Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Plastic Injection Mold Design Checklist

Caricato da

Selvaraj Balasundram100%(1)Il 100% ha trovato utile questo documento (1 voto)

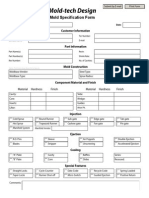

1K visualizzazioni2 pagineThe document provides a checklist for plastic injection mold design that includes verifying materials, components, dimensions, specifications, and features across the mold's BOM, design, components, cooling system, runner and gate system, ejection system, size, venting system, side action, cavity identification, mold base, and any hot runner system. The checklist aims to ensure the mold drawing and design satisfy all requirements before manufacturing.

Descrizione originale:

Plastic Injection Molding

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe document provides a checklist for plastic injection mold design that includes verifying materials, components, dimensions, specifications, and features across the mold's BOM, design, components, cooling system, runner and gate system, ejection system, size, venting system, side action, cavity identification, mold base, and any hot runner system. The checklist aims to ensure the mold drawing and design satisfy all requirements before manufacturing.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

1K visualizzazioni2 paginePlastic Injection Mold Design Checklist

Caricato da

Selvaraj BalasundramThe document provides a checklist for plastic injection mold design that includes verifying materials, components, dimensions, specifications, and features across the mold's BOM, design, components, cooling system, runner and gate system, ejection system, size, venting system, side action, cavity identification, mold base, and any hot runner system. The checklist aims to ensure the mold drawing and design satisfy all requirements before manufacturing.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

Plastic injection mold design checklist

BOM/drawing for plastic injection mold design

Are the correct materials being shown on injection mold drawing?

Have all components been identified on the planned view with detailed numbers?

Eye bolt holes are installed according to engineering prints to ensure safety of handling and are properly threads?

Is BOM completed with Material, component description, HRC and steel type?

Are the tie bars for the press shown on injection mold drawings?

Is the Injection Mold Size (LxWxH) indicated on the plastic injection mold drawing?

Design / part specification for plastic injection mold design

Rockwell hardness in C scale for each component identified in the text box on injection mold print.

Is plastic material verified with part drawing?

Is the shrink factor correct and verified?

Is there a minimum of 2-4 HRC points between movable components of injection mold?

Does the surface finish specified satisfy plastic part molding requirements?

Has the injection mold design been checked for mold function?

Is the injection mold designed for easy assembly and disassembly?

Plastic injection mold components inspection

Is the locating ring shown as per customer injection machine specification?

Are the sprue R and orifice dimensions shown on the plastic injection mold drawing?

Are support pillar locations shown on the injection mold drawings?

Do the leader pins bushings have vent relief milled into the mold base?

Is the shot counter location shown on the drawing if required?

Have standard purchased items such as hose fittings and electrical connectors been specified on the parts list?

Does mold drawing have parting line locks such as side lock or taper lock?

Plastic injection mold mark and guide system inspection

Is there one return pin and leader pin offset and marked O on the injection mold drawing?

Are the top two leader pins long enough to protrude 1/2 inch beyond the floating plate in the forward position?

Are all pockets and outside edges of the mold plates chamfered to eliminate the possibility of sharp corners.

Is there the capability for changing inserts/cores in the press for multiple version molds?

Are the leader pins long enough to pilot into the bushings before the cores enter the cavities?

Plastic injection mold design-cooling system inspection

Do the prints have 2-D water diagrams to show the flow of water?

Are the water line plugs shown properly, circuits numbered, the in and out, and levels identified?

Do the water lines in and out avoid the tie rods, mounting bolts, and clamp areas?

Is the cooling to the inserts adequate?

Plastic injection mold design-runner and gate system

Are runner, gate location and type shown on the drawing?

Does the gate type match the mold design specification sheet?

Is delayed ejection needed?

Are the runners sharp corners broken by 1 mm minimum and blend the transitional points of all cross-sectional size reductions?

Is there a cold slug well machined at the end of all runner turns and where the runner changes direction?

Is the runner designed to drop free and clear of the mold?

Is the sprue bushing keyed to prevent turning?

Are the runners polished to a minimum B-3 standard finish?

Plastic injection mold design-ejection system

Does the ejection side of mold have a cavity support plate?

Do ejector plates show spring return?

Do ejector plates have guide pins and bushings?

Are K.O. pin locations shown on the view of the core half of drawing?

Do the KO holes miss the water lines, support posts, stop buttons, and core pin water fountains?

Are the rails of the ejector housing doweled if it is DME standard mold base?

Is the length of the ejector plate assembly 0.01-inch per/end shorter than the ejector housing?

Have there been provisions made to return the ejector plate before the mold closes when there are ejector pins under the slides or core pins?

Are all contoured ejector pins keyed to prevent rotation with D shape ejection pin head?

Is the clearance and chamfer for the ejector pins shown on the mold drawings?

Has part ejection been reviewed to determine any effects for distortion, hitting the other mold surface, or needing shields to contain parts?

Plastic injection mold design-molding pressure /mold size

Does the mold fit within the machine minimum and maximum mold height specifications?

Do the clamping slots line-up with bolt holes on the platen?

Does the machine have adequate opening stroke to clear parts and runner? Will mold fit in the machine for which it is intended?

Does the machine have adequate KO stroke?

Plastic injection mold design-Venting system

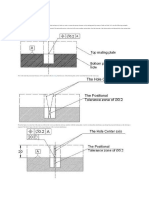

Do the Primary vents have 0.08 primary land and then exit to atmosphere through a minimum of 0.020 deep by 0.0125 wide channel? Does the mold drawing

show the area of venting?

Do mold drawings show the venting as a separate detailed view detail?

Plastic injection mold design-side action

Are core and cavity proud of the mold base parting line 0.004 minimum? Are Lifters and slifters < 15 from vertical?

Are the slide locking angles a minimum of 2 degrees greater than angles of the pull pins?

Plastic injection mold design-cavity ID and markings

Are the cavities and spare cavities sequentially identified and have sub inserts been identified for traceability purposes?

Are cavity numbers to be located as close to the gate as possible and shown on the print?

Have all areas been identified for mold cleaning and has the access of these areas been considered in design?

Has the engraving and texturing surface finish been identified on the molding details?

Does the size/font/location and depth of engraving conform to part drawings?

CAVITY /CORE

Have the molding inserts been keyed to prevent rotation where necessary?

Is the steel of core and cavity as customers specification and suitable for molding the specified resin?

Plastic injection mold design-Mold base

Does every plate have a pry bar slot?

Do the Leader pins or bushings have grease groves?

Are the eyebolt holes size and proper location shown? Is the parting line safety strap been shown on the print?

Is mold tag location shown and recessed below the surface of the tool to ensure the tag does not get damaged or removed during mold disassembly and

assembly?

Are eyebolt holes at least 1 deep and on all four sides of the mold.

Plastic injection mold design-Hot runner system

Do the mold drawings show the wiring schematics for hot runner molds? Do the mold drawings show the electrical box location?

Is Hot runner manifold layout shown in drawing? (If Applicable) Are the insulator plates shown on top and bottom of the mold for Hot runner tool?

Are the electrical boxes must be insulated against heat transfer from mold base.

Is the thermocouple connector and power connector information must be engraved on plaque(s) and fixed nearby electrical connection.

Are corners and edges along wire grooves chamfered or radiused.

Are corners and edges along wire grooves chamfered or radiused.

Are the electrical connectors for power and thermocouple mounted on the top of the mold. Using Std. DME type Junction box of 12-zone connector or as

customers specification

Are the hot-runner and/or valve-gate system drawing(s) or manufacturers tags included in the documentation package.

Are the valve-gate systems air actuated.

Potrebbero piacerti anche

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Da EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Nessuna valutazione finora

- Mold and Die - PPTDocumento110 pagineMold and Die - PPTThaloengsak Kucharoenpaisan100% (2)

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Da EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Nessuna valutazione finora

- Mold Design ChecklistDocumento2 pagineMold Design ChecklistWerner SchrammelNessuna valutazione finora

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Da EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Valutazione: 5 su 5 stelle5/5 (2)

- Molds and DiesDocumento101 pagineMolds and DiesRavindra ReddyNessuna valutazione finora

- Advance Injection Mould DesignDocumento175 pagineAdvance Injection Mould DesignŠetkić SemirNessuna valutazione finora

- Injection Molding Troubleshooting Flash BurnmarksDocumento60 pagineInjection Molding Troubleshooting Flash Burnmarkswawawa1100% (1)

- Chapter 2 Injection MoldsDocumento83 pagineChapter 2 Injection MoldsRadia ElkhaniNessuna valutazione finora

- Injection Mold Design Engineering Complete Self-Assessment GuideDa EverandInjection Mold Design Engineering Complete Self-Assessment GuideNessuna valutazione finora

- Joining Methods: Tolerances: Fit Between PartsDocumento11 pagineJoining Methods: Tolerances: Fit Between PartsChiara RipaltiNessuna valutazione finora

- DFX design for X A Complete Guide - 2019 EditionDa EverandDFX design for X A Complete Guide - 2019 EditionNessuna valutazione finora

- Mould Design Part OneDocumento15 pagineMould Design Part Oneazizmaarof100% (3)

- Mould Tool Design 02Documento64 pagineMould Tool Design 02skumaranspNessuna valutazione finora

- Clamping Force & Tonnage CalculationDocumento3 pagineClamping Force & Tonnage CalculationJyoti KaleNessuna valutazione finora

- Feed Is The Path, Which Plastic Melt From Nozzle Traverses To Reach The Impressions Without Much Loss of andDocumento26 pagineFeed Is The Path, Which Plastic Melt From Nozzle Traverses To Reach The Impressions Without Much Loss of andS Karthick KeyanNessuna valutazione finora

- Seminar On Split Cavity MouldDocumento43 pagineSeminar On Split Cavity MouldasgrutuNessuna valutazione finora

- Injection Mould Design: Central Institute of Plastics Engineering and TechnologyDocumento64 pagineInjection Mould Design: Central Institute of Plastics Engineering and TechnologyAnirudh100% (2)

- Snap Fit DesignDocumento4 pagineSnap Fit DesignJagadish_kNessuna valutazione finora

- Mold Design FeasabilityDocumento16 pagineMold Design FeasabilitySreedhar PugalendhiNessuna valutazione finora

- Cavity Mold Cooling Construction DesignDocumento141 pagineCavity Mold Cooling Construction DesignJayson Serato50% (2)

- PS Injection Mold Tool StandardsDocumento107 paginePS Injection Mold Tool StandardsНикола МедићNessuna valutazione finora

- Design of The Injection MouldDocumento19 pagineDesign of The Injection MouldSiddhant Prakash GoyalNessuna valutazione finora

- Theory of Moulds - ContentsDocumento9 pagineTheory of Moulds - Contentsnagesh_sprao19275% (4)

- Moulding Technology: by Balraj TanwarDocumento37 pagineMoulding Technology: by Balraj TanwarVinod KumarNessuna valutazione finora

- Injection MoldingDocumento23 pagineInjection MoldingAditya DhikaNessuna valutazione finora

- Snap-Fit Joints DesignDocumento26 pagineSnap-Fit Joints DesignDavid García SalvatierraNessuna valutazione finora

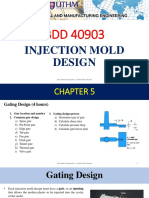

- BDD 40903 Injection Mold Design Chapter 5Documento35 pagineBDD 40903 Injection Mold Design Chapter 5Churreya Chai LomNessuna valutazione finora

- Injection Molding - Design Guidelines - Solid Concepts IncDocumento12 pagineInjection Molding - Design Guidelines - Solid Concepts InckaranNessuna valutazione finora

- Mold CalculationDocumento2 pagineMold CalculationMohammed Khatib100% (1)

- Techdesign Study: Plastic Mould Technology Duration: 30 DaysDocumento14 pagineTechdesign Study: Plastic Mould Technology Duration: 30 DaysAnkit NaphadeNessuna valutazione finora

- Blow Molding Design GuidlinesDocumento13 pagineBlow Molding Design Guidlinesmayank123Nessuna valutazione finora

- Injection Molding Part CostingDocumento4 pagineInjection Molding Part CostingfantinnoNessuna valutazione finora

- Mould Theory PDFDocumento35 pagineMould Theory PDFArunava Bala75% (4)

- Mold Design CalculationsDocumento23 pagineMold Design CalculationsARUN KUMAR Koterimadathil100% (2)

- Injection MoldingDocumento45 pagineInjection MoldingJagdeep SinghNessuna valutazione finora

- Molding CavityDocumento7 pagineMolding CavitySudarno BaraNessuna valutazione finora

- Automotive - Presentation - Plastics-3rd June-2015 (Compatibility Mode) (Repaired)Documento108 pagineAutomotive - Presentation - Plastics-3rd June-2015 (Compatibility Mode) (Repaired)Annavarapu Gopalakrishna100% (1)

- Injection Molding Methods Design Optimization Simulation of Plastic Toy Building Block by Mold Flow AnalysisDocumento10 pagineInjection Molding Methods Design Optimization Simulation of Plastic Toy Building Block by Mold Flow AnalysisIAEME PublicationNessuna valutazione finora

- How To Select Plastic Injection Moulding MachineDocumento48 pagineHow To Select Plastic Injection Moulding MachineDiego Sáchica60% (5)

- Mold Design Fundamental Calculation BATTERY COVERDocumento10 pagineMold Design Fundamental Calculation BATTERY COVERBoby SaputraNessuna valutazione finora

- Trouble Shooting in Plastic Injection MoldingDocumento24 pagineTrouble Shooting in Plastic Injection MoldingKaixin Go50% (2)

- Injection Molding MethodsDocumento23 pagineInjection Molding MethodsKi SeyNessuna valutazione finora

- Pressure Requirements: Flow LengthDocumento43 paginePressure Requirements: Flow Lengthanirudha_jewalikar1100% (2)

- Injection Molding Mold DesignDocumento26 pagineInjection Molding Mold DesignDiligence100% (1)

- Injection Molding CalculationDocumento25 pagineInjection Molding Calculationsharuzi100% (1)

- PIM 101 Ebook-1Documento33 paginePIM 101 Ebook-1agniflameNessuna valutazione finora

- MLD TheoryDocumento96 pagineMLD TheorySheik Abdullah100% (1)

- Injection Molding Defect OzDocumento12 pagineInjection Molding Defect Oztopkaya100% (1)

- Mold Design Spec SheetDocumento1 paginaMold Design Spec Sheetomerscheen0% (1)

- 4.0 Number of Cavities CalculationDocumento40 pagine4.0 Number of Cavities CalculationStelwin Fernandez80% (5)

- DFM Injection Molding Analysis 0614Documento9 pagineDFM Injection Molding Analysis 0614anjal22Nessuna valutazione finora

- INTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Documento162 pagineINTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Selvaraj BalasundramNessuna valutazione finora

- Iso 2768 1Documento7 pagineIso 2768 1Gary Ren100% (2)

- Color in Plastic Parts Part 3Documento3 pagineColor in Plastic Parts Part 3Nitin PatilNessuna valutazione finora

- Advance Injection Mould Design: Corporate Training and PlanningDocumento175 pagineAdvance Injection Mould Design: Corporate Training and PlanningAkash SinghNessuna valutazione finora

- INTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Documento162 pagineINTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Selvaraj BalasundramNessuna valutazione finora

- Iso 2768-1: 1989Documento7 pagineIso 2768-1: 1989jferreiraNessuna valutazione finora

- Tool Steel SelectionDocumento11 pagineTool Steel SelectionSelvaraj BalasundramNessuna valutazione finora

- PC MaterialsDocumento1 paginaPC MaterialsSelvaraj BalasundramNessuna valutazione finora

- Troubleshooting: Injection Molding Seven Steps Toward Scientific TroubleshootingDocumento5 pagineTroubleshooting: Injection Molding Seven Steps Toward Scientific TroubleshootingSelvaraj BalasundramNessuna valutazione finora

- How To Get Better MFI ResultsDocumento5 pagineHow To Get Better MFI ResultsSelvaraj BalasundramNessuna valutazione finora

- Measuring Internal Stress Using Polarised LightDocumento5 pagineMeasuring Internal Stress Using Polarised LightSelvaraj BalasundramNessuna valutazione finora

- How Nestle Fought Back - Business News Aug 2016Documento9 pagineHow Nestle Fought Back - Business News Aug 2016Selvaraj BalasundramNessuna valutazione finora

- High Gate - Hot RunnerDocumento2 pagineHigh Gate - Hot RunnerSelvaraj BalasundramNessuna valutazione finora

- Process Validation - IQ, OQ, PQDocumento2 pagineProcess Validation - IQ, OQ, PQSelvaraj BalasundramNessuna valutazione finora

- Eliminate These Obstacles Before You Implement Predictive Maintenance-GoodDocumento3 pagineEliminate These Obstacles Before You Implement Predictive Maintenance-GoodSelvaraj BalasundramNessuna valutazione finora

- Statistical Tolerance AnalysisDocumento2 pagineStatistical Tolerance AnalysisSelvaraj BalasundramNessuna valutazione finora

- Measuring Internal Stress Using Polarised LightDocumento5 pagineMeasuring Internal Stress Using Polarised LightSelvaraj BalasundramNessuna valutazione finora

- Dimension IngDocumento6 pagineDimension IngvasantNessuna valutazione finora

- Dimension IngDocumento6 pagineDimension IngvasantNessuna valutazione finora

- CZ - Common ZoneDocumento1 paginaCZ - Common ZoneSelvaraj BalasundramNessuna valutazione finora

- Six Steps To Condition Based Maintenance - GoodDocumento3 pagineSix Steps To Condition Based Maintenance - GoodSelvaraj BalasundramNessuna valutazione finora

- 8 Steps To Ensure PDM Success - Excellent - Not Taken Yet !!!Documento5 pagine8 Steps To Ensure PDM Success - Excellent - Not Taken Yet !!!Selvaraj BalasundramNessuna valutazione finora

- A Letter On Good and Bad Kaizen Practices - TakenDocumento5 pagineA Letter On Good and Bad Kaizen Practices - TakenSelvaraj BalasundramNessuna valutazione finora

- What Is Projected Tolerance ZoneDocumento2 pagineWhat Is Projected Tolerance ZoneSelvaraj BalasundramNessuna valutazione finora

- TPM 8 PillarsDocumento6 pagineTPM 8 PillarsSelvaraj BalasundramNessuna valutazione finora

- How To PERSUADE Your BossDocumento8 pagineHow To PERSUADE Your BossSelvaraj BalasundramNessuna valutazione finora

- Productivity A Better Way From Stratex HubDocumento17 pagineProductivity A Better Way From Stratex HubSelvaraj BalasundramNessuna valutazione finora

- 5 Steps To GDT ApplicationDocumento4 pagine5 Steps To GDT ApplicationSelvaraj BalasundramNessuna valutazione finora

- Conference Call TipsDocumento7 pagineConference Call TipsSelvaraj BalasundramNessuna valutazione finora

- Tutorials - 1st Angle Vs 3rd AngleDocumento6 pagineTutorials - 1st Angle Vs 3rd AngleSelvaraj BalasundramNessuna valutazione finora

- THE REFUND - Frigyes Karinthy: AuthorDocumento6 pagineTHE REFUND - Frigyes Karinthy: AuthorMilind JamnekarNessuna valutazione finora

- Summative 1Documento4 pagineSummative 1Nean YsabelleNessuna valutazione finora

- AIMMS Modeling Guide - Linear Programming TricksDocumento16 pagineAIMMS Modeling Guide - Linear Programming TricksgjorhugullNessuna valutazione finora

- H&M Case Study AssignmentDocumento7 pagineH&M Case Study AssignmentwqvyakNessuna valutazione finora

- Burnay, Bushman & Laroi - 2019Documento10 pagineBurnay, Bushman & Laroi - 2019TinyjurshNessuna valutazione finora

- ZTE V4 RNC Commissioning and Integration TrainingDocumento2 pagineZTE V4 RNC Commissioning and Integration TrainingBeena SinghNessuna valutazione finora

- One Wavelength To Loop SkywireDocumento2 pagineOne Wavelength To Loop SkywireRobert TurnerNessuna valutazione finora

- Chapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Documento27 pagineChapter 1 MPLS OAM Configuration Commands ...................................................................... 1-1Randy DookheranNessuna valutazione finora

- HVS Hotel Cost Estimating Guide 2021Documento124 pagineHVS Hotel Cost Estimating Guide 2021pascal rosasNessuna valutazione finora

- Researchpaper Should Removable Media Be Encrypted - PDF - ReportDocumento15 pagineResearchpaper Should Removable Media Be Encrypted - PDF - ReportSakshi Dhananjay KambleNessuna valutazione finora

- Post War TheatreDocumento11 paginePost War TheatrePaulPogba77Nessuna valutazione finora

- Stripper EZ-range US v3 Web-1Documento2 pagineStripper EZ-range US v3 Web-1irwin kurniadiNessuna valutazione finora

- Bhaktavatsalam Memorial College For Women: Hand Book 2020 - 21Documento37 pagineBhaktavatsalam Memorial College For Women: Hand Book 2020 - 21Anu RsNessuna valutazione finora

- Alignment Technique - The Steam TurbineDocumento2 pagineAlignment Technique - The Steam TurbineRajeswar KulanjiNessuna valutazione finora

- Inglês - Degrees of ComparisonDocumento4 pagineInglês - Degrees of ComparisonVersehgi IINessuna valutazione finora

- Functional Materials For Sustainable Energy TechnologiesDocumento15 pagineFunctional Materials For Sustainable Energy TechnologiesChristhy Vanessa Ruiz MadroñeroNessuna valutazione finora

- Interjections NotesDocumento2 pagineInterjections NotesKanna ImuiNessuna valutazione finora

- Response 2000 IntroductionDocumento24 pagineResponse 2000 IntroductionRory Cristian Cordero RojoNessuna valutazione finora

- Anger Management: Gaurav Sharma 138Documento21 pagineAnger Management: Gaurav Sharma 138gaurav_sharma_19900Nessuna valutazione finora

- UnitPlan (P.E) Grade 6Documento13 pagineUnitPlan (P.E) Grade 6Lou At CamellaNessuna valutazione finora

- Wakit, Nico P.Documento5 pagineWakit, Nico P.yeng botzNessuna valutazione finora

- Compressor-Less: Historical ApplicationsDocumento70 pagineCompressor-Less: Historical Applicationssuryakantshrotriya100% (1)

- P&G Interview QuestionsDocumento2 pagineP&G Interview Questionssupu100% (3)

- Olympiad Problem 2Documento3 pagineOlympiad Problem 2Đạt Nguyễn BáNessuna valutazione finora

- Passmore Et Al (2019) Workplace CoachingDocumento47 paginePassmore Et Al (2019) Workplace CoachingMalarvilie KrishnasamyNessuna valutazione finora

- Module 1 Inclusive Education Lecture 1 & Introduction - OnlineDocumento32 pagineModule 1 Inclusive Education Lecture 1 & Introduction - OnlineSharon ShenNessuna valutazione finora

- Wearable BiosensorsDocumento16 pagineWearable BiosensorsShreehari Haridasan100% (1)

- Prof Ed 9-A - Module 6 - Tumacder, DHMLDocumento6 pagineProf Ed 9-A - Module 6 - Tumacder, DHMLDanica Hannah Mae TumacderNessuna valutazione finora

- Module 14-Area ComputationsDocumento5 pagineModule 14-Area ComputationsGerovic Parinas50% (2)

- Hemo TecaDocumento17 pagineHemo TecaMafer PilcoNessuna valutazione finora

- House Rules: How to Decorate for Every Home, Style, and BudgetDa EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNessuna valutazione finora

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiDa EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiValutazione: 4 su 5 stelle4/5 (3)

- The Martha Manual: How to Do (Almost) EverythingDa EverandThe Martha Manual: How to Do (Almost) EverythingValutazione: 4 su 5 stelle4/5 (11)

- Crochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeDa EverandCrochet with London Kaye: Projects and Ideas to Yarn Bomb Your LifeValutazione: 5 su 5 stelle5/5 (1)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiDa Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiValutazione: 5 su 5 stelle5/5 (2)

- The Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsDa EverandThe Botanical Hand Lettering Workbook: Draw Whimsical & Decorative Styles & ScriptsValutazione: 4.5 su 5 stelle4.5/5 (2)

- Crochet Impkins: Over a million possible combinations! Yes, really!Da EverandCrochet Impkins: Over a million possible combinations! Yes, really!Valutazione: 4.5 su 5 stelle4.5/5 (10)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesDa EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNessuna valutazione finora

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastDa EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastValutazione: 5 su 5 stelle5/5 (1)

- Timeless Textured Baby Crochet: 20 heirloom crochet patterns for babies and toddlersDa EverandTimeless Textured Baby Crochet: 20 heirloom crochet patterns for babies and toddlersNessuna valutazione finora

- Crochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysDa EverandCrochet Donut Buddies: 50 easy amigurumi patterns for collectible crochet toysValutazione: 4.5 su 5 stelle4.5/5 (7)

- Dream Sewing Spaces: Design & Organization for Spaces Large & SmallDa EverandDream Sewing Spaces: Design & Organization for Spaces Large & SmallValutazione: 4 su 5 stelle4/5 (24)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsDa EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsValutazione: 4.5 su 5 stelle4.5/5 (10)

- Crochet Collage Garden: 100 patterns for crochet flowers, plants and petalsDa EverandCrochet Collage Garden: 100 patterns for crochet flowers, plants and petalsValutazione: 5 su 5 stelle5/5 (1)

- Celtic Line Drawing - Simplified InstructionsDa EverandCeltic Line Drawing - Simplified InstructionsValutazione: 5 su 5 stelle5/5 (4)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Da EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Nessuna valutazione finora

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreDa EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreValutazione: 5 su 5 stelle5/5 (5)

- Crochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestDa EverandCrochet Southwest Spirit: Over 20 Bohemian Crochet Patterns Inspired by the American SouthwestValutazione: 5 su 5 stelle5/5 (2)

- Friends: The One with the Crochet: The Official Crochet Pattern BookDa EverandFriends: The One with the Crochet: The Official Crochet Pattern BookValutazione: 5 su 5 stelle5/5 (1)

- Tunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!Da EverandTunisian Crochet for Beginners: Step-by-step Instructions, plus 5 Patterns!Valutazione: 5 su 5 stelle5/5 (3)

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionDa EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionValutazione: 4.5 su 5 stelle4.5/5 (23)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchDa EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchValutazione: 5 su 5 stelle5/5 (1)

- Two Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Da EverandTwo Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Valutazione: 3 su 5 stelle3/5 (2)

- Big Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreDa EverandBig Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreValutazione: 4.5 su 5 stelle4.5/5 (3)

- Creative Watercolor: A Step-by-Step Guide for BeginnersDa EverandCreative Watercolor: A Step-by-Step Guide for BeginnersValutazione: 4 su 5 stelle4/5 (8)

- Knit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyDa EverandKnit Soxx for Everyone: 25 Colorful Sock Patterns for the Whole FamilyValutazione: 4.5 su 5 stelle4.5/5 (2)

- Crochet Lace: Techniques, Patterns, and ProjectsDa EverandCrochet Lace: Techniques, Patterns, and ProjectsValutazione: 3.5 su 5 stelle3.5/5 (3)