Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Undisturbed Soil Block

Caricato da

Dastaggir KarimiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Undisturbed Soil Block

Caricato da

Dastaggir KarimiCopyright:

Formati disponibili

Designation: D 7015 04

Standard Practices for

Obtaining Undisturbed Block (Cubical and Cylindrical)

Samples of Soils1

This standard is issued under the fixed designation D 7015; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope intended to represent or replace the standard of care by which

1.1 This designation outlines the procedures for obtaining the adequacy of a given professional service must be judged,

undisturbed block (cubical and cylindrical) soil samples. nor should this document be applied without consideration of

1.2 Undisturbed block samples are obtained for laboratory a projects many unique aspects. The word 9Standard9 in the

tests to determine the strength, consolidation, permeability, and title of this document means only that the document has been

other geotechnical engineering or physical properties of the approved through the ASTM consensus process.

undisturbed soil. 1.8 This standard does not purport to address all of the

1.3 Two sampling practices are presented. Practice A covers safety concerns, if any, associated with its use. It is the

cubical block sampling, while Practice B covers cylindrical responsibility of the user of this standard to establish appro-

block sampling. priate safety and health practices and determine the applica-

1.4 These practices usually involve test pit excavation and bility of regulatory requirements prior to use. For specific

are limited to relatively shallow depths. Except in the case of hazard statements, see Section 6.

large diameter (that is, >0.75 m) bored shafts of circular 2. Referenced Documents

cross-section in unsaturated soils, for depths greater than about

1 to 112 meters or depths below the water table, the cost and 2.1 ASTM Standards: 2

difficulties of excavating, cribbing, and dewatering generally D 653 Terminology Relating to Soil, Rock, and Contained

make block sampling impractical and uneconomical. For these Fluids

conditions, use of a thin-walled push tube soil sampler (Prac- D 1587 Practice for Thin-Walled Tube Sampling of Soils

tice D 1587), a piston-type soil sampler (Practice D 6519), or for Geotechnical Purposes

Hollow-Stem Auger (D 6151), Dennison, or Pitcher-type soil D 1785 Specification for Poly (Vinyl Chloride) (PVC) Plas-

core samplers, or freezing the soil and coring may be required. tic Pipe, Schedules 40, 80, and 120

This practice does not address environmental sampling; consult D 2488 Practice for Determining Unified Soil Classification

Guides D 6169 and D 6232 for information on sampling for (Visual Method)

environmental investigations. D 2937 Test Method for Density of Soils in Place by the

1.5 Successful sampling of granular materials requires suf- Drive-Cylinder Method

ficient cohesion, cementation, or apparent cohesion (due to D 3740 Practice for Minimum Requirements for Agencies

moisture tension (suction)) of the soil for it to be isolated in a Engaged in the Testing and/or Inspection of Soil and Rock

column shape without undergoing excessive deformations. as Used in Engineering Design and Construction

Additionally, care must be exercised in the excavation, pres- D 4220 Practices for Preserving and Transporting Soil

ervation and transportation of undisturbed samples (see Prac- Samples

tice D 4220, Group D). D 5434 Guide for Field Logging of Subsurface Explora-

1.6 The values stated in SI units are to be regarded as the tions of Soil and Rock

standard. No other units are included in this standard. D 6151 Practice for Using Hollow-Stem Augers for Geo-

--``,```,`,`,`,,,````,`,``,,,,,-`-`,,`,,`,`,,`---

1.7 This practice offers a set of instructions for performing technical Exploration and Soil Sampling

one or more specific operations. This document cannot replace D 6169 Guide for Selection of Soil and Rock Sampling

education or experience and should be used in conjunction Devices Used With Drill Rigs for Environmental Investi-

with professional judgment. Not all aspects of this practice may gations

be applicable in all circumstances. This ASTM standard is not D 6232 Guide for Selection of Sampling Equipment for

1 2

These practices are under the jurisdiction of ASTM Committee D18 on Soil and For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Rock and is the direct responsibility of Subcommittee D18.02 on Sampling and contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Related Field Testing for Soil Investigations. Standards volume information, refer to the standards Document Summary page on

Current edition approved Feb. 1, 2004. Published February 2004. the ASTM website.

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Provided by IHS under license with ASTM Licensee=Army Hdqrtrs/7838506107

No reproduction or networking permitted without license from IHS Not for Resale, 04/16/2007 08:06:44 MDT

D 7015 04

Waste and Contaminated Media Data Collection Activities cutting process (see 7.1.8) or transportation or both. Steel

D 6519 Practice for Sampling of Soil Using the Hydrauli- boxes should have some form of protective coating as outlined

cally Operated Stationary Piston Sampler in 5.3, unless the soil is to be extruded in less than 3 days. The

box should be fastened using screws, or bolts and nuts

3. Terminology preferable before going to the field to verify that the parts fit

3.1 DefinitionsFor definition of terms in this standard together and can be assembled without vibration of the sample.

refer to Terminology D 653. Do not use nails or other devices that require hammering to

assemble or dissemble the box.

4. Significance and Use 5.3 For cylindrical block sampling, cylindrical tubes made

4.1 Undisturbed block samples are suitable for laboratory of steel or any relatively rigid material may be used to contain

tests where large-sized samples of undisturbed material are the cylindrical block sample during the required cutting pro-

required or where such sampling is more practical than cess (see 7.2.5) or transportation or both. Steel tubes should

conventional tube sampling (Practices D 1587 and D 6519), or have some form of protective coating, unless the soil is to be

both. extruded in less than 3 days. The type of coating to be used

4.2 This method of sampling is advantageous where the soil may vary depending upon the material to be sampled. Plating

to be sampled is near the ground surface. This is the best of the tubes or alternate base metals may be specified.

available method for obtaining large undisturbed samples of Galvanized tubes are often used when long-term storage is

very stiff and brittle soils, partially cemented soils, and some required. Tubes may be protected with a light coating of

soils containing coarse gravel. lubricating oil, lacquer, epoxy, TFR fluorocarbon, or zinc

4.3 Excavating a column of soil may relieve stresses in the oxide. One end of the tube should have a sharpened cutting

soil and may result in some expansion of the soil and a edge to assist in cutting the soil. Cylindrical tubes made of

corresponding decrease in its unit weight (density) or increase PVC pipe should have a minimum sidewall thickness of no less

in sampling disturbance, or both. Usually the expansion is than that of a Schedule 80 pipe (Specification D 1785).

small in magnitude because of the shallow depth. Stress NOTE 2Experience with thin-wall push tube sampling of soils (Prac-

changes alone can cause enough disturbances in some soils to tice D 1587) indicates disturbance is minimized when the cutting edge is

significantly alter their engineering properties. about 10 degrees or less. This sharp angle is possible with metal tubes, but

4.4 The chain saw has proved advantageous in sampling may not be with other materials such as PVC, and a sharp angle may not

difficult soils, which are blocky, slickensided, or gravelly, or be critical to hand trimmed samples.

materials containing alternating layers of hard and soft mate- 5.4 Cheesecloth or similar cloth wrapping material.

rial.3 The chain saw uses a special carbide-tipped chain.4 5.5 Sealing wax, paintbrush, and melting stove or heater.

NOTE 1The quality of the result produced by this standard is

Use a sealing wax that does not shrink appreciably, does not

dependent on the competence of the personnel performing it, and the permit evaporation from the sample, and does not exhibit

suitability of the equipment and facilities used. Agencies that meet the brittle characteristics. Microcrystalline waxes are preferable to

criteria of Practice D 3740 are generally considered capable of competent paraffin.

and objective sampling. Users of this practice are cautioned that compli- 5.6 Shipping containers, packing materials, labels, data

ance with Practice D 3740 does not in itself assure reliable results. forms, and other necessary supplies. Packing material may be

Reliable results depend on many factors; Practice D 3740 provides a

light, resilient polystyrene plastic, sawdust, or smaller material.

means of evaluating some of those factors.

5.7 Fuel for the wax melting stove or heater, and fuel and

5. Apparatus lubricating oil for the chain saw.

5.1 Excavating and trimming tools are required. This may 5.8 Personal protective equipment (PPE) should be consid-

include such items as backhoe, pick, shovel, chain saw, trowel, ered when necessary. If a chain saw is used, eye and hearing

large and small knives, hacksaw blades, thin wire such as piano protection are necessary. A hard hat may also be appropriate. A

wire. In addition, a sample container having sufficient strength first aid kit should be available and a fire extinguisher should

and rigidity to avoid deformations that could damage the also be handy especially where a stove or heater is being used.

sample. 6. Hazards

5.1.1 The chain for the chain saw is of standard design

except that carbide tips are brazed to the cutting teeth. The 6.1 Warning StatementTrenching and excavation work

chain saws bar length should be greater than 457 mm. presents serious risks, such as slope instability, ventilation,

5.2 For cubical block sampling, a cubical wooden, steel box hearing etc. to all workers involved. All excavations must be

or any relatively rigid material that can be assembled into a box constructed in accordance with applicable OSHA require-

10 mm to 15 mm larger than the sample side dimensions may ments.5

be used to contain the cubical block sample during the required 7. Procedure

7.1 Practice ACubical Block Sampling:

3

7.1.1 At the location where the block sample is to be

Tiedemann, D. A., GR-83-8, Undisturbed Block Sampling Using a Chain

Saw, Bureau of Reclamation, Denver, CO, 1983, p. 19.

obtained level and smooth the ground surface and mark the

4

USBR 7100-89, Obtaining Undisturbed Block Samples by the Hand and

Chain Saw Methods, Earth ManualPart 2, Bureau of Reclamation, Denver, CO,

5

1990, pp. 1079-1083. 29 CFR 1926 Labor, Code of Federal Regulations, U.S. Printing office, 1991.

--``,```,`,`,`,,,````,`,``,,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International 2

Provided by IHS under license with ASTM Licensee=Army Hdqrtrs/7838506107

No reproduction or networking permitted without license from IHS Not for Resale, 04/16/2007 08:06:44 MDT

D 7015 04

outline of a face of the block. Surface soils containing roots or with Practice D 2488, and describe the in-place condition of

other organic matter should be removed. the soil, such as color, odor, moisture condition, consistency,

cementation and structure. Record the soils classification and

NOTE 3The size of the sample depends upon its intended use. For

most investigations, a cube about 0.3 m per side, with a mass of about 55 in-place condition on a data sheet, see Section 9. Photographs

kg, provides sufficient material and can be handled easily. of the block location (before and after trimming around the

block) are desirable.

7.1.2 Carefully excavate a trench around the sample to the

7.1.6 Cover the freshly exposed faces of the sample (ped-

required depth, removing a sufficient amount of material to

estal) with cheesecloth and paint with melted wax as shown in

provide space in which to work as shown on Fig. 1. If a

Fig. 2. Apply additional layers of cheesecloth and wax to form

backhoe is used to excavate the trench, first dig out an

a total of three (minimum) layers. Hot wax should not be

oversized column (pedestal) large enough that the soil to be

poured directly over the sample. If the soil is fragile, apply

sampled is not disturbed by the backhoe operation.

cheesecloth and then wax to individual faces of the sample as

NOTE 4Generally, a pedestal 0.9 or 1.2 m on a side and 0.9 to 1.2 m they are exposed.

high is adequate. If the soil is fragile and easily broken, backhoe usage 7.1.7 Identify the sample (number, location, elevation, etc.),

may be limited to excavation of only two or three sides of the pedestal, and mark the top of sample and the north orientation. A piece

with the remaining side or sides excavated by chain saw and/or by hand

methods. In addition, if the soil is fragile and easily broken, the cylindrical

of heavy paper showing this information should be waxed to

block sampling procedure (see 7.2) should be considered, provided the the top of the sample and if applicable, add a second copy to

pushing in one continuous motion or drive-cylinder methods are not the top of the box containing the block sample, see Section 8.

used. 7.1.8 To remove the cubical block sample, carefully cut or

7.1.3 Gradually remove excess soil on the sides of the block shear the base of the sample from the underlying soil using a

using the chain saw and/or hand methods until a pedestal of the thin wire such as piano wire if in clayey soils, or with either a

desired size is obtained. chain saw, shovels, or knives if in other soil types. If the soil is

7.1.4 Measure and record the elevation (or depth below the disturbed easily, a sturdy box with both ends removed should

ground surface) to the top of the sample and depth to water be placed over the sample, and fill the space between the

level if encountered. sample and the box with packing material and attach the top to

7.1.5 Visually classify the soil(s) in the sample based on the the box with screws, or with bolts and nuts prior to removing

trimmings and exposed surfaces of the block in accordance the base of the sample (see Fig. 3).

7.1.9 Carefully tilt the sample on one side. Add appropriate

packing materials to minimize any voids between the box and

sample. Cover the exposed bottom face with at least three

layers of cheesecloth and wax as described in 7.1.6.

7.1.10 Record all necessary information on a data sheet as

specified in Section 9. A copy of a sample data sheet is

included in Appendix X1.

7.2 Practice BCylindrical Block Sampling:

7.2.1 At the location where the cylindrical sample is to be

--``,```,`,`,`,,,````,`,``,,,,,-`-`,,`,,`,`,,`---

obtained, level and smooth the ground surface. Surface soils

containing roots or other organic matter should be removed.

Samples may be obtained from the bottom or the side of a test

pit as shown on Fig. 1. Pushing in one continuous motion

without hand trimming can be performed in accordance with

Practice D 1587. Another method for advancing cylindrical

samples by hammer impact is the Drive-Cylinder method (Test

Method D 2937) (see Notes 5 and 6).

7.2.2 Carefully excavate a trench around the sample to the

required depth, removing a sufficient amount of material to

provide space in which to work. If a backhoe is used to

FIG. 1 Procedure for Rectangular Block Sampling FIG. 2 Procedure for Placing Cheesecloth and Wax

Copyright ASTM International 3

Provided by IHS under license with ASTM Licensee=Army Hdqrtrs/7838506107

No reproduction or networking permitted without license from IHS Not for Resale, 04/16/2007 08:06:44 MDT

D 7015 04

mass and density of the specimen can be determined. Water

content of the specimen can be determined from the trimmings

and the dry density of sample can be calculated.

7.2.9 Cover the freshly exposed faces of the sample with

cheesecloth and paint with melted wax. Apply additional layers

of cheesecloth and wax to form a total of three (minimum)

layers. Hot wax should not be poured over the sample. If the

exposed faces are fragile, apply cheesecloth and wax to

individual faces as they are exposed. Alternatively, after

measurement, the sample may be sealed with plastic caps and

tape on the ends of the sample.

FIG. 3 Procedure for Placing Box Around R 7.2.10 Identify the sample (number, location, elevation,

etc.), and mark the top of sample and the north orientation. A

piece of heavy paper showing this information should be

excavate the trench, first dig out an oversized column (pedes-

waxed to the top of the sample and if applicable, add a second

tal) large enough that the soil to be sampled is not disturbed by

copy to the top of the box containing the block sample, see

the backhoe operation.

Section 8.

7.2.3 Place the sample container on the surface and gradu-

7.2.11 Record all necessary information on a data sheet as

ally remove excess soil around the perimeter of the container

--``,```,`,`,`,,,````,`,``,,,,,-`-`,,`,,`,`,,`---

specified in Section 9. A copy of a sample data sheet is

using a tool like a cutter knife to a diameter several millimeters

included in Appendix X1.

larger than the inner diameter of the sampling tube until 5 to 6

mm of soil is exposed.

8. Preparation for Shipment

7.2.4 Gently push down vertically and uniformly to retain

the sample. Repeat the above cutting and pushing procedures 8.1 Prepare and immediately affix labels or apply markings

until the surface of the sample extends above the sampling tube as necessary to identify the sample (see Section 7). Top end of

by approximately 3 cm (see Fig. 4). the sample container should be labeled top. Assure that the

markings or labels are adequate to survive transportation and

NOTE 5For soft soil and soils wet of optimum compaction, the tube storage in accordance with Practice D 4220, Group C or D

can be pushed without any hand trimming using a thin-walled tube as

described in Practice D 1587 or by drive cylinder (Test Method D 2937).

requirements. For unstable soils, the samples should be trans-

NOTE 6For sensitive, fragile or brittle soils, there could be distur- ported and stored in an upright position.

bance from pushing or hammering and if disturbance is suspected,

consider using smaller trimming and pushing increments as covered in 9. Report

7.2.4 .

9.1 An example of a sample data sheet is included in

7.2.5 After filling the sample container, the bottom is Appendix X1.

separated from the ground as described in 7.1.8, and the upper 9.2 Record the information that may be required for prepar-

and lower ends of the separated sample are trimmed. ing the field data sheet in general accordance to Guide D 5434.

7.2.6 Measure and record the elevation (or depth below the Record as a minimum the following information (data):

ground surface) to the top of the sample and depth to water 9.2.1 Project information, such as Project No. or name.

level, if encountered. 9.2.2 Sampling information, such as:

7.2.7 Visually classify soils in the sample in accordance 9.2.2.1 General location or referenced to site map,

with Practice D 2488, and describe the in-place condition of 9.2.2.2 ProcedurePractice A (cubical block sampling) or

the soil and record information on data sheet, see Section 9. Practice B (cylindrical block sampling),

Photographs of the block location (before and after trimming 9.2.2.3 Date and time of sampling,

around the block) are desirable. 9.2.2.4 Name of sampling personnel and their affiliation and

7.2.8 Trim the sample ends flush with the ends of the inspector, as appropriate and

cylinder. If the volume and mass of the cylinder is known, the 9.2.2.5 Any weather conditions that could affect the sam-

pling process such as raining, snowing, freezing or unusually

hot temperatures, and very windy.

9.2.3 Sample data, such as:

9.2.3.1 Sample number,

9.2.3.2 Depth to top of sample to the nearest 0.2 m or better,

9.2.3.3 Dimensions to the nearest cm or better,

9.2.3.4 Orientation (north arrow on samples top), see 7.1.7

or 7.2.10 and

9.2.3.5 Visual description of the soil(s) contained in the

sample (Practice D 2488) along with the in-place condition of

the soil such as color, odor, moisture condition, consistency

and structure.

FIG. 4 9.3 Other data that may be required include:

Copyright ASTM International 4

Provided by IHS under license with ASTM Licensee=Army Hdqrtrs/7838506107

No reproduction or networking permitted without license from IHS Not for Resale, 04/16/2007 08:06:44 MDT

D 7015 04

9.3.1 Surface elevation or reference to a datum to the

nearest 0.5 m or better, and

9.3.2 Depth of groundwater, if encountered.

10. Keywords

10.1 block sample; block sampling; cylindrical sampling;

geologic investigations; sampling; soil exploration; soil inves-

tigations; subsurface investigations; undisturbed

APPENDIX

(Nonmandatory Information)

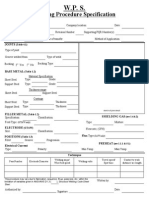

X1. EXAMPLE DATA SHEET

FIG. X1.1 Example Data Sheet

--``,```,`,`,`,,,````,`,``,,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International 5

Provided by IHS under license with ASTM Licensee=Army Hdqrtrs/7838506107

No reproduction or networking permitted without license from IHS Not for Resale, 04/16/2007 08:06:44 MDT

D 7015 04

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

--``,```,`,`,`,,,````,`,``,,,,,-`-`,,`,,`,`,,`---

Copyright ASTM International 6

Provided by IHS under license with ASTM Licensee=Army Hdqrtrs/7838506107

No reproduction or networking permitted without license from IHS Not for Resale, 04/16/2007 08:06:44 MDT

Potrebbero piacerti anche

- Astm D6519 - 08Documento7 pagineAstm D6519 - 08Black GokuNessuna valutazione finora

- UNIPLOT ClassificationModule PDFDocumento77 pagineUNIPLOT ClassificationModule PDFcmtheboss100% (1)

- 05 Mazier Retractable Core Barrels PDFDocumento1 pagina05 Mazier Retractable Core Barrels PDFCut MutiaNessuna valutazione finora

- Standard Penetration Test Method for Soil SamplingDocumento9 pagineStandard Penetration Test Method for Soil SamplingFranco PretellNessuna valutazione finora

- Stability of Compacted Rockfill SlopesDocumento10 pagineStability of Compacted Rockfill Slopesakhila s100% (1)

- Equations for the Soil-Water Characteristic CurveDocumento12 pagineEquations for the Soil-Water Characteristic CurveburlandNessuna valutazione finora

- US 0702-3A Design and Execution-F3Documento42 pagineUS 0702-3A Design and Execution-F3almirante_andreNessuna valutazione finora

- Laterite Final AFCAPgen124 v140525Documento74 pagineLaterite Final AFCAPgen124 v140525Deven PatleNessuna valutazione finora

- Stability of Natural Deposits During Earthquakes: La Stabilitydesdepots Naturelslorsdestremblements DeterreDocumento56 pagineStability of Natural Deposits During Earthquakes: La Stabilitydesdepots Naturelslorsdestremblements Deterrejoake spasNessuna valutazione finora

- Laboratory Manual of Test Procedures February 2021Documento120 pagineLaboratory Manual of Test Procedures February 2021Lencho KebedeNessuna valutazione finora

- Technical Note: Safe But Economical Working Platform DesignDocumento3 pagineTechnical Note: Safe But Economical Working Platform DesignSalvatore MirandaNessuna valutazione finora

- Site investigation checklistDocumento3 pagineSite investigation checklistSumanth GundetiNessuna valutazione finora

- Geotechnical Investigations of Dams, Their Foundations, and Supporting StructuresDocumento12 pagineGeotechnical Investigations of Dams, Their Foundations, and Supporting StructuresMarieamme BinaleNessuna valutazione finora

- Determination of Dynamic Soil PropertiesDocumento14 pagineDetermination of Dynamic Soil PropertiesredpolNessuna valutazione finora

- Open Ended Lab Geotechnic (Constant Head Permeability Test)Documento11 pagineOpen Ended Lab Geotechnic (Constant Head Permeability Test)tashadzureen0% (1)

- Method Statement For Survey Monitoring of Excavated SlopesDocumento20 pagineMethod Statement For Survey Monitoring of Excavated Slopesmohamedamine.zemouriNessuna valutazione finora

- Advances in Inclinometer Data AnalysisDocumento13 pagineAdvances in Inclinometer Data AnalysismOchONessuna valutazione finora

- Design and Construction of Road Embankments in Swampy Area-A Case Study of Uganda in East AfricaDocumento14 pagineDesign and Construction of Road Embankments in Swampy Area-A Case Study of Uganda in East AfricaNancy NiolaNessuna valutazione finora

- Casa GrandeDocumento6 pagineCasa GrandeXendra AqeylaaNessuna valutazione finora

- CITEPH Final Report NDR Rev04Documento94 pagineCITEPH Final Report NDR Rev04dogen1980Nessuna valutazione finora

- The Behaviour of Embankments On Clay FoundationsDocumento1 paginaThe Behaviour of Embankments On Clay FoundationspicottNessuna valutazione finora

- En 14490 After CEN Enquiry (Soil Nailing)Documento59 pagineEn 14490 After CEN Enquiry (Soil Nailing)Abraham FIgueroa ARevaloNessuna valutazione finora

- Role of Pore Water Pressures in Embankment Stability PDFDocumento6 pagineRole of Pore Water Pressures in Embankment Stability PDFfaroeldrNessuna valutazione finora

- Manual de Piezómetro Neumático RSTDocumento10 pagineManual de Piezómetro Neumático RSTedgarias00Nessuna valutazione finora

- Undisturb Sample PDFDocumento174 pagineUndisturb Sample PDFKristina LanggunaNessuna valutazione finora

- Effects of Slaking On The Strength of Clay Shales: A Critical State ApproachDocumento13 pagineEffects of Slaking On The Strength of Clay Shales: A Critical State Approachmbotts100% (1)

- Soil testing methods guideDocumento2 pagineSoil testing methods guideDr Wong Kim YuenNessuna valutazione finora

- Caisson PresentationDocumento21 pagineCaisson Presentationjinja100% (1)

- Micro Pile Liquefaction MitigationDocumento6 pagineMicro Pile Liquefaction MitigationViswanathan NaraNessuna valutazione finora

- VibrofloatationDocumento6 pagineVibrofloatationSelvemNessuna valutazione finora

- Undisturbed Soil SampleDocumento4 pagineUndisturbed Soil SampleDissasekaraNessuna valutazione finora

- UGS2011 Application of The Hardening Soil Model in Deep Excavation AnalysisDocumento14 pagineUGS2011 Application of The Hardening Soil Model in Deep Excavation AnalysisfreezefreezeNessuna valutazione finora

- BRAIN User Manual EN - 00 - 18 PDFDocumento44 pagineBRAIN User Manual EN - 00 - 18 PDFSale GISNessuna valutazione finora

- In Situ Ground Freezing To Obtain Undisturbed Samples - Hofmann (2000)Documento11 pagineIn Situ Ground Freezing To Obtain Undisturbed Samples - Hofmann (2000)jorge.jimenezNessuna valutazione finora

- CSTC Essais Micropieux Limelette PDFDocumento285 pagineCSTC Essais Micropieux Limelette PDFmichalakis483Nessuna valutazione finora

- BS 1377 Part 9: 1990 StandardDocumento9 pagineBS 1377 Part 9: 1990 StandardDetoned StonedNessuna valutazione finora

- Aashto T 180-74Documento9 pagineAashto T 180-74ORUSNessuna valutazione finora

- Geogrids Isochronous CurvesDocumento12 pagineGeogrids Isochronous Curveslimara65Nessuna valutazione finora

- Researchpaper Karst Limestone Foundation Geotechnical Problems Detection and TreatmentDocumento12 pagineResearchpaper Karst Limestone Foundation Geotechnical Problems Detection and Treatmentinigo38Nessuna valutazione finora

- As 1726-1993 Geotechnical Site InvestigationsDocumento8 pagineAs 1726-1993 Geotechnical Site InvestigationsSAI Global - APACNessuna valutazione finora

- 6 - Johnson, K - Geotechnical Investigations For Dredging Projects PDFDocumento16 pagine6 - Johnson, K - Geotechnical Investigations For Dredging Projects PDFAhmed GadNessuna valutazione finora

- Use of Ménard Pressuremeter Modulus in Finite Element Models For Retaining Walls DesignDocumento11 pagineUse of Ménard Pressuremeter Modulus in Finite Element Models For Retaining Walls DesignAgustin MOLINERO GUERRANessuna valutazione finora

- CD 225 Design For New Pavement Foundations-WebDocumento49 pagineCD 225 Design For New Pavement Foundations-Websomesh2727100% (1)

- PD 06682-8-2004Documento18 paginePD 06682-8-2004Jorge Salasën100% (1)

- GeoMos 2010 SchweigerDocumento13 pagineGeoMos 2010 SchweigerIancu-Bogdan TeodoruNessuna valutazione finora

- MIKE SHE Basic ExercisesDocumento160 pagineMIKE SHE Basic ExercisesQecil GamingNessuna valutazione finora

- Prime Tack Coats FHWA July 2005Documento18 paginePrime Tack Coats FHWA July 2005mzaimNessuna valutazione finora

- Chapter 18 - Pavement DesignDocumento18 pagineChapter 18 - Pavement DesignDiyoke HenryNessuna valutazione finora

- Efectiveness of Impulse CompactionDocumento8 pagineEfectiveness of Impulse CompactionMagdalena PanekNessuna valutazione finora

- Paper On Fuzzy Logic in Selecting Piles For Testing PDFDocumento13 paginePaper On Fuzzy Logic in Selecting Piles For Testing PDFHarshana MolligodaNessuna valutazione finora

- CBR Improvement of Clayey Soil With Geogrid ReinforcementDocumento4 pagineCBR Improvement of Clayey Soil With Geogrid Reinforcementbkollarou9632Nessuna valutazione finora

- Comparative Study of BS5930 and ISO 14688 StandardsDocumento14 pagineComparative Study of BS5930 and ISO 14688 StandardsNathan VincentNessuna valutazione finora

- Basf Masterbrace Adh 1414 TdsDocumento3 pagineBasf Masterbrace Adh 1414 TdsAzhar ShaikhNessuna valutazione finora

- Geosythetic Reinforced Unpaved RoadDocumento10 pagineGeosythetic Reinforced Unpaved RoadPalak ShivhareNessuna valutazione finora

- Construction of Deep Plastic Concrete Cut-Off Wall in Upstream Coffer Dam of Punatsangchhu-I Hydropower Project, BhutanDocumento8 pagineConstruction of Deep Plastic Concrete Cut-Off Wall in Upstream Coffer Dam of Punatsangchhu-I Hydropower Project, BhutanVetriselvan ArumugamNessuna valutazione finora

- HIPAVE Workshop 3 Slides Per PageDocumento90 pagineHIPAVE Workshop 3 Slides Per PageRicardo Zapata SaavedraNessuna valutazione finora

- Pond Reclamation SpecificationDocumento6 paginePond Reclamation SpecificationK H V V MADUSHANKANessuna valutazione finora

- ASTM D7015 - 07, Obtaining Intact Block (Cubical and Cylindrical) Samples of SoilsDocumento6 pagineASTM D7015 - 07, Obtaining Intact Block (Cubical and Cylindrical) Samples of SoilsBárbara RodríguezNessuna valutazione finora

- Uruguay PCH. Feasibility Study ReportDocumento67 pagineUruguay PCH. Feasibility Study ReportAsif MuhammadNessuna valutazione finora

- A Full - Blown Feasibility Study Report: Proposed Upper Sepaka Micro - Hydropower ProjectDocumento44 pagineA Full - Blown Feasibility Study Report: Proposed Upper Sepaka Micro - Hydropower ProjectDastaggir KarimiNessuna valutazione finora

- C140C140M 16 PDFDocumento24 pagineC140C140M 16 PDFDastaggir KarimiNessuna valutazione finora

- ACI 301-10 - Specifications - For - Structural - Concrete (2010) PDFDocumento81 pagineACI 301-10 - Specifications - For - Structural - Concrete (2010) PDFfarhadam75% (4)

- T 019M-93 Unit Weight and Voids in Aggregate PDFDocumento4 pagineT 019M-93 Unit Weight and Voids in Aggregate PDFDastaggir KarimiNessuna valutazione finora

- D560D560M 15.PDF (EngPedia - Ir)Documento6 pagineD560D560M 15.PDF (EngPedia - Ir)Dastaggir KarimiNessuna valutazione finora

- SKW 500 Complete Soil Kit InstructionsDocumento50 pagineSKW 500 Complete Soil Kit InstructionsDastaggir KarimiNessuna valutazione finora

- 304 2R-96Documento25 pagine304 2R-96farhadamNessuna valutazione finora

- Technical Contradictions in EN 206 Durability NormDocumento12 pagineTechnical Contradictions in EN 206 Durability NormyolandaNessuna valutazione finora

- Corrosivity Testing of Waters and SoilsDocumento17 pagineCorrosivity Testing of Waters and Soilsrcollado telloNessuna valutazione finora

- EURAMET cg-4 v2.0 03-2011Documento23 pagineEURAMET cg-4 v2.0 03-2011Nico MaliNessuna valutazione finora

- Continuity of Porcelain Enamel Coatings: Standard Test Method ForDocumento4 pagineContinuity of Porcelain Enamel Coatings: Standard Test Method ForDastaggir KarimiNessuna valutazione finora

- Astm A325m PDFDocumento8 pagineAstm A325m PDFDastaggir KarimiNessuna valutazione finora

- D3080 - Direct Shear (Consolidated Drained) PDFDocumento6 pagineD3080 - Direct Shear (Consolidated Drained) PDFdrNessuna valutazione finora

- Curing ConcreteDocumento10 pagineCuring ConcreteShariq KhanNessuna valutazione finora

- Astm - Standard Test Method For Penetration of Bituminous MaterialsDocumento3 pagineAstm - Standard Test Method For Penetration of Bituminous Materialsnica tamNessuna valutazione finora

- Viscosity Grade of BitumenDocumento2 pagineViscosity Grade of BitumenDastaggir KarimiNessuna valutazione finora

- Weld DefectsDocumento78 pagineWeld DefectsKevin CheungNessuna valutazione finora

- Astm - Standard Test Method For Penetration of Bituminous MaterialsDocumento3 pagineAstm - Standard Test Method For Penetration of Bituminous Materialsnica tamNessuna valutazione finora

- A 6Documento64 pagineA 6Dastaggir KarimiNessuna valutazione finora

- E190 Bend Test WeldsDocumento4 pagineE190 Bend Test WeldsDastaggir KarimiNessuna valutazione finora

- A 6Documento64 pagineA 6Dastaggir KarimiNessuna valutazione finora

- 9907X0049 - 1 Operating InstructionsDocumento5 pagine9907X0049 - 1 Operating InstructionsDastaggir KarimiNessuna valutazione finora

- Washington State Department of TransportationDocumento182 pagineWashington State Department of TransportationDastaggir KarimiNessuna valutazione finora

- Astm D698Documento11 pagineAstm D698Dastaggir KarimiNessuna valutazione finora

- Tolerances According To ASTM E230-E230M-12Documento1 paginaTolerances According To ASTM E230-E230M-12Dastaggir KarimiNessuna valutazione finora

- Astm - Standard Test Method For Penetration of Bituminous MaterialsDocumento3 pagineAstm - Standard Test Method For Penetration of Bituminous Materialsnica tamNessuna valutazione finora

- ASTM D2435 Standard Test Method For One Dimensional Consolidatin Properties of SoilsUsing Incremental LoadingDocumento15 pagineASTM D2435 Standard Test Method For One Dimensional Consolidatin Properties of SoilsUsing Incremental Loadingiapsid100% (1)

- BS 1370-1979-Specification For Low Heat Portland CementDocumento12 pagineBS 1370-1979-Specification For Low Heat Portland CementDastaggir Karimi100% (1)

- Cement Technology: ReclaimerDocumento17 pagineCement Technology: ReclaimerYana Damayanti100% (1)

- Catalytic Reaction EngineeringDocumento48 pagineCatalytic Reaction EngineeringM Deepika100% (1)

- Act 3 ConclusionDocumento13 pagineAct 3 ConclusionVon A. DamirezNessuna valutazione finora

- Chemical Equilibrium: Problem Set: Chapter 16 Questions 25, 27, 33, 35, 43, 71Documento36 pagineChemical Equilibrium: Problem Set: Chapter 16 Questions 25, 27, 33, 35, 43, 71abdooufNessuna valutazione finora

- Choice of Specifications and Design Codes For Duplex Stainless SteelsDocumento12 pagineChoice of Specifications and Design Codes For Duplex Stainless SteelsRonald Leyva GiraldoNessuna valutazione finora

- Packed Beds Safety IssuesDocumento4 paginePacked Beds Safety IssuesrmaganNessuna valutazione finora

- 2022 ASRJC H2 Current of Electricity AQ SolnsDocumento7 pagine2022 ASRJC H2 Current of Electricity AQ SolnsBooNessuna valutazione finora

- Expansion JointDocumento10 pagineExpansion JointMohammed BaquarNessuna valutazione finora

- Lecture 5.2 Inorganic MaterialsDocumento22 pagineLecture 5.2 Inorganic Materialsdawit gashuNessuna valutazione finora

- Spring Manufacturing ProcessDocumento4 pagineSpring Manufacturing ProcessUzma sijratNessuna valutazione finora

- PN JunctionDocumento36 paginePN JunctionTiniNessuna valutazione finora

- Sumber Penelitian NaOH TerdahuluDocumento7 pagineSumber Penelitian NaOH TerdahuluAulia NafarinNessuna valutazione finora

- WPS D1.3-2012 BlankDocumento1 paginaWPS D1.3-2012 BlankpjbedelNessuna valutazione finora

- Underground Works GuideDocumento80 pagineUnderground Works GuidedanielamayavNessuna valutazione finora

- Horiba - XGT 9000 IIDocumento1 paginaHoriba - XGT 9000 IIAmanah WatiiNessuna valutazione finora

- M-Phi Singly Reinforced Rectangular Concrete SectionDocumento26 pagineM-Phi Singly Reinforced Rectangular Concrete SectionRishabh LalaNessuna valutazione finora

- PSIHCass12 10Documento2 paginePSIHCass12 10Kingefrain Yusuke AmamiyaNessuna valutazione finora

- Commitment To Sustainability: Parson Adhesives' Environmental ResponsibilityDocumento1 paginaCommitment To Sustainability: Parson Adhesives' Environmental ResponsibilityParson AdhesivesNessuna valutazione finora

- 2) Data Sheet VDek-703 Standard 2021 FTDocumento1 pagina2) Data Sheet VDek-703 Standard 2021 FTJean CausilNessuna valutazione finora

- Sand Casting Over View and Defect AnalysisDocumento29 pagineSand Casting Over View and Defect AnalysisNindya HauraNessuna valutazione finora

- 11 Chemistry Notes - The S-Block ElementsDocumento21 pagine11 Chemistry Notes - The S-Block ElementsAishwary yadav100% (1)

- Form Checklist Civil.Documento91 pagineForm Checklist Civil.Iki Hendro100% (2)

- Elementos PreesforzadosDocumento42 pagineElementos PreesforzadosJohn Steven Anaya InfantesNessuna valutazione finora

- Water's Versatility as a Universal SolventDocumento7 pagineWater's Versatility as a Universal SolventTropz RenNessuna valutazione finora

- Closed Book API RP 577 Practice QuestionsDocumento10 pagineClosed Book API RP 577 Practice QuestionsIslam Fawzy100% (1)

- Differences between pure metals and alloysDocumento31 pagineDifferences between pure metals and alloysSinh LeNessuna valutazione finora

- 10 - Confined SpaceDocumento53 pagine10 - Confined SpaceghufranahmedkhanNessuna valutazione finora

- Ebara Pump UVDocumento4 pagineEbara Pump UVrahmanfahamNessuna valutazione finora

- Nstse Class 8 Solved Paper 2011Documento20 pagineNstse Class 8 Solved Paper 2011api-280319234Nessuna valutazione finora

- TRUEDocumento50 pagineTRUECLARISSA TAGUBANessuna valutazione finora