Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Dresser Rand 2134 RLHA

Caricato da

ashumishra007Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Dresser Rand 2134 RLHA

Caricato da

ashumishra007Copyright:

Formati disponibili

RLHA

Single-Stage Steam Turbine

The API 611 compliant RLHA is a sturdy, versatile mechanical drive steam turbine for

applications up to 2,500 HP (1,865kW). Its routinely specified by refineries, petro-

chemical plants, sugar mills, food processing and other industries using steam for pro-

cess to drive lube oil pumps, feed water pumps, process pumps, fans, compressors,

and generators.

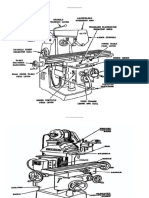

Axial Split Casing

The axial split construction of the RLHA steam turbine allows the upper half of the

casing to be removed for easy access to internal components for inspection and main-

tenance. The bearings can be inspected and replaced independent of each other and

without removing the casing cover.

Overspeed Trip System

The overspeed trip actuating mechanism is a bolt-type, spring-restrained weight, posi-

tioned on the turbine shaft. At a pre-selected speed the bolt is released to unlatch the

overspeed trip valve and completely stop the turbine.

The overspeed trip valve is a force-actuated, single-seated, piloted positive shutoff

independent of the governor valve. Its designed to minimize pressure drop in the open

position and to instantly shut off steam when tripped by the overspeed trip mechanism,

optional electronic trip actuators or manually. The valve can be manually reset against

full-line pressure.

Governing Systems

The Woodward TG series constant speed oil relay governor is standard equipment for

RLHA steam turbines. Alternate governing systems are supplied when required for

some operating conditions or when specified by the client.

Rotors, Bearings, Sealing Glands

RLHA 24

Single-disc, two-row Curtis impulse-type wheels, shouldered, keyed

and shrunk to a large diameter 4140HT steel shaft, prevent

wheel movement relative to the shaft throughout the

turbine speed range. Turbine wheels are located

Forged single dics wheel shrunk between the bearings; balancing and vibration

Removable 50,000 hour L-10 life

and keyed to shaft

split carbon ring thrust bearing testing are in compliance with the dynamics sec-

gland housings

Woodward TG governor

Axial split casting tion of API 611.

Snap-acting bolt

Liner type split Hard chrome type trip

Flinger type,

non-sparking

sleeve bearings plated shaft

Permanently

lubricated rod

Radial bearings and housings are split at

seals end ball joints the horizontal centerline for easy access

and replacement. Snap-in, liner-type

Removable

stainless sleeve bearings are steel backed, tin

Oil ring steel steam

lubrication strainer based babbitt for long life. Both oil ring and

Force actuated trip valve pressure lubrication are available.

Cooling

water

jackets

Anti-friction journal bearings also are avail-

able for quick-start applications or where

Low

oil mist lubrication systems are specified.

friction

carbon

Stainless Cage sleeve

steel guided

True center line support nozzels throttle valve

For more information on RLHA single- Split carbon ring steam sealing glands are

stage steam turbines, contact our readily accessible and easy to remove with-

Worcester, MA Technology Center at: out disturbing other parts of the turbine.

Dresser-Rand

299 Lincoln Street Standard Features

Worcester, MA 01605

Tel: 1-888-268-8726 Meets or exceeds API 611 requirements

Fax: 508-595-1788 Direct drive, oil relay (Woodward TG

Series) or NEMA Class A constant

For a complete list of D-R products speed governor

and services, visit us at Overspeed mechanical trip and shut off

www.dresser-rand.com or contact us system

at the following locations:

Manual speed changer

Dresser-Rand Curtis type wheel

Corporate Headquarters Carbon ring sealing glands

Built-in removable steam strainer

West8 Tower Suite 1000

10205 Westheimer Road

Centerline support with vertical jacking

Houston, TX 77042 USA screws

Tel: (Intl +1) 713-354-6100 Lagging-blanket insulation (API applications)

Fax: (Intl +1) 713-354-6110

email: info@dresser-rand.com

Optional Features

112, Avenue Kleber

75784 Paris Cedex 16 NEMA Class D and variable speed governors

Tel: (Intl +33) 156 26 71 71 Solenoid trips for remote shutdown

Fax: (Intl +33) 156 26 71 72 High backpressure trip

email: info@dresser-rand.com

Forged steel wheels

Regional Headquarters Manual nozzle hand valves

Special and double shaft extensions

The Americas Copper-free construction for corrosive atmosphere

Dresser-Rand

West8 Tower Suite 1000 Pneumatic valve actuation

10205 Westheimer Road High inlet and back pressure construction

Houston, TX 77042 USA Labyrinth, carbon/labyrinth, mechanical and six carbon ring steam seal designs

Tel: (Intl +1) 713-354-6100

Fax: (Intl +1) 713-354-6110

EMEA Maximum Capabilities

(Europe, Middle East, Eurasia, Africa)

Dresser-Rand S.A. Model Power Inlet Pressure Inlet Temp Exhaust RPM Inlet Dia. Exhaust Dia.

31 Boulevard Winston Churchill HP (kW) PSIG1 (BARG) F (C) PSIG2 (BARG) In (mm) In (mm)

Cedex 7013 RLHA-15 450 (335) 600 (41) 750 (400) 105 (7) 6000 3 (75) 6 (150)

Le Havre 76080 France

Tel: (Intl +33) 2-35-25-5225 RLHA-24 2500 (1865) 900 (62) 950 (510) 300 (20) 6300 6 (150) 10 (250)

Fax: (Intl +33) 2-35-25-5366 / 5367

Asia-Pacific

Dresser-Rand Asia Pacific Sdn Bhd

Unit 8-1, 8th Floor Note: Steam inlet locations

Bangunan Malaysian Re

are fixed as illustrated.

17 Lorong Dungun

Damansara Heights Steam exhaust locations

50490 Kuala Lumpur, Malaysia available as right or left

Tel: (Intl +60) 3-2093-6633 hand orientation.

Fax: (Intl +60) 3-2093-2622

2007 Dresser-Rand.

This document comprises a general overview Dimensions - in (mm)

of the products described herein. It is solely

for informational purposes, does not represent RLHA15 RLHA24

a warranty or guarantee of the information A 46 (1166) 57 (1454)

contained herein and is not to be construed as

an offer to sell or a solicitation to buy. Contact B 5 (136) 5 (136)

Dresser-Rand for detailed design and engineer- C 13 (324) 22 (552)

ing information suitable to your specific applica-

tions. Dresser-Rand reserves the right to modify D 35.5 (902) 44 (1110)

its products and related product information at E 22 (562) 42 (1075)

any time without prior notice.

Form 2134

Potrebbero piacerti anche

- Elliott YR Turbines: Flexibility and Reliability for Decades of ServiceDocumento8 pagineElliott YR Turbines: Flexibility and Reliability for Decades of ServiceOscar Barajas BNessuna valutazione finora

- Keep Pumps Running with Condition MonitoringDocumento14 pagineKeep Pumps Running with Condition MonitoringABRAHAM ESTRADANessuna valutazione finora

- How to dismantle and inspect a recirculating ball steering gear boxDocumento4 pagineHow to dismantle and inspect a recirculating ball steering gear boxsaffrin100% (1)

- 825 Series Product Overview & General DataDocumento30 pagine825 Series Product Overview & General Datamauricio cañonNessuna valutazione finora

- 120 Ton Power Swivels PISDocumento17 pagine120 Ton Power Swivels PISgheorgheNessuna valutazione finora

- TC Product SpecificationDocumento8 pagineTC Product SpecificationNitin AmbarNessuna valutazione finora

- Goulds LF 3171: Low Flow, High Head Vertical Sump PumpDocumento4 pagineGoulds LF 3171: Low Flow, High Head Vertical Sump PumpPaul CastroNessuna valutazione finora

- Testing and Commissioning of Water Booster Pump Set Method Statement PDFDocumento3 pagineTesting and Commissioning of Water Booster Pump Set Method Statement PDFHumaid Shaikh100% (1)

- I Reliable/Durable Built I Ease I - I Convenience T - : OperatingDocumento14 pagineI Reliable/Durable Built I Ease I - I Convenience T - : Operatingrene hernandezNessuna valutazione finora

- I A G T C: Ndustrial Pplication OF AS Urbines OmmitteeDocumento13 pagineI A G T C: Ndustrial Pplication OF AS Urbines Ommittee'Izzad AfifNessuna valutazione finora

- APA DOC No. 2014 PDFDocumento67 pagineAPA DOC No. 2014 PDFThanapaet RittirutNessuna valutazione finora

- Part List GA55+90 MKVDocumento68 paginePart List GA55+90 MKVRamraj EnterprisesNessuna valutazione finora

- Product Manual 82566 (Revision N) : EG-6P, EG-6PC, EG-10P, EG-10PC ActuatorDocumento42 pagineProduct Manual 82566 (Revision N) : EG-6P, EG-6PC, EG-10P, EG-10PC ActuatorManuel Alejandro Pontio Ramirez100% (2)

- DD 24 DD 22Documento2 pagineDD 24 DD 22evega97Nessuna valutazione finora

- Report on blade failure of LP last stages in a 210 MW steam turbineDocumento5 pagineReport on blade failure of LP last stages in a 210 MW steam turbinemanojpuru100% (1)

- Ge Industrial Aeroderivative Gas TurbinesDocumento2 pagineGe Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZ0% (1)

- Pivot Arm Turning GearDocumento24 paginePivot Arm Turning Gearoom_tgw100% (1)

- Steam Turbines - TurbotechDocumento29 pagineSteam Turbines - TurbotechArjun PatelNessuna valutazione finora

- Coppus Product GuideDocumento6 pagineCoppus Product GuideSayed KassarNessuna valutazione finora

- Variable Speed Fluid Couplings - Brochure 2014 (Voith)Documento20 pagineVariable Speed Fluid Couplings - Brochure 2014 (Voith)RudanekNessuna valutazione finora

- Hot Gas Path Inspection 1Documento27 pagineHot Gas Path Inspection 1khacsau2904Nessuna valutazione finora

- Se Brochure Dresser Rand Steam Turbines 2021Documento24 pagineSe Brochure Dresser Rand Steam Turbines 2021Irfan FatahilahNessuna valutazione finora

- Shroud Blocks For GE Gas TurbinesDocumento2 pagineShroud Blocks For GE Gas Turbineshernang100% (2)

- Maintenance Elliott TurbinesDocumento8 pagineMaintenance Elliott TurbinesVILLANUEVA_DANIEL2064Nessuna valutazione finora

- Rla / Rlva: Single-Stage Steam TurbineDocumento2 pagineRla / Rlva: Single-Stage Steam TurbineMauricio GuanellaNessuna valutazione finora

- Factsheet Industrial Trent 60 Us LowresDocumento2 pagineFactsheet Industrial Trent 60 Us LowresAsri GaniNessuna valutazione finora

- 2.4 MBM Combustor Dilution Air SystemDocumento6 pagine2.4 MBM Combustor Dilution Air SystemmiladNessuna valutazione finora

- VBR Strategic Spare Parts Planning-2Documento18 pagineVBR Strategic Spare Parts Planning-2jampukNessuna valutazione finora

- Woodward EG-3P, Proportional ActuatorDocumento4 pagineWoodward EG-3P, Proportional ActuatorMohd Ridzuan AhmadNessuna valutazione finora

- Bombas Reciprocantes PDFDocumento43 pagineBombas Reciprocantes PDFSamuel Arias CamachoNessuna valutazione finora

- Solar Turbines - Centifugal Gas Compressor BookletDocumento48 pagineSolar Turbines - Centifugal Gas Compressor Bookletsetyo ardiNessuna valutazione finora

- SST-140 Corporate BrochureDocumento8 pagineSST-140 Corporate Brochureandri.plneNessuna valutazione finora

- Preventive Maintenance 3300AP K609758Documento99 paginePreventive Maintenance 3300AP K609758Francisco Javier Burgos100% (2)

- Tools Turbine PDFDocumento117 pagineTools Turbine PDFamjadNessuna valutazione finora

- Renk Single Marine Gears UnitsDocumento2 pagineRenk Single Marine Gears Unitsharith faiz100% (1)

- 2013 Brochure Modernizations Upgrades Steam Turbines enDocumento16 pagine2013 Brochure Modernizations Upgrades Steam Turbines enrodruren01Nessuna valutazione finora

- OM0401 Overview of Turbine Version GDocumento41 pagineOM0401 Overview of Turbine Version Gمحمد خالدNessuna valutazione finora

- Steam Turbine FFCDocumento31 pagineSteam Turbine FFCTaha KhanNessuna valutazione finora

- 4g Alarms TroubleshootingDocumento22 pagine4g Alarms TroubleshootingNirdosh Chhasatiya78% (9)

- Couplings and Mechanical Soft Starts: CatalogDocumento52 pagineCouplings and Mechanical Soft Starts: Catalogashumishra007Nessuna valutazione finora

- Pre-Designed Steam Turbines enDocumento8 paginePre-Designed Steam Turbines enBoos Kanhaiya LalNessuna valutazione finora

- Single-Stage Steam TurbinesDocumento8 pagineSingle-Stage Steam Turbinesfouzi gherNessuna valutazione finora

- ES9-414 Leveling Install - CDocumento29 pagineES9-414 Leveling Install - CIfran Sierra100% (1)

- Sistema de Lubricacion de Turbina SGT 800Documento10 pagineSistema de Lubricacion de Turbina SGT 800ginoNessuna valutazione finora

- Scope of Work FR 9Documento3 pagineScope of Work FR 9Dharmesh Kumar KewatNessuna valutazione finora

- Waukesha Knock Index Power CurveDocumento1 paginaWaukesha Knock Index Power CurveparathasiNessuna valutazione finora

- Elliott Brush Ring Seals: Installation KitDocumento2 pagineElliott Brush Ring Seals: Installation Kitfouzi gher100% (1)

- GTG Information Sharing: Components, Systems & MaintenanceDocumento30 pagineGTG Information Sharing: Components, Systems & Maintenanceaden mng100% (1)

- Baa1 PDFDocumento149 pagineBaa1 PDFfebyNessuna valutazione finora

- Turning GearDocumento5 pagineTurning GearkshalawiNessuna valutazione finora

- GEK106881-MS6001 Starting System Detroit Diesel EngineDocumento8 pagineGEK106881-MS6001 Starting System Detroit Diesel EnginekuldeepNessuna valutazione finora

- Terry TurbineDocumento8 pagineTerry TurbinealexmontellNessuna valutazione finora

- Gea32081a LM6000 - Pa - Us - R1 - LRDocumento1 paginaGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNessuna valutazione finora

- Steam turbine operational guidelinesDocumento25 pagineSteam turbine operational guidelinesThanh SonNessuna valutazione finora

- Section08 A4 PDFDocumento808 pagineSection08 A4 PDFjakkyjeryNessuna valutazione finora

- Service Bulletin: Subject: Ingestive Cleaning of Solar Gas Turbine EnginesDocumento6 pagineService Bulletin: Subject: Ingestive Cleaning of Solar Gas Turbine EnginesIfran SierraNessuna valutazione finora

- Axial Thrust Dummy PistonDocumento12 pagineAxial Thrust Dummy Pistondeevan rajNessuna valutazione finora

- Operating and maintenance norms for hydraulic cylindersDocumento4 pagineOperating and maintenance norms for hydraulic cylinderszsmithNessuna valutazione finora

- Bleed ValveDocumento8 pagineBleed Valvejanju81Nessuna valutazione finora

- NIC 13.20 Rev.01Documento15 pagineNIC 13.20 Rev.01Mahmoud Ahmed100% (1)

- 4-Hour Lockout Avoidance For LM2500 and LM6000 Gas Turbines: Conversion, Modification and Upgrade OfferingDocumento1 pagina4-Hour Lockout Avoidance For LM2500 and LM6000 Gas Turbines: Conversion, Modification and Upgrade OfferingabedurahmanNessuna valutazione finora

- 12 SiemensDocumento37 pagine12 SiemensrodrigocampospkNessuna valutazione finora

- Compressor piston rings and rider rings guideDocumento22 pagineCompressor piston rings and rider rings guidemauricioNessuna valutazione finora

- 03 Product OverviewDocumento44 pagine03 Product OverviewMamdouh ElhanafyNessuna valutazione finora

- Imtt Bayonne Cogen Inventory 08012018 by TopsDocumento32 pagineImtt Bayonne Cogen Inventory 08012018 by TopsThanapaet RittirutNessuna valutazione finora

- 140g 1990 (c1b)Documento16 pagine140g 1990 (c1b)Roberto GuillenNessuna valutazione finora

- Valtek Mark One Control Valves Valtek Mark One Control ValvesDocumento21 pagineValtek Mark One Control Valves Valtek Mark One Control ValvesMgc ElektronikNessuna valutazione finora

- Cat-Tormax-Es40 in 01Documento8 pagineCat-Tormax-Es40 in 01Patricio ValenciaNessuna valutazione finora

- Brochure UCL ENG 2018Documento12 pagineBrochure UCL ENG 2018ashumishra007Nessuna valutazione finora

- Example Interaction Matrix For Identifying Process HazardsDocumento1 paginaExample Interaction Matrix For Identifying Process Hazardsashumishra007Nessuna valutazione finora

- Storage of Raw Materials Category Checklist ItemsDocumento6 pagineStorage of Raw Materials Category Checklist Itemsashumishra007Nessuna valutazione finora

- Useful TerminologiesDocumento1 paginaUseful Terminologiesashumishra007Nessuna valutazione finora

- Examples of Process HazardsDocumento1 paginaExamples of Process Hazardsashumishra007Nessuna valutazione finora

- Anatomy of An AccidentDocumento1 paginaAnatomy of An Accidentashumishra007Nessuna valutazione finora

- Examples of Human Factors in Chemical Process OperationsDocumento1 paginaExamples of Human Factors in Chemical Process Operationsashumishra007Nessuna valutazione finora

- Vitaprime - : Self-Priming Centrifugal Pump For Sterile ApplicationsDocumento2 pagineVitaprime - : Self-Priming Centrifugal Pump For Sterile Applicationsashumishra007Nessuna valutazione finora

- Teesing Type of ThreadDocumento13 pagineTeesing Type of ThreadVic Blázquez100% (1)

- Price List: Item Net Price Euro Water Booster Systems LineDocumento11 paginePrice List: Item Net Price Euro Water Booster Systems Lineashumishra007Nessuna valutazione finora

- Chemical Process Hazards Analysis: Useful AcronymsDocumento1 paginaChemical Process Hazards Analysis: Useful Acronymsashumishra007Nessuna valutazione finora

- OSHA Standards On Machine GuardingDocumento1 paginaOSHA Standards On Machine GuardingpatrickNessuna valutazione finora

- Teesing Type of ThreadDocumento13 pagineTeesing Type of ThreadVic Blázquez100% (1)

- P&E March2021Documento56 pagineP&E March2021bmacavanzaNessuna valutazione finora

- PumpLecture6 PDFDocumento14 paginePumpLecture6 PDFFaisca_RNessuna valutazione finora

- DFT Check Valve Catalog 52pg V42018 1Documento52 pagineDFT Check Valve Catalog 52pg V42018 1carlosNessuna valutazione finora

- ME406 Diesel Engine Fundamentals PDFDocumento51 pagineME406 Diesel Engine Fundamentals PDFNwabulue NzubeNessuna valutazione finora

- WHITE PAPER SLICING BETTER THAN CHOPPINGDocumento2 pagineWHITE PAPER SLICING BETTER THAN CHOPPINGashumishra007Nessuna valutazione finora

- Engineeringpractice July2020 CompressedDocumento41 pagineEngineeringpractice July2020 CompressedPatricia.PNessuna valutazione finora

- Valve Magazine, Summer 2020Documento40 pagineValve Magazine, Summer 2020GordinhorsNessuna valutazione finora

- VFD Maintenance Tips: Restarting Your Electrical Equipment After A Long ShutdownDocumento3 pagineVFD Maintenance Tips: Restarting Your Electrical Equipment After A Long Shutdownashumishra007Nessuna valutazione finora

- What Are The Performance Advantages of Seal-Less Pumps?Documento13 pagineWhat Are The Performance Advantages of Seal-Less Pumps?ashumishra007Nessuna valutazione finora

- Magnetic Flow MeterDocumento2 pagineMagnetic Flow Meterashumishra007Nessuna valutazione finora

- IEC PublishesDocumento3 pagineIEC Publishesashumishra007Nessuna valutazione finora

- Hydrogen Detection in Oil RefineriesDocumento8 pagineHydrogen Detection in Oil Refineriesashumishra007Nessuna valutazione finora

- New Cloud-Based, Remote Performance Monitoring and Alert System For AODD PumpsDocumento3 pagineNew Cloud-Based, Remote Performance Monitoring and Alert System For AODD Pumpsashumishra007Nessuna valutazione finora

- Yokogawa DX Ebook 20200904Documento60 pagineYokogawa DX Ebook 20200904ashumishra007Nessuna valutazione finora

- Understanding Suction Cavitation & Avoiding Ugly Pump Rental Repair BillsDocumento4 pagineUnderstanding Suction Cavitation & Avoiding Ugly Pump Rental Repair Billsashumishra007Nessuna valutazione finora

- Operator'S Manual Backhoe: ModelDocumento46 pagineOperator'S Manual Backhoe: ModelGayitri KanabiranNessuna valutazione finora

- Bi Cmos TechnologyDocumento26 pagineBi Cmos Technologyjeevan432Nessuna valutazione finora

- Metal DetectorDocumento23 pagineMetal Detectorelectrical engineeringNessuna valutazione finora

- Service Manual: Split Type Room Air Conditioner Ae-X9Ghr AE-X12GHR Ay-Xp9Ghr Ay-Xp12GhrDocumento11 pagineService Manual: Split Type Room Air Conditioner Ae-X9Ghr AE-X12GHR Ay-Xp9Ghr Ay-Xp12GhrMuhamad PriyatnaNessuna valutazione finora

- Co2 Dragster SpecsDocumento3 pagineCo2 Dragster Specsapi-233611534Nessuna valutazione finora

- Yt 1000R 20081Documento2 pagineYt 1000R 20081Ion CimirinschiNessuna valutazione finora

- CAR 66 Module 5.6 Basic Computer StructureDocumento34 pagineCAR 66 Module 5.6 Basic Computer StructurepontooNessuna valutazione finora

- McCloskey J40v2 Track Crusher SpecsDocumento5 pagineMcCloskey J40v2 Track Crusher Specsмаргарита100% (1)

- PCB Design: Dr. Daryl Beetner Missouri S&T Electromagnetic Compatibility Laboratory P y yDocumento51 paginePCB Design: Dr. Daryl Beetner Missouri S&T Electromagnetic Compatibility Laboratory P y ySafwen SelmiNessuna valutazione finora

- Brochure Hunter Douglas HD60D MotorDocumento14 pagineBrochure Hunter Douglas HD60D MotorNhi Võ Trần YếnNessuna valutazione finora

- Polo Brochure April 2020 PDFDocumento19 paginePolo Brochure April 2020 PDFAneesh ChackoNessuna valutazione finora

- Data Sheet Prolec - 1500 Kva - 22860V - 480-240VDocumento2 pagineData Sheet Prolec - 1500 Kva - 22860V - 480-240VAlfrhNessuna valutazione finora

- Valve Catalogue General Imsubs Pvt. Ltd.Documento20 pagineValve Catalogue General Imsubs Pvt. Ltd.Spark MeditechNessuna valutazione finora

- Astrol AA 21002 003 Water Cooled DC Breaker DatasheetDocumento6 pagineAstrol AA 21002 003 Water Cooled DC Breaker Datasheetrzg712Nessuna valutazione finora

- Surge Arrester - Wikipedia, The Free EncyclopediaDocumento2 pagineSurge Arrester - Wikipedia, The Free EncyclopediaMuhammad Nico PermanaNessuna valutazione finora

- Catalogo XMDocumento42 pagineCatalogo XMAlejandro Saco HerreraNessuna valutazione finora

- STS 114 MCSA Report-J200628Documento26 pagineSTS 114 MCSA Report-J200628Haitham YoussefNessuna valutazione finora

- D1780 - EN - 02 (Signets) GL314F3 - AlstomDocumento224 pagineD1780 - EN - 02 (Signets) GL314F3 - Alstomtuantz206Nessuna valutazione finora

- #Milling Presentation 2011Documento47 pagine#Milling Presentation 2011HABTAMU FEKADUNessuna valutazione finora

- ECEN 454: Digital Integrated Circuit DesignDocumento36 pagineECEN 454: Digital Integrated Circuit DesignJoe KingNessuna valutazione finora

- Aw033 Gpe Motor StarterDocumento4 pagineAw033 Gpe Motor Startermzaid1979Nessuna valutazione finora

- ST 92195Documento22 pagineST 92195tashi869Nessuna valutazione finora

- Driving Controls Guide for FamiliarisationDocumento175 pagineDriving Controls Guide for FamiliarisationpetarstarNessuna valutazione finora

- Inspection and Preventive Maintenance Procedures-78-81Documento4 pagineInspection and Preventive Maintenance Procedures-78-81Christian Alexander100% (1)