- Prosses Validation Protocol For Ivermectin InjectionDocumento25 pagineProsses Validation Protocol For Ivermectin Injectionمحمد عطاNessuna valutazione finora

- F03qa038-00 VMPDocumento24 pagineF03qa038-00 VMPMeet Vermaa100% (1)

- TEMPLATE FOR PROCESS VALIDATION PROTOCOL - Pharmaceutical GuidanceDocumento6 pagineTEMPLATE FOR PROCESS VALIDATION PROTOCOL - Pharmaceutical GuidancePackaging Development BernofarmNessuna valutazione finora

- Protocol For Process Validation of Cefowin Cefotaxime 1000mgDocumento31 pagineProtocol For Process Validation of Cefowin Cefotaxime 1000mgShafaq ALI100% (2)

- Ointment Process Validation-OriginalDocumento26 pagineOintment Process Validation-Originalasit_m100% (1)

- Tablet Process ValidationDocumento37 pagineTablet Process ValidationOsama Mahmoud75% (4)

- BMR of Vericef 500capsuleDocumento17 pagineBMR of Vericef 500capsuleShagorShagor100% (1)

- Process Validation Final ReportDocumento9 pagineProcess Validation Final ReportShagorShagor75% (4)

- BMR Cephracap 500 Cap Checked 1Documento16 pagineBMR Cephracap 500 Cap Checked 1jordan7half7don100% (1)

- Annual Product Review Developing An SOPDocumento26 pagineAnnual Product Review Developing An SOPanants2567% (3)

- BMR - fp025-01 v-1 Azinil Pfs 35mlDocumento14 pagineBMR - fp025-01 v-1 Azinil Pfs 35mlShagorShagorNessuna valutazione finora

- Film Coated Tablet Process Validation SchemeDocumento12 pagineFilm Coated Tablet Process Validation SchemeFarhana Shermeen83% (6)

- Aphrin 500 MG Capsule BPR 1Documento12 pagineAphrin 500 MG Capsule BPR 1ShagorShagor100% (1)

- Co Dabamal Tablet 9m606001Documento22 pagineCo Dabamal Tablet 9m606001joerichladNessuna valutazione finora

- cGMP Current Good Manufacturing Practices for PharmaceuticalsDa EverandcGMP Current Good Manufacturing Practices for PharmaceuticalsValutazione: 1 su 5 stelle1/5 (2)

- RM-Method Validation ProtocolDocumento12 pagineRM-Method Validation ProtocolShagorShagorNessuna valutazione finora

- Cleaning Validation ProtocolDocumento21 pagineCleaning Validation Protocolmarkandey gupta100% (6)

- Ointment Process ValidationDocumento25 pagineOintment Process ValidationMuqeet Kazmi75% (12)

- Annual Product ReviewDocumento25 pagineAnnual Product ReviewBhupendra Tomar100% (2)

- BPR - FP025-1 V-1Azinil 35ml PFSDocumento17 pagineBPR - FP025-1 V-1Azinil 35ml PFSShagorShagor100% (1)

- 2-E.BMR Liquid InjectionDocumento28 pagine2-E.BMR Liquid InjectionMohammed Zubair100% (7)

- Batch Manufacturing Record (Capsule) : TitleDocumento25 pagineBatch Manufacturing Record (Capsule) : TitleMohammed Zubair100% (3)

- Assay by Titration Validation Protocol-ModelDocumento9 pagineAssay by Titration Validation Protocol-ModelAnzari Muhammad100% (4)

- Tablet Process ValidationDocumento33 pagineTablet Process ValidationJivan Battu94% (17)

- Analytical Report For Ketofast 10 TabletDocumento20 pagineAnalytical Report For Ketofast 10 TabletShagorShagorNessuna valutazione finora

- Vatakulantka Rasa TabletDocumento7 pagineVatakulantka Rasa Tabletreflectprakash3610Nessuna valutazione finora

- Ezetimibe VPGQC14061 00 YaDocumento16 pagineEzetimibe VPGQC14061 00 YaDany RockNessuna valutazione finora

- Bulk Holding Time Study ReportDocumento8 pagineBulk Holding Time Study ReportFaress RabiNessuna valutazione finora

- Hold Time Study Sample Protocol PDFDocumento4 pagineHold Time Study Sample Protocol PDFElena Trofin50% (2)

- Parenteral Process ValidationDocumento30 pagineParenteral Process Validationravindra82% (11)

- Capsule Process ValidationDocumento28 pagineCapsule Process Validationasit_m89% (28)

- Master Cleaning Validation PlanDocumento25 pagineMaster Cleaning Validation PlanWidya Lukitasari100% (1)

- BMR - Elfexo 120 TabletDocumento13 pagineBMR - Elfexo 120 TabletShagorShagor100% (1)

- Area Qualification ProtocolDocumento19 pagineArea Qualification ProtocolBRIJENDRA KUMAR SINGH100% (1)

- Tablet Process ValidationDocumento38 pagineTablet Process Validationasit_m100% (6)

- Emiset - BPRDocumento25 pagineEmiset - BPRjordan7half7donNessuna valutazione finora

- Validation of Coating Equipment (Ketik Ulang)Documento6 pagineValidation of Coating Equipment (Ketik Ulang)Dedhieaja0% (1)

- Prepared by Production: Approved by QA/QC:: TERASOL® 600 BolusDocumento19 paginePrepared by Production: Approved by QA/QC:: TERASOL® 600 BolusLegese HailuNessuna valutazione finora

- Process Validation of LiquidDocumento24 pagineProcess Validation of LiquidAshutosh Shukla100% (2)

- Process Validation Protocol of Desvel 50Mg Tablet: Medisure Laboratories Pakistan (PVT.) LTDDocumento16 pagineProcess Validation Protocol of Desvel 50Mg Tablet: Medisure Laboratories Pakistan (PVT.) LTDsamia khanNessuna valutazione finora

- Process Validation of LiquidDocumento24 pagineProcess Validation of Liquidasit_m92% (25)

- Aphrin 500 MG Capsule BPR 2Documento16 pagineAphrin 500 MG Capsule BPR 2ShagorShagor100% (2)

- Batch Manufacturing Record: Wellborne Pharmachem & BiologicalsDocumento23 pagineBatch Manufacturing Record: Wellborne Pharmachem & BiologicalsMohammed Zubair100% (1)

- Cipro - MFR 500r1Documento18 pagineCipro - MFR 500r1Anonymous IVUj0uiNessuna valutazione finora

- Ointment Process ValidationDocumento25 pagineOintment Process ValidationTrinh Huy CongNessuna valutazione finora

- Guide To Master Formulae Final 2012Documento119 pagineGuide To Master Formulae Final 2012MohamedRefaatMohamedNessuna valutazione finora

- 01 - Assay Procedure Development Protocol (APDP) of Celozin TabletDocumento5 pagine01 - Assay Procedure Development Protocol (APDP) of Celozin TabletShagorShagorNessuna valutazione finora

- Hold Time Studies For FBD BagsDocumento12 pagineHold Time Studies For FBD BagsShubam Sharma100% (1)

- Oos-Out of SpecificationDocumento12 pagineOos-Out of Specificationasit_m50% (2)

- Cleaning Validation ProtocolDocumento9 pagineCleaning Validation Protocolyash143565100% (2)

- Method Validation - ReportDocumento8 pagineMethod Validation - ReportShagorShagorNessuna valutazione finora

- Aphrin Pfs BPR p1 v-1Documento13 pagineAphrin Pfs BPR p1 v-1ShagorShagorNessuna valutazione finora

- Validation master plan Complete Self-Assessment GuideDa EverandValidation master plan Complete Self-Assessment GuideNessuna valutazione finora

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersDa EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersNessuna valutazione finora

- Production of Plasma Proteins for Therapeutic UseDa EverandProduction of Plasma Proteins for Therapeutic UseValutazione: 3 su 5 stelle3/5 (5)

- A Textbook of Pharmaceutical Quality AssuranceDa EverandA Textbook of Pharmaceutical Quality AssuranceValutazione: 3 su 5 stelle3/5 (6)

- Concepts of Quality Management in Pharmaceutical IndustryDa EverandConcepts of Quality Management in Pharmaceutical IndustryNessuna valutazione finora

- Regulatory Aspects of Pharmaceutical Quality System: Brief IntroductionDa EverandRegulatory Aspects of Pharmaceutical Quality System: Brief IntroductionNessuna valutazione finora

- List of Raw Material ActiveDocumento11 pagineList of Raw Material ActiveShagorShagor0% (1)

- Inner Carton Perizol 15 16Documento4 pagineInner Carton Perizol 15 16ShagorShagorNessuna valutazione finora

- Verimet 500 Tablet CCDocumento1 paginaVerimet 500 Tablet CCShagorShagorNessuna valutazione finora

- Analytical Report For Ketofast 10 TabletDocumento20 pagineAnalytical Report For Ketofast 10 TabletShagorShagorNessuna valutazione finora

- FP Spec.Documento3 pagineFP Spec.ShagorShagorNessuna valutazione finora

- 01 - Assay Procedure Development Protocol (APDP) of Celozin TabletDocumento5 pagine01 - Assay Procedure Development Protocol (APDP) of Celozin TabletShagorShagorNessuna valutazione finora

- BPR - FP025-1 V-1Azinil 35ml PFSDocumento17 pagineBPR - FP025-1 V-1Azinil 35ml PFSShagorShagor100% (1)

- QC Report 2014 01 (28 10 14 To 07 11 14)Documento5 pagineQC Report 2014 01 (28 10 14 To 07 11 14)ShagorShagorNessuna valutazione finora

- Cefuroxime Axetil USP COADocumento1 paginaCefuroxime Axetil USP COAShagorShagorNessuna valutazione finora

- QC Report 2014 01 (28 10 14 To 07 11 14)Documento5 pagineQC Report 2014 01 (28 10 14 To 07 11 14)ShagorShagorNessuna valutazione finora

- QC Report October 2014Documento5 pagineQC Report October 2014ShagorShagorNessuna valutazione finora

- 1-Test Report of AceclofenacDocumento1 pagina1-Test Report of AceclofenacShagorShagorNessuna valutazione finora

- 3-Test Report of Amlodipine Besilate 3Documento1 pagina3-Test Report of Amlodipine Besilate 3ShagorShagorNessuna valutazione finora

- 2-Test Report of Ambroxol HCL 2Documento1 pagina2-Test Report of Ambroxol HCL 2ShagorShagorNessuna valutazione finora

- COA - Finished ProductDocumento1 paginaCOA - Finished ProductShagorShagorNessuna valutazione finora

- Finished Product SpecDocumento1 paginaFinished Product SpecShagorShagor100% (2)

- Process Validation Final ReportDocumento9 pagineProcess Validation Final ReportShagorShagor75% (4)

- StorageDocumento2 pagineStorageShagorShagorNessuna valutazione finora

- Manufacturing Process & Process ControlDocumento3 pagineManufacturing Process & Process ControlShagorShagorNessuna valutazione finora

- Finished Product - Test ProcedureDocumento13 pagineFinished Product - Test ProcedureShagorShagor100% (3)

- STP Avicel PH 102Documento6 pagineSTP Avicel PH 102ShagorShagorNessuna valutazione finora

- Method Validation - ReportDocumento8 pagineMethod Validation - ReportShagorShagorNessuna valutazione finora

- 5-Cefoprox 50 ML PFSDocumento1 pagina5-Cefoprox 50 ML PFSShagorShagorNessuna valutazione finora

- STP Opadry IIDocumento2 pagineSTP Opadry IIShagorShagorNessuna valutazione finora

- STP Aerosil 200Documento3 pagineSTP Aerosil 200ShagorShagor100% (1)

- 4-Novazith 35 ML PFSDocumento1 pagina4-Novazith 35 ML PFSShagorShagorNessuna valutazione finora

- RM COA - SupplierDocumento2 pagineRM COA - SupplierShagorShagorNessuna valutazione finora

- Stability ReportDocumento9 pagineStability ReportShagorShagorNessuna valutazione finora

- STP Aerosil 200Documento3 pagineSTP Aerosil 200ShagorShagor100% (1)

- 6-Fluact 35 ML PFSDocumento1 pagina6-Fluact 35 ML PFSShagorShagorNessuna valutazione finora

- Model A SOLUTIONSDocumento8 pagineModel A SOLUTIONSasdfNessuna valutazione finora

- MPI Report 009 Sub Structure B668Documento1 paginaMPI Report 009 Sub Structure B668John DolanNessuna valutazione finora

- (Studies in American Popular History and Culture) Gail Fowler Mohanty - Labor and Laborers of The Loom - Mechanization and Handloom Weavers, 1780-1840 - Routledge (2006)Documento292 pagine(Studies in American Popular History and Culture) Gail Fowler Mohanty - Labor and Laborers of The Loom - Mechanization and Handloom Weavers, 1780-1840 - Routledge (2006)Милош Станојловић100% (1)

- Emcoturn 365Documento362 pagineEmcoturn 365mikadoturkNessuna valutazione finora

- Gmail - Welcome To Clarion Crossing!Documento4 pagineGmail - Welcome To Clarion Crossing!sagarnr gowdaNessuna valutazione finora

- Manual For Noncommissioned Officers and Privates of Infantry of The Army of The United StatesDocumento250 pagineManual For Noncommissioned Officers and Privates of Infantry of The Army of The United StatesGutenberg.org100% (1)

- 06ESL37 Analog Electronics Lab MANUALDocumento70 pagine06ESL37 Analog Electronics Lab MANUALSan AngadiNessuna valutazione finora

- VENUS e CatalogueDocumento38 pagineVENUS e CatalogueGanesh BabuNessuna valutazione finora

- Squares and Square Roots Chapter Class ViiiDocumento24 pagineSquares and Square Roots Chapter Class ViiiManas Hooda100% (1)

- API 571 Quick ReviewDocumento32 pagineAPI 571 Quick ReviewMahmoud Hagag100% (1)

- Research On Strip Deformation in The Cage Roll-Forming Process of ERW Round PipesDocumento7 pagineResearch On Strip Deformation in The Cage Roll-Forming Process of ERW Round PipesJames PhillipsNessuna valutazione finora

- Ilmu KhotifDocumento28 pagineIlmu KhotifAndré Martins78% (27)

- Biology Unit 4Documento44 pagineBiology Unit 4Mohammad KhanNessuna valutazione finora

- Curvature CorrectionDocumento7 pagineCurvature CorrectionE J SNessuna valutazione finora

- 2.PsychoCrash Social Psy-1Documento62 pagine2.PsychoCrash Social Psy-1Gopika Sureshnv0% (1)

- Engineering Drawings and Plans: Engr. Rolly S. TambeDocumento4 pagineEngineering Drawings and Plans: Engr. Rolly S. TambeFred Joseph G. AlacayanNessuna valutazione finora

- Consent For Diagnostic And/or Therapeutic ParacentesisDocumento2 pagineConsent For Diagnostic And/or Therapeutic ParacentesisnaveenNessuna valutazione finora

- Balmatech Go Ep Tds 2022-03 GBDocumento2 pagineBalmatech Go Ep Tds 2022-03 GBAnalista De CalidadNessuna valutazione finora

- 9 Daftar Pustaka VaricelaDocumento2 pagine9 Daftar Pustaka VaricelaAfrina FaziraNessuna valutazione finora

- SmartSlope C 110 Installation Manual PDFDocumento5 pagineSmartSlope C 110 Installation Manual PDFAivan Dredd PunzalanNessuna valutazione finora

- Mold Maintenance StepDocumento0 pagineMold Maintenance StepMonica JoynerNessuna valutazione finora

- Nastran Preference Guide Volume 1 Structural AnalysisDocumento724 pagineNastran Preference Guide Volume 1 Structural AnalysisGuido RossiNessuna valutazione finora

- StairsDocumento57 pagineStairsArun K RajNessuna valutazione finora

- OKM 54MP FlyerDocumento1 paginaOKM 54MP FlyerJohnsonNessuna valutazione finora

- Inguinal Hernia - QuizDocumento17 pagineInguinal Hernia - Quizemily5890Nessuna valutazione finora

- Definition of Logistics ManagementDocumento4 pagineDefinition of Logistics ManagementzamaneNessuna valutazione finora

- CSA Pre-Test QuestionnaireDocumento16 pagineCSA Pre-Test Questionnairedaniella balaquitNessuna valutazione finora

- Sop Toh Engine PT MarminDocumento5 pagineSop Toh Engine PT MarminBeni WantaraNessuna valutazione finora

- Latest Research Papers On Manet SecurityDocumento7 pagineLatest Research Papers On Manet Securitygz9g97haNessuna valutazione finora

- Course Specification Course Title: Basic Architectural DraftingDocumento1 paginaCourse Specification Course Title: Basic Architectural DraftingDinah Fe Tabaranza-OlitanNessuna valutazione finora